Comparative Evaluation of Selected Biological Methods for the Removal of Hydrophilic and Hydrophobic Odorous VOCs from Air

Abstract

:1. Introduction

1.1. Air Deodorization by Biological Methods

1.2. Assessment of Biological Methods of Air Treatment

1.3. Aim of Investigations

2. Materials and Methods

2.1. Data Collection

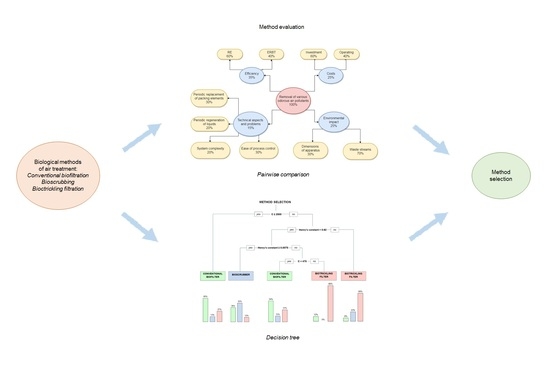

2.2. Comparative Analysis

- - weight of a given sub-criterion Ci,j,

- - result of an alternative to the sub-criterion Ci,j,

- - result of an alternative to the criterion Ci,

- - weight of given criterion Ci,j,

- R

- - overall result of the alternative,

- n

- - number of analyzed criteria.

2.3. Decision Tree for the Preliminary Selection of the Deodorization Method

2.4. Calculation of Process Performance Parameters

- - inlet concentration of target compound,

- - outlet concentration of target compound,

- - volume of the filter bed,

- - inlet gas flow rate.

3. Results and Discussion

3.1. Selection of Comparison Main Criteria

3.2. Assigning of Weights to Criteria and Sub-Criteria

3.3. Assigning of Indicators

3.4. Results of a Pairwise Comparison

3.5. Result of Decision Tree for the Preliminary Selection of the Deodorization Method

3.6. Practical Applications and Future Research Perspectives

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Barbusinski, K.; Kalemba, K.; Kasperczyk, D.; Urbaniec, K.; Kozik, V. Biological methods for odor treatment—A review. J. Clean. Prod. 2017, 152, 223–241. [Google Scholar] [CrossRef]

- Qian, H.; Cheng, Y.; Yang, C.; Wu, S.; Zeng, G.; Xi, J. Performance and biofilm characteristics of biotrickling filters for ethylbenzene removal in the presence of saponins. Environ. Sci. Pollut. Res. 2018, 25, 30021–30030. [Google Scholar] [CrossRef]

- Wu, H.; Yan, H.; Quan, Y.; Zhao, H.; Jiang, N.; Yin, C. Recent progress and perspectives in biotrickling filters for VOCs and odorous gases treatment. J. Environ. Manag. 2018, 222, 409–419. [Google Scholar] [CrossRef] [PubMed]

- Brancher, M.; Griffiths, K.D.; Franco, D.; de Melo Lisboa, H. A review of odour impact criteria in selected countries around the world. Chemosphere 2017, 168, 1531–1570. [Google Scholar] [CrossRef]

- Rybarczyk, P.; Szulczyński, B.; Gębicki, J.; Hupka, J. Treatment of malodorous air in biotrickling filters: A review. Biochem. Eng. J. 2019, 141, 146–162. [Google Scholar] [CrossRef]

- Darlington, A.B.; Dat, J.F.; Dixon, M.A. The Biofiltration of Indoor Air: Air Flux and Temperature Influences the Removal of Toluene, Ethylbenzene, and Xylene. Environ. Sci. Technol. 2001, 35, 240–246. [Google Scholar] [CrossRef] [PubMed]

- Darlington, A.; Chan, M.; Malloch, D.; Pilger, C.; Dixon, M.A. The Biofiltration of Indoor Air: Implications for Air Quality. Indoor Air 2000, 10, 39–46. [Google Scholar] [CrossRef]

- Torpy, F.; Clements, N.; Pollinger, M.; Dengel, A.; Mulvihill, I.; He, C.; Irga, P. Testing the single-pass VOC removal efficiency of an active green wall using methyl ethyl ketone (MEK). Air Qual. Atmos. Health 2018, 11, 163–170. [Google Scholar] [CrossRef]

- Ondarts, M.; Hort, C.; Platel, V.; Sochard, S. Indoor Air Purification by Compost Packed Biofilter. Int. J. Chem. React. Eng. 2010, 8. [Google Scholar] [CrossRef]

- Pratt, C.; Walcroft, A.S.; Tate, K.R.; Ross, D.J.; Roy, R.; Reid, M.H.; Veiga, P.W. Biofiltration of methane emissions from a dairy farm effluent pond. Agric. Ecosyst. Environ. 2012, 152, 33–39. [Google Scholar] [CrossRef]

- Dumont, E.; Hamon, L.; Lagadec, S.; Landrain, P.; Landrain, B.; Andrès, Y. NH3 biofiltration of piggery air. J. Environ. Manag. 2014, 140, 26–32. [Google Scholar] [CrossRef]

- Miller, U.; Sówka, I.; Grzelka, A.; Pawnuk, M. Application of biological deodorization methods in the aspect of sustainable development. In Proceedings of the SHS Web Conference, Gdańsk-Nynäshamn, Poland, 18–20 September 2018; Volume 57. [Google Scholar]

- Szulczyński, B.; Wasilewski, T.; Wojnowski, W.; Majchrzak, T.; Dymerski, T.; Namieśnik, J.; Gębicki, J. Different Ways to Apply a Measurement Instrument of E-Nose Type to Evaluate Ambient Air Quality with Respect to Odour Nuisance in a Vicinity of Municipal Processing Plants. Sensors 2017, 17, 2671. [Google Scholar] [CrossRef] [PubMed]

- Khan, F.I.; Ghoshal, A.K. Removal of Volatile Organic Compounds from polluted air. J. Loss Prev. Process Ind. 2000, 13, 527–545. [Google Scholar] [CrossRef]

- Oliva, G.; Zarra, T.; Naddeo, V.; Munoz, R.; Lebrero, R.; Angeles, R.; Belgiorno, V.; Ángeles, R.; Belgiorno, V. Comparative Analysis of AOPs and Biological Processes for the Control of VOCs Industrial Emissions. In Proceedings of the Chemical Engineering Transactions, Milan, Italy, 9–12 September 2018; Volume 68, pp. 451–456. [Google Scholar]

- Schiavon, M.; Ragazzi, M.; Rada, E.C.; Torretta, V. Air pollution control through biotrickling filters: A review considering operational aspects and expected performance. Crit. Rev. Biotechnol. 2016, 36, 1143–1155. [Google Scholar] [CrossRef] [PubMed]

