Sequential Scheduling Method for FJSP with Multi-Objective under Mixed Work Calendars

Abstract

:1. Introduction

2. Problem Description

3. Definition of Types, Variables and Arrays

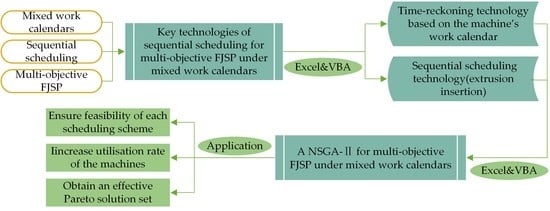

4. Key Technologies

4.1. Time Reckoning Technology Based on the Machine’s Work Calendar

4.1.1. Design and Configuration of Work Calendar

4.1.2. Design of Time-Reckoning Function Based on Work Calendar

4.2. Sequential Scheduling Technology

5. Non-Dominated Sorting Genetic Algorithm with an Elite Strategy (NSGA-II) Design

5.1. Algorithm Flow

5.2. Obtaining Input Parameters

5.3. Encoding Method

5.4. Population Initialization

5.5. Select Operation

5.6. Genetic Operation

5.7. Crossover Operation

5.8. Mutation Operation

5.9. Decoding Operation

5.10. Calculating Objectives

6. Case Study

7. Discussion

8. Conclusions

- The algorithm can ensure feasibility of the scheduling scheme by accurately calculating adjusting start and end time, processing start and end time of each process through time reckoning functions in the process of arranging processes.

- The algorithm can increase the utilization rate of the machines in the sequential scheduling by the following two technologies. One is taking the time status of the machines of the previous schedule as the initial status of the machines of the next schedule. The other is adopting the “extrusion insertion” method to arrange each process.

- The proposed method can help to obtain an effective Pareto solution set of the sequential scheduling problem for FJSP with multi-objectives under mixed work calendars for the dispatcher to make decisions in acceptable time.

Author Contributions

Funding

Conflicts of Interest

References

- Gao, L.; Pan, Q.K. A shuffled multi-swarm micro-migrating birds optimizer for a multi-resource-constrained flexible job shop scheduling problem. Inf. Sci. 2016, 372, 655–676. [Google Scholar] [CrossRef]

- Amirghasemi, M.; Zamani, R. An effective asexual genetic algorithm for solving the job shop scheduling problem. Comput. Ind. Eng. 2015, 83, 123–138. [Google Scholar] [CrossRef]

- Kundakci, N.; Kulak, O. Hybrid genetic algorithms for minimizing makespan in dynamic job shop scheduling problem. Comput. Ind. Eng. 2016, 96, 31–51. [Google Scholar] [CrossRef]

- Xiong, W.; Li, Z.B.; Hao, J.B. Research on methods to solve key problems of dynamic job shop scheduling. Modul. Mach. Tool Autom. Manuf. Tech. 2008, 7, 105–108, 112. [Google Scholar]

- Wu, Z.J.; Ning, R.X.; Wan, C.H. Research and Implementation of Dynamic Workday System in Job Shop Scheduling. Manuf. Autom. 2006, 4, 46–48, 75. [Google Scholar]

- Huang, Y.Y.; Li, K.Q.; Zheng, X.F. Job Shop Equal-Scale Batch Scheduling Algorithm Considering Shift Constraints. Sci. Technol. Eng. 2013, 1, 1–7, 16. [Google Scholar]

- Stefan, K.; Julia, R.; Jürgen, Z. Models and solution procedures for the resource-constrained project scheduling problem with general temporal constraints and calendars. Eur. J. Oper. Res. 2016, 251, 387–403. [Google Scholar]

- Wan, C.H.; Yan, Y.; Wu, Z.J.; Wang, G.X. Research on Dynamic Workday System for Dynamic Scheduling of Workshop Production. Modul. Mach. Tool Autom. Manuf. Tech. 2006, 3, 102–104. [Google Scholar]

- Wu, X.L.; Sun, S.D.; Yu, J.J.; Zhang, H.F. Research on Multi-Objective Flexible Job Shop Scheduling Optimization. Comput. Integr. Manuf. Syst. 2006, 5, 731–736. [Google Scholar]

- He, G.X. The application of multi-objective programming in the problem of transshipment of railway partial load freight. China Railw. Sci. 2007, 4, 111–116. [Google Scholar] [CrossRef]

