Laser Manufacturing of Superwetting Oil–Water Separation Materials: A Review

Abstract

:1. Introduction

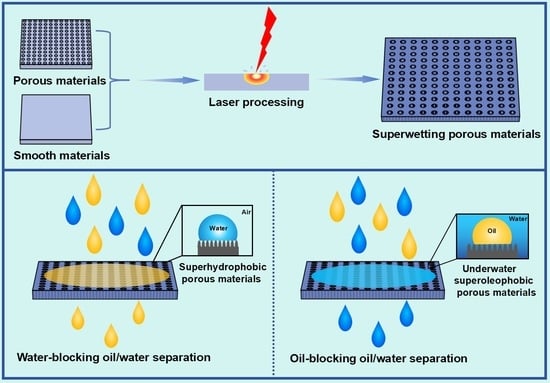

2. Wettability Theory and Design Strategy of Laser-Fabricated Oil–Water Separation Materials

2.1. Basic Wettability Theory

2.2. Wettability Theory of Underwater Oil

2.3. Oil–Water Separation Mechanism of Superwetting Materials

2.4. Design Strategy of Laser-Fabricated Oil–Water Separation Materials

3. Superwetting Porous Materials Fabricated by Ultrafast Laser for Oil–Water Separation

3.1. Superoleophilic and Superhydrophobic Porous Materials

3.2. Superhydrophilic and Superoleophobic Porous Materials

3.3. Superwetting Porous Materials with Reversible or Superamphiphilic Wettability

4. Summary and Outlooks

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Govindarajan, S.K.; Mishra, A.; Kumar, A. Oil spill in a marine environment: Requirements following an offshore oil spill. Rud. Geološko Naft. Zb. 2021, 36, 1–9. [Google Scholar] [CrossRef]

- Ismail, N.H.; Salleh, W.N.W.; Ismail, A.F.; Hasbullah, H.; Yusof, N.; Aziz, F.; Jaafar, J. Hydrophilic Polymer-Based Membrane for Oily Wastewater Treatment: A Review. Sep. Purif. Technol. 2020, 233, 116007. [Google Scholar] [CrossRef]

- Sutrisna, P.D.; Kurnia, K.A.; Siagian, U.W.R.; Ismadji, S.; Wenten, I.G. Membrane Fouling and Fouling Mitigation in Oil–Water Separation: A Review. J. Environ. Chem. Eng. 2022, 10, 107532. [Google Scholar] [CrossRef]

- Chu, Z.; Feng, Y.; Seeger, S. Oil/Water Separation with Selective Superantiwetting/Superwetting Surface Materials. Angew. Chem. Int. Ed. 2015, 54, 2328–2338. [Google Scholar] [CrossRef] [PubMed]

- Cao, X.; Chang, Y.-C. A Two-Dimensional Assessment of China’s Approach Concerning the Compensation Fund for Ship-Induced Oil Pollution Damage: Pollution Governance and Victim Compensation. Front. Mar. Sci. 2022, 9, 817049. [Google Scholar] [CrossRef]

- Aseev, N.A.; Agoshkov, V.I.; Zalesny, V.B.; Aps, R.; Kujala, P.; Rytkönen, J. The Problem of Control of Oil Pollution Risk in the Baltic Sea. Russ. J. Numer. Anal. Math. Model. 2014, 29, 93–105. [Google Scholar] [CrossRef]

- Sauer, T.C.; Brown, J.S.; Boehm, P.D.; Aurand, D.V.; Michel, J.; Hayes, M.O. Hydrocarbon Source Identification and Weathering Characterization of Intertidal and Subtidal Sediments along the Saudi Arabian Coast after the Gulf War Oil Spill. Mar. Pollut. Bull. 1993, 27, 117–134. [Google Scholar] [CrossRef]

- Bruckberger, M.C.; Morgan, M.J.; Bastow, T.P.; Walsh, T.; Prommer, H.; Mukhopadhyay, A.; Kaksonen, A.H.; Davis, G.B.; Puzon, G.J. Investigation into the Microbial Communities and Associated Crude Oil-Contamination along a Gulf War Impacted Groundwater System in Kuwait. Water Res. 2020, 170, 115314. [Google Scholar] [CrossRef] [PubMed]

- Bejarano, A.C.; Michel, J. Large-Scale Risk Assessment of Polycyclic Aromatic Hydrocarbons in Shoreline Sediments from Saudi Arabia: Environmental Legacy after Twelve Years of the Gulf War Oil Spill. Environ. Pollut. 2010, 158, 1561–1569. [Google Scholar] [CrossRef]