- Yu, J.; Liu, W.; Cheng, Z.; Jiang, Y.; Cai, W.; Chen, J. Dichloromethane removal and microbial variations in a combination of UV pretreatment and biotrickling filtration. J. Hazard. Mater. 2014, 268, 14–22. [Google Scholar]

- Abraham, S.; Joslyn, S.; Suffet, I.H. (Mel) Treatment of odor by a seashell biofilter at a wastewater treatment plant. J. Air Waste Manag. Assoc. 2015, 65, 1217–1228. [Google Scholar] [CrossRef] [PubMed]

- Mudliar, S.; Giri, B.; Padoley, K.; Satpute, D.; Dixit, R.; Bhatt, P.; Pandey, R.; Juwarkar, A.; Vaidya, A. Bioreactors for treatment of VOCs and odours—A review. J. Environ. Manag. 2010, 91, 1039–1054. [Google Scholar] [CrossRef]

- Vikrant, K.; Kim, K.H.; Szulejko, J.E.; Pandey, S.K.; Singh, R.S.; Giri, B.S.; Brown, R.J.C.; Lee, S.H. Bio-filters for the treatment of VOCs and odors—A review. Asian J. Atmos. Environ. 2017, 11, 139–152. [Google Scholar] [CrossRef]

- Szulczyński, B.; Gębicki, J.; Namieśnik, J. Monitoring and efficiency assessment of biofilter air deodorization using electronic nose prototype. Chem. Pap. 2018, 72, 527–532. [Google Scholar] [CrossRef]

- McNevin, D.; Barford, J. Biofiltration as an odour abatement strategy. Biochem. Eng. J. 2000, 5, 231–242. [Google Scholar] [CrossRef]

- Chmiel, K.; Jastrzębski, A.B.; Palica, M. Biofiltracja lotnych związków organicznych. Przem. Chem. 2005, 6, 442–445. [Google Scholar]

- Ferdowsi, M.; Avalos Ramirez, A.; Jones, J.P.; Heitz, M. Elimination of mass transfer and kinetic limited organic pollutants in biofilters: A review. Int. Biodeterior. Biodegrad. 2017, 119, 336–348. [Google Scholar] [CrossRef]

- Szulczyński, B.; Rybarczyk, P.; Gębicki, J. Monitoring of n-butanol vapors biofiltration process using an electronic nose combined with calibration models. Monatshefte für Chem. Chem. Mon. 2018, 149, 1693–1699. [Google Scholar] [CrossRef] [PubMed]

- Viotti, P.; Schiavon, M.; Gavasci, R.; Capodaglio, A.G. Removal of benzene and toluene from a refinery waste air stream by water sorption and biotrickling filtration. Interdiscip. J. Appl. Sci. 2015, 10, 720–727. [Google Scholar]

- Zdeb, M.; Lebiocka, M. Microbial removal of selected volatile organic compounds from the model landfill gas. Ecol. Chem. Eng. S 2016, 23, 215–228. [Google Scholar] [CrossRef] [Green Version]

- Lebrero, R.; Rodríguez, E.; Estrada, J.M.; García-Encina, P.A.; Muñoz, R. Odor abatement in biotrickling filters: Effect of the EBRT on methyl mercaptan and hydrophobic VOCs removal. Bioresour. Technol. 2012, 109, 38–45. [Google Scholar] [CrossRef]

- Yang, C.; Qian, H.; Li, X.; Cheng, Y.; He, H.; Zeng, G.; Xi, J. Simultaneous Removal of Multicomponent VOCs in Biofilters. Trends Biotechnol. 2018, 36, 673–685. [Google Scholar] [CrossRef]

- Cheng, Y.; He, H.; Yang, C.; Zeng, G.; Li, X.; Chen, H.; Yu, G. Challenges and solutions for biofiltration of hydrophobic volatile organic compounds. Biotechnol. Adv. 2016, 34, 1091–1102. [Google Scholar] [CrossRef] [PubMed]

- Iranpour, R.; Cox, H.H.J.; Deshusses, M.A.; Schroeder, E.D. Literature review of air pollution control biofilters and biotrickling filters for odor and volatile organic compound removal. Environ. Prog. 2005, 24, 254–267. [Google Scholar] [CrossRef]

- Lu, C.; Lin, M.-R.; Chu, C. Temperature Effects of Trickle-Bed Biofilter for Treating BTEX Vapors. J. Environ. Eng. 1999, 125, 775–779. [Google Scholar] [CrossRef]

- Mirpuri, R.; Jones, W.; Bryers, J.D. Toluene degradation kinetics for planktonic and biofilm-grown cells ofPseudomonas putida 54G. Biotechnol. Bioeng. 1997, 53, 535–546. [Google Scholar] [CrossRef]

- Vaiškūnaitė, R.; Zagorskis, A. Modelling of a biofiltration process of volatile organic compound mixtures in a biofilter. Biotechnol. Biotechnol. Equip. 2016, 30, 1217–1222. [Google Scholar] [CrossRef]

- Gąszczak, A.; Bartelmus, G.; Burghardt, A.; Rotkegel, A.; Sarzyński, R. Experiments and modelling of a biotrickling filter (BTF) for removal of styrene from airstreams. J. Chem. Technol. Biotechnol. 2018, 93, 2659–2670. [Google Scholar] [CrossRef]

- Ahmed, W.; Shareefdeen, Z.M.; Jabbar, N.A. Dynamic modeling and analysis of biotrickling filters in continuous operation for H2S removal. Clean Technol. Environ. Policy 2014, 16, 1757–1765. [Google Scholar] [CrossRef]

- Almenglo, F.; Ramírez, M.; Gómez, J.M.; Cantero, D.; Gamisans, X.; Dorado, A.D. Modeling and control strategies for anoxic biotrickling filtration in biogas purification. J. Chem. Technol. Biotechnol. 2016, 91, 1782–1793. [Google Scholar] [CrossRef]

- Vergara-Fernández, A.; Revah, S.; Moreno-Casas, P.; Scott, F. Biofiltration of volatile organic compounds using fungi and its conceptual and mathematical modeling. Biotechnol. Adv. 2018, 36, 1079–1093. [Google Scholar] [CrossRef]

- Yoon, H.; Song, M.J.; Kim, D.D.; Sabba, F.; Yoon, S. A Serial Biofiltration System for Effective Removal of Low-Concentration Nitrous Oxide in Oxic Gas Streams: Mathematical Modeling of Reactor Performance and Experimental Validation. Environ. Sci. Technol. 2019, 53, 2063–2074. [Google Scholar] [CrossRef]

- Toledo-Cervantes, A.; Lebrero, R.; Cavinato, C.; Muñoz, R. Biogas upgrading using algal-bacterial processes. Microalgae Based Biofuels Bioprod. 2017, 283–304. [Google Scholar] [CrossRef]

