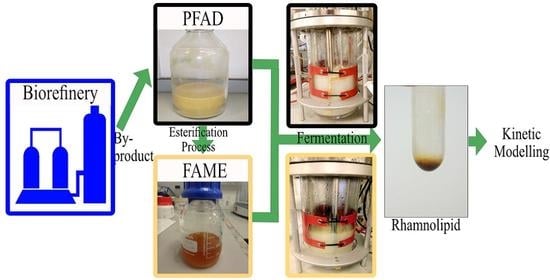

Bioreactor Rhamnolipid Production Using Palm Oil Agricultural Refinery By-Products

Abstract

:Simple Summary

Abstract

1. Introduction

2. Modelling of Reaction Kinetics

3. Materials and Methods

3.1. Experiment

3.2. Measurement of Growth

3.3. Extraction of Rhamnolipid

3.4. Identification of Biosurfactant

3.5. Characterization of Biosurfactant

4. Results

4.1. Bioreactor Production of Biosurfactant by P. aeruginosa PAO1 Using PFAD and FAME as Carbon Sources

| Bioreactor Volume (L) | Microorganism | Substrate | Concentration (g L−1) | Timemax (h) | DCWmax (g L−1) | RLmax (g L−1) | *YX/S (g g −1) | *YP/S (g g −1) | PRL (g L−1 h−1) | References |

|---|---|---|---|---|---|---|---|---|---|---|

| 2 | Pseudomonas aeruginosa PAO1 | PFAD | 20 | 60 | 2.99 | 1.07 | 0.15 | 0.05 | 0.02 | This study |

| FAME | 20 | 72 | 2.09 | 2.11 | 0.11 | 0.11 | 0.03 | |||

| 2 | Pseudomonas aeruginosa C2 | Waste of Catla catla fish | 20 | 72 | 0.20 | 1.30 | 0.01 | 0.065 | 0.02 | [36] |

| 3.1 | Pseudomonas aeruginosa AMB AS7 | Coconut oil sludge | 20 | 60 | 2.45 | 0.71 | 0.12 | 0.04 | 0.01 | [37] |

| 5 | Pseudomonas aeruginosa MR01 | Soybean oil Soapstock | 80 | 240 | 5.00 | 25.50 | 0.06 | 0.32 | 0.11 | [30] |

| 5 | Pseudomonas aeruginosa #112 | Olive oil mill wastewater | 250 | 168 | 5.00 | 5.12 | 0.02 | 0.02 | 0.03 | [35] |

4.2. Biosurfactant Identification

4.3. Biosurfactant Characterization

4.4. Modelling of Bioreactor Fermentation

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Morais, A.; Bogel-Lukasik, R. Green chemistry and the biorefinery concept. Sustain. Chem. Process. 2013, 1, 18. [Google Scholar] [CrossRef] [Green Version]

- Ayodele, B.; Cheng, C.K. Biorefinery for the Production of Biodiesel, Hydrogen and Synthesis Gas Integrated with CHP from Oil Palm in Malaysia. Chem. Prod. Process. Model. 2016, 11, 305–314. [Google Scholar] [CrossRef]

- PEMANDU. Palm Oil & Rubber. Performance Management & Delivery Unit (PEMANDU). 2015. Available online: http://etp.pemandu.gov.my/Palm_Oil-@-Palm_Oil_-%E2%97%98-_Rubber.aspx (accessed on 1 September 2017).

- Toh, T. 100 glorious years of palm oil in Malaysia. The Star. 2017. Available online: http://www.star2.com/palmoil/2017/05/18/100-glorious-years-of-palm-oil-in-malaysia/ (accessed on 1 September 2017).

- MPOB. Production of Crude Palm Oil 2017. Malaysian Palm Oil Board (MPOB). 2017. Available online: http://bepi.mpob.gov.my/index.php/en/statistics/production/177-production-2017/792-production-of-crude-oil-palm-2017.html (accessed on 1 September 2017).