- Readman, J.W.; Fowler, S.W.; Villeneuve, J.-P.; Cattini, C.; Oregioni, B.; Mee, L.D. Oil and Combustion-Product Contamination of the Gulf Marine Environment Following the War. Nature 1992, 358, 662–665. [Google Scholar] [CrossRef]

- Michel, J.; Owens, E.H.; Zengel, S.; Graham, A.; Nixon, Z.; Allard, T.; Holton, W.; Reimer, P.D.; Lamarche, A.; White, M.; et al. Extent and Degree of Shoreline Oiling: Deepwater Horizon Oil Spill, Gulf of Mexico, USA. PLoS ONE 2013, 8, e65087. [Google Scholar] [CrossRef]

- Valentine, D.L.; Fisher, G.B.; Bagby, S.C.; Nelson, R.K.; Reddy, C.M.; Sylva, S.P.; Woo, M.A. Fallout Plume of Submerged Oil from Deepwater Horizon. Proc. Natl. Acad. Sci. USA 2014, 111, 15906–15911. [Google Scholar] [CrossRef]

- Kujawinski, E.B.; Kido Soule, M.C.; Valentine, D.L.; Boysen, A.K.; Longnecker, K.; Redmond, M.C. Fate of Dispersants Associated with the Deepwater Horizon Oil Spill. Environ. Sci. Technol. 2011, 45, 1298–1306. [Google Scholar] [CrossRef]

- Reddy, C.M.; Arey, J.S.; Seewald, J.S.; Sylva, S.P.; Lemkau, K.L.; Nelson, R.K.; Carmichael, C.A.; McIntyre, C.P.; Fenwick, J.; Ventura, G.T.; et al. Composition and Fate of Gas and Oil Released to the Water Column during the Deepwater Horizon Oil Spill. Proc. Natl. Acad. Sci. USA 2012, 109, 20229–20234. [Google Scholar] [CrossRef] [PubMed]

- Korshunova, T.Y.; Chetverikov, S.P.; Bakaeva, M.D.; Kuzina, E.V.; Rafikova, G.F.; Chetverikova, D.V.; Loginov, O.N. Microorganisms in the Elimination of Oil Pollution Consequences (Review). Appl. Biochem. Microbiol. 2019, 55, 344–354. [Google Scholar] [CrossRef]

- Dijkstra, A. Integrated Pollution Control in Seed Oil Refining. Fett/Lipid 1999, 101, 132–137. [Google Scholar] [CrossRef]

- Dai, X.; Lv, J.; Fu, P.; Guo, S. Microbial Remediation of Oil-Contaminated Shorelines: A Review. Environ. Sci. Pollut. Res. 2023, 30, 93491–93518. [Google Scholar] [CrossRef] [PubMed]

- Renegar, D.A.; Schuler, P.A.; Knap, A.H.; Dodge, R.E. TRopical Oil Pollution Investigations in Coastal Systems [TROPICS]: A Synopsis of Impacts and Recovery. Mar. Pollut. Bull. 2022, 181, 113880. [Google Scholar] [CrossRef] [PubMed]

- Wolok, E.; Barafi, J.; Joshi, N.; Girimonte, R.; Chakraborty, S. Study of Bio-Materials for Removal of the Oil Spill. Arab. J. Geosci. 2020, 13, 1244. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, W.; Wan, Z.; Li, S.; Huang, T.; Fei, Y. Oil Spills from Global Tankers: Status Review and Future Governance. J. Clean. Prod. 2019, 227, 20–32. [Google Scholar] [CrossRef]

- Frising, T.; Noïk, C.; Dalmazzone, C. The Liquid/Liquid Sedimentation Process: From Droplet Coalescence to Technologically Enhanced Water/Oil Emulsion Gravity Separators: A Review. J. Dispers. Sci. Technol. 2006, 27, 1035–1057. [Google Scholar] [CrossRef]

- Li, B.; Qi, B.; Guo, Z.; Wang, D.; Jiao, T. Recent Developments in the Application of Membrane Separation Technology and Its Challenges in Oil-Water Separation: A Review. Chemosphere 2023, 327, 138528. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Zhao, Z.; Qiao, C.; Yang, W.; Huang, Y.; McKay, P.; Yang, D.; Liu, Q.; Zeng, H. Techniques for Treating Slop Oil in Oil and Gas Industry: A Short Review. Fuel 2020, 279, 118482. [Google Scholar] [CrossRef]

- Borja, R.; Raposo, F.; Rincón, B. Treatment Technologies of Liquid and Solid Wastes from Two-Phase Olive Oil Mills. Grasas y Aceites 2006, 57, 32–46. [Google Scholar] [CrossRef]

