Effect of Dry and Wet Cycles on the Strength Characteristics of Biochar–Clay Mixture

Abstract

:1. Introduction

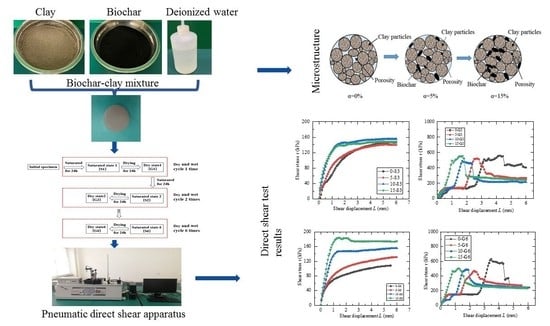

2. Materials and Methods

2.1. Materials

2.2. Apparatus

2.3. Test Method

3. Results

3.1. Shear Stress–Shear Displacement Curves of Biochar–Clay Mixture after Dry and Wet Cycles

3.2. Shear Strength of Biochar–Clay Mixture after Dry and Wet Cycles

3.3. Cohesion and Internal Friction Angle of Biochar–Clay Mixture after Dry and Wet Cycles

4. Discussion

4.1. Mechanisms of Biochar Contents on the Strength Characteristics of Biochar–Clay Soil Mix

4.2. Mechanism of the Effect of Dry and Wet Cycles on the Strength Characteristics of Biochar–Clay Mixture

5. Conclusions

- (1)

- In the saturated state, the shear stress–shear displacement curve of the mixture after dry and wet cycles is weakly hardened; under the same dry and wet cycles, the shear strength increases with increasing biochar contents, with increases of 18%, 18%, and 10% at 100 kPa, 200 kPa, and 400 kPa of vertical pressures, respectively; under the same normal stress, the shear strength generally decreases with dry and wet cycles, with a decrease of approximately 11%. Shear strength reduction range from 6% to 19%;

- (2)

- In the dry state, the shear stress–shear displacement curve of the mixture is strain-softened; at the same biochar contents, the shear strength of the clay and the mixture decreases with the number of dry–wet cycles. Shear strength reduction range from 14% to 21%;

- (3)

- After the clay and biochar–clay mixture undergoes dry–wet cycles, the particles are denser, and the cohesion and internal friction angle of the clay and biochar–clay mixture in the dry state are greater than those in the saturated state. The cohesion and internal friction angle of clay and biochar–clay mixture show a decreasing trend after dry and wet cycles. The angles of internal friction and cohesion reduction range from 2% to 16%.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Reddy, K.R.; Giri, R.K.; Kulkarni, H.S. Modeling coupled hydromechanical behavior of landfilled waste in bioreactor landfills: Numerical formulation and validation. J. Hazard. Toxic Radioact. Waste 2017, 21, D4015004. [Google Scholar] [CrossRef] [Green Version]

- Parise, M.; Pascali, V. Surface and subsurface environmental degradation in the karst of Apulia (southern Italy). Environ. Geol. 2003, 44, 247–256. [Google Scholar] [CrossRef]

- Jalilzadeh, H. Field Performance and Water Balance Predictions of Evapotranspirative Landfill Biocovers. Master’s Thesis, Schulich School of Engineering, University of Calgary, Calgary, AB, Canada, 2019. [Google Scholar]

- Shi, J.; Shu, S.; Qian, X.; Wang, Y. Shear strength of landfill liner interface in the case of varying normal stress. Geotext. Geomembr. 2020, 48, 713–723. [Google Scholar] [CrossRef]

- Mittal, A.; Shrivastava, A.K. Stress–strain characteristics of landfill clay cover barriers under geogrid reinforcements. Innov. Infrastruct. Solut. 2020, 5, 19. [Google Scholar] [CrossRef]

- US-EPA (United States Environmental Protection Agency). Available and Emerging Technologies for Reducing Greenhouse Air Emissions from Municipal Solid Waste Landfills; Office of Air and Radiation U.S. EPA: Washington, DC, USA, 2011.

- Phanikumar, B.; Nagaraju, T.V. Engineering behaviour of expansive clays blended with cement and GGBS. Proc. Inst. Civ. Eng.-Ground Improv. 2018, 171, 167–173. [Google Scholar] [CrossRef]

- Varma, N.; Kumar, T.; Nagaraju, V. Compressive Strength of High Plastic Clay Stabilized with Fly Ash-Based Geopolymer and Its Synthesis Parameters. In Transportation, Water and Environmental Geotechnics: Proceedings of Indian Geotechnical Conference 2020; Springer: Singapore, 2021; Volume 4, pp. 25–37. [Google Scholar]

- Phanikumar, B.R.; Nagaraju, T.V. Effect of fly ash and rice husk ash on index and engineering properties of expansive clays. Geotech. Geol. Eng. 2018, 36, 3425–3436. [Google Scholar] [CrossRef]

- Ng, C.W.W.; Peprah-Manu, D. Pore structure effects on the water retention behaviour of a compacted silty sand soil subjected to drying-wetting cycles. Eng. Geol. 2023, 313, 106963. [Google Scholar] [CrossRef]

- Alisha, S.S.; Nagaraju, T.V.; Murty, P.S.R.; Sarma, V.V.S.; Sireesha, M. Strength and stiffness prediction models of expansive clays blended with sawdust ash. IOP Conf. Ser. Mater. Sci. Eng. 2023, 1273, 012018. [Google Scholar] [CrossRef]

- Nagaraju, T.V.; Prasad, C.D. Swarm-assisted multiple linear regression models for compression index (C c) estimation of blended expansive clays. Arab. J. Geosci. 2020, 13, 331. [Google Scholar] [CrossRef]

- Xu, J.; Wu, Z.; Chen, H.; Shao, L.; Zhou, X.; Wang, S. Influence of dry-wet cycles on the strength behavior of basalt-fiber reinforced loess. Eng. Geol. 2022, 302, 106645. [Google Scholar] [CrossRef]

- Hussain, R.; Yaghoubi, P.; Yukselen-Aksoy, Y. Effects of biochar amendment on geotechnical properties of landfill cover soil. Waste Manag. Res. 2015, 33, 524–532. [Google Scholar]

- Li, M.; Sun, W.; Chen, Z. Strength Characteristics of Biochar-Amended Clay Covered Soil Mixed with Methane-Oxidizing Bacteria. Appl. Sci. 2022, 12, 12954. [Google Scholar] [CrossRef]

- Tang, C.; Shi, B.; Liu, C.; Zhao, L.; Wang, B. Influencing factors of geometrical structure of surface shrinkage cracks in clayey soils. Eng. Geol. 2008, 101, 204–217. [Google Scholar] [CrossRef]

- Wang, H.; Garg, A.; Huang, S.; Mei, G. Mechanism of compacted biochar-amended expansive clay subjected to drying–wetting cycles: Simultaneous investigation of hydraulic and mechanical properties. Acta Geophys. 2020, 68, 737–749. [Google Scholar] [CrossRef]

- Lu, Y.; Gu, K.; Zhang, Y.; Tang, C.; Shen, Z.; Shi, B. Impact of biochar on the desiccation cracking behavior of silty clay and its mechanisms. Sci. Total Environ. 2021, 794, 148608. [Google Scholar] [CrossRef] [PubMed]

- Cuilan, W.E.I.; Weida, G.A.O.; Whalley, W.R.; Li, B. Shrinkage characteristics of lime concretion black soil as affected by biochar amendment. Pedosphere 2018, 28, 713–725. [Google Scholar]

- GB 50123; Standard for Soil Test Method. Ministry of Water Resources of China: Beijing, China, 2019.

- ASTM D559; Standard Test Method for Chemical Analysis of Wood Charcoal. ASTM International: West Conshohocken, PA, USA, 2007.

- GB 51220; Technical Code for Municipal Solid Waste Sanitary Landfill Closure. Ministry of Housing and Urban-Rural Development: Beijing, China, 2017.

- ASTM D559; Standard Test Methods for Wetting and Drying Compacted Soil-Cement Mixtures. ASTM International: West Conshohocken, PA, USA, 2015.

- Aldaood, A.; Bouasker, M.; Al-Mukhtar, M. Impact of wetting–drying cycles on the microstructure and mechanical properties of lime-stabilized gypseous soils. Eng. Geol. 2014, 174, 11–21. [Google Scholar] [CrossRef]

- Hoy, M.; Rachan, R.; Horpibulsuk, S.; Arulrajah, A.; Mirzababaei, M. Effect of wetting–drying cycles on compressive strength and microstructure of recycled asphalt pavement–Fly ash geopolymer. Constr. Build. Mater. 2017, 144, 624–634. [Google Scholar] [CrossRef]

- Ma, Q.; Li, Z.; Xiao, H.; Hu, Z.; Pung, L. Mechanical properties of clay reinforced with Bermuda grass root under drying–wetting cycles. Environ. Earth Sci. 2021, 80, 31. [Google Scholar] [CrossRef]

- Zhu, W.W. The effect of dry-wet cycle on crack propagation and shear strength index of yunnan laterite in china. Appl. Ecol. Environ. Res. 2019, 17, 7881–7889. [Google Scholar] [CrossRef]

- Xu, X.; Shao, L.; Huang, J.; Xu, X.; Liu, D.-Q.; Xian, Z.-X.; Jian, W.-B. Effect of wet-dry cycles on shear strength of residual soil. Soils Found. 2021, 61, 782–797. [Google Scholar] [CrossRef]

- Atkinson, C.J. How good is the evidence that soil-applied biochar improves water-holding capacity? Soil Use Manag. 2018, 34, 177–186. [Google Scholar] [CrossRef] [Green Version]

| Biochar | |||||||

|---|---|---|---|---|---|---|---|

| Bulk Density ρ (g/cm3) | Specific Surface Area AAS/(m2/g) | Specific Gravity ds | pH | Ash Content (%) | |||

| 0.55 | 385.60 | 1.99 | 9.8 | 18.80 | |||

| α (%) | Liquid limit wL (%) | Plastic limit wP(%) | Plasticity index Ip | Maximum dry density ρdmax (g/cm3) | Optimum moisture content wopt (%) | Specific gravity ds | pH |

| 0 | 35.98 | 22.20 | 13.78 | 1.65 | 22.40 | 2.72 | 7.70 |

| 5 | 41.13 | 22.96 | 18.17 | 1.56 | 23.80 | 2.64 | 7.90 |

| 10 | 42.15 | 25.92 | 16.23 | 1.42 | 28.70 | 2.60 | 8.00 |

| 15 | 45.44 | 28.39 | 17.05 | 1.27 | 29.30 | 2.57 | 8.30 |

| Number | Biochar Contents α (%) | State | Dry Density ρd (g/cm3) | Number of Cycles N | Vertical Pressure P (kPa) |

|---|---|---|---|---|---|

| 0-S1 | 0 | Saturated/Dry | 1.5 | 1 | 100/200/400 |

| 0-S3 | 3 | ||||

| 0-S6 | 6 | ||||

| 5-S1 | 5 | 1 | 100/200/400 | ||

| 5-S3 | 3 | ||||

| 5-S6 | 6 | ||||

| 10-S1 | 10 | 1 | 100/200/400 | ||

| 10-S3 | 3 | ||||

| 10-S6 | 6 | ||||

| 15-S1 | 15 | 1 | 100/200/400 | ||

| 15-S3 | 3 | ||||

| 15-S6 | 6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, D.; Sun, W.; Kong, Y.; Zhang, S. Effect of Dry and Wet Cycles on the Strength Characteristics of Biochar–Clay Mixture. Processes 2023, 11, 970. https://doi.org/10.3390/pr11030970

Liu D, Sun W, Kong Y, Zhang S. Effect of Dry and Wet Cycles on the Strength Characteristics of Biochar–Clay Mixture. Processes. 2023; 11(3):970. https://doi.org/10.3390/pr11030970

Chicago/Turabian StyleLiu, Deyang, Wenjing Sun, Yi Kong, and Shuyun Zhang. 2023. "Effect of Dry and Wet Cycles on the Strength Characteristics of Biochar–Clay Mixture" Processes 11, no. 3: 970. https://doi.org/10.3390/pr11030970

APA StyleLiu, D., Sun, W., Kong, Y., & Zhang, S. (2023). Effect of Dry and Wet Cycles on the Strength Characteristics of Biochar–Clay Mixture. Processes, 11(3), 970. https://doi.org/10.3390/pr11030970