- Han, M.-F.; Wang, C.; Liu, H. Comparison of physical technologies for biomass control in biofilters treating gaseous toluene. J. Air Waste Manag. Assoc. 2018, 68, 1118–1125. [Google Scholar] [CrossRef]

- López de León, L.R.; Deaton, K.E.; Deshusses, M.A. Miniaturized Biotrickling Filters and Capillary Microbioreactors for Process Intensification of VOC Treatment with Intended Application to Indoor Air. Environ. Sci. Technol. 2019, 53, 1518–1526. [Google Scholar] [CrossRef]

- Aguirre, A.; Bernal, P.; Maureira, D.; Ramos, N.; Vásquez, J.; Urrutia, H.; Gentina, J.C.; Aroca, G. Biofiltration of trimethylamine in biotrickling filter inoculated with Aminobacter aminovorans. Electron. J. Biotechnol. 2018, 33, 63–67. [Google Scholar] [CrossRef]

- San-Valero, P.; Gabaldón, C.; Álvarez-Hornos, F.J.; Izquierdo, M.; Martínez-Soria, V. Removal of acetone from air emissions by biotrickling filters: Providing solutions from laboratory to full-scale. J. Environ. Sci. Health Part A 2018, 1–8. [Google Scholar] [CrossRef]

- Dumont, É. Impact of the treatment of NH3 emissions from pig farms on greenhouse gas emissions. Quantitative assessment from the literature data. New Biotechnol. 2018, 46, 31–37. [Google Scholar] [CrossRef] [PubMed]

- Wysocka, I.; Gębicki, J.; Namieśnik, J. Technologies for deodorization of malodorous gases. Environ. Sci. Pollut. Res. 2019, 1–26. [Google Scholar] [CrossRef] [PubMed]

- Potivichayanon, S.; Pokethitiyook, P.; Kruatrachue, M. Hydrogen sulfide removal by a novel fixed-film bioscrubber system. Process Biochem. 2006, 41, 708–715. [Google Scholar] [CrossRef]

- Barbusiński, K.; Kalemba, K. Use of biological methods for removal of H2S from biogas in wastewater treatment plants—A review. Archit. Civ. Eng. Environ. 2016, 9, 103–112. [Google Scholar] [CrossRef]

- Malakar, S.; Saha, P.D.; Baskaran, D.; Rajamanickam, R. Comparative study of biofiltration process for treatment of VOCs emission from petroleum refinery wastewater—A review. Environ. Technol. Innov. 2017, 8, 441–461. [Google Scholar] [CrossRef]

- Taghipour, H.; Shahmansoury, M.R.; Bina, B.; Movahdian, H. Comparison of the biological NH3 removal characteristics of a three stage biofilter with a one stage biofilter. Int. J. Environ. Sci. Technol. 2006, 3, 417–424. [Google Scholar] [CrossRef]

- Gao, L.; Keener, T.C.; Zhuang, L.; Siddiqui, K.F. A technical and economic comparison of biofiltration and wet chemical oxidation (scrubbing) for odor control at wastewater treatment plants. Environ. Eng. Policy 2001, 2, 203–212. [Google Scholar] [CrossRef]

- Saaty, T.L. Relative Measurement and Its Generalization in Decision Making Why Pairwise Comparisons are Central in Mathematics for the Measurement of Intangible Factors The Analytic Hierarchy/Network Process. RACSAM-Revista de la Real Academia de Ciencias Exactas Fisicas y Naturales Serie A Matematicas 2008, 102, 251–318. [Google Scholar] [CrossRef]

- Brunelli, M.; Canal, L.; Fedrizzi, M. Inconsistency indices for pairwise comparison matrices: A numerical study. Ann. Oper. Res. 2013, 211, 493–509. [Google Scholar] [CrossRef]

- Chang, D.Y. Applications of the extent analysis method on fuzzy AHP. Eur. J. Oper. Res. 1996, 95, 649–655. [Google Scholar] [CrossRef]

- Kabir, G.; Sadiq, R.; Tesfamariam, S. A review of multi-criteria decision-making methods for infrastructure management. Struct. Infrastruct. Eng. 2014, 10, 1176–1210. [Google Scholar] [CrossRef]

- Soltani, A.; Sadiq, R.; Hewage, K. Selecting sustainable waste-to-energy technologies for municipal solid waste treatment: A game theory approach for group decision-making. J. Clean. Prod. 2016, 113, 388–399. [Google Scholar] [CrossRef]

- Palmer, E.J.; Devitt, P.G.; De Young, N.J.; Morris, D. Assessment of an electronic voting system within the tutorial setting: A randomised controlled trial [ISRCTN54535861]. BMC Med. Educ. 2005, 5, 24. [Google Scholar] [CrossRef]

- Laukkanen, S.; Kangas, A.; Kangas, J. Applying voting theory in natural resource management: A case of multiple-criteria group decision support. J. Environ. Manag. 2002, 64, 127–137. [Google Scholar] [CrossRef]

- Nurmi, H. Voting Procedures: A Summary Analysis. Br. J. Political Sci. 1983, 13, 181–208. [Google Scholar] [CrossRef]

- Oishi, S.; Hahn, J.; Schimmack, U.; Radhakrishan, P.; Dzokoto, V.; Ahadi, S. The measurement of values across cultures: A pairwise comparison approach. J. Res. Pers. 2005, 39, 299–305. [Google Scholar] [CrossRef]

- Martignon, L.; Hoffrage, U. Fast, frugal, and fit: Simple heuristics for paired comparison. Theory Decis. 2002, 52, 29–71. [Google Scholar] [CrossRef]

- Chan, F.T.S.; Jiang, B.; Tang, N.K.H. The development of intelligent decision support tools to aid the design of flexible manufacturing systems. Int. J. Prod. Econ. 2000, 65, 73–84. [Google Scholar] [CrossRef]

- Kok, M.; Lootsma, F.A. Pairwise-comparison methods in multiple objective programming, with applications in a long-term energy-planning model. Eur. J. Oper. Res. 1985, 22, 44–55. [Google Scholar] [CrossRef]

- Kaya, T.; Kahraman, C. Multicriteria decision making in energy planning using a modified fuzzy TOPSIS methodology. Expert Syst. Appl. 2011, 38, 6577–6585. [Google Scholar] [CrossRef]

- Colombo, J.; Richman, W.A.; Shaddy, D.J.; Follmer Greenhoot, A.; Maikranz, J.M. Heart Rate-Defined Phases of Attention, Look Duration, and Infant Performance in the Paired-Comparison Paradigm. Child Dev. 2001, 72, 1605–1616. [Google Scholar] [CrossRef]

- Quinlan, J.R. Induction of decision trees. Mach. Learn. 1986, 1, 81–106. [Google Scholar] [CrossRef] [Green Version]

- Breiman, L.; Friedman, J.H.; Olshen, R.A.; Stone, C.J. Classification and Regression Trees; Chapman & Hall/CRC: New York, NY, USA, 1984. [Google Scholar]

- Hastie, T.; Tibshirani, R.; Friedman, J. The Element of Statistical Learning; Springer: New York, NY, USA, 2001. [Google Scholar]

- Chang, L.-Y.; Wang, H.-W. Analysis of traffic injury severity: An application of non-parametric classification tree techniques. Accid. Anal. Prev. 2006, 38, 1019–1027. [Google Scholar] [CrossRef] [PubMed]

- RStudio Team. RStudio Integrated Development Environment for R. Available online: https://www.rstudio.com/ (accessed on 25 February 2019).

