Optimal Ultrasound-Assisted Process Extraction, Characterization, and Functional Product Development from Flaxseed Meal Derived Polysaccharide Gum

Abstract

:1. Introduction

2. Materials and Methods

2.1. Partially Defatted Flaxseed Meal (PDFM) and Characterization

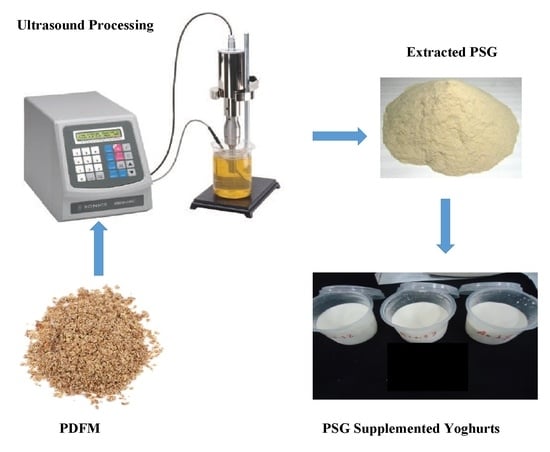

2.2. Ultrasound-Assisted Extraction of PSG from PDFM

2.3. Physico-Chemical Characterization of PSG

2.4. Functional Characterization of PSG Samples

2.5. Development and Characterization of PSG Supplemented Functional Yoghurt

2.6. Sensory Evaluation of PSG Supplemented Functional Yoghurt Samples

2.7. Statistical Analysis

3. Results and Discussion

3.1. Partially Defatted Flaxseed Meal (PDFM) Characterization

3.2. Ultrasound-Assisted Optimal Extraction of PSG

3.3. Fitting the Experimental Model

- A = Extraction Temperature (°C)

- B = Water to Meal Ratio

- C = Amplitude Level (%)

- D = pH

- E = Time

- Temp = Extraction Temperature (°C)

- WMR = Water to Meal Ratio

- Amp = Amplitude Level (%)

3.4. Single Factor Analysis

3.5. Analysis of Mutual Interaction Effect

3.6. Physico-Chemical Characterization of PSG

3.7. Functional Properties PSG

3.7.1. Solubility and Swelling Power

3.7.2. Viscosity

3.7.3. Foaming Properties

3.7.4. Emulsion Properties

3.8. Characterization of PSG-Supplemented Yoghurts

3.8.1. Viscosity

3.8.2. Syneresis

3.8.3. pH

3.9. Sensory Evaluation of PSG-Supplemented Yoghurt

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Pradhan, R.; Meda, V.; Rout, P.; Naik, S.; Dalai, A. Supercritical CO2 extraction of fatty oil from flaxseed and comparison with screw press expression and solvent extraction processes. J. Food Eng. 2010, 98, 393–397. [Google Scholar] [CrossRef]

- Bernacchia, R.; Preti, R.; Vinci, G. Chemical Composition and Health Benefits of Flaxseed. Aust. J. Nutr. Food Sci. 2014, 2, 1045. [Google Scholar]

- Oomah, B.D.; Mazza, G. Flaxseed Products for Diseases Prevention, in Functional Foods—Biochemical and Processing Aspects; Mazza, G., Ed.; Technomic Publishing Company, Inc.: Lancaster, PA, USA, 1998; pp. 91–138. [Google Scholar]

- Wang, Y.; Li, D.; Wang, L.J.; Li, S.J.; Adhikari, B. Effects of drying methods on the functional properties of flaxseed gum powders. Carbohydr. Polym. 2010, 81, 128–133. [Google Scholar] [CrossRef]

- Mueller, K.; Eisner, P.; Kirchhoff, E. Simplified fractionation process for linseed meal by alkaline extraction—Functional properties of protein and fibre fractions. J. Food Eng. 2010, 99, 49–54. [Google Scholar] [CrossRef]

- Cui, W.; Mazza, G. Physicochemical Characteristics of Flaxseed Gum. Food Res. Int. 1996, 29, 397–402. [Google Scholar] [CrossRef]