- Ge, J.; Zong, D.; Jin, Q.; Yu, J.; Ding, B. Biomimetic and Superwettable Nanofibrous Skins for Highly Efficient Separation of Oil-in-Water Emulsions. Adv. Funct. Mater. 2018, 28, 1705051. [Google Scholar] [CrossRef]

- Chen, C.; Weng, D.; Mahmood, A.; Chen, S.; Wang, J. Separation Mechanism and Construction of Surfaces with Special Wettability for Oil/Water Separation. ACS Appl. Mater. Interfaces 2019, 11, 11006–11027. [Google Scholar] [CrossRef] [PubMed]

- Kang, S.M.; Choi, J.S.; An, J.H. Reliable and Robust Fabrication Rules for Springtail-Inspired Superomniphobic Surfaces. ACS Appl. Mater. Interfaces 2020, 12, 21120–21126. [Google Scholar] [CrossRef]

- Hensel, R.; Finn, A.; Helbig, R.; Braun, H.-G.; Neinhuis, C.; Fischer, W.-J.; Werner, C. Biologically Inspired Omniphobic Surfaces by Reverse Imprint Lithography. Adv. Mater. 2014, 26, 2029–2033. [Google Scholar] [CrossRef]

- Yun, G.-T.; Jung, W.-B.; Oh, M.S.; Jang, G.M.; Baek, J.; Kim, N.I.; Im, S.G.; Jung, H.-T. Springtail-Inspired Superomniphobic Surface with Extreme Pressure Resistance. Sci. Adv. 2018, 4, eaat4978. [Google Scholar] [CrossRef]

- Ensikat, H.J.; Ditsche-Kuru, P.; Neinhuis, C.; Barthlott, W. Superhydrophobicity in Perfection: The Outstanding Properties of the Lotus Leaf. Beilstein J. Nanotechnol. 2011, 2, 152–161. [Google Scholar] [CrossRef]

- Li, X.; Gong, F.; Liu, D.; He, S.; Yuan, H.; Dai, L.; Cai, X.; Liu, J.; Guo, J.; Jin, Y.; et al. A Lotus Leaf Based Random Laser. Org. Electron. 2019, 69, 216–219. [Google Scholar] [CrossRef]

- Barthlott, W.; Schimmel, T.; Wiersch, S.; Koch, K.; Brede, M.; Barczewski, M.; Walheim, S.; Weis, A.; Kaltenmaier, A.; Leder, A.; et al. The Salvinia Paradox: Superhydrophobic Surfaces with Hydrophilic Pins for Air Retention Under Water. Adv. Mater. 2010, 22, 2325–2328. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Yang, J.; Lv, K.; Papadopoulos, P.; Sun, J.; Wang, D.; Zhao, Y.; Chen, L.; Wang, D.; Wang, Z.; et al. Salvinia-like Slippery Surface with Stable and Mobile Water/Air Contact Line. Natl. Sci. Rev. 2021, 8, nwaa153. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Sun, L.; Wang, Y.; Bian, F.; Wang, Y.; Zhao, Y. Multibioinspired Slippery Surfaces with Wettable Bump Arrays for Droplets Pumping. Proc. Natl. Acad. Sci. USA 2019, 116, 20863–20868. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Zhang, P.; Zhang, L.; Liu, H.; Jiang, Y.; Zhang, D.; Han, Z.; Jiang, L. Continuous Directional Water Transport on the Peristome Surface of Nepenthes Alata. Nature 2016, 532, 85–89. [Google Scholar] [CrossRef]

- Zheng, Y.; Bai, H.; Huang, Z.; Tian, X.; Nie, F.-Q.; Zhao, Y.; Zhai, J.; Jiang, L. Directional Water Collection on Wetted Spider Silk. Nature 2010, 463, 640–643. [Google Scholar] [CrossRef] [PubMed]

- Feng, S.; Zhu, P.; Zheng, H.; Zhan, H.; Chen, C.; Li, J.; Wang, L.; Yao, X.; Liu, Y.; Wang, Z. Three-Dimensional Capillary Ratchet-Induced Liquid Directional Steering. Science 2021, 373, 1344–1348. [Google Scholar] [CrossRef] [PubMed]

- Feng, L.; Zhang, Y.; Xi, J.; Zhu, Y.; Wang, N.; Xia, F.; Jiang, L. Petal Effect: A Superhydrophobic State with High Adhesive Force. Langmuir 2008, 24, 4114–4119. [Google Scholar] [CrossRef]

- Liu, M.; Wang, S.; Wei, Z.; Song, Y.; Jiang, L. Bioinspired Design of a Superoleophobic and Low Adhesive Water/Solid Interface. Adