Wheat Germ Drying with Different Time-Temperature Combinations in a Fluidized Bed Dryer

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Analytical Methods

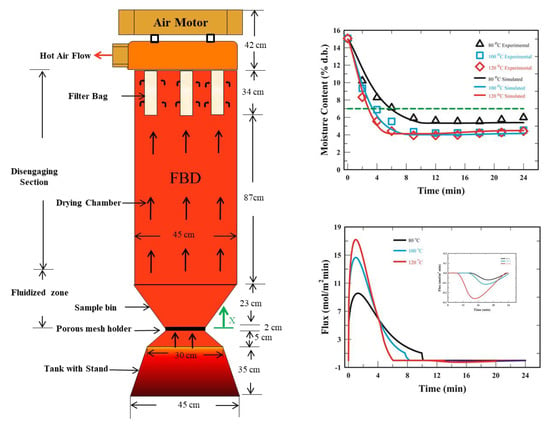

2.3. Fluidized Bed Dryer and Process

2.4. Drying Strategy

3. Mathematical Modelling

3.1. Governing Equations

3.1.1. Microscopic Energy Balance for Wheat Germ

3.1.2. Microscopic Mass Balance for Wheat Germ

3.1.3. Macroscopic Energy Balance of Emulsion Phase

3.1.4. Macroscopic Mass Balance of Emulsion Phase

3.1.5. Macroscopic Mass Balance of Bubble Phase

3.2. Simulation of the Inlet Air Temperature of FBD

3.3. Diffusivity of Moisture in Wheat Germ

3.4. Thermal Input for Wheat Germ Drying

4. Results and Discussion

4.1. Measured and Simulated Responses of the Inlet Temperature of FBD

4.2. Model Verification

4.3. Measured and Simulated Responses of the Moisture Content of WG

4.4. Measured and Simulated Responses of the Water Activity of WG

4.5. Simulated Responses of the Air Temperature and Germ Temperature in the FBD Chamber

4.6. Simulated Responses of the Thermal Input and the Diffusivity of Moisture in WG

4.7. Simulated Responses of WG Temperature Distribution

4.8. Simulated Responses of WG Moisture Distribution

4.9. Simulated Responses of the Dehydration Flux and the Condensation Flux on the WG Surface

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Symbol | Meaning (units) |

| surface area per unit volume of wheat germ (1/m) | |

| concentration of moisture in bubble phase (mol/m3) | |

| concentration of moisture in emulsion phase (mol/m3) | |

| concentration of moisture in wheat germ (mol/m3) | |

| saturation concentration (mol/m3) | |

| equilibrium moisture content (mol/m3) | |

| effective heat capacity (J/(kg·K)) | |

| effective diffusivity of water in wheat germ (m2/s) | |

| pre-exponential factor (m2/s) | |

| Diffusivity of water vapor (m2/s) | |

| activation energy of water diffusion (J/mol) | |

| step numerical parameter for condensation | |

| step numerical parameter for dehydration = (1 − ) | |

| height of fluidization (m) | |

| h | convective heat transfer coefficient (W/(m·K)) |

| mass transfer coefficient between bubble phase and emulsion phase (1/s) | |

| mass transfer coefficient for condensation (m/s) | |

| mass transfer coefficient for dehydration (m/s) | |

| molecular weight of water (kg/mol) | |

| Psat | saturated vapor pressure of water (Pa) |

| radius of wheat germ (m) | |

| rate of mass transfer between bubble phase and emulsion phase (mol/(m3·s)) | |

| Rg | gas constant (J/(mol·K)) |

| gas constant (atm/(mol·K)) | |

| relative humidity of air (-) | |

| temperature (K, unless it is specified in °C) | |

| t | time (s) |

| VT | volume of fluidization (m3) |

| loading of wheat germ (kg) | |

| initial moisture content of wheat germ (% d.b.) | |

| r, x | coordination (m) |

| Greek symbols | |

| κ | thermal conductivity (W/(m·K)) |

| porosity of bed (-) | |

| ρ | density (kg/m3) |

| latent heat of vaporization (J/mol) | |

| Subscript | |

| b | bed |

| c | cooling |

| con | condensation |

| e | effective or emulsion |

| g | germ |

| h | heating |

| i | initial |

| in | inlet |

| m | moisture |

| mb | water vapor in bubble phase |