- Therneau, T.; Atkinson, B. Rpart: Recursive Partitioning and Regression Trees; Comprehensive R Archive Network (CRAN): Rochester, MN, USA, 2018. [Google Scholar]

- Joanna, K.; Mazur-Chrzanowska, B.; Wyszyński, B. Odory; Wydawnictwo Naukowe PWN: Warszawa, Poland, 2012. [Google Scholar]

- Estrada, J.M.; Bart Kraakman, N.J.R.; Muñoz, R.; Lebrero, R. A Comparative Analysis of Odour Treatment Technologies in Wastewater Treatment Plants. Environ. Sci. Technol. 2011, 45, 1100–1106. [Google Scholar] [CrossRef] [PubMed]

- Estrada, J.M.; Kraakman, B.; Lebrero, R.; Muñoz, R. A sensitivity analysis of process design parameters, commodity prices and robustness on the economics of odour abatement technologies. Biotechnol. Adv. 2012, 30, 1354–1363. [Google Scholar] [CrossRef] [PubMed]

- Webb, D.S. Best Design Practices for Odour Management for Organics Processing Facilities. In Proceedings of the A&WMA Waste Conference 2014, Long Beach, CA, USA, 24–27 June 2014. [Google Scholar]

- Rybarczyk, P.; Szulczyński, B.; Gębicki, J. Investigations on the Removal of Hydrophobic Odorous Volatile Organic Compounds by Biotrickling Filtration Monitored with Electronic Nose. Chem. Eng. Trans. 2018, 68. [Google Scholar] [CrossRef]

- Sander, R. Compilation of Henry’s law constants (version 4.0) for water as solvent. Atmos. Chem. Phys. 2015, 15, 4399–4981. [Google Scholar] [CrossRef]

- Eshraghi, M.; Parnian, P.; Zamir, S.M.; Halladj, R. Biofiltration of n-butanol vapor at different operating temperatures: Experimental study and mathematical modeling. Int. Biodeterior. Biodegrad. 2017, 119, 361–367. [Google Scholar] [CrossRef]

- Schmidt, T.; Anderson, W.A.; Schmidt, T.; Anderson, W.A. Biotrickling Filtration of Air Contaminated with 1-Butanol. Environments 2017, 4, 57. [Google Scholar] [CrossRef]

- Wübker, S.M.; Friedrich, C.G. Reduction of biomass in a bioscrubber for waste gas treatment by limited supply of phosphate and potassium ions. Appl. Microbiol. Biotechnol. 1996, 46, 475–480. [Google Scholar] [CrossRef]

- Li, G.; Wan, S.; An, T. Efficient bio-deodorization of aniline vapor in a biotrickling filter: Metabolic mineralization and bacterial community analysis. Chemosphere 2012, 87, 253–258. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Krailas, S.; Tongta, S.; Meeyoo, V. Macrokinetic determination of isopropanol removal using a downward flow biofilter. Songklanakarin J. Sci. Technol. 2004, 26, 55–64. [Google Scholar]

- San-Valero, P.; Penya-Roja, J.M.; Sempere, F.; Gabaldón, C. Biotrickling filtration of isopropanol under intermittent loading conditions. Bioprocess Biosyst. Eng. 2013, 36, 975–984. [Google Scholar] [CrossRef] [PubMed]

- Whaley, M.B.; Monroig, P.; Villarubia, E. Allergan-isopropyl alcohol emissions removal using a unique biological system. Environ. Prog. 1998, 17, 256–260. [Google Scholar] [CrossRef]

- Auria, R.; Aycaguer, A.-C.; Devinny, J.S. Influence of Water Content on Degradation Rates for Ethanol in Biofiltration. J. Air Waste Manag. Assoc. 1998, 48, 65–70. [Google Scholar] [CrossRef] [Green Version]

- Morotti, K.; Ramirez, A.A.; Jones, J.P.; Heitz, M. Analysis and comparison of biotreatment of air polluted with ethanol using biofiltration and biotrickling filtration. Environ. Technol. 2011, 32, 1967–1973. [Google Scholar] [CrossRef]

- Singh, A.; Shareefdeen, Z.; Ward, O.P. Bioscrubber Technology. In Biotechnology for Odor and Air Pollution Control; Springer: Berlin/Heidelberg, Germany, 2005; pp. 169–193. [Google Scholar]

- Allen, L.; Ellis, S. Laboratory Evaluation of Trickling Biofiltration for Treatment of Kraft Mill Noncombustion Air Emissions. In Proceedings of the TAPPI 2000 Environmental Confrence Processdins, Denver, CO, USA, 21–24 May 2000; pp. 293–309. [Google Scholar]

- Avalos Ramirez, A.; Peter Jones, J.; Heitz, M. Control of methanol vapours in a biotrickling filter: Performance analysis and experimental determination of partition coefficient. Bioresour. Technol. 2009, 100, 1573–1581. [Google Scholar] [CrossRef]

- DeHollander, G.R.; Overcamp, T.J.; Grady, C., Jr.; Grady, C. Performance of a Suspended-Growth Bioscrubber for the Control of Methanol. J. Air Waste Manag. Assoc. 1998, 48, 872–876. [Google Scholar] [CrossRef] [Green Version]

- Prekumar, R.; Krishnamohan, N. Removal of Methanol from Waste Gas Using Biofiltration. J. Appl. Sci. Res. 2010, 6, 1898–1907. [Google Scholar]

- Lalanne, F.; Malhautier, L.; Roux, J.-C.; Fanlo, J.-L. Absorption of a mixture of volatile organic compounds (VOCs) in aqueous solutions of soluble cutting oil. Bioresour. Technol. 2008, 99, 1699–1707. [Google Scholar] [CrossRef] [PubMed]

