Spiral Vibration Cooler for Continual Cooling of Biomass Pellets

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Optimizing Pellet Transport on a Spiral Vibrating Feeder

3.2. Pellet Cooling

3.2.1. Cooling on a Spiral Trough (Variant A)

3.2.2. Cooling on the Spiral Trough with a Distribution of Air Hoses (Variant B)

3.2.3. Cooling of Pellets on Free Surface (Variant C)

3.3. Mechanical Properties of Pellets

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature/Abbreviations

| AZ | Z direction amplitude | (m) |

| AZ120° | Z direction amplitude for vibration motors inclination of 120° | (m) |

| DT | trough diameter | (m) |

| FE | excitation force | (N) |

| H | height | (m) |

| l0 | average pellet length before cooling process | (m) |

| l1 | average pellet length after cooling process | (m) |

| MA | pellets moisture after cooling process | (%) |

| MB | pellets moisture before cooling process | (%) |

| MRR | moisture reduction ratio | (-) |

| MS | rape straw moisture | (%) |

| n | vibration motor revolutions | (rpm) |

| PDI | pellet durability index | (%) |

| Q | mass flow rate | (kg∙s−1) |

| QAZ120° | mass flow rate for vibration motors inclination of 120° | (kg∙s−1) |

| QAZ60° | mass flow rate for vibration motors inclination of 60° | (kg∙s−1) |

| QAZ90° | mass flow rate for vibration motors inclination of 90° | (kg∙s−1) |

| R | radius | (m) |

| t | time | (s) |

| Ww | mass of eccentric weights | (kg) |

| X | X axis direction | (-) |

| Y | Y axis direction | (-) |

| Z | Z axis direction | (-) |

| φ´ | angular amplitude | (°) |

| β | inclination of vibration motors | (°) |

| ρ | density | (kg∙m−3) |

| ρB | bulk density | (kg∙m−3) |

| ωv | vibration motor angular velocity | (s−1) |

| Aoutlet | pellets cooling process outlet of A construction design | |

| Boutlet | pellets cooling process outlet of B construction design | |

| Coutlet | pellets cooling process outlet of C construction design | |

| MRR | moisture reduction ratio | |

| PDI | pellet durability index | |

References

- Holm-Nielsen, J.B.; Ehimen, E.A. Biomass Supply Chains for Bioenergy and Biorefining, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Maier, D.E.; Bakker-Arkema, F.W. The Counterflow Cooling of Feed Pellets. J. Agric. Eng. Res. 1992, 53, 305–319. [Google Scholar] [CrossRef]

- Thomas, M.; Van Zuilichem, D.J.; Van Der Poel, A.F.B. Physical Quality of Pelleted Animal Feed. 2. Contribution of Processes and its Conditions. Anim. Feed Sci. Technol. 1997, 64, 173–192. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Wright, C.T.; Hess, J.R.; Kenney, K.L. A Review of Biomass Densification Systems to Develop Uniform Feedstock Commodities for Bioenergy Application. Biofuels Bioprod. Biorefining 2011, 5, 683–707. [Google Scholar] [CrossRef]

- Arshadi, M.; Gref, R.; Geladi, P.; Dahlqvist, S.A.; Lestander, T. The Influence of Raw Material Characteristics on the Industrial Pelletizing Process and Pellet Quality. Fuel Process. Technol. 2018, 89, 1442–1447. [Google Scholar] [CrossRef]

- Nielsen, N.P.K.; Gardner, D.J.; Poulsen, T.; Felby, C. Importance of Temperature, Moisture Content, and Species for the Conversion Process of Wood Residues into Fuel Pellets. Wood Fiber Sci. 2009, 41, 414–425. [Google Scholar]

- Miranda, M.T.; Sepúlveda, F.J.; Arranz, J.I.; Montero, I.; Rojas, C.V. Analysis of Pelletizing from Corn Cob Waste. J. Environ. Manag. 2018, 228, 303–311. [Google Scholar] [CrossRef]