- Knorr, D.; Froehling, A.; Jaeger, H.; Reineke, K.; Schlueter, O.; Schoessler, K. Emerging technologies in food processing. Annu. Rev. Food Sci. Technol. 2011, 2, 203–235. [Google Scholar] [CrossRef] [PubMed]

- Vilkhu, K.; Mawson, R.; Simons, L.; Bates, D. Applications and opportunities for ultrasound assisted extraction in the food industry—A review. Innov. Food Sci. Emerg. Technol. 2008, 9, 161–169. [Google Scholar] [CrossRef]

- Putnik, P.; Lorenzo, J.; Barba, F.; Roohinejad, S.; Režek-Jambrak, A.; Granato, D.; Montesano, D.; Bursać-Kovačević, D. Novel food processing and extraction technologies of high-added value compounds from plant materials. Foods 2018, 7, 106. [Google Scholar] [CrossRef]

- Kovačević, D.B.; Maras, M.; Barba, F.J.; Granato, D.; Roohinejad, S.; Mallikarjunan, K.; Montesano, D.; Lorenzo, J.M.; Putnik, P. Innovative technologies for the recovery of phytochemicals from Stevia rebaudiana Bertoni leaves. Food Chem. 2018, 268, 513–521. [Google Scholar]

- Awad, T.S.; Moharram, H.A.; Shaltout, O.E.; Asker, D.; Youssef, M.M. Applications of ultrasound in analysis, processing and quality control of food: A review. Food Res. Int. 2012, 48, 410–427. [Google Scholar] [CrossRef]

- Thakur, G.; Mitra, A.; Pal, K.; Rousseau, D. Effect of flaxseed gum on reduction of blood glucose and cholesterol in Type 2 diabetic patients. Int. J. Food Sci. Nutr. 2009, 60, 126–136. [Google Scholar] [CrossRef] [PubMed]

- El-Aziz, M.A.; Haggag, H.F.; Kaluoubi, M.M.; Hassan, L.K.; El-Sayed, M.M.; Sayed, A.F. Physical Properties of Ice Cream Containing Cress Seed and Flaxseed Mucilages Compared with Commercial Guar Gum. Int. J. Dairy Sci. 2015, 10, 160–172. [Google Scholar] [CrossRef]

- Goff, H.D. Instability and Partial Coalescence in shippable Dairy Emulsions. J. Dairy Sci. 1997, 80, 2620–2630. [Google Scholar] [CrossRef]

- American Association of Cereal Chemists. Approved Methods of Analysis, 10th ed.; AACC International Press: St. Paul, MN, USA, 2000. [Google Scholar]

- Association of Official Analytical Chemists. Official Methods of Analysis of the AOAC, 15th ed.; Association of Official Analytical Chemists: Arlington, VA, USA, 1990. [Google Scholar]

- Schanderi, S.H. Methods in Food Analysis; Academic Press: New York, NY, USA, 1970. [Google Scholar]

- Oomah, B.D.; Mazza, G. Optimization of a spray drying process for flaxseed gum. Int. J. Food Sci. Technol. 2001, 36, 135–143. [Google Scholar] [CrossRef]

- Sittikijyoothin, W.; Sampaio, P.; Goncalves, M.P. Microstructure and rheology of β-lactoglobulin galactomannan aqueous mixtures. Food Hydrocoll. 2010, 24, 726–734. [Google Scholar] [CrossRef]

- Shahidi, F.; Han, X.Q.; Synowiecki, J. Production and characteristics of protein hydrolysates from capelin (Mallotus villosus). Food Chem. 1995, 53, 285–291. [Google Scholar] [CrossRef]

- Pearce, K.N.; Kinsella, J.E. Emulsifying properties of proteins: Evaluation of a turbidimetric technique. J. Agric. Food Chem. 1978, 26, 716–723. [Google Scholar] [CrossRef]

- Hematyar, N.; Samarin, A.M.; Poorazarang, H. and Elhamirad, A.H. Effect of Gums on Yoghurt Characteristics. World Appl. Sci. J. 2012, 20, 661–665. [Google Scholar]