- Radzuan, M.N.; Banat, I.M.; Winterburn, J. Production and characterization of rhamnolipid using palm oil agricultural refinery waste. Bioresour. Technol. 2017, 225, 99–105. [Google Scholar] [CrossRef]

- Chabukswar, D.D.; Heer, P.K.K.S.; Gaikar, V.G. Esterification of Palm Fatty Acid Distillate Using Heterogeneous Sulfonated Microcrystalline Cellulose Catalyst and Its Comparison with H2SO4 Catalyzed Reaction. Ind. Eng. Chem. Res. 2013, 52, 7316–7326. [Google Scholar] [CrossRef]

- Hosseini, S.; Janaun, J.; Choong, T.S. Feasibility of honeycomb monolith supported sugar catalyst to produce biodiesel from palm fatty acid distillate (PFAD). Process. Saf. Environ. Prot. 2015, 98, 285–295. [Google Scholar] [CrossRef]

- Lokman, I.M.; Rashid, U.; Yunus, R.; Taufiq-Yap, Y.H. Carbohydrate-derived Solid Acid Catalysts for Biodiesel Production from Low-Cost Feedstocks: A Review. Catal. Rev. 2014, 56, 187–219. [Google Scholar] [CrossRef]

- Marchant, R.; Banat, I. Microbial biosurfactants: Challenges and opportunities for future exploitation. Trends Biotechnol. 2012, 30, 558–565. [Google Scholar] [CrossRef] [PubMed]

- Marchant, R.; Banat, I. Biosurfactants: A sustainable replacement for chemical surfactants? Biotechnol. Lett. 2012, 34, 1597–1605. [Google Scholar] [CrossRef] [PubMed]

- Paulino, B.N.; Pessôa, M.G.; Mano, M.C.R.; Molina, G.; Numa, I.A.N.; Pastore, G.M. Current status in biotechnological production and applications of glycolipid biosurfactants. Appl. Microbiol. Biotechnol. 2016, 100, 10265–10293. [Google Scholar] [CrossRef] [PubMed]

- Santos, D.K.F.; Rufino, R.D.; Luna, J.M.; Santos, V.A.; Sarubbo, L.A. Biosurfactants: Multifunctional Biomolecules of the 21st Century. Int. J. Mol. Sci. 2016, 17, 401. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- De Almeida, D.G.; Silva, R.D.C.F.S.D.; Luna, J.M.; Rufino, R.D.; Santos, V.A.; Banat, I.; Sarubbo, L.A. Biosurfactants: Promising Molecules for Petroleum Biotechnology Advances. Front. Microbiol. 2016, 7, 1718. [Google Scholar] [CrossRef] [Green Version]

- Mnif, I.; Ghribi, D. Glycolipid biosurfactants: Main properties and potential applications in agriculture and food industry. J. Sci. Food Agric. 2016, 96, 4310–4320. [Google Scholar] [CrossRef] [PubMed]

- Fariq, A.; Saeed, A. Production and Biomedical Applications of Probiotic Biosurfactants. Curr. Microbiol. 2016, 72, 489–495. [Google Scholar] [CrossRef] [PubMed]

- Perfumo, A.; Banat, I.M.; Marchant, R. Going Green and Cold: Biosurfactants from Low-Temperature Environments to Biotechnology Applications. Trends Biotechnol. 2018, 36, 277–289. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Geetha, S.J.; Banat, I.M.; Joshi, S.J. Biosurfactants: Production and potential applications in microbial enhanced oil recovery (MEOR). Biocatal. Agric. Biotechnol. 2018, 14, 23–32. [Google Scholar] [CrossRef]

- Geys, R.; Soetaert, W.; Van Bogaert, I. Biotechnological opportunities in biosurfactant production. Curr. Opin. Biotechnol. 2014, 30, 66–72. [Google Scholar] [CrossRef]

- Nabais, R.M.; Malcata, F.X. Modelling of lactic fermentation of carrot slices in salted brines. Food Sci. Technol. Int. 1997, 3, 263–283. [Google Scholar] [CrossRef]

- Shang, L.; Di Fan, D.; Kim, M.I.; Choi, J.-D.; Chang, H.N. Modeling of poly(3-hydroxybutyrate) production by high cell density fed-batch culture of Ralstonia eutropha. Biotechnol. Bioprocess. Eng. 2007, 12, 417–423. [Google Scholar] [CrossRef]

- Radzuan, M.N.; Banat, I.M.; Winterburn, J. Biorefining palm oil agricultural refinery waste for added value rhamnolipid production via fermentation. Ind. Crops Prod. 2018, 116, 64–72. [Google Scholar] [CrossRef]

- Clark, D.S.; Blanch, H.W. Biochemical Engineering, 2nd ed.; Taylor & Francis: Boca Raton, FL, USA, 1997. [Google Scholar]

- Mercier, P.; Yerushalmi, L.; Rouleau, D.; Dochain, D. Kinetics of lactic acid fermentation on glucose and corn by Lactobacillus amylophilus. J. Chem. Technol. Biotechnol. 1992, 55, 111–121. [Google Scholar] [CrossRef]

- Soberón-Chávez, G.; Lépine, F.; Déziel, E. Production of rhamnolipids by Pseudomonas aeruginosa. Appl. Microbiol. Biotechnol. 2005, 68, 718–725. [Google Scholar] [CrossRef] [PubMed]