- Gil, M.; Arauzo, I.; Pelet, I.C.A. Hammer Mill Operating and Biomass Physical Conditions Effects on Particle Size Distribution of Solid Pulverized Biofuels. Fuel Process. Technol. 2014, 127, 80–87. [Google Scholar] [CrossRef]

- Labbé, R.; Paczkowski, S.; Knappe, V.; Russ, M.; Wöhler, M.; Pelz, S. Effect of Feedstock Particle Size Distribution and Feedstock Moisture Content on Pellet Production Efficiency, Pellet Quality, Transport and Combustion Emissions. Fuel 2020, 263, 116662. [Google Scholar] [CrossRef]

- Lyu, F.; Thomas, M.; Hendriks, W.H.; Van der Poel, A.F.B. Size Reduction in Feed Technology and Methods for Determining, Expressing and Predicting Particle Size: A Review. Anim. Feed Sci. Technol. 2020, 261, 114347. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, R.V. Densification Characteristics of Corn Cobs. Fuel Process. Technol. 2010, 91, 559–565. [Google Scholar] [CrossRef]

- Rezaei, H.; Yazdanpanah, F.; Lim, C.J.; Sokhansanj, S. Pelletization Properties of Refuse-Derived Fuel-Effects of Particle Size and Moisture Content. Fuel Process Technol. 2020, 205, 106437. [Google Scholar] [CrossRef]

- Jezerska, L.; Drozdova, J.; Rozbroj, J.; Zegzulka, J.; Frydrych, J. Pelletization of Energy Grasses: A study on the Influence of Process and Material Parameters on Pellet Quality. Int. J. Green Energy 2019, 16, 1278–1286. [Google Scholar] [CrossRef]

- Jezerska, L.; Zegzulka, J.; Palkovska, B.; Kucerova, R.; Zadrapa, F. Pelletization of Invasive Reynoutria Japonica with Spruce Sawdust for Energy Recovery. Wood Res. 2018, 63, 1045–1058. [Google Scholar]

- Lehtikangas, P. Quality Properties of Pelletised Sawdust, Logging Residues and Bark. Biomass Bioenergy 2015, 50, 351–360. [Google Scholar] [CrossRef]

- Miranda, T.; Montero, I.; Sepúlveda, F.J.; Arranz, J.I.; Rojas, C.V.; Nogales, S. A review of Pellets from Different Sources. Materials 2015, 8, 1413–1427. [Google Scholar] [CrossRef] [Green Version]

- Pradhan, P.; Mahajani, S.M.; Arora, A. Production and Utilization of Fuel Pellets from Biomass: A review. Fuel Process. Technol. 2018, 181, 215–232. [Google Scholar] [CrossRef]

- Döring, S. Power from Pellets: Technology and Applications; Springer: Berlin, Germany, 2013. [Google Scholar]

- Machinery Amisy Pellet, n.d. Biomass Pellet Plant. Available online: https://www.pellet-plant.net/ (accessed on 23 June 2020).

- Obernberger, I.; Thek, G. The Pellet Handbook: The Production and Thermal Utilisation of Biomass Pellets; Earthscan Ltd.: London, UK, 2010. [Google Scholar]

- Tumuluru, J.S. Effect of process variables on the density and durability of the pellets made from high moisture corn stover. Biosyst. Eng. 2014, 119, 44–57. [Google Scholar] [CrossRef] [Green Version]

- Vekamaf Services, B.V., n.d. Feed and Biomass Installations and Equipment. Available online: https://www.vekamaf.com/industry/feed-and-biomass/ (accessed on 28 May 2021).