- Cueva, O.; Aryana, K.J. Quality attributes of a heart healthy yoghurt. LWT-Food Sci. Technol. 2008, 41, 537–544. [Google Scholar] [CrossRef]

- Meilgaard, M.M.; Civille, G.V.; Carr, T. Overall difference tests: Does a sensory difference exist between samples? In Sensory Evaluation Techniques, 4th ed.; CRC Press: New York, NY, USA, 2007; pp. 63–104. [Google Scholar]

- Montgomery, D.C. Response surface methods and designs. In Design and Analysis of Experiments; Wiley: New York, NY, USA, 2008; p. 440. [Google Scholar]

- Wang, Y.; Li, D.; Wang, L.J.; Chiu, Y.L.; Chen, X.D.; Mao, Z.H.; Song, C.F. Optimization of extrusion of flaxseeds for in vitro protein digestibility analysis using response surface methodology. J. Food Eng. 2008, 5, 59–64. [Google Scholar] [CrossRef]

- Imran, M.; Anjum, F.M.; Butt, M.S.; Sheikh, M.A. Influence of Extrusion Processing on Tannin Reduction and Oil Loss in Flaxseed (Linum usitatissimum L.) Meal. J. Food Process. Preserv. 2012, 1–8. [Google Scholar] [CrossRef]

- Cui, W.; Mazza, G.; Oomah, B.D.; Biliaderis, C.G. Optimization of an aqueous extraction process for flaxseed gum by response surface methodology. LWT-Food Sci. Technol. 1994, 27, 363–369. [Google Scholar] [CrossRef]

- Maherani, B.; Barzegar, M.; Sahari, M.A. Extraction conditions and physico-chemical properties of flaxseed gum. J. Food Sci. Technol. 2007, 44, 250–254. [Google Scholar]

- Koocheki, A.; Mortazavi, S.A.; Shahidi, F.; Razavi, S.M.A.; Kadkhodaee, R.; Mohamadzadeh Milani, J. Optimization of mucilage extraction from Qodume shirazi seed (Alyssum homolocarpum) using response surface methodology. J. Food Process Eng. 2010, 33, 861–882. [Google Scholar] [CrossRef]

- Wu, H.; Pan, A.; Yu, Z.; Qi, Q.; Lu, L.; Zhang, G.; Yu, D.; Zong, G.; Zhou, Y.; Chen, X.; et al. Lifestyle counseling and supplementation with flaxseed or walnuts influence the management of metabolic syndrome. J. Nutr. 2010, 14011, 1937–1942. [Google Scholar] [CrossRef] [PubMed]

- Koocheki, A.; Taherian, A.R.; Razavi, S.M.A.; Bostan, A. Response surface methodology for optimization of extraction yield, viscosity, hue and emulsion stability of mucilage extracted from Lepidium perfoliatum seeds. Food Hydrocoll. 2009, 23, 2369–2379. [Google Scholar] [CrossRef]

- Ziolkovska, A. Laws of flaxseed mucilage extraction. Food Hydrocoll. 2012, 26, 197–204. [Google Scholar] [CrossRef]

- Balke, D.T.; Diosady, L.L. Rapid aqueous extraction of mucilage from whole white mustard seed. Food Res. Int. 2000, 33, 347–356. [Google Scholar] [CrossRef]

- Estevez, A.M.; Saenz, C.; Hurtado, M.L.; Escobar, B.; Espinoza, S.; Suarez, C. Extraction methods and some physical properties of mesquite (Prosopis chilensis (Mol) Stuntz) seed gum. J. Sci. Food Agric. 2004, 84, 1487–1492. [Google Scholar] [CrossRef]

- Somboonpanyakul, P.; Wang, Q.; Cui, W.; Barbut, S.; Jantawat, P. Malva nut gum. (Part I): Extraction and physicochemical characterization. Carbohydr. Polym. 2006, 64, 247–253. [Google Scholar] [CrossRef]

- Mazza, G.; Biliaderis, C.G. Functional properties of flax seed mucilage. J. Food Sci. 1989, 10, 1365–2621. [Google Scholar] [CrossRef]