- Zhou, G.G. Efficiency coefficient method for solving multi-objective optimization problems. J. Shanghai Inst. Meenanical Eng. 1987, 3, 103–108. [Google Scholar]

- Song, L.F.; Wei, G.; Wang, Q.S. Segmentation of Video Objects by Multi-Objective Optimization of Contour Positioning. J. Electron. Inf. Technol. 2002, 11, 1551–1558. [Google Scholar]

- Wang, B.G.; Rao, Y.Q.; Shao, X.Y.; Xu, C. A MOGA-based Algorithm for Sequencing a Mixed-model Fabrication/Assembly System. China Mech. Eng. 2009, 20, 1434–1438. [Google Scholar]

- Liu, A.J.; Yang, Y.; Xing, Q.S.; Lu, H.; Zhang, Y.D. Research on Niche Genetic Annealing Algorithm with Elite Strategy and Its Applications. China Mech. Eng. 2012, 23, 556–563. [Google Scholar]

- Zitzler, E.; Thiele, L. Multi-objective evolutionary algorithms: A comparative case study and the strength pareto approach. IEEE Trans. Evolut. Comput. 1993, 3, 257–271. [Google Scholar] [CrossRef]

- Zitzler, E.; Laumanns, M.; Thiele, L. SPEA2: Improving the strength pareto evolutionary algorithm for multi-objective optimization. In Proceedings of the Evolutionary Methods for Design, Optimization and Control with Applications to Industrial Problems (EUROGEN’2001), Athens, Greece, 19–21 September 2001; pp. 95–100. [Google Scholar]

- Ju, L.Y.; Yang, J.J.; Zhang, J.B.; Guo, L.L.; Li, S.B. Improved NSGA for Multi-Objective Flexible Job-Shop Scheduling Problem. Comput. Eng. Appl. 2019, 55, 260–265, 270. [Google Scholar]

- Qiu, Z.P.; Zhang, Y.X. Application of Improved Genetic Algorithm in Aircraft Overall Parameter Optimization. J. Beijing Univ. Aeronaut. Astronaut. 2008, 10, 1182–1185. [Google Scholar]

- Bekkar, A.; Guemri, O.; Bekrar, A.; Aissani, N.; Beldjilali, B.; Trentesaux, D. An Iterative Greedy Insertion Technique for Flexible Job Shop Scheduling Problem. IFAC-Pap. Online 2016, 12, 1956–1961. [Google Scholar] [CrossRef]

- Chen, H.P.; Gu, F.; Lu, B.Y.; Gu, C.S. Application of Self-Adaptive Multi-Objective Genetic Algorithm in Flexible Job Shop Scheduling. J. Syst. Simul. 2006, 18, 2271–2274, 2288. [Google Scholar]

| Name | Meaning | Element Type | Category 1 | Category 2 |

|---|---|---|---|---|

| jnum | number of scheduled workpieces | integer | global | input parameter |

| tpnum | number of scheduled processes | integer | global | input parameter |

| mnum | number of scheduled machines | integer | global | input parameter |

| bt | scheduling start time | date | global | input parameter |

| tln | large time | double | global | input parameter |

| popsize | population size | integer | global | input parameter |

| pc | crossover rate | double | global | input parameter |

| pm | mutation rate | double | global | input parameter |

| cr | crossover ratio | double | global | input parameter |

| mr | mutation ratio | double | global | input parameter |

| mbs | number of objectives | integer | global | input parameter |

| maxgen | maximum evolution algebra | integer | global | input parameter |

| nws | number of work systems | integer | global | input parameter |

| nwt | number of work shifts | integer | global | input parameter |

| thr | positive real number close to 0 | double | local | middle parameter |

| epoc | current evolutionary algebra | Integer | local | middle parameter |

| P1, P2 | two parent individuals before crossover operation | chr | local | middle parameter |

| ch | individual | chr | local | middle parameter |

| r | random real number between 0 and 1 | double | local | middle parameter |

| st | adjusting time, h | double | local | middle parameter |

| ct | processing time, h | double | local | middle parameter |

| g | the earliest adjustable time of a process | date | local | middle parameter |

| frnum | number of idle periods of a machine | integer | local | middle parameter |

| tb | start time of the kth idle period of a machine | date | local | middle parameter |

| te | end time of the kth idle periods of a machine | date | local | middle parameter |