- Arriaga, S.; Revah, S. Removal of n-hexane by Fusarium solani with a gas-phase biofilter. J. Ind. Microbiol. Biotechnol. 2005, 32, 548–553. [Google Scholar] [CrossRef] [PubMed]

- Tu, Y.; Yang, C.; Cheng, Y.; Zeng, G.; Lu, L.; Wang, L. Effect of saponins on n-hexane removal in biotrickling filters. Bioresour. Technol. 2015, 175, 231–238. [Google Scholar] [CrossRef] [PubMed]

- Arriaga, S.; Revah, S. Improving hexane removal by enhancing fungal development in a microbial consortium biofilter. Biotechnol. Bioeng. 2005, 90, 107–115. [Google Scholar] [CrossRef] [Green Version]

- Nikiema, J.; Bibeau, L.; Lavoie, J.; Brzezinski, R.; Vigneux, J.; Heitz, M. Biofiltration of methane: An experimental study. Chem. Eng. J. 2005, 113, 111–117. [Google Scholar] [CrossRef]

- Lebrero, R.; Hernández, L.; Pérez, R.; Estrada, J.M.; Muñoz, R. Two-liquid phase partitioning biotrickling filters for methane abatement: Exploring the potential of hydrophobic methanotrophs. J. Environ. Manag. 2015, 151, 124–131. [Google Scholar] [CrossRef] [PubMed]

- Liu, F.; Fiencke, C.; Guo, J.; Rieth, R.; Dong, R.; Pfeiffer, E.-M. Performance evaluation and optimization of field-scale bioscrubbers for intensive pig house exhaust air treatment in northern Germany. Sci. Total Environ. 2017, 579, 694–701. [Google Scholar] [CrossRef]

- Kim, J.-O. Degradation of benzene and ethylene in biofilters. Process Biochem. 2003, 39, 447–453. [Google Scholar] [CrossRef]

- Barzgar, S.; Hettiaratchi, J.P.; Pearse, L.; Kumar, S. Inhibitory effects of acidic pH and confounding effects of moisture content on methane biofiltration. Bioresour. Technol. 2017, 245, 633–640. [Google Scholar] [CrossRef]

- van Groenestijn, J.W.; Liu, J.X. Removal of alpha-pinene from gases using biofilters containing fungi. Atmos. Environ. 2002, 36, 5501–5508. [Google Scholar] [CrossRef] [Green Version]

- Montes, M.; Daugulis, A.J.; Veiga, M.C.; Kennes, C. Removal of α-pinene from waste gases in biotrickling filters with the addition of silicone oil or polymers. J. Biotechnol. 2010, 150, 221. [Google Scholar] [CrossRef]

- Miller, M.J.; Allen, D.G. Modelling transport and degradation of hydrophobic pollutants in biofilter biofilms. Chem. Eng. J. 2005, 113, 197–204. [Google Scholar] [CrossRef]

- Kraakman, N.J.R.; van Groenestijn, J.W.; Koers, B.; Heslinga, D.C. Mededelingen Faculteit Lanbouwkundige en Toegepaste Biologische Wetenschapper. Univ. Gent 1997, 62, 1535–1541. [Google Scholar]

- Zamir, S.M.; Babatabar, S.; Shojaosadati, S.A. Styrene vapor biodegradation in single- and two-liquid phase biotrickling filters using Ralstonia eutropha. Chem. Eng. J. 2015, 268, 21–27. [Google Scholar] [CrossRef]

- Ramay, M.J.; Porter, R.; Johnson, S.; Dasgupta, A.; Robbins, J. Pilot biofilter demonstration for styrene, MEK (methyl ethyl ketone), and methylene chloride emissions. In Proceedings of the 4th International In Situ On-Site Bioremediation Symposium, New Orleans, LA, USA, 28 April–1 May 1997; Volume 5, pp. 225–230. [Google Scholar]

- San-Valero, P.; Dorado, A.D.; Martínez-Soria, V.; Gabaldón, C. Biotrickling filter modeling for styrene abatement. Part 1: Model development, calibration and validation on an industrial scale. Chemosphere 2018, 191, 1066–1074. [Google Scholar] [CrossRef]

- Rene, E.R.; Murthy, D.V.S.; Swaminathan, T. Performance evaluation of a compost biofilter treating toluene vapours. Process Biochem. 2005, 40, 2771–2779. [Google Scholar] [CrossRef]

- Kim, D.; Cai, Z.; Sorial, G.A. Behavior of trickle-bed air biofilter for toluene removal: Effect of non-use periods. Environ. Prog. 2005, 24, 155–161. [Google Scholar] [CrossRef]

- Díaz, L.F.; Muñoz, R.; Bordel, S.; Villaverde, S. Toluene biodegradation by Pseudomonas putida F1: Targeting culture stability in long-term operation. Biodegradation 2008, 19, 197–208. [Google Scholar] [CrossRef] [PubMed]

- Delhoménie, M.-C.; Bibeau, L.; Gendron, J.; Brzezinski, R.; Heitz, M. A study of clogging in a biofilter treating toluene vapors. Chem. Eng. J. 2003, 94, 211–222. [Google Scholar] [CrossRef]

- Cox, H.H.J.; Deshusses, M.A. Co-treatment of H2S and toluene in a biotrickling filter. Chem. Eng. J. 2002, 87, 101–110. [Google Scholar] [CrossRef] [Green Version]

- García-Peña, E.I.; Hernández, S.; Favela-Torres, E.; Auria, R.; Revah, S. Toluene biofiltration by the fungus Scedosporium apiospermum TB1. Biotechnol. Bioeng. 2001, 76, 61–69. [Google Scholar] [CrossRef]

- Cox, H.H.J.; Deshusses, M.A. Biomass control in waste air biotrickling filters by protozoan predation. Biotechnol. Bioeng. 1999, 62, 216–224. [Google Scholar] [CrossRef]

- Liang, Y.; Quan, X.; Chen, J.; Chung, J.S.; Sung, J.Y.; Chen, S.; Xue, D.; Zhao, Y. Long-term results of ammonia removal and transformation by biofiltration. J. Hazard. Mater. 2000, 80, 259–269. [Google Scholar] [CrossRef]

- Melse, R.W.; Ploegaert, J.P.M.; Ogink, N.W.M. Biotrickling filter for the treatment of exhaust air from a pig rearing building: Ammonia removal performance and its fluctuations. Biosyst. Eng. 2012, 113, 242–252. [Google Scholar] [CrossRef]

- Nisola, G.M.; Cho, E.; Orata, J.D.; Redillas, M.C.F.R.; Farnazo, D.M.C.; Tuuguu, E.; Chung, W.J. NH3 gas absorption and bio-oxidation in a single bioscrubber system. Process Biochem. 2009, 44, 161–167. [Google Scholar] [CrossRef]