- Barbary, O.M.; El-Sohaimy, S.A.; El-Saadani, M.A.; Zeitun, A.M.A. Extraction, composition and physicochemical properties of flaxseed mucilage. J. Adv. Agric. Res. 2009, 14, 605–622. [Google Scholar]

- Wanasundara, U.; Amarowicz, R.; Shahidi, F. Isolation and Identification of an Antioxidative Component in Canola Meal. J. Agric. Food Chem. 1994, 42, 1285–1290. [Google Scholar] [CrossRef]

- Fedeniuk, R.W.; Biliaderis, C.G. Composition and physicochemical properties of Linseed (Linum usitatissimum L.) Mucilage. J. Agric. Food Chem. 1994, 42, 240–247. [Google Scholar] [CrossRef]

- Wu, Y.; Cui, S.W.; Eskin, M.; Goff, H.D. Fractionation and partial characterization of non-pectic polysaccharides from yellow mustard mucilage. Food Hydrocoll. 2009, 23, 1535–1541. [Google Scholar] [CrossRef]

- Izydorczyk, M.S.; Lagassé, S.L.; Hatcher, D.W.; Dexter, J.E.; Rossnagel, B.G. The enrichment of Asian noodles with fiber-rich fractions derived from roller milling of hull-less barley. J. Sci. Food Agric. 2005, 85, 2094–2104. [Google Scholar] [CrossRef]

- Makri, E.A.; Doxastakis, G.I. Study of emulsions stabilized with Phaseolus vulgaris or Phaseolus coccineus with the addition of Arabic gum, locust bean gum and xanthan gum. Food Hydrocoll. 2006, 20, 1141–1152. [Google Scholar] [CrossRef]

- Sciarini, L.S.; Maldonado, F.; Ribotta, P.D.; Pérez, G.T. Chemical composition and functional properties of Gleditsia triacanthos gum. Food Hydrocoll. 2009, 23, 306–313. [Google Scholar] [CrossRef]

- Kishk, Y.F.M. Optimization of isolation flaxseed mucilage from methanolic extract and its functional characteristics. J. Food Dairy Sci. 2013, 4, 539–556. [Google Scholar]

- Mathur, N.K. Gallactomannan Polysaccharides in Industrial Polysaccharides; CRC Press: Boca Raton, FL, USA, 2012; pp. 148–152. [Google Scholar]

- Keogh, M.K.; O’kennedy, B.T. Rheology of Stirred Yoghurt as Affected by Added Milk Fat, Protein and Hydrocolloids. J. Food Sci. 1998, 63, 108–112. [Google Scholar] [CrossRef]

- Thaiudom, S.; Goff, H.D. Effect of κ-carrageenan on milk protein polysaccharide mixtures. Int. Dairy J. 2003, 13, 763–771. [Google Scholar] [CrossRef]

- Hussein, M.M.; Hassan, F.A.M.; Daym, H.H.A.; Salama, A.; Enab, A.K.; Asmaa, A.; El-Galil, A. Utilization of some plant polysaccharides for improving yoghurt consistency. Ann. Agric. Sci. 2011, 56, 97–103. [Google Scholar] [CrossRef] [Green Version]

- Jadhav, B.A.; Pawar, V.S. Effect of utilization of (Galactomannan) guar gum blended with acacia gum in yoghurt. Food Sci. Res. J. 2016, 7, 234–238. [Google Scholar] [CrossRef]

- Marshall, R.T. Ice cream and frozen desserts. In Encyclopaedia of Dairy Sciences; Roginski, H., Fuquay, J.W., Fox, P.F., Eds.; Academic Press: London, UK, 2003; pp. 1367–1375. [Google Scholar]

- Hassan, L.K.; Haggag, H.F.; ElKalyoubi, M.H.; El-Aziz, M.A.; El-Sayed, M.M.; Sayed, A.F. Physico-chemical properties of yoghurt containing cress seed mucilage or guar gum. Ann. Agric. Sci. 2015, 60, 21–28. [Google Scholar] [CrossRef] [Green Version]

