Energy Recovery Efficiency of Integrating Anaerobic Co-Digestion of Pig Slurry and Feedlot Cattle Manure and Hydrothermal Carbonization of Anaerobic Sludge Cake

Abstract

:1. Introduction

2. Materials and Methods

2.1. Process Scheme

2.2. Determination of Process Parameters

2.2.1. Anaerobic Digestion

2.2.2. Hydrothermal Carbonization

2.3. Methane Production Potential of HTC-L

2.3.1. Theoretical Methane Potential

2.3.2. Methane Potential Assay of HTC-L

2.4. Analysis

2.5. Efficiency Parameters

3. Results and Discussion

3.1. Livestock Manure Anaerobic Co-Digestion

3.2. Hydrothermal Carbonization Reaction Using Anaerobic Co-Digestion Sludge from Livestock Manure

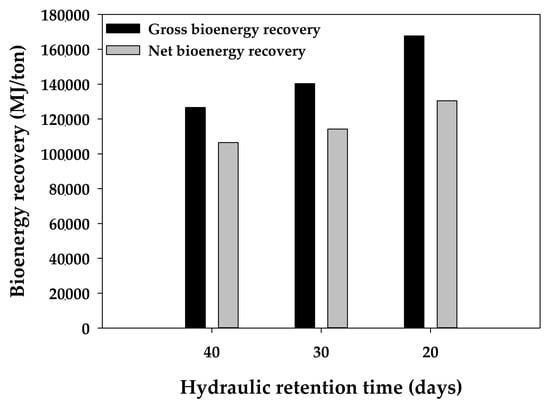

3.3. Evaluation of Bioenergy Recovery Efficiency in Anaerobic Co-Digestion and Hydrothermal Carbonization Integrated Process for Livestock Manure

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- MOTIE [Ministry of Trade Industry and Energy]. New & Renewable Energy White Paper; Ministry of Trade Industry and Energy: Sejong City, Republic of Korea, 2020. [Google Scholar]

- Zubair, M.; Wang, S.; Zhang, P.; Ye, J.; Liang, J.; Nabi, M.; Zhou, Z.; Tao, X.; Chen, N.; Sun, K. Biological nutrient removal and recovery from solid and liquid livestock manure: Recent advance and perspective. Bioresour. Technol. 2020, 301, 122823. [Google Scholar] [CrossRef] [PubMed]

- Zhang, T.; Li, P.; Fang, C.; Jiang, R. Phosphate recovery from animal manure wastewater by struvite crystallization and CO degasification reactor. Ecol. Chem. Eng. S 2014, 21, 89–99. [Google Scholar] [CrossRef]

- Larson, C. China’s lakes of pig manure spawn antibiotic resistance. Science 2015, 347, 704. [Google Scholar] [CrossRef] [PubMed]

- MAFRA [Ministry of Agriculture Food and Rural Affairs]. 2050 Agricultural and Food Carbon Neutrality Promotion Strategy; Ministry of Agriculture Food and Rural Affairs: Sejong-si, Republic of Korea, 2021. [Google Scholar]

- Nicholson, F.A.; Groves, S.J.; Chambers, B.J. Pathogen survival during livestock manure storage and following land application. Bioresour. Technol. 2005, 96, 135–143. [Google Scholar] [CrossRef] [PubMed]

- Meegoda, J.N.; Li, B.; Patel, K.; Wang, L.B. A review of the processes, parameters, and optimization of anaerobic digestion. Int. J. Environ. Res. Public Health 2018, 15, 2224. [Google Scholar] [CrossRef] [PubMed]

- Laiq Ur Rehman, M.; Iqbal, A.; Chang, C.C.; Li, W.; Ju, M. Anaerobic digestion. Water Environ. Res. 2019, 91, 1253–1271. [Google Scholar] [CrossRef]

- ME [Ministry of Environment]. Status of Installation and Operation of Food Waste Treatment Facilities in 2020; Ministry of Environment: Sejong-si, Republic of Korea, 2021. [Google Scholar]

- Kim, J.; Yoon, Y.-M.; Jeong, K.-H.; Kim, C.-H. Effects of supplementation of mixed methanogens and rumen cellulolytic bacteria on biochemical methane potential with pig slurry. Korean J. Soil Sci. Fertil. 2012, 45, 1049–1057. [Google Scholar] [CrossRef]

- Yoon, Y.; Kim, C.; Kim, Y.; Park, H. The economical evaluation of biogas production facility of pig waste. Korean J. Agric. Manag. Policy 2009, 36, 137–157. [Google Scholar]

- Lehtomäki, A.; Huttunen, S.; Rintala, J. Laboratory investigations on co-digestion of energy crops and crop residues with cow manure for methane production: Effect of crop to manure ratio. Resour. Conserv. Recycl. 2007, 51, 591–609. [Google Scholar] [CrossRef]

- Lee, J.-H.; Kim, C.-H.; Yoon, Y.-M. Effects of hydrothermal pretreatment on methane potential of anaerobic digestion sludge cake of cattle manure containing sawdust as bedding materials. Anim. Biosci. 2023, 36, 818. [Google Scholar] [CrossRef]

- Park, S.Y.; Jang, J.A.; Zhao, X.; Hong, J.K.; Jho, E.H. Effect of Rice Straw on Methane Production Potential of Cow Manure. Korean J. Environ. Agric. 2022, 41, 71–81. [Google Scholar] [CrossRef]

- ME [Ministry of Environment]. The Study for the Establishment of Quality and Classification Criteria of Solid Fuel Using Livestock Manure; Ministry of Environment: Sejong-si, Republic of Korea, 2013. [Google Scholar]

- Oh, S.-Y.; Kim, C.-H.; Yoon, Y.-M. The bioenergy conversion characteristics of feedlot manure discharging from beef cattle barn. Korean J. Soil Sci. Fertil. 2015, 48, 697–704. [Google Scholar] [CrossRef]

- MarañóN, E.; Castrillón, L.; Vázquez, I.; Sastre, H. The influence of hydraulic residence time on the treatment of cattle manure in UASB reactors. Waste Manag. Res. 2001, 19, 436–441. [Google Scholar] [CrossRef] [PubMed]

- Omar, R.; Harun, R.M.; Mohd Ghazi, T.; Wan Azlina, W.; Idris, A.; Yunus, R. Anaerobic treatment of cattle manure for biogas production. In Proceedings of the Annual Meeting of American Institute of Chemical Engineers, Philadelphia, PA, USA, 16–21 November 2008; pp. 1–10. [Google Scholar]

- Acharya, B.; Dutta, A.; Minaret, J. Review on comparative study of dry and wet torrefaction. Sustain. Energy Technol. Assess. 2015, 12, 26–37. [Google Scholar] [CrossRef]

- Chen, W.-H.; Lin, B.-J.; Lin, Y.-Y.; Chu, Y.-S.; Ubando, A.T.; Show, P.L.; Ong, H.C.; Chang, J.-S.; Ho, S.-H.; Culaba, A.B. Progress in biomass torrefaction: Principles, applications and challenges. Prog. Energy Combust. Sci. 2021, 82, 100887. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, Y.; Zhu, G.; Xu, J.; Yuan, Q.; Zhu, Y.; Sarma, J.; Wang, Y.; Wang, J.; Ji, L. Microwave-assisted hydrothermal carbonization of dairy manure: Chemical and structural properties of the products. Energy 2018, 165, 662–672. [Google Scholar] [CrossRef]

- Kim, H.; Jeon, Y.-W. Effects of hydro-thermal reaction temperature on anaerobic biodegradability of piggery manure hydrolysate. Korean J. Soil Sci. Fertil. 2015, 48, 602–609. [Google Scholar] [CrossRef]

- Ahring, B.K.; Ibrahim, A.A.; Mladenovska, Z. Effect of temperature increase from 55 to 65 degrees C on performance and microbial population dynamics of an anaerobic reactor treating cattle manure. Water Res. 2001, 35, 2446–2452. [Google Scholar] [CrossRef]

- Kim, D.J. Pre-treatment Technology of Wastewater Sludge for Enhanced Biogas Production in Anaerobic Digestion. Clean Technol. 2013, 19, 355–369. [Google Scholar] [CrossRef]

- Marin-Batista, J.; Villamil, J.; Qaramaleki, S.; Coronella, C.; Mohedano, A.; de La Rubia, M. Energy valorization of cow manure by hydrothermal carbonization and anaerobic digestion. Renew. Energy 2020, 160, 623–632. [Google Scholar] [CrossRef]

- González, R.; Ellacuriaga, M.; Aguilar-Pesantes, A.; Carrillo-Peña, D.; García-Cascallana, J.; Smith, R.; Gómez, X. Feasibility of coupling anaerobic digestion and hydrothermal carbonization: Analyzing thermal demand. Appl. Sci. 2021, 11, 11660. [Google Scholar] [CrossRef]

- Lu, Y.; Fang, Z.; Gao, C. Stabilization of (state, input)-disturbed CSTRs through the port-Hamiltonian systems approach. arXiv 2017, arXiv:1707.01560. [Google Scholar] [CrossRef]

- Han, S.K.; Kim, M.I. Solid Fuel Carbonization Characteristics through Hydrothermal Carbonization of Sewage Sludge. J. Korea Org. Resour. Recycl. Assoc. 2023, 31, 53–61. [Google Scholar] [CrossRef]

- Boyle, W. Energy recovery from sanitary landfills—A review. Microb. Energy Convers. 1977, 119–138. [Google Scholar] [CrossRef]

- Lee, J.-H.; Lee, J.-H.; Kim, S.-Y.; Yoon, Y.-M. Effect of Addition of Zero-Valent Iron (Fe) and Magnetite (Fe3O4) on Methane Yield and Microbial Consortium in Anaerobic Digestion of Food Wastewater. Processes 2023, 11, 759. [Google Scholar] [CrossRef]

- Luna-deRisco, M.; Normak, A.; Orupõld, K. Biochemical methane potential of different organic wastes and energy crops from Estonia. Agron. Res. 2011, 9, 331–342. [Google Scholar]

- Rao, M.; Singh, S.; Singh, A.; Sodha, M. Bioenergy conversion studies of the organic fraction of MSW: Assessment of ultimate bioenergy production potential of municipal garbage. Appl. Energy 2000, 66, 75–87. [Google Scholar] [CrossRef]

- APHA. Standard Methods for the Examination of Water and Wastewater; APHA: Washington, DC, USA, 1998; p. 324. [Google Scholar]

- Lay, J.-J.; Li, Y.-Y.; Noike, T. Mathematical model for methane production from landfill bioreactor. J. Environ. Eng. 1998, 124, 730–736. [Google Scholar] [CrossRef]

- ME [Ministry of Environment]. Practical Guidelines for Maintenance of Public Sewerage Facilities; Ministry of Environment: Sejong-si, Republic of Korea, 2005. [Google Scholar]

- Song, E.; Kim, H.; Kim, K.W.; Yoon, Y.-M. Characteristic Evaluation of Different Carbonization Processes for Hydrochar, Torrefied Char, and Biochar Produced from Cattle Manure. Energies 2023, 16, 3265. [Google Scholar] [CrossRef]

- ME [Ministry of Environment]. Energy-Saving (Less than 210 Mcal/Ton Raw Material) Solid Fuel Production Technology Using a Hydrothermal Carbonization Reactor Using a Sewage/Wastewater Sludge (Water Content of around 80%); Ministry of Environment: Sejong-si, Republic of Korea, 2020. [Google Scholar]

- Van Velsen, A. Adaptation of methanogenic sludge to high ammonia-nitrogen concentrations. Water Res. 1979, 13, 995–999. [Google Scholar] [CrossRef]

- Lili, M.; Biró, G.; Sulyok, E.; Petis, M.; Borbély, J.; Tamás, J. Novel approach on the basis of FOS/TAC method. Analele Univ. Din Oradea Fasc. Protecţia Mediu. 2011, 17, 713–718. [Google Scholar]