| tsb | adjusting start time of a process | date | local | middle parameter |

| tse | adjusting end time of a process | date | local | middle parameter |

| tcb | processing start time of a process | date | local | middle parameter |

| tce | processing end time of a process | date | local | middle parameter |

| jc | details of a process | string | local | middle parameter |

| Name | Meaning | Type | Size | Type 1 | Type 2 |

|---|---|---|---|---|---|

| MA | machine | variant | mnum × 5 | global | input parameter |

| JB | workpiece | job | jnum × 1 | global | input parameter |

| MMB | machines’ time status before scheduling | mach | mnum × 1 | global | input parameter |

| WS | work systems | variant | 500 × 2nws | global | input parameter |

| WT | work shifts | variant | 8 × 7nwt | global | input parameter |

| PPOP | parent population | chr | Popsize × 1 | local | middle parameter |

| PLPOP | pairing pool | chr | popsize/2 × 1 | local | middle parameter |

| OPOP | population after crossover and mutation operation | chr | popsize/2 × 1 | local | middle parameter |

| INPOP | combined population | chr | popsize × 1 | local | middle parameter |

| CPOP | offspring population | chr | popsize × 1 | local | middle parameter |

| OC | two offspring individuals after crossover operation | chr | 2 × 1 | local | middle parameter |

| Workpiece No. | Workpiece Name | Type |

|---|---|---|

| 1 | L2027 | X5 |

| 2 | G46-100F | L5 |

| 3 | ZU30100B2 | M3 |

| 4 | L90GF | M2 |

| 5 | L35MC | X5 |

| 6 | HP6100 | Y2 |

| 7 | 16V32G | M6 |

| 8 | G-45B | N7 |

| 9 | RT-flex | Y1 |

| 10 | DK28 | X8 |

| Workpiece Name | Process No. | Process Name | Feasible Machine No. | Processing Time (h) | Adjusting Time (h) | Processing Cost Per Hour (yuan/h) | Adjusting Cost Per Hour (yuan/h) |

|---|---|---|---|---|---|---|---|

| L2027 | 1 | machining shape | 1, 2, 3, 4 | 9, 12, 11.25, 15 | 0.96, 1.2, 1.2, 1.5 | 390, 300, 337, 259 | 336, 240, 297, 212 |

| L2027 | 2 | vehicle end face | 2, 4 | 10, 13 | 1.2, 1.5 | 250, 216 | 200, 177 |

| L2027 | 3 | vehicle circle | 2, 4 | 8, 10 | 1.2, 1.5 | 280, 242 | 240, 212 |

| L2027 | 4 | cone surface | 1, 2, 3, 4 | 5.25, 7, 6.75, 9 | 0.96, 1.2, 1.2, 15 | 390, 300, 337, 259 | 322, 230, 285, 203 |

| L2027 | 5 | drilling and hinge pin holes | 5, 6, 7 | 5.63, 7.5, 10 | 0.64, 0.8, 1 | 507, 390, 300 | 470, 336, 240 |

| L2027 | 6 | milling 20 | 8, 9 | 9, 12 | 0.8, 1 | 390, 300 | 350, 250 |

| L2027 | 7 | grinding middle hole | 10, 11, 12 | 5.63, 7.5, 10 | 0.64, 0.8, 1 | 406, 312, 240 | 353, 252, 180 |

| L2027 | 8 | grinding chamfer | 13, 14 | 6.75, 9 | 0.66, 0.83 | 390, 300 | 336, 240 |

| L2027 | 9 | grinding cylindrical | 15, 16 | 9, 12 | 0.66, 0.83 | 351, 270 | 336, 240 |

| L2027 | 10 | grinding end face | 17, 18 | 7.5, 10 | 0.94, 1.17 | 312, 240 | 252, 180 |

| G46-100F | 1 | machining shape | 1, 2, 3, 4 | 9.75, 13, 10.5, 14 | 0.96, 1.2, 1.2, 1.5 | 390, 300, 314, 241 | 336, 240, 279, 199 |

| G46-100F | 2 | vehicle end face | 2, 4 | 11, 13 | 1.2, 1.5 | 250, 241 | 200, 199 |

| G46-100F | 3 | vehicle circle | 2, 4 | 12, 10 | 1.2, 1.5 | 280, 241 | 240, 199 |

| G46-100F | 4 | cone surface | 1, 2, 3, 4 | 7.5, 10, 8.25, 11 | 1, 1.2, 1.2, 1.5 | 390, 300, 314, 241 | 322, 230, 279, 199 |

| G46-100F | 5 | drilling and hinge pin holes | 5, 6, 7 | 6.75, 9, 12 | 0.64, 0.8, 1 | 507, 390, 300 | 470, 336, 240 |