| me | water vapor in emulsion phase |

| s | set |

| sat | saturation |

| w | water |

Appendix A

| 80 °C | 100 °C | 120 °C | ||||

|---|---|---|---|---|---|---|

| Time (min) | Exp. | Sim. | Exp. | Sim. | Exp. | Sim. |

| 0 | 15.07 | 15.00 | 15.07 | 15.00 | 15.07 | 15.00 |

| 2 | 10.21 | 11.64 | 9.19 | 9.81 | 8.32 | 9.05 |

| 4 | 8.28 | 8.70 | 6.89 | 6.19 | 5.56 | 5.14 |

| 6 | 7.12 | 6.92 | 5.64 | 4.62 | 4.43 | 4.13 |

| 9 | 5.92 | 5.62 | 4.56 | 4.02 | 3.94 | 4.13 |

| 12 | 5.64 | 5.34 | 4.36 | 4.02 | 3.94 | 4.14 |

| 15 | 5.55 | 5.34 | 4.33 | 4.02 | 3.98 | 4.26 |

| 18 | 5.53 | 5.36 | 4.49 | 4.07 | 4.18 | 4.39 |

| 21 | 5.75 | 5.40 | 4.32 | 4.13 | 4.27 | 4.47 |

| 24 | 5.99 | 5.41 | 4.68 | 4.15 | 4.42 | 4.49 |

| ADD | 0.40 | 0.47 | 0.26 | |||

| R2 | 0.976 | 0.989 | 0.992 | |||

References

- Brandolini, A.; Hidalgo, A. Wheat germ: Not only a by-product. Int. J. Food Sci. Nutr. 2012, 63, 71–74. [Google Scholar] [CrossRef] [PubMed]

- Mahmoud, A.A.; Mohdaly, A.A.A.; Elneairy, N.A.A. Wheat germ: An overview on nutritional value, antioxidant potential and antibacterial characteristics. Food Nutr. Sci. 2015, 6, 265–277. [Google Scholar] [CrossRef]

- Zhu, K.X.; Lian, C.X.; Guo, X.N.; Peng, W.; Zhou, H.M. Antioxidant activities and total phenolic content of various extracts from defatted wheat germ. Food Chem. 2011, 126, 1122–1126. [Google Scholar] [CrossRef]

- Gili, R.D.; Martín Torrez Irigoyen, R.; Cecilia Penci, M.; Giner, S.A.; Ribotta, P.D. Wheat germ thermal treatment in fluidised bed. Experimental study and mathematical modelling of the heat and mass transfer. J. Food Eng. 2018, 221, 11–19. [Google Scholar] [CrossRef]

- Fernando, W.J.N.; Hewavitharana, L.G. Effect of fluidized bed drying on stabilization of rice bran. Dry. Technol. 1993, 11, 1115–1125. [Google Scholar] [CrossRef]

- Martinez, M.L.; Marin, M.A. Optimization of soybean heat-treating using a fluidized bed dryer. J. Food Sci. Technol. 2013, 50, 1144–1150. [Google Scholar] [CrossRef] [PubMed]

- Romeo, T.T. Fundamentals of Food Process Engineering, 3rd ed.; Springer Asia Limited: Hong Kong, China, 2007. [Google Scholar]

- Hemis, M.; Singh, C.B.; Jaya, D.S.; Bettahar, A. Simulation of coupled heat and mass transfer in granular porous media: Application to the drying of wheat. Dry. Technol. 2011, 29, 1267–1272. [Google Scholar] [CrossRef]

- Srivastava, V.K.; John, J. Deep bed grain drying model. Energy Convers. Manag. 2002, 43, 1689–1708. [Google Scholar] [CrossRef]

- Giner, S.A.; De Michelis, A. Evaluation of the thermal efficiency of wheat drying in fluidized beds: Influence of air temperature and heat recovery. J. Agric. Eng. Res. 1988, 41, 11–23. [Google Scholar] [CrossRef]

- Naghavi, Z.; Moheb, A.; Ziaei-Rad, S. Numerical simulation of rough rice drying in a deep-bed dryer using non-equilibrium model. Eng. Convers. Manag. 2010, 51, 258–264. [Google Scholar] [CrossRef]

- Giner, S.A.; Calvelo, A. Modeling of wheat drying in fluidized bed. J. Food Sci. 1987, 52, 1358–1363. [Google Scholar] [CrossRef]

- Yang, W.C. Handbook of Fluidization and Fluid–Particle System; Marcel Dekker: New York, NY, USA, 2003. [Google Scholar]

- Levenspiel, O. Chemical Reaction Engineering, 3rd ed.; John Wiley & Sons, Inc.: New York, NY, USA, 1999. [Google Scholar]