- Henkel, M.; Schmidberger, A.; Kühnert, C.; Beuker, J.; Bernard, T.; Schwartz, T.; Syldatk, C.; Hausmann, R. Kinetic modeling of the time course of N-butyryl-homoserine lactone concentration during batch cultivations of Pseudomonas aeruginosa PAO1. Appl. Microbiol. Biotechnol. 2013, 97, 7607–7616. [Google Scholar] [CrossRef]

- El-Fouly, M.; Sharaf, A.; Shahin, A.; El-Bialy, H.A.; Omara, A. Biosynthesis of pyocyanin pigment byPseudomonas aeruginosa. J. Radiat. Res. Appl. Sci. 2014, 8, 36–48. [Google Scholar] [CrossRef] [Green Version]

- Pacheco, G.J.; Reis, R.S.; Fernandes, A.C.L.B.; da Rocha, S.L.G.; Pereira, M.D.; Perales, J.; Freire, D.M.G. Rhamnolipid production: Effect of oxidative stress on virulence factors and proteome of Pseudomonas aeruginosa PA1. Appl. Microbiol. Biotechnol. 2012, 95, 1519–1529. [Google Scholar] [CrossRef] [PubMed]

- Junker, B. Foam and Its Mitigation in Fermentation Systems. Biotechnol. Prog. 2007, 23, 767–784. [Google Scholar] [CrossRef]

- Lotfabad, T.B.; Ebadipour, N.; RoostaAzad, R. Evaluation of a recycling bioreactor for biosurfactant production byPseudomonas aeruginosaMR01 using soybean oil waste. J. Chem. Technol. Biotechnol. 2015, 91, 1368–1377. [Google Scholar] [CrossRef]

- Funston, S.J.; Tsaousi, K.; Rudden, M.; Smyth, T.; Stevenson, P.S.; Marchant, R.; Banat, I. Characterising rhamnolipid production in Burkholderia thailandensis E264, a non-pathogenic producer. Appl. Microbiol. Biotechnol. 2016, 100, 7945–7956. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- De Rienzo, M.D.; Kamalanathan, I.; Martin, P. Comparative study of the production of rhamnolipid biosurfactants by B. thailandensis E264 and P. aeruginosa ATCC 9027 using foam fractionation. Process. Biochem. 2016, 51, 820–827. [Google Scholar] [CrossRef]

- Zhu, L.; Yang, X.; Xue, C.; Chen, Y.; Qu, L.; Lu, W. Enhanced rhamnolipids production by Pseudomonas aeruginosa based on a pH stage-controlled fed-batch fermentation process. Bioresour. Technol. 2012, 117, 208–213. [Google Scholar] [CrossRef]

- Wu, T.; Jiang, J.; He, N.; Jin, M.; Ma, K.; Long, X. High-Performance Production of Biosurfactant Rhamnolipid with Nitrogen Feeding. J. Surfactants Deterg. 2019, 22, 395–402. [Google Scholar] [CrossRef]

- Gudiña, E.J.; Rodrigues, A.; Freitas, V.; Azevedo, Z.; Teixeira, J.; Rodrigues, L.R. Valorization of agro-industrial wastes towards the production of rhamnolipids. Bioresour. Technol. 2016, 212, 144–150. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sana, S.; Datta, S.; Biswas, D.; Bhattacharya, M. Production kinetics of Rhamnolipid using fish fat: A step towards environmental hazard control of sewage. Environ. Technol. Innov. 2017, 8, 299–308. [Google Scholar] [CrossRef]

- Samykannu, M.; Achary, A. Utilization of Agro-Industry Residue for Rhamnolipid Production by P. aeruginosa AMB AS7 and Its Application in Chromium Removal. Appl. Biochem. Biotechnol. 2017, 183, 70–90. [Google Scholar] [CrossRef] [PubMed]

- Müller, M.M.; Hörmann, B.; Syldatk, C.; Hausmann, R. Pseudomonas aeruginosa PAO1 as a model for rhamnolipid production in bioreactor systems. Appl. Microbiol. Biotechnol. 2010, 87, 167–174. [Google Scholar] [CrossRef] [PubMed]

- Aparna, A.; Srinikethan, G.; Smitha, H. Production and characterization of biosurfactant produced by a novel Pseudomonas sp. 2B. Colloids Surf. B Biointerfaces 2012, 95, 23–29. [Google Scholar] [CrossRef]