| G46-100F | 6 | milling 20 | 8, 9 | 9, 12 | 0.8, 1 | 390, 300 | 350, 250 |

| G46-100F | 7 | grinding middle hole | 10, 11, 12 | 4.5, 6, 8 | 0.64, 0.8, 1 | 406, 312, 240 | 353, 252, 180 |

| G46-100F | 8 | grinding chamfer | 13, 14 | 6, 8 | 0.66, 0.83 | 390, 300 | 336, 240 |

| G46-100F | 9 | grinding cylindrical | 15, 16 | 11.25, 15 | 0.66, 0.83 | 351, 270 | 336, 240 |

| G46-100F | 10 | grinding end face | 17, 18 | 6.75, 9 | 0.94, 1.17 | 312, 240 | 252, 180 |

| ZU30100B2 | 1 | machining shape | 2, 4 | 12, 12 | 1.2, 1.5 | 300, 241 | 240, 199 |

| ZU30100B2 | 2 | vehicle end fac | 1, 2, 4 | 7.5, 10, 10 | 0.96, 1.2, 1.5 | 325, 250, 241 | 280, 200, 199 |

| ZU30100B2 | 3 | vehicle circle | 1, 2, 4 | 6, 8, 13 | 0.96, 1.2, 1.5 | 364, 280, 241 | 336, 240, 199 |

| ZU30100B2 | 4 | cone surface | 2, 4 | 7, 15 | 1.2, 1.5 | 300, 241 | 230, 199 |

| ZU30100B2 | 5 | drilling and hinge pin holes | 5, 6, 7 | 6.75, 9, 12 | 0.64, 0.8, 1 | 507, 390, 300 | 470, 336, 240 |

| ZU30100B2 | 6 | milling 20 | 8, 9 | 12, 16 | 0.8, 1 | 390, 300 | 350, 250 |

| ZU30100B2 | 7 | grinding middle hole | 10, 11, 12 | 6.75, 9, 12 | 0.64, 0.8, 1 | 406, 312, 240 | 353, 252, 180 |

| ZU30100B2 | 8 | grinding chamfer | 13, 14 | 7.5, 10 | 0.66, 0.83 | 390, 300 | 336, 240 |

| ZU30100B2 | 9 | grinding cylindrical | 15, 16 | 9.75, 13 | 0.66, 0.83 | 351, 270 | 336, 240 |

| ZU30100B2 | 10 | grinding end face | 17, 18 | 8.25, 11 | 0.94, 1.17 | 312, 240 | 252, 180 |

| L90GF | 1 | machining shape | 1, 2, 3, 4 | 9, 12, 11.25, 15 | 0.96, 1.2, 1.2, 1.5 | 390, 300, 314, 241 | 336, 240, 279, 199 |

| L90GF | 2 | vehicle end face | 1, 2, 3, 4 | 7.5, 10, 9.75, 13 | 0.96, 1.2, 1.2, 1.5 | 325, 250, 314, 241 | 280, 200, 279, 199 |

| L90GF | 3 | vehicle circle | 3, 4 | 9, 12 | 1.2, 1.5 | 314, 241 | 279, 199 |

| L90GF | 4 | cone surface | 1, 2, 3, 4 | 9, 12, 9.75, 13 | 0.96, 1.2, 1.2, 1.5 | 390, 300, 314, 241 | 322, 230, 279, 199 |

| L90GF | 5 | drilling and hinge pin holes | 5, 6, 7 | 8.44, 11.25, 15 | 0.64, 0.8, 1 | 507, 390, 300 | 470, 336, 240 |

| L90GF | 6 | milling 20 | 8, 9 | 9, 12 | 0.8, 1 | 390, 300 | 350, 250 |

| L90GF | 7 | grinding middle hole | 10, 11, 12 | 5.06, 6.75, 9 | 0.64, 0.8, 1 | 406, 312, 240 | 353, 252, 180 |

| L90GF | 8 | grinding chamfer | 13, 14 | 8.25, 11 | 0.66, 0.83 | 390, 300 | 336, 240 |

| L90GF | 9 | grinding cylindrical | 15, 16 | 10.5, 14 | 0.66, 0.83 | 351, 270 | 336, 240 |

| L90GF | 10 | grinding end face | 17, 18 | 9, 12 | 0.94, 1.17 | 312, 240 | 252, 180 |