- El-Sayed, E.; El-Gawad, I.A.; Murad, H.; Salah, S. Utilization of laboratory produced Xanthan gum in the manufacture of yoghurt and soy yoghurt. Eur. J. Food Res. Technol. 2002, 215, 298–304. [Google Scholar]

| Sonication Variables | Coded Levels | ||

|---|---|---|---|

| −1 | 0 | 1 | |

| Extraction temperature (°C) | 50 | 70 | 90 |

| Water to meal ratio | 10 | 15 | 20 |

| Amplitude level (%) | 30 | 50 | 70 |

| Sonication pH | 5 | 7 | 9 |

| Sonication extraction time (min) | 10 | 20 | 30 |

| Analyzed Parameter | Flaxseed Meal | PSG |

|---|---|---|

| Moisture (%) | 5.12 ± 0.27 | 5.89 ± 0.37 |

| Crude protein (%) | 33.19 ± 0.68 | 12.94 ± 0..24 |

| Crude oil (%) | 8.14 ± 0.38 | 0.78 ± 0.13 |

| Ash (%) | 6.73 ± 0.23 | 12.06 ± 0.42 |

| NFE (%) | 35.93 ± 0.66 | 68.33 ± 0.76 |

| HCN (mg/kg) | 242.25 ± 0.76 | 24.21 ± 0.64 |

| Tannin (mg/100 g) | 176.24 ± 0.46 | 42.81 ± 0.15 |

| Sonication Run | Sonication Variables | PSG Yield (%) | ||||

|---|---|---|---|---|---|---|

| Sonication Temperature (°C) | Water/Meal Ratio | Amplitude Level (%) | Sonication pH | Sonication Time (Minutes) | ||