- Shingare, S.P.; Thorat, B.N. Fluidized bed drying of sprouted wheat (Triticum aestivum). Int. J. Food Eng. 2014, 10, 29–37. [Google Scholar] [CrossRef]

- Srivastava, A.K.; Sudha, M.L.; Baskaran, V.; Leelavathi, K. Studies on heat stabilized wheat germ and its influence on rheological characteristics of dough. Eur. Food Res. Technol. 2007, 224, 365–372. [Google Scholar] [CrossRef]

- Yondem-Makascıoglu, F.; Gurun, B.; Dik, T.; Kıncal, N.S. Use of a spouted bed to improve the storage stability of wheat germ followed in paper and polyethylene packages. J. Sci. Food Agric. 2005, 85, 1329–1336. [Google Scholar] [CrossRef]

- Chan, D.S.; Chan, J.S.; Kuo, M.I. Modelling Condensation and Simulation for Wheat Germ Drying in Fluidized Bed Dryer. Processes 2018, 6, 71. [Google Scholar] [CrossRef]

- American Association of Cereal Chemists. Approved Methods of Analysis, 10th ed.; AACC International Press: St. Paul, MN, USA, 2000. [Google Scholar]

- Damodaran, S.; Parkin, K. Fennema’s Food Chemistry, 5th ed.; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Nielsen, S.S. Food Analysis, 5th ed.; Springer: Gewerbestrasse, Switzerland, 2017. [Google Scholar]

| Stages (min) | Set Temperature | ||

|---|---|---|---|

| 80 °C | 100 °C | 120 °C | |

| Preheating | 10.0 | 10.0 | 10.0 |

| Sample Loading | 1.0 | 1.0 | 1.0 |

| Heating | 9.4 | 7.5 | 3.0 |

| Cooling | 14.6 | 16.5 | 21.0 |

| Variable | Meaning | Expression |

|---|---|---|

| Rate of mass transfer | ||

| Saturated vapor pressure | ||

| Saturated concentration | ||

| Step function | ||

| Step function |

| Panel A: Parameters and corresponding values used in this study | ||||||||||

| Par. | Value | Par. | Value | Par. | Value | Par. | Value | |||

| Ag | 3239 1/m e | Tgi | 298.15 K m | Xwi | 0.15 d.b. m | h | 32.5 W/m2 ·K s | |||

| rg | 9.26 × 10−3 m e | Tin | 303.15 K m | 0.92 (-) m | Kbe | 1.2 × 10−3 m/s s | ||||

| Hf | 0.57 m m | WL | 2.0 kg m | Do | 7.5 × 10−4 m2/s s | Mw | 0.018 kg/mol t | |||

| RHi | 0.75 (-) m | u | 1.2 m/s m | Dv | 1.0 × 10−5 m2/s s | RT | 0.08205 atm/(mol·K) t | |||

| RHin | 0.75 (-) m | VT | 0.214 m3 m | Ea | 29.4 × 103 J/mol s | Rg | 8.314 J/(mol·K) t | |||

| Panel B: Parameters and corresponding values for different set temperature operation | ||||||||||

| Parameter | Set Temperature | |||||||||

| 80 °C | 100 °C | 120 °C | ||||||||

| Kcon (m/s) | 1.5 × 10−3 s | 2.5 × 10−3 s | 4.0 × 10−3 s | |||||||

| Kde (m/s) | 7.0 × 10−3 s | 9.0 × 10−3 s | 12.0 × 10−3 s | |||||||

| n | 0.36 s | 0.37 s | 0.39 s | |||||||

| Tstart | 70.0 m | 85.0 m | 101.0 m | |||||||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chan, D.-S.; Kuo, M.-I. Wheat Germ Drying with Different Time-Temperature Combinations in a Fluidized Bed Dryer. Processes 2018, 6, 245. https://doi.org/10.3390/pr6120245

Chan D-S, Kuo M-I. Wheat Germ Drying with Different Time-Temperature Combinations in a Fluidized Bed Dryer. Processes. 2018; 6(12):245. https://doi.org/10.3390/pr6120245

Chicago/Turabian StyleChan, Der-Sheng, and Meng-I Kuo. 2018. "Wheat Germ Drying with Different Time-Temperature Combinations in a Fluidized Bed Dryer" Processes 6, no. 12: 245. https://doi.org/10.3390/pr6120245

APA StyleChan, D. -S., & Kuo, M. -I. (2018). Wheat Germ Drying with Different Time-Temperature Combinations in a Fluidized Bed Dryer. Processes, 6(12), 245. https://doi.org/10.3390/pr6120245