| L35MC | 1 | machining shape | 1, 2, 3, 4 | 9, 12, 11.25, 15 | 0.96, 1.2, 1.2, 1.5 | 390, 300, 314, 241 | 336, 240, 279, 199 |

| L35MC | 2 | vehicle end face | 3, 4 | 9.75, 13 | 1.2, 1.5 | 314, 241 | 279, 199 |

| L35MC | 3 | vehicle circle | 3, 4 | 7.5, 10 | 1.2, 1.5 | 314, 241 | 279, 199 |

| L35MC | 4 | cone surface | 1, 2, 3, 4 | 9, 12, 10.5, 14 | 0.96, 1.2, 1.2, 1.5 | 390, 300, 314, 241 | 322, 230, 279, 199 |

| L35MC | 5 | drilling and hinge pin holes | 5, 6, 7 | 6.19, 8.25, 11 | 0.64, 0.8, 1 | 507, 390, 300 | 470, 336, 240 |

| L35MC | 6 | milling 20 | 8, 9 | 6.75, 9 | 0.8, 1 | 390, 300 | 350, 250 |

| L35MC | 7 | grinding middle hole | 10, 11, 12 | 4.5, 6, 8 | 0.64, 0.8, 1 | 406, 312, 240 | 353, 252, 180 |

| L35MC | 8 | grinding chamfer | 13, 14 | 9, 12 | 0.66, 0.83 | 390, 300 | 336, 240 |

| L35MC | 9 | grinding cylindrical | 15, 16 | 9, 12 | 0.66, 0.83 | 351, 270 | 336, 240 |

| L35MC | 10 | grinding end face | 17, 18 | 9.75, 13 | 0.94, 1.17 | 312, 240 | 252, 180 |

| HP6100 | 1 | machining shape | 1, 2, 3, 4 | 9, 12, 11.25, 15 | 0.96, 12, 1.2, 1.5 | 390, 300, 314, 241 | 336, 240, 279, 199 |

| HP6100 | 2 | vehicle end face | 1, 2 | 7.5, 10 | 0.96, 1.2 | 325, 250 | 280, 200 |

| HP6100 | 3 | vehicle circle | 1, 2 | 6, 8 | 0.96, 1.2 | 364, 280 | 336, 240 |

| HP6100 | 4 | cone surface | 1, 2, 3, 4 | 11.25, 15, 11.25, 15 | 0.96, 1.2, 1.2, 1.5 | 390, 300, 314, 241 | 322, 230, 279, 199 |

| HP6100 | 5 | drilling and hinge pin holes | 5, 6, 7 | 6.75, 9, 12 | 0.64, 0.8, 1 | 507, 390, 300 | 470, 336, 240 |

| HP6100 | 6 | milling 20 | 8, 9 | 9, 12 | 0.8, 1 | 390, 300 | 350, 250 |

| HP6100 | 7 | grinding middle hole | 10, 11, 12 | 4.78, 6.38, 8.5 | 0.64, 0.8, 1 | 406, 312, 240 | 353, 252, 180 |

| HP6100 | 8 | grinding chamfer | 13, 14 | 7.5, 10 | 0.66, 0.83 | 390, 300 | 336, 240 |

| HP6100 | 9 | grinding cylindrical | 15, 16 | 8.25, 11 | 0.66, 0.83 | 351, 270 | 336, 240 |

| HP6100 | 10 | grinding end face | 17, 18 | 8.25, 11 | 0.94, 1.17 | 312, 240 | 252, 180 |

| 16V32G | 1 | machining shape | 1, 2 | 9, 12 | 0.96, 1.2 | 390, 300 | 336, 240 |

| 16V32G | 2 | vehicle end face | 1, 2 | 7.5, 10 | 0.96, 1.2 | 325, 250 | 280, 200 |

| 16V32G | 3 | vehicle circle | 2, 3, 4 | 12, 7.5, 10 | 1.2, 1.2, 1.5 | 280, 314, 241 | 240, 279, 199 |

| 16V32G | 4 | cone surface | 2, 3, 4 | 12, 11.25, 15 | 1.2, 1.2, 1.5 | 300, 314, 241 | 230, 279, 199 |

| 16V32G | 5 | drilling and hinge pin holes | 5, 6, 7 | 8.44, 11.25, 15 | 0.64, 0.8,1 | 507, 390, 300 | 470, 336, 240 |