| 1 | 70 (0) | 15 (0) | 50 (0) | 7 (0) | 20 (0) | 8.93 ± 0.21 |

| 2 | 50 (−1) | 15 (0) | 50 (0) | 7 (0) | 10 (−1) | 7.78 ± 0.18 |

| 3 | 90 (1) | 15 (0) | 50 (0) | 9 (1) | 20 (0) | 10.85 ± 0.21 |

| 4 | 70 (0) | 20 (1) | 70 (1) | 7 (0) | 20 (0) | 10.37 ± 0.17 |

| 5 | 70 (0) | 15 (0) | 50 (0) | 5 (−1) | 10 (−1) | 8.41 ± 0.31 |

| 6 | 90 (1) | 15 (0) | 50 (0) | 7 (0) | 10 (−1) | 9.87 ± 0.22 |

| 7 | 70 (0) | 10 (−1) | 30 (−1) | 7 (0) | 20 (0) | 8.01 ± 0.23 |

| 8 | 50 (−1) | 15 (0) | 50 (0) | 9 (1) | 20 (0) | 9.04 ± 0.17 |

| 9 | 70 (0) | 20 (1) | 50 (0) | 7 (0) | 10 (−1) | 8.98 ± 0.21 |

| 10 | 70 (0) | 15 (0) | 50 (0) | 7 (0) | 20 (0) | 8.94 ± 0.24 |

| 11 | 70 (0) | 15 (0) | 70 (1) | 7 (0) | 10 (−1) | 9.91 ± 0.08 |

| 12 | 70 (0) | 20 (1) | 50 (0) | 9 (1) | 20 (0) | 10.31 ± 0.27 |

| 13 | 70 (0) | 15 (0) | 70 (1) | 7 (0) | 30 (1) | 10.39 ± 0.09 |

| 14 | 70 (0) | 10 (−1) | 50 (0) | 9 (1) | 20 (0) | 9.91 ± 0.23 |

| 15 | 70 (0) | 20 (1) | 50 (0) | 7 (0) | 30 (1) | 9.72 ± 0.17 |

| 16 | 70 (0) | 15 (0) | 30 (−1) | 7 (0) | 30 (1) | 8.41 ± 0.14 |

| 17 | 90 (1) | 20 (1) | 50 (0) | 7 (0) | 20 (0) | 10.34 ± 0.07 |

| 18 | 90 (1) | 15 (0) | 30 (−1) | 7 (0) | 20 (0) | 8.97 ± 0.09 |

| 19 | 70 (0) | 10 (−1) | 50 (0) | 7 (0) | 30 (1) | 9.21 ± 0.27 |

| 20 | 50 (−1) | 15 (0) | 70 (1) | 7 (0) | 20 (0) | 8.98 ± 0.22 |

| 21 | 70 (0) | 10 (−1) | 70 (1) | 7 (0) | 20 (0) | 9.94 ± 0.18 |

| 22 | 70 (0) | 20 (1) | 30 (−1) | 7 (0) | 20 (0) | 8.47 ± 0.25 |

| 23 | 70 (0) | 15 (0) | 50 (0) | 7 (0) | 20 (0) | 8.97 ± 0.24 |

| 24 | 70 (0) | 20 (1) | 50 (0) | 5 (−1) | 20 (0) | 8.95 ± 0.19 |

| 25 | 70 (0) | 15 (0) | 50 (0) | 7 (0) | 20 (0) | 8.96 ± 0.17 |

| 26 | 50 (−1) | 15 (0) | 30 (−1) | 7 (0) | 20 (0) | 7.24 ± 0.21 |

| 27 | 90 (1) | 10 (−1) | 50 (0) | 7 (0) | 20 (0) | 9.84 ± 0.09 |

| 28 | 90 (1) | 15 (0) | 70 (1) | 7 (0) | 20 (0) | 11.04 ± 0.28 |

| 29 | 50 (−1) | 10 (−1) | 50 (0) | 7 (0) | 20 (0) | 7.91 ± 0.14 |

| 30 | 50 (−1) | 15 (0) | 50 (0) | 5 (−1) | 20 (0) | 7.85 ± 0.18 |

| 31 | 50 (−1) | 15 (0) | 50 (0) | 7 (0) | 30 (1) | 8.47 ± 0.19 |

| 32 | 50 (−1) | 20 (1) | 50 (0) | 7 (0) | 20 (0) | 8.38 ± 0.12 |

| 33 | 70 (0) | 15 (0) | 30 (−1) | 5 (−1) | 20 (0) | 7.93 ± 0.17 |

| 34 | 70 (0) | 15 (0) | 30 (−1) | 7 (0) | 10 (−1) | 7.87 ± 0.23 |

| 35 | 70 (0) | 15 (0) | 50 (0) | 7 (0) | 20 (0) | 8.95 ± 0.21 |

| 36 | 70 (0) | 15 (0) | 70 (1) | 9 (1) | 20 (0) | 10.98 ± 0.27 |

| 37 | 90 (1) | 15 (0) | 50 (0) | 5 (−1) | 20 (0) | 9.76 ± 0.19 |

| 38 | 70 (0) | 15 (0) | 30 (−1) | 9 (1) | 20 (0) | 8.98 ± 0.08 |

| 39 | 70 (0) | 10 (−1) | 50 (0) | 5 (−1) | 20 (0) | 8.64 ± 0.17 |

| 40 | 70 (0) | 15 (0) | 70 (1) | 5 (−1) | 20 (0) | 9.87 ± 0.24 |

| 41 | 70 (0) | 15 (0) | 50 (0) | 7 (0) | 20 (0) | 8.97 ± 0.15 |

| 42 | 70 (0) | 15 (0) | 50 (0) | 9 (1) | 10 (−1) | 9.81 ± 0.19 |

| 43 | 70 (0) | 10 (−1) | 50 (0) | 7 (0) | 10 (−1) | 8.71 ± 0.23 |

| 44 | 70 (0) | 15 (0) | 50 (0) | 9 (1) | 30 (1) | 10.37 ± 0.28 |

| 45 | 70 (0) | 15 (0) | 50 (0) | 5 (−1) | 30 (1) | 9.14 ± 0.18 |