- Rosentrater, K.A.; Evers, A.D. Kent’s Technology of Cereals an Introduction for Students of Food Science and Agriculture; Woodhead Publishing: Cambridge, UK, 2018. [Google Scholar]

- Behnke, K.C. Feed manufacturing technology: Current Issues and Challenges. Anim. Feed Sci. Technol. 1996, 62, 49–57. [Google Scholar] [CrossRef]

- Spinelli, R.; Cavallo, E.; Eliasson, L.; Facello, A.; Magagnotti, N. The Effect of Drum Design on Chipper Performance. Renew. Energy 2015, 81, 57–61. [Google Scholar] [CrossRef]

- Warguła, Ł.; Krawiec, P.; Waluś, K.J.; Kukla, M. Fuel Consumption Test Results for a Self-Adaptive, Maintenance-Free Wood Chipper Drive Control System. Appl. Sci. 2020, 10, 2727. [Google Scholar] [CrossRef] [Green Version]

- Warguła, Ł.; Kukla, M.; Lijewski, P.; Dobrzyński, M.; Markiewicz, F. Influence of Innovative Woodchipper Speed Control Systems on Exhaust Gas Emissions and Fuel Consumption in Urban Areas. Energies 2020, 13, 3330. [Google Scholar] [CrossRef]

- Spinelli, R.; Eliasson, L.; Magagnotti, N. Increasing Wood Fuel Processing Efficiency by Fine-Tuning Chipper Settings. Fuel Process. Technol. 2016, 151, 126–130. [Google Scholar] [CrossRef]

- Liška, M. Situation and Outlook Report of the Oilseed; Ministry of Agriculture: Prague, Czech Republic, 2017. [Google Scholar]

- Jezerska, L.; Zajonc, O.; Zegzulka, J.; Kovalova, L.; Janouchova, R. Mechanical Material Properties effect on Pelletization. Proceedings of 21st International Congress of Chemical and Process Engineering CHISA 2014 and 17th Conference on Process Integration, Modelling and Optimisation for Energy Saving and Pollution Reduction PRES 2014, Prague, Czech Republic, 23–27 August 2014; p. 1061. [Google Scholar]

- ISO 18847:2016. Solid biofuels-Determination of Particle Density of Pellets and Briquettes; ISO: Geneva, Switzerland, 2016. [Google Scholar]

- ISO 17828:2015. Solid Biofuels-Determination of Bulk Density; ISO: Geneva, Switzerland, 2015. [Google Scholar]

- Rabier, F.; Temmerman, M.; Böhm, T.; Hartmann, H.; Daugbjerg Jensen, P.; Rathbauer, J.; Carrasco, J.; Fernández, M. Particle Density Determination of Pellets and Briquettes. Biomass Bioenergy 2006, 30, 954–963. [Google Scholar] [CrossRef]

- ISO 17831-1:2015. Solid biofuels-Determination of Mechanical Durability of Pellets and Briquettes 30-Part 1: Pellets; ISO: Geneva, Switzerland, 2015. [Google Scholar]

- ISO 18134-2:2017. Solid biofuels -Determination of Moisture Content-Oven Dry Method-Part 2: Total Moisture-Simplified Method; ISO: Geneva, Switzerland, 2017. [Google Scholar]

- ISO 17829:2015. Solid Biofuels-Determination of Length and Diameter of Pellets; ISO: Geneva, Switzerland, 2015. [Google Scholar]

- Gilbert, P.; Ryu, C.; Sharifi, V.; Swithenbank, J. Effect of Process Parameters on Pelletisation of Herbaceous Crops. Fuel 2009, 88, 1491–1497. [Google Scholar] [CrossRef]

- Whittaker, C.; Shield, I. Factors Affecting Wood, Energy Grass and Straw Pellet Durability-A review. Renew. Sustain. Energy Rev. 2017, 71, 1–11. [Google Scholar] [CrossRef]

- Stelte, W.; Holm, J.K.; Sanadi, A.R.; Barsberg, S.; Ahrenfeldt, J.; Henriksen, U.B. A Study of Bonding and Failure Mechanisms in Fuel Pellets from Different Biomass Resources. Biomass Bioenergy 2011, 35, 910–918. [Google Scholar] [CrossRef] [Green Version]