| 16V32G | 6 | milling 20 | 8, 9 | 7.5, 10 | 0.8, 1 | 390, 300 | 350, 250 |

| 16V32G | 7 | grinding middle hole | 10, 11, 12 | 6.08, 8.1, 9 | 0.74, 0.92, 1 | 374, 288, 240 | 290, 207, 180 |

| 16V32G | 8 | grinding chamfer | 13, 14 | 9, 12 | 0.66, 0.83 | 390, 300 | 336, 240 |

| 16V32G | 9 | grinding cylindrical | 15, 16 | 10.5, 14 | 0.66, 0.83 | 351, 270 | 336, 240 |

| 16V32G | 10 | grinding end face | 17, 18 | 8.25, 11 | 0.94, 1.17 | 312, 240 | 252, 180 |

| G-45B | 1 | machining shape | 2, 4 | 8, 10 | 1.2, 1.5 | 300, 241 | 240, 199 |

| G-45B | 2 | vehicle end face | 1, 2, 3, 4 | 7.5, 10, 9.75, 13 | 0.96, 1.2, 1.2, 1.5 | 325, 250, 314, 241 | 280, 200, 279, 199 |

| G-45B | 3 | vehicle circle | 2, 4 | 8, 10 | 1.2, 1.5 | 280, 241 | 240, 199 |

| G-45B | 4 | cone surface | 1, 2, 3, 4 | 8.25, 11, 11.25, 15 | 0.96, 1.2, 1.2, 1.5 | 390, 300, 314, 241 | 322, 230, 279, 199 |

| G-45B | 5 | drilling and hinge pin holes | 5, 6, 7 | 7.31, 9.75, 13 | 0.64, 0.8, 1 | 338, 260, 200 | 314, 224, 160 |

| G-45B | 6 | milling 20 | 8, 9 | 8.25, 11 | 0.8, 1 | 390, 300 | 350, 250 |

| G-45B | 7 | grinding middle hole | 10, 11, 12 | 7.43, 9.9, 11 | 0.74, 0.92, 1 | 374, 288, 240 | 290, 207, 180 |

| G-45B | 8 | grinding chamfer | 13, 14 | 9, 12 | 0.66, 0.83 | 390, 300 | 336, 240 |

| G-45B | 9 | grinding cylindrical | 15, 16 | 7.5, 10 | 0.66, 0.83 | 351, 270 | 336, 240 |

| G-45B | 10 | grinding end face | 17, 18 | 7.5, 10 | 0.94, 1.17 | 312, 240 | 252, 180 |

| Machine No. | Machine Code | Machine Type | Work System | Work Shift |

|---|---|---|---|---|

| 1 | 300T | NC lathe | X | A |

| 2 | 200T | NC lathe | Y | B |

| 3 | T52 | NC lathe | Z | A |

| 4 | T42 | NC lathe | Y | C |

| 5 | Z6018 | bench drill | X | A |

| 6 | Z5018 | bench drill | X | A |

| 7 | Z4018 | bench drill | Y | B |

| 8 | X8126 | milling machine | Z | C |

| 9 | X5126 | milling machine | Y | B |

| 10 | M5515 | horizontal grinding machine tool | X | A |

| 11 | M4515 | horizontal grinding machine tool | X | C |

| 12 | M3515 | horizontal grinding machine tool | Y | B |

| 13 | J5001 | semi-automatic cylindrical grinder | Z | A |

| 14 | J4001 | semi-automatic cylindrical grinder | Y | B |

| 15 | 3U5 | cylindrical grinder | X | C |

| 16 | 2U5 | cylindrical grinder | X | A |

| 17 | 120CNC | internal grinder | Y | B |

| 18 | 111CNC | internal grinder | Z | C |

| Workpiece No. | Workpiece Name | Type | Total Process Number | Delivery Time | Earlier Completion Rate (yuan /d) | Delayed Completion Rate (yuan/d) |

|---|---|---|---|---|---|---|

| 1 | L2027 | X5 | 10 | 2017/4/16 | 100 | 1000 |

| 2 | G46-100F | L5 | 10 | 2017/4/15 | 150 | 1200 |

| 3 | ZU30100B2 | M3 | 10 | 2017/5/13 | 80 | 800 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| jnum | 7 | cr | 0.7 |