| 46 | 90 (1) | 15 (0) | 50 (0) | 7 (0) | 30 (1) | 10.36 ± 0.21 |

| SOV | DF | F-Value | p-Value | Remarks | |

|---|---|---|---|---|---|

| Linear | Model | 20 | 522.38 | <0.0001 | Significant |

| A-Temperature | 1 | 3923.57 | <0.0001 | Significant | |

| B-Water/meal ratio | 1 | 186.15 | <0.0001 | Significant | |

| C-Amplitude level | 1 | 4036.62 | <0.0001 | Significant | |

| D-pH | 1 | 1560.68 | <0.0001 | Significant | |

| E-Time | 1 | 371.10 | <0.0001 | Significant | |

| Interaction | AB | 1 | 0.0597 | 0.8089 | Non-Significant |

| AC | 1 | 7.23 | 0.0126 | Significant | |

| AD | 1 | 0.6635 | 0.4230 | Non-Significant | |

| AE | 1 | 2.65 | 0.1158 | Non-Significant | |

| BC | 1 | 0.0597 | 0.8089 | Non-Significant | |

| BD | 1 | 0.5374 | 0.4703 | Non-Significant | |

| BE | 1 | 3.82 | 0.0619 | Significant | |

| CD | 1 | 0.2389 | 0.6293 | Non-Significant | |

| CE | 1 | 0.2389 | 0.6293 | Non-Significant | |

| DE | 1 | 1.92 | 0.1784 | Non-Significant | |

| Quadratic | A2 | 1 | 3.52 | 0.0725 | Significant |

| B2 | 1 | 35.11 | <0.0001 | Significant | |

| C2 | 1 | 21.18 | 0.0001 | Significant | |

| D2 | 1 | 338.50 | <0.0001 | Significant | |

| E2 | 1 | 23.07B | <0.0001 | Significant | |

| Residual | 25 | - | - | ||

| Lack of Fit | 20 | 17.41 | 0.0025 | ||

| Pure Error | 5 | - | - | ||

| Cor Total | 45 | - | - | ||

| Treatment | Viscosity (cp) | Synersis (%) | pH |

|---|---|---|---|

| T0 | 502 ± 3 | 13.58 ± 1.07 | 3.97 ± 0.68 |

| T1 | 548 ± 2 | 12.02 ± 1.24 | 4.16 ± 0.54 |

| T2 | 593 ± 4 | 11.30 ± 1.12 | 4.30 ± 0.59 |

| T3 | 641 ± 2 | 9.95 ± 0.94 | 4.42 ± 0.61 |

| T4 | 688 ± 2 | 8.63 ± 0.87 | 4.65 ± 0.66 |

| T5 | 735 ± 3 | 7.04 ± 1.01 | 4.78 ± 0.52 |

| T6 | 776 ± 5 | 5.87 ± 0.95 | 4.91 ± 0.63 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akhtar, M.N.; Mushtaq, Z.; Ahmad, N.; Khan, M.K.; Ahmad, M.H.; Hussain, A.I.; Imran, M. Optimal Ultrasound-Assisted Process Extraction, Characterization, and Functional Product Development from Flaxseed Meal Derived Polysaccharide Gum. Processes 2019, 7, 189. https://doi.org/10.3390/pr7040189

Akhtar MN, Mushtaq Z, Ahmad N, Khan MK, Ahmad MH, Hussain AI, Imran M. Optimal Ultrasound-Assisted Process Extraction, Characterization, and Functional Product Development from Flaxseed Meal Derived Polysaccharide Gum. Processes. 2019; 7(4):189. https://doi.org/10.3390/pr7040189

Chicago/Turabian StyleAkhtar, Muhammad Nadeem, Zarina Mushtaq, Nazir Ahmad, Muhammad Kamran Khan, Muhammad Haseeb Ahmad, Abdullah Ijaz Hussain, and Muhammad Imran. 2019. "Optimal Ultrasound-Assisted Process Extraction, Characterization, and Functional Product Development from Flaxseed Meal Derived Polysaccharide Gum" Processes 7, no. 4: 189. https://doi.org/10.3390/pr7040189

APA StyleAkhtar, M. N., Mushtaq, Z., Ahmad, N., Khan, M. K., Ahmad, M. H., Hussain, A. I., & Imran, M. (2019). Optimal Ultrasound-Assisted Process Extraction, Characterization, and Functional Product Development from Flaxseed Meal Derived Polysaccharide Gum. Processes, 7(4), 189. https://doi.org/10.3390/pr7040189