- Jun, Y.; Xu, W. Ammonia biofiltration and community analysis of ammonia-oxidizing bacteria in biofilters. Bioresour. Technol. 2009, 100, 3869–3876. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Allen, E.R. Biofiltration Control of Hydrogen Sulfide 1. Design and Operational Parameters. Air Waste 1994, 44, 863–868. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Wang, X.; He, S.; Zhu, S.; Shen, S. The performance of a two-layer biotrickling filter filled with new mixed packing materials for the removal of H2S from air. J. Environ. Manag. 2016, 165, 11–16. [Google Scholar] [CrossRef]

- Morgenroth, E.; Schroeder, E.D.; Chang, D.P.Y.; Scow, K.M. Nutrient Limitation in a Compost Biofilter Degrading Hexane. J. Air Waste Manag. Assoc. 1996, 46, 300–308. [Google Scholar]

- Zilli, M.; Converti, A.; Lodi, A.; Borghi, M.D.; Ferraiolo, G. Phenol removal from waste gases with a biological filter byPseudomonas putida. Biotechnol. Bioeng. 1993, 41, 693–699. [Google Scholar] [CrossRef] [PubMed]

- Ergas, S.J.; Kinney, K.; Fuller, M.E.; Scow, K.M. Characterization of compost biofiltration system degrading dichloromethane. Biotechnol. Bioeng. 1994, 44, 1048–1054. [Google Scholar] [CrossRef] [PubMed]

- Chou, M.-S.; Shiu, W.-Z.; Chou, S. Bioconversion of Methylamine in Biofilters. J. Air Waste Manag. Assoc. 1997, 47, 58–65. [Google Scholar] [CrossRef] [Green Version]

- Smet, E.; Van Langenhove, H.; Verstraete, W. Isobutyraldehyde as a competitor of the dimethyl sulfide degrading activity in biofilters. Biodegradation 1997, 8, 53–59. [Google Scholar] [CrossRef]

- Tang, H.-M.; Hwang, S.-J.; Hwang, S.-C. Waste Gas Treatment in Biofilters. J. Air Waste Manag. Assoc. 1996, 46, 349–354. [Google Scholar]

- Shareefdeen, Z.; Baltzis, B.C. Biofiltration of toluene vapor under steady-state and transient conditions: Theory and experimental results. Chem. Eng. Sci. 1994, 49, 4347–4360. [Google Scholar] [CrossRef]

- Arnold, M.; Reittu, A.; von Wright, A.; Martikainen, P.J.; Suihko, M.-L. Bacterial degradation of styrene in waste gases using a peat filter. Appl. Microbiol. Biotechnol. 1997, 48, 738–744. [Google Scholar] [CrossRef] [PubMed]

- Hecht, V.; Brebbermann, D.; Bremer, P.; Deckwer, W.-D. Cometabolic degradation of trichloroethylene in a bubble column bioscrubber. Biotechnol. Bioeng. 1995, 47, 461–469. [Google Scholar] [CrossRef]

- Hammervold, R.E.; Overcamp, T.J.; Grady, C., Jr.; Smets, B.F.; Hammervold Enotech, R.E.; Thomas Overcamp, C.J.; Grady, C. Sorptive Slurry Bioscrubber for the Control of Acetone. J. Air Waste Manag. Assoc. 2000, 50, 954–960. [Google Scholar] [CrossRef]

- Koutinas, M.; Martin, J.; Peeva, L.G.; Mantalaris, A.; Livingston, A.G. An Oil-Absorber−Bioscrubber System To Stabilize Biotreatment of Pollutants Present in Waste Gas. Fluctuating Loads of 1,2-Dichloroethane. Environ. Sci. Technol. 2006, 40, 595–602. [Google Scholar] [CrossRef] [PubMed]

- Koutinas, M.; Peeva, L.G.; Livingston, A.G. An attempt to compare the performance of bioscrubbers and biotrickling filters for degradation of ethyl acetate in gas streams. J. Chem. Technol. Biotechnol. 2005, 80, 1252–1260. [Google Scholar] [CrossRef]

- Oh, Y.-S.; Bartha, R. Removal of nitrobenzene vapors by a trickling air biofilter. J. Ind. Microbiol. Biotechnol. 1997, 18, 293–296. [Google Scholar] [CrossRef]

- Quan, Y.; Wu, H.; Yin, Z.; Fang, Y.; Yin, C. Effect of static magnetic field on trichloroethylene removal in a biotrickling filter. Bioresour. Technol. 2017, 239, 7–16. [Google Scholar] [CrossRef] [PubMed]

- Zilli, M.; Nicolella, C. Removal of monochlorobenzene from air in a trickling biofilter at high loading rates. J. Chem. Technol. Biotechnol. 2012, 87, 1141–1149. [Google Scholar] [CrossRef]

- Wu, H.; Yin, Z.; Quan, Y.; Fang, Y.; Yin, C. Removal of methyl acrylate by ceramic-packed biotrickling filter and their response to bacterial community. Bioresour. Technol. 2016, 209, 237–245. [Google Scholar] [CrossRef]

- Rene, E.R.; Špačková, R.; Veiga, M.C.; Kennes, C. Biofiltration of mixtures of gas-phase styrene and acetone with the fungus Sporothrix variecibatus. J. Hazard. Mater. 2010, 184, 204–214. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Prado, Ó.J.; Veiga, M.C.; Kennes, C. Removal of formaldehyde, methanol, dimethylether and carbon monoxide from waste gases of synthetic resin-producing industries. Chemosphere 2008, 70, 1357–1365. [Google Scholar] [CrossRef] [PubMed]

- Pérez, M.C.; Álvarez-Hornos, F.J.; San-Valero, P.; Marzal, P.; Gabaldón, C. Microbial community analysis in biotrickling filters treating isopropanol air emissions. Environ. Technol. 2013, 34, 2789–2798. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Criterion | wi (%) | Sub-Criterion | wi,j (%) | Range of the Indicators (ID) |

|---|---|---|---|---|

| C1 (Efficiency) | 35 | C1.1 (RE) | 60 | 0…1 (low…high) |

| C1.2 (EBRT) | 40 | 1…0 (low…high) | ||

| C2 (Costs) | 25 | C2.1 (Investment costs) | 60 | 1…0 (low…high) |

| C2.2 (Operating costs) | 40 | 1…0 (low…high) | ||

| C3 (Technical aspects and problems) | 15 | C3.1 (Periodic replacement of packing elements) | 30 | 1…0 (slow…fast) |

| C3.2 (Periodic regeneration of liquids) | 20 | 1…0 (rarely…often) | ||

| C3.3 (System complexity) | 20 | 1…0 (low…high) | ||

| C3.4 (Ease of process control) | 30 | 0…1 (complex…simple) | ||

| C4 (Environmental impact) | 25 | C4.1 (Dimensions of apparatus) | 30 | 1…0 (small…big) |

| C4.2 (Waste streams) | 70 | 1…0 (yes…no) |

| Conventional Biofilter | Biotrickling Filter | Bioscrubber | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Compounds | H (mol∙m−3∙Pa−1) | Hc (-) | Cin (mg∙m−3) | RE (%) | EBRT (s) | Reference | Cin (mg∙m−3) | RE (%) | EBRT (s) | Reference | Cin (mg∙m−3) | RE (%) | EBRT (s) | Reference |

| Hydrophilic | - | - | - | 99 | - | [73] | - | 99 | - | [73] | - | 99 | - | [73] |

| butanol | 1.2 [77] | 3.4 × 10−4 | 900–2600 | >73 | 60 | [78] | 400–1200 | 15–99 | 60–124 | [79] | - | 98–100 | 48 | [80] |

| aniline | 1.1 [5] | 3.7 × 10−4 | - | - | - | - | 300 | <99 | 42–166 | [81] | - | - | - | - |

| isopropanol | 1.3 [77] | 3.1 × 10−4 | 1000–8000 | 81 | 94.2 | [82] | 20–65 (g m−3∙h−1) | <95 | 14–160 | [83] | 200–500 | 99 | - | [84] |

| ethanol | 9.0 [77] | 4.5 × 10−5 | 3700 | 63–85 | 101 | [85] | 470 | ~80 | 66 | [86] | - | 80–99 | - | [87] |

| methanol | 2.0 [77] | 2.0 × 10−4 | - | >95 | 25 | [88] | 300–37,000 | 65 | 20–65 | [89] | 50–100 | 69–81 | 600 | [90] |

| 0.79–3.3 | 93.33 | 38 | [91] | - | 75 | 2.5 | [92] | |||||||

| Hydrophobic | - | - | - | 75 | - | [73] | - | 50 | - | [73] | - | 50 | - | [73] |

| hexane | 6.1 × 10−3 [77] | 6.6 × 10−2 | 500–11,000 | 79 | 60 | [93] | 600 | 57–91 | 8–30 | [94] | 6200 | 70 | 420 | [92] |

| 200–10,000 | 59–76 | 60 | [95] | |||||||||||

| methane | 1.4 × 10−5 [77] | 2.9 × 10−1 | 4581–4908 | 43 | 257 | [96] | 0–500 | ~40 | 240 | [97] | - | 5–25 | 1.6 | [98] |

| ethylene | 5.9 × 10−5 [77] | 6.8 | 331 | 100 | 2160 | [99] | 8–100 (g m−3∙h−1) | 70–95 | 30 | [27,100] | - | - | - | - |

| α-pinene | 2.9∙× 10−4 [77] | 1.4 | 100–450 | 90 | 42 | [101] | - | - | 14–60 | [102] | - | - | - | - |

| 4227 | 47–67 | 78 | [103] | |||||||||||

| styrene | 2.7 × 10−3 [77] | 1.5 × 10−1 | 0.1–0.9 | 90 | 9–18 | [104] | 800–3300 | 95 | 60–120 | [105] | - | - | - | - |

| 0.85 | 97 | 1845 | [106] | 55–312 | 90 | 15–30 | [107] | - | - | - | - | |||

| toluene | 1.5 × 10−3 [77] | 2.7 × 10−1 | 2.3 | 90 | 137–825 | [108] | 2–1128 | 99 | 400 | [109] | 3300 | 89 | - | [110] |

| 1.9 | >80 | 21.6 | [111] | 2200 | <99 | 16.2 | [112] | |||||||

| 6 | <98 | 70 | [113] | 1000 | 60 | 57 | [114] | |||||||

| Inorganic | ||||||||||||||

| ammonia | 5.5 × 10−1 [77] | 7.3 × 10−4 | 14–350 | 92–100 | 17 | [115] | 9.6 | 82 | 1.2 | [116] | 14 | 99 | 142 | [117] |

| 20–100 | 99 | 960 | [118] | |||||||||||

| H2S | 1.0 × 10−3 [77] | 4.0 × 10−1 | 7–3750 | 100 | 23–200 | [119] | 300–650 | 65–100 | 53-79 | [120] | 14–140 | 98 | 12–32 | [47] |

| Criteria and Sub-Criteria | Units | BF | BTF | BS | Reference | ||

|---|---|---|---|---|---|---|---|

| 2 | Costs | ||||||

| 2.1 | Investment | ||||||

| (€ per m3∙h−1) | 6 | 11 | 4 | [73] | |||

| (€ per m3∙h−1) | 5 | 10 | 4 | [12] | |||

| 2.2 | Operating | ||||||

| (€ per m3∙h−1) | 2 | 1.2 | 3.6 | [74] | |||

| (€∙10−4∙m−3) | 0.2 | 0.1 | 0.28 | [73] | |||

| 3 | Technical aspects and problems | ||||||

| 3.1 | Periodic replacement of element | ||||||

| Packing material | (years) | 2 | 10 | 10 | [73] | ||

| Annual/material-reagents | (kg m3∙h) | 4 | 0.1 | 0.1 | [73] | ||

| Packing material | (%) | 47 | 44 | 4 | [74] | ||

| 3.2 | Periodic regeneration of liquids | ||||||

| Annual water consumption | (L∙m−3∙h∙102) | 2.4 | 6.3 | 3.3 | [73] | ||

| Water that can be replaced with secondary effluent | (-) | Possible | Possible | Impossible | [73] | ||

| 3.3 | Complexity of the system | ||||||

| Basic elements of the apparatus | (-) | -Humidification chamber -Packed bioreactor | -Packed bioreactor -Liquid container -Pump | -Absorption column -Pump -Absorbent tank | [5] | ||

| number of basic elements of the apparatus | (-) | 2 | 3 | 3 | (-) | ||

| 3.4 | Ease of process control | ||||||

| impact on the control process | V | Low | High | Medium | (-) | ||

| Customization at work | (-) | Impossible | High | Medium | (-) | ||

| 4 | Environmental impact | ||||||

| 4.1 | Dimensions of the apparatus | ||||||

| The size of the apparatus | [m2∙m−3∙h∙102] | 1.75 | 0.25 | 0.1 | [73] | ||

| Surface area | (-) | High | Low | Low | [87] | ||

| 4.2 | Waste streams | ||||||

| Use of filling | (-) | Possible | Impossible | Impossible | [73] | ||

| The possibility of replacing water with sewage | (-) | Possible | Possible | Impossible | [12] | ||

| Volume of liquid | vol<<VOL | - | vol | VOL | [12] | ||

| - | - | Very low | Medium | High | [-] | ||

| Process | Hydrophilic Compounds | Hydrophobic Compounds | Inorganic Compounds | ||||||

|---|---|---|---|---|---|---|---|---|---|

| BF | BTF | BS | BF | BTF | BS | BF | BTF | BS | |

| C1 | 0.76 | 0.93 | 0.59 | 0.90 | 0.88 | 0.44 | 0.71 | 0.67 | 0.65 |

| C2 | 0.80 | 0.58 | 0.73 | 0.80 | 0.58 | 0.73 | 0.80 | 0.58 | 0.73 |

| C3 | 0.56 | 0.88 | 0.69 | 0.56 | 0.88 | 0.69 | 0.56 | 0.88 | 0.69 |

| C4 | 0.76 | 0.80 | 0.37 | 0.76 | 0.80 | 0.37 | 0.76 | 0.80 | 0.37 |

| Summary | 0.74 | 0.77 | 0.60 | 0.78 | 0.76 | 0.56 | 0.72 | 0.71 | 0.61 |

| Process | Compound | H (mol∙m−3∙Pa−1) | Cin (mg∙m−3) | EBRT (s) | References |

|---|---|---|---|---|---|

| BF | butanol | 1.2 | 2600 | 60 | [78] |

| BF | isopropanol | 1.3 | 8000 | 94.1 | [82] |

| BF | ethanol | 9 | 3700 | 101 | [85] |

| BF | methanol | 2 | 3.3 | 38 | [91] |

| BF | hexane | 0.0061 | 10,000 | 60 | [95] |

| BF | methane | 0.000014 | 4908 | 257 | [96] |

| BF | ethylene | 0.000059 | 331 | 2160 | [99] |

| BF | α-pinene | 0.00029 | 450 | 42 | [101] |

| BF | styrene | 0.0027 | 0.85 | 1845 | [106] |

| BF | toluene | 0.0015 | 1.9 | 21.6 | [111] |

| BF | ammonia | 0.59 | 350 | 17 | [115] |

| BF | hydrogen sulfide | 0.001 | 3750 | 200 | [119] |

| BF | hexane | 0.0061 | 700 | 30 | [121] |

| BF | ethanol | 9 | 3700 | 150 | [85] |

| BF | phenol | 0.025 | 1000 | 54 | [122] |

| BF | dichloromethane | 0.0036 | 175 | 60 | [123] |

| BF | methylamine | 0.35 | 136 | 220 | [124] |

| BF | dimethyl sulfide | 0.0056 | 400 | 27 | [125] |

| BF | triethylamine | 0.066 | 3000 | 60 | [126] |

| BF | toluene | 0.0015 | 2800 | 516 | [127] |

| BF | styrene | 0.0027 | 250 | 81 | [128] |

| BS | butanol | 1.2 | 1000 | 48 | [80] |

| BS | isopropanol | 1.3 | 500 | 60 | [84] |

| BS | methanol | 2 | 100 | 600 | [90] |

| BS | hexane | 0.0061 | 6200 | 420 | [92] |

| BS | toluene | 0.0015 | 3300 | 89 | [110] |

| BS | ammonia | 0.59 | 14 | 142 | [117] |

| BS | hydrogen sulfide | 0.001 | 140 | 32 | [47] |

| BS | trichloroethylene | 0.0011 | 300 | 931 | [129] |

| BS | acetone | 0.27 | 118 | 195 | [130] |

| BS | 1,2-dichloroethane | 0.0089 | 2400 | 300 | [131] |

| BS | ethyl acetate | 0.059 | 500 | 84 | [132] |

| BTF | butanol | 1.2 | 1200 | 124 | [79] |

| BTF | aniline | 1.1 | 300 | 166 | [81] |

| BTF | isopropanol | 1.3 | 65 | 160 | [83] |

| BTF | ethanol | 9 | 470 | 66 | [86] |

| BTF | methanol | 2 | 300 | 65 | [89] |

| BTF | hexane | 0.0061 | 600 | 30 | [94] |

| BTF | methane | 0.000014 | 500 | 240 | [97] |

| BTF | ethylene | 0.000059 | 100 | 30 | [27,100] |

| BTF | styrene | 0.0027 | 3300 | 120 | [105] |

| BTF | toluene | 0.0015 | 1128 | 400 | [109] |

| BTF | ammonia | 0.59 | 100 | 960 | [118] |

| BTF | hydrogen sulfide | 0.001 | 650 | 79 | [120] |

| BTF | methyl mercaptan | 0.0038 | 25 | 50 | [28] |

| BTF | dimethyl sulfide | 0.0056 | 25 | 123 | [120] |

| BTF | nitrobenzene | 0.64 | 300 | 24 | [133] |

| BTF | aniline | 52 | 60 | 42 | [81] |

| BTF | trichloroethylene | 0.0011 | 300 | 21 | [134] |

| BTF | chlorobenzene | 0.0027 | 1700 | 60 | [135] |

| BTF | toluene | 0.0015 | 1000 | 60 | [114] |

| BTF | methyl acrylate | 0.049 | 5000 | 400 | [136] |

| BTF | methyl acrylate | 0.049 | 5000 | 200 | [136] |

| BTF | acetone | 0.27 | 8000 | 137 | [137] |

| BTF | styrene | 0.0027 | 1000 | 90 | [105] |

| BTF | formaldehyde | 3.2 | 100 | 80 | [138] |

| BTF | isopropanol | 1.3 | 1000 | 140 | [139] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gospodarek, M.; Rybarczyk, P.; Szulczyński, B.; Gębicki, J. Comparative Evaluation of Selected Biological Methods for the Removal of Hydrophilic and Hydrophobic Odorous VOCs from Air. Processes 2019, 7, 187. https://doi.org/10.3390/pr7040187

Gospodarek M, Rybarczyk P, Szulczyński B, Gębicki J. Comparative Evaluation of Selected Biological Methods for the Removal of Hydrophilic and Hydrophobic Odorous VOCs from Air. Processes. 2019; 7(4):187. https://doi.org/10.3390/pr7040187

Chicago/Turabian StyleGospodarek, Milena, Piotr Rybarczyk, Bartosz Szulczyński, and Jacek Gębicki. 2019. "Comparative Evaluation of Selected Biological Methods for the Removal of Hydrophilic and Hydrophobic Odorous VOCs from Air" Processes 7, no. 4: 187. https://doi.org/10.3390/pr7040187

APA StyleGospodarek, M., Rybarczyk, P., Szulczyński, B., & Gębicki, J. (2019). Comparative Evaluation of Selected Biological Methods for the Removal of Hydrophilic and Hydrophobic Odorous VOCs from Air. Processes, 7(4), 187. https://doi.org/10.3390/pr7040187