| tpnum | 42 | mr | 0.3 |

| mnum | 10 | maxgen | 200 |

| bt | 2017/3/4 8:00:00 | mbs | 2 |

| tln | 4637/11/26 0:00:00 | nws | 3 |

| popsize | 40 | nwt | 3 |

| pc | 0.5 | thr | 0.001 |

| pm | 0.1 |

| No. | Workpiece No. | Process No. | Machine No. | Adjusting Time (h) | Processing Time (h) | Adjusting Start Time | Adjusting End Time | Processing Start Time | Processing End Time | Adjusting Cost (yuan) | Processing Cost (yuan) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 3 | 1 | 4 | 1.5 | 12 | 2017/3/4 9:00 | 2017/3/4 10:30 | 2017/3/4 10:30 | 2017/3/6 6:30 | 299.01 | 2895.69 |

| 2 | 3 | 2 | 4 | 1.5 | 10 | 2017/3/6 6:30 | 2017/3/6 8:00 | 2017/3/6 9:00 | 2017/3/7 3:00 | 299.01 | 2413.07 |

| 3 | 1 | 1 | 1 | 0.96 | 9 | 2017/3/6 8:00 | 2017/3/6 8:57 | 2017/3/6 8:57 | 2017/3/6 19:57 | 322.56 | 3510.00 |

| 4 | 1 | 2 | 2 | 1.2 | 10 | 2017/3/6 15:48 | 2017/3/6 17:00 | 2017/3/7 8:00 | 2017/3/8 10:00 | 240.00 | 2500.00 |

| 5 | 3 | 3 | 1 | 0.96 | 6 | 2017/3/6 21:02 | 2017/3/6 22:00 | 2017/3/7 8:00 | 2017/3/7 15:00 | 322.56 | 2184.00 |

| 6 | 3 | 4 | 2 | 1.2 | 7 | 2017/3/8 10:00 | 2017/3/8 11:12 | 2017/3/8 11:12 | 2017/3/9 10:12 | 276.00 | 2100.00 |

| 7 | 2 | 1 | 4 | 1.5 | 14 | 2017/3/7 3:00 | 2017/3/7 4:30 | 2017/3/7 4:30 | 2017/3/8 3:30 | 299.01 | 3378.30 |

| 8 | 2 | 2 | 2 | 1.2 | 11 | 2017/3/9 10:12 | 2017/3/9 11:24 | 2017/3/9 11:24 | 2017/3/10 15:24 | 240.00 | 2750.00 |

| 9 | 3 | 5 | 5 | 0.64 | 6.75 | 2017/3/9 9:33 | 2017/3/9 10:12 | 2017/3/9 10:12 | 2017/3/9 18:57 | 301.06 | 3422.25 |

| 10 | 2 | 3 | 4 | 1.5 | 10 | 2017/3/10 13:54 | 2017/3/10 15:24 | 2017/3/10 15:24 | 2017/3/11 9:24 | 299.01 | 2413.07 |

| 11 | 3 | 6 | 8 | 0.8 | 12 | 2017/3/9 16:12 | 2017/3/9 17:00 | 2017/3/10 0:00 | 2017/3/10 14:00 | 280.00 | 4680.00 |

| 12 | 1 | 3 | 4 | 1.5 | 10 | 2017/3/8 11:30 | 2017/3/8 14:00 | 2017/3/8 14:00 | 2017/3/9 7:00 | 318.10 | 2421.72 |

| 13 | 2 | 4 | 4 | 1.5 | 11 | 2017/3/11 9:24 | 2017/3/11 10:54 | 2017/3/11 10:54 | 2017/3/13 5:54 | 299.01 | 2654.38 |

| 14 | 3 | 7 | 10 | 0.64 | 6.75 | 2017/3/10 13:21 | 2017/3/10 14:00 | 2017/3/10 14:00 | 2017/3/10 21:45 | 225.79 | 2737.80 |

| 15 | 2 | 5 | 5 | 0.64 | 6.75 | 2017/3/10 21:21 | 2017/3/10 22:00 | 2017/3/13 8:00 | 2017/3/13 15:45 | 301.06 | 3422.25 |

| 16 | 1 | 4 | 1 | 0.96 | 5.25 | 2017/3/8 21:02 | 2017/3/8 22:00 | 2017/3/9 8:00 | 2017/3/9 14:15 | 309.12 | 2047.50 |

| 17 | 1 | 5 | 5 | 0.64 | 5.625 | 2017/3/9 18:57 | 2017/3/9 19:35 | 2017/3/9 19:35 | 2017/3/10 11:12 | 301.06 | 2851.88 |

| 18 | 1 | 6 | 8 | 0.8 | 9 | 2017/3/10 14:00 | 2017/3/10 14:48 | 2017/3/10 14:48 | 2017/3/11 6:48 | 280.00 | 3510.00 |