- Hošková, M.; Ježdík, R.; Schreiberová, O.; Chudoba, J.; Šír, M.; Čejková, A.; Masák, J.; Jirků, V.; Řezanka, T. Structural and physiochemical characterization of rhamnolipids produced by Acinetobacter calcoaceticus, Enterobacter asburiae and Pseudomonas aeruginosa in single strain and mixed cultures. J. Biotechnol. 2015, 193, 45–51. [Google Scholar] [CrossRef] [PubMed]

- Nitschke, M.; Costa, S.G.V.A.O.; Contiero, J. Structure and Applications of a Rhamnolipid Surfactant Produced in Soybean Oil Waste. Appl. Biochem. Biotechnol. 2009, 160, 2066–2074. [Google Scholar] [CrossRef]

- Sakthipriya, N.; Doble, M.; Sangwai, J. Biosurfactant from Pseudomonas species with waxes as carbon source—Their production, modeling and properties. J. Ind. Eng. Chem. 2015, 31, 100–111. [Google Scholar] [CrossRef]

- Partovi, M.; Lotfabad, T.B.; Roostaazad, R.; Bahmaei, M.; Tayyebi, S. Management of soybean oil refinery wastes through recycling them for producing biosurfactant using Pseudomonas aeruginosa MR01. World J. Microbiol. Biotechnol. 2013, 29, 1039–1047. [Google Scholar] [CrossRef] [PubMed]

| Mono- to Di- Rhamnolipid Ratio (Rha-C10-C10: Rha-Rha-C10-C10) | Congeners of Rhamnolipid (Pseudomolecular Ion, m/z) | |

|---|---|---|

| Carbon Source | Ratio | |

| PFAD | 3.18 | Rha-C10-C10 (503) Rha-Rha-C10-C10 (649) |

| FAME | 3.22 | |

| Microorganism | Substrate | Surface Tension Reduction (mN m−1) | CMC (mg L−1) | Rhamnolipid Concentration (g L−1) | Emulsion Index (24 h, %) | References | |||

|---|---|---|---|---|---|---|---|---|---|

| Hexadecane | Kerosene | Sunflower Oil | Rapeseed Oil | ||||||

| P. aeruginosa PAO1 | PFAD | 28 | 62 | 1 | 47 | 40 | 22 | 33 | This study |

| FAME | 28 | 62 | 48 | 44 | 38 | 46 | |||

| P. aeruginosa MR01 | Soybean oil soap stock | 29 | 24 | 10 | - | 63 | - | - | [30] |

| P. aeruginosa #112 | Olive oil mill wastewater | 29 | 13 | 5 | 58 | - | - | - | [35] |

| P. aeruginosa ATCC 9027 | Glucose | 24 | 20 | 0.9 | - | 48 | - | - | [32] |

| P. aeruginosa | Sodium citrate | - | 56 | 1 | - | - | 5 | - | [40] |

| Microorganism | Carbon Sources | Exponential Time (H) | Specific Growth Rate, µ (h−1) | Doubling Time, td (h−1) | R2 | Initial Rate of Rhamnolipid Produced, Pexp (g L−1 h−1) | References |

|---|---|---|---|---|---|---|---|

| P. aeruginosa PAO1 | PFAD | 60 | 0.05 | 13.86 | 0.87 | 0.02 | This study |

| FAME | 24 | 0.11 | 6.30 | 0.97 | 0.02 | ||

| P. aeruginosa CPCL | n-Hexadecane | 40 | 0.056 | 12.37 | 0.97 | 0.48 | [42] |

| n-Eicosane | 40 | 0.034 | 20.38 | 0.96 | 0.24 | ||

| P. aeruginosa MR01 | Soybean oil | 50 | 0.20 | - | - | - | [43] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Radzuan, M.N.; Winterburn, J.; Banat, I. Bioreactor Rhamnolipid Production Using Palm Oil Agricultural Refinery By-Products. Processes 2021, 9, 2037. https://doi.org/10.3390/pr9112037

Radzuan MN, Winterburn J, Banat I. Bioreactor Rhamnolipid Production Using Palm Oil Agricultural Refinery By-Products. Processes. 2021; 9(11):2037. https://doi.org/10.3390/pr9112037

Chicago/Turabian StyleRadzuan, Mohd Nazren, James Winterburn, and Ibrahim Banat. 2021. "Bioreactor Rhamnolipid Production Using Palm Oil Agricultural Refinery By-Products" Processes 9, no. 11: 2037. https://doi.org/10.3390/pr9112037

APA StyleRadzuan, M. N., Winterburn, J., & Banat, I. (2021). Bioreactor Rhamnolipid Production Using Palm Oil Agricultural Refinery By-Products. Processes, 9(11), 2037. https://doi.org/10.3390/pr9112037