- Demirer, G.; Chen, S. Two-phase anaerobic digestion of unscreened dairy manure. Process Biochem. 2005, 40, 3542–3549. [Google Scholar] [CrossRef]

- Li, R.; Chen, S.; Li, X.; Saifullah Lar, J.; He, Y.; Zhu, B. Anaerobic codigestion of kitchen waste with cattle manure for biogas production. Energy Fuels 2009, 23, 2225–2228. [Google Scholar] [CrossRef]

- Wei, L.; Qin, K.; Ding, J.; Xue, M.; Yang, C.; Jiang, J.; Zhao, Q. Optimization of the co-digestion of sewage sludge, maize straw and cow manure: Microbial responses and effect of fractional organic characteristics. Sci. Rep. 2019, 9, 2374. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Zhao, J.; Krooneman, J.; Euverink, G.J.W. Strategies to boost anaerobic digestion performance of cow manure: Laboratory achievements and their full-scale application potential. Sci. Total Environ. 2021, 755, 142940. [Google Scholar] [CrossRef]

- Gao, J.; Chen, L.; Yuan, K.; Huang, H.; Yan, Z. Ionic liquid pretreatment to enhance the anaerobic digestion of lignocellulosic biomass. Bioresour. Technol. 2013, 150, 352–358. [Google Scholar] [CrossRef] [PubMed]

- Gao, P.; Zhou, Y.; Meng, F.; Zhang, Y.; Liu, Z.; Zhang, W.; Xue, G. Preparation and characterization of hydrochar from waste eucalyptus bark by hydrothermal carbonization. Energy 2016, 97, 238–245. [Google Scholar] [CrossRef]

- Ferrer, I.; Ponsá, S.; Vázquez, F.; Font, X. Increasing biogas production by thermal (70 C) sludge pre-treatment prior to thermophilic anaerobic digestion. Biochem. Eng. J. 2008, 42, 186–192. [Google Scholar] [CrossRef]

- Kim, S.-H.; Kim, H.; Kim, C.-H.; Yoon, Y.-M. Effect of the pretreatment by thermal hydrolysis on biochemical methane potential of piggery sludge. Korean J. Soil Sci. Fertil. 2012, 45, 524–531. [Google Scholar] [CrossRef]

- Oh, S.-Y.; Yoon, Y.-M. Energy recovery efficiency of poultry slaughterhouse sludge cake by hydrothermal carbonization. Energies 2017, 10, 1876. [Google Scholar] [CrossRef]

- Gossett, R.W.; Brown, D.A.; Young, D.R. Predicting the bioaccumulation and toxicity of organic compounds. Coast. Water Res. Proj. Bienn. Rep. 1981, 1982, 149–156. [Google Scholar]

- Jain, S.; Sharma, M. Power generation from MSW of Haridwar city: A feasibility study. Renew. Sustain. Energy Rev. 2011, 15, 69–90. [Google Scholar] [CrossRef]

- Bougrier, C.; Delgenès, J.P.; Carrère, H. Effects of thermal treatments on five different waste activated sludge samples solubilisation, physical properties and anaerobic digestion. Chem. Eng. J. 2008, 139, 236–244. [Google Scholar] [CrossRef]

- Martins, S.I.; Jongen, W.M.; Van Boekel, M.A. A review of Maillard reaction in food and implications to kinetic modelling. Trends Food Sci. Technol. 2000, 11, 364–373. [Google Scholar] [CrossRef]

- Imeni, S.M.; Pelaz, L.; Corchado-Lopo, C.; Busquets, A.M.; Ponsá, S.; Colón, J. Techno-economic assessment of anaerobic co-digestion of livestock manure and cheese whey (Cow, Goat & Sheep) at small to medium dairy farms. Bioresour. Technol. 2019, 291, 121872. [Google Scholar] [CrossRef]

- Kim, D.; Lee, K.; Park, K.Y. Hydrothermal carbonization of anaerobically digested sludge for solid fuel production and energy recovery. Fuel 2014, 130, 120–125. [Google Scholar] [CrossRef]

- Aragón-Briceño, C.; Ross, A.; Camargo-Valero, M. Evaluation and comparison of product yields and bio-methane potential in sewage digestate following hydrothermal treatment. Appl. Energy 2017, 208, 1357–1369. [Google Scholar] [CrossRef]

| Parameters | pH | TS 1 | VS 2 | TKN 3 | NH4+-N 4 | COD 5 | SCOD 6 | Alkalinity (as CaCO3) | TVFAs 7 (as Acetate) |

|---|---|---|---|---|---|---|---|---|---|

| mg/L | |||||||||

| Inoculum | 8.4 (0.02) 8 | 33,150 (650) | 19,233 (858) | 6006 (179) | 4810 (277) | 21,033 (816) | 5667 (165) | 28,650 (177) | 617 (23) |

| Parameters | TS 1 | VS 2 | TKN 3 | NH4+-N 4 |

|---|---|---|---|---|

| mg/kg (mg/L for PS) | ||||

| PS (Pig slurry) | 47,550 (1493) 5 | 33,467 (1258) | 7086 (295) | 5503 (194) |

| FCM (Feedlot cattle manure) | 219,991 (2116) | 189,914 (2953) | 5064 (76) | 1412 (67) |

| Mixture (PS:FCM = 1:1 (w/w)) | 132,907 (119) | 109,631 (851) | 6719 (543) | 3543 (119) |

| Parameters | pH | TS 1 | VS 2 | TKN 3 | NH4+-N 4 | COD 5 | SCOD 6 | Alkalinity (as CaCO3) | TVFAs 7 (as Acetate) |

|---|---|---|---|---|---|---|---|---|---|

| mg/L | |||||||||

| Inoculum | 7.9 (0.01) 8 | 59,347 (1634) | 31,007 (1146) | 5188 (176) | 3262 (79) | 39,250 (823) | 2498 (361) | 34,238 (430) | 1165 (37) |

| Operation Stages | Units | R1 | R2 | R3 |

|---|---|---|---|---|

| HRT 1 | days | 40 | 30 | 20 |

| Operation period | 72 | 56 | 56 | |

| Bu-exp 2 | Nm3/kg-VSadded | 0.16 | 0.15 | 0.14 |

| Methane production | Nm3/ton | 17.4 | 16.3 | 15.2 |

| pH | - | 8.0 (0.12) 10 | 7.9 (0.10) | 7.9 (0.10) |

| TS 3 | mg/L | 51,648 (11,438) | 68,246 (12,126) | 95,877 (17,751) |

| VS 4 | mg/L | 37,574 (10,764) | 53,227 (11,643) | 76,392 (16,877) |

| COD 5 | mg/L | 36,291 (5307) | 45,498 (9154) | 64,333 (13,712) |

| SCOD 6 | mg/L | 9107 (1090) | 12,122 (3276) | 16,395 (3928) |

| TKN 7 | mg/L | 5614 (448) | 4938 (369) | 5631 (586) |

| NH4+-N 8 | mg/L | 4146 (388) | 3450 (289) | 3734 (314) |

| Alkalinity | mg/L as (CaCO3) | 21,054 (1088) | 19,843 (1011) | 22,730 (1152) |

| TVFAs 9 | mg/L (as acetate) | 2728 (454) | 2302 (305) | 2106 (103) |

| Parameters | AD-T 1 | AD-S 2 | HTC-H 3 | ||||

|---|---|---|---|---|---|---|---|

| 160 °C | 180 °C | 200 °C | 220 °C | ||||

| TS 4 | mg/kg | 168,468 (365) 8 | 267,370 (7083) | 260,375 (2942) | 257,419 (5411) | 203,799 (8802) | 227,572 (3485) |

| VS 5 | 116,030 (866) | 189,545 (7139) | 181,628 (982) | 171,833 (3869) | 140,056 (5315) | 145,909 (4003) | |

| TKN 6 | 10,233 (165) | 11,448 (145) | 9577 (264) | 9886 (192) | 8867 (534) | 9759 (237) | |

| NH4+-N 7 | 5431 (213) | 6180 (32) | 4430 (126) | 4213 (49) | 4220 (171) | 4334 (142) | |

| Parameters | HTC-S 1 | ||||

|---|---|---|---|---|---|

| 160 °C | 180 °C | 200 °C | 220 °C | ||

| TS 2 | mg/kg | 325,556 (6959) 7 | 285,978 (6142) | 317,879 (4227) | 345,129 (1439) |

| VS 3 | 220,473 (8687) | 191,284 (4225) | 214,302 (2569) | 218,607 (1476) | |

| TKN 4 | 10,784 (336) | 11,610 (391) | 11,452 (269) | 11,709 (361) | |

| NH4+-N 5 | 4530 (76) | 5522 (31) | 4555 (85) | 4331 (108) | |

| HHV 6 | kJ/kg | 16,050 | 15,661 | 15,945 | 15,313 |

| Parameters | HTC-L 1 | |||||

|---|---|---|---|---|---|---|

| 160 °C | 180 °C | 200 °C | 220 °C | |||

| pH | - | 8.7 (0.01) 9 | 8.3 (0.01) | 8.4 (0.01) | 8.1 (0.01) | |

| TS 2 | mg/L | 51,833 (1235) | 51,333 (2941) | 50,289 (499) | 46,200 (1014) | |

| VS 3 | mg/L | 33,489 (683) | 33,133 (2641) | 31,511 (440) | 25,622 (1887) | |

| TKN 4 | mg/L | 6755 (194) | 7576 (77) | 7131 (481) | 7362 (432) | |

| NH4+-N 5 | mg/L | 4212 (170) | 5089 (16) | 4811 (280) | 4886 (51) | |

| COD 6 | mg/L | 51,850 (879) | 46,450 (1203) | 49,600 (265) | 44,150 (862) | |

| SCOD 7 | mg/L | 39,595 (2202) | 43,900 (482) | 48,215 (436) | 42,620 (1351) | |

| Alkalinity | mg/L (as CaCO3) | 20,775 (416) | 24,050 (350) | 20,600 (325) | 20,225 (513) | |

| TVFAs 8 | mg/L (as acetate) | 2039 (33) | 2842 (15) | 4180 (19) | 13,729 (24) | |

| Elemental composition | C | % | 32.1 | 30.6 | 30.1 | 31.6 |

| H | % | 2.8 | 3.2 | 2.7 | 2.8 | |

| O | % | 27.1 | 32.7 | 21.6 | 38.2 | |

| N | % | 3.3 | 1.5 | 3.0 | 1.7 | |

| S | % | 2.2 | 1.2 | 1.2 | 1.5 | |

| Parameters | Reaction Temperature | HTC-L 1 | ||||

|---|---|---|---|---|---|---|

| 160 °C | 180 °C | 200 °C | 220 °C | |||

| Bth 2 | Nm3/kg-VSadded | 0.38 | 0.36 | 0.44 | 0.30 | |

| Bu-exp 3 | Nm3/kg-VSadded | 0.11 | 0.17 | 0.23 | 0.27 | |

| Methane production | Nm3/ton | 3.8 | 5.6 | 7.2 | 6.9 | |

| VSr 4 | % | 30.1 | 46.7 | 51.5 | 90.2 | |

| Model parameters | Bu-p 5 | Nm3/kg-VSadded | 0.11 | 0.16 | 0.22 | 0.27 |

| Bmax 6 | mL | 141 | 200 | 276 | 335 | |

| fe 7 | - | 0.61 | 0.64 | 0.56 | 0.56 | |

| k1 8 | - | 0.11 | 0.09 | 0.07 | 0.05 | |

| k2 9 | - | 0.04 | 0.05 | 0.05 | 0.05 | |

| HRT 1 | Process | Input and Output Materials | Input | Output | ||||

|---|---|---|---|---|---|---|---|---|

| Amount | Solid | Calorific Value | Solid Yield | Methane Yield | Calorific Value | |||

| days | kg | kg | MJ/kg | kg | Nm3/kg-VSadded | MJ/kg | ||

| Input | FCM 2 | 0.5 | 0.110 | 15.3 | - | - | - | |

| PS 3 | 0.5 | 0.024 | 18.9 | - | - | - | ||

| Mixture | 1.0 | 0.133 | 17.1 | - | - | - | ||

| 40 | AD 4 | AD-T 5 | - | - | 0.052 | 0.157 | - | |

| AD-S 6 | - | - | 0.039 | - | - | |||

| HTC 7 | HTC-H 8 | - | - | 0.038 | - | - | ||

| HTC-S 9 | - | - | 0.036 | - | 16.05 | |||

| HTC-L 10 | - | - | 0.002 | 0.103 | - | |||

| 30 | AD | AD-T | - | - | 0.068 | 0.149 | - | |

| AD-S | - | - | 0.050 | - | - | |||

| HTC | HTC-H | - | - | 0.049 | - | - | ||

| HTC-S | - | - | 0.046 | - | 16.05 | |||

| HTC-L | - | - | 0.003 | 0.097 | - | |||

| 20 | AD | AD-T | - | - | 0.096 | 0.138 | - | |

| AD-S | - | - | 0.071 | - | - | |||

| HTC | HTC-H | - | - | 0.070 | - | - | ||

| HTC-S | - | - | 0.066 | - | 16.05 | |||

| HTC-L | - | - | 0.004 | 0.086 | - | |||

| HRT 1 | Days | 40 | 30 | 20 | ||

|---|---|---|---|---|---|---|

| Input energy 2 | MJ/day, (%) | 171,167 | 171,167 | 171,167 | ||

| (100.0) | (100.0) | (100.0) | ||||

| Output energy | Solid fuel | HTC-S 3 | 58,082 | 75,161 | 107,259 | |

| (33.9) | (43.9) | (62.7) | ||||

| Gas fuel (methane) | Livestock manure | 68,517 | 65,100 | 60,336 | ||

| (40.0) | (38.0) | (35.3) | ||||

| HTC-L 4 | 24.8 | 39.1 | 70.6 | |||

| (0.01) | (0.02) | (0.04) | ||||

| Loss energy 5 | 87,016 | 73,339 | 45,973 | |||

| (26.0) | (18.0) | (2.1) | ||||

| Consumption energy | HTC 6 | MJ/day | 14,568 | 18,852 | 26,903 | |

| Dry 7 | 5563 | 7199 | 10,273 | |||

| Gross bioenergy recovery 8 | % | 74.0 | 82.0 | 98.0 | ||

| Net bioenergy recovery 9 | 62.2 | 66.5 | 76.2 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.-H.; Yoon, Y.-M. Energy Recovery Efficiency of Integrating Anaerobic Co-Digestion of Pig Slurry and Feedlot Cattle Manure and Hydrothermal Carbonization of Anaerobic Sludge Cake. Processes 2024, 12, 198. https://doi.org/10.3390/pr12010198

Lee J-H, Yoon Y-M. Energy Recovery Efficiency of Integrating Anaerobic Co-Digestion of Pig Slurry and Feedlot Cattle Manure and Hydrothermal Carbonization of Anaerobic Sludge Cake. Processes. 2024; 12(1):198. https://doi.org/10.3390/pr12010198

Chicago/Turabian StyleLee, Jun-Hyeong, and Young-Man Yoon. 2024. "Energy Recovery Efficiency of Integrating Anaerobic Co-Digestion of Pig Slurry and Feedlot Cattle Manure and Hydrothermal Carbonization of Anaerobic Sludge Cake" Processes 12, no. 1: 198. https://doi.org/10.3390/pr12010198

APA StyleLee, J. -H., & Yoon, Y. -M. (2024). Energy Recovery Efficiency of Integrating Anaerobic Co-Digestion of Pig Slurry and Feedlot Cattle Manure and Hydrothermal Carbonization of Anaerobic Sludge Cake. Processes, 12(1), 198. https://doi.org/10.3390/pr12010198