| 19 | 1 | 7 | 10 | 0.64 | 5.625 | 2017/3/10 21:45 | 2017/3/13 8:23 | 2017/3/13 8:23 | 2017/3/13 15:00 | 225.79 | 2281.50 |

| 20 | 1 | 8 | 13 | 0.664 | 6.75 | 2017/3/13 14:21 | 2017/3/13 15:00 | 2017/3/13 15:00 | 2017/3/14 8:45 | 223.10 | 2632.50 |

| 21 | 1 | 9 | 15 | 0.664 | 9 | 2017/3/14 11:20 | 2017/3/14 12:00 | 2017/3/14 13:00 | 2017/3/15 5:00 | 223.10 | 3159.00 |

| 22 | 3 | 8 | 13 | 0.664 | 7.5 | 2017/3/10 21:05 | 2017/3/10 21:45 | 2017/3/10 21:45 | 2017/3/13 11:15 | 223.10 | 2925.00 |

| 23 | 3 | 9 | 15 | 0.664 | 9.75 | 2017/3/13 10:35 | 2017/3/13 11:15 | 2017/3/13 11:15 | 2017/3/14 5:00 | 223.10 | 3422.25 |

| 24 | 2 | 6 | 8 | 0.8 | 9 | 2017/3/13 14:57 | 2017/3/13 15:45 | 2017/3/13 15:45 | 2017/3/14 7:45 | 280.00 | 3510.00 |

| 25 | 2 | 7 | 11 | 0.8 | 6 | 2017/3/14 6:57 | 2017/3/14 7:45 | 2017/3/14 7:45 | 2017/3/14 15:45 | 201.60 | 1872.00 |

| 26 | 3 | 10 | 17 | 0.936 | 8.25 | 2017/3/13 16:03 | 2017/3/13 17:00 | 2017/3/14 8:00 | 2017/3/15 8:15 | 235.87 | 2574.00 |

| 27 | 2 | 8 | 13 | 0.664 | 6 | 2017/3/14 15:05 | 2017/3/14 15:45 | 2017/3/14 15:45 | 2017/3/15 8:45 | 223.10 | 2340.00 |

| 28 | 2 | 9 | 15 | 0.664 | 11.25 | 2017/3/15 11:20 | 2017/3/15 12:00 | 2017/3/15 13:00 | 2017/3/16 7:15 | 223.10 | 3948.75 |

| 29 | 1 | 10 | 18 | 1.17 | 10 | 2017/3/15 3:49 | 2017/3/15 5:00 | 2017/3/15 5:00 | 2017/3/15 17:00 | 210.60 | 2400.00 |

| 30 | 2 | 10 | 17 | 0.936 | 6.75 | 2017/3/15 16:03 | 2017/3/15 17:00 | 2017/3/16 8:00 | 2017/3/16 15:45 | 235.87 | 2106.00 |

| Workpiece No. | Workpiece Name | Type | Total Process Number | Delivery Date | Earlier Completion Rate (yuan /d) | Delayed Completion Rate (yuan/d) |

|---|---|---|---|---|---|---|

| 2 | G46-100F | L5 | 10 | 2017/4/15 | 150 | 1200 |

| 4 | L90GF | M2 | 10 | 2017/4/20 | 120 | 1500 |

| 5 | L35MC | X5 | 10 | 2017/4/13 | 70 | 600 |

| 6 | HP6100 | Y2 | 10 | 2017/4/16 | 50 | 500 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, Q.; Wang, M.; Shen, L.; Song, H. Sequential Scheduling Method for FJSP with Multi-Objective under Mixed Work Calendars. Processes 2019, 7, 888. https://doi.org/10.3390/pr7120888

Zeng Q, Wang M, Shen L, Song H. Sequential Scheduling Method for FJSP with Multi-Objective under Mixed Work Calendars. Processes. 2019; 7(12):888. https://doi.org/10.3390/pr7120888

Chicago/Turabian StyleZeng, Qiang, Menghua Wang, Ling Shen, and Hongna Song. 2019. "Sequential Scheduling Method for FJSP with Multi-Objective under Mixed Work Calendars" Processes 7, no. 12: 888. https://doi.org/10.3390/pr7120888

APA StyleZeng, Q., Wang, M., Shen, L., & Song, H. (2019). Sequential Scheduling Method for FJSP with Multi-Objective under Mixed Work Calendars. Processes, 7(12), 888. https://doi.org/10.3390/pr7120888