- Jägers, J.; Wirtz, S.; Scherer, V.; Behr, M. Experimental Analysis of Wood Pellet Degradation during Pneumatic Conveying Processes. Powder Technol. 2020, 359, 282–291. [Google Scholar] [CrossRef]

- Mediavilla, I.; Fernández, M.J.; Esteban, L.S. Optimization of Pelletisation and Combustion in a Boiler of 17.5 kWth for Vine Shoots and Industrial Cork Residue. Fuel Process. Technol. 2009, 90, 621–628. [Google Scholar] [CrossRef]

|  |  | |

| Eccentric Weight Adjustment (°) | 60 | 90 | 120 |

| Vibration motor centrifugal force (N) | 850 | 693 | 489 |

| Vertical amplitude Az (mm) | 0.85 | 0.63 | 0.48 |

| Angular amplitude φ´ (°) | 0.24 | 0.24 | 0.18 |

| ρ (kg∙m−3) | ρB (kg∙m−3) | |

|---|---|---|

| Raw material—Rape straw | - | 127.2 ± 4.5 |

| Cooler inlet | 1320 ± 16 | 625.0 ± 2.8 |

| Cooler outlet—variant Aoutlet | 1321 ± 18 | 615.1 ± 3.0 |

| Cooler outlet—variant Boutlet | 1345 ± 10 | 610.7 ± 3.2 |

| Cooler outlet—variant Coutlet | 1321 ± 9 | 605.8 ± 3.6 |

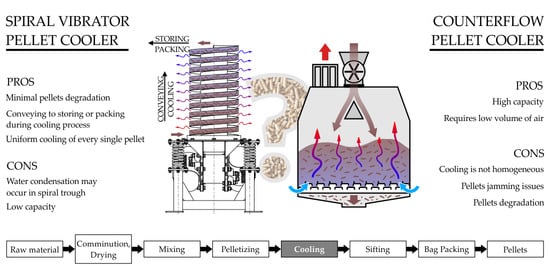

| Cooling Variant | Advantages | Disadvantages |

|---|---|---|

| A | Cooling of every single pellet, low energy consumption, handling coupled with cooling process, no air distribution requirements, easy process setup | A little bit slower cooling process, water condensation may occur in spiral trough |

| B | Cooling of every single pellet, handling coupled with cooling process after pellets production, easy process setup | Noise (extra air flow), high energy consumption, air distribution requirements |

| C | No investment, no air distribution requirements | Very slow cooling process, space requirements, pilot-plant use only |

| Counterflow cooler | High capacity | Inhomogeneous cooling process, noise, pellets jamming, pellets degradation, investment, space requirements, air distribution requirements |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Žurovec, D.; Jezerská, L.; Nečas, J.; Hlosta, J.; Diviš, J.; Zegzulka, J. Spiral Vibration Cooler for Continual Cooling of Biomass Pellets. Processes 2021, 9, 1060. https://doi.org/10.3390/pr9061060

Žurovec D, Jezerská L, Nečas J, Hlosta J, Diviš J, Zegzulka J. Spiral Vibration Cooler for Continual Cooling of Biomass Pellets. Processes. 2021; 9(6):1060. https://doi.org/10.3390/pr9061060

Chicago/Turabian StyleŽurovec, David, Lucie Jezerská, Jan Nečas, Jakub Hlosta, Jan Diviš, and Jiří Zegzulka. 2021. "Spiral Vibration Cooler for Continual Cooling of Biomass Pellets" Processes 9, no. 6: 1060. https://doi.org/10.3390/pr9061060

APA StyleŽurovec, D., Jezerská, L., Nečas, J., Hlosta, J., Diviš, J., & Zegzulka, J. (2021). Spiral Vibration Cooler for Continual Cooling of Biomass Pellets. Processes, 9(6), 1060. https://doi.org/10.3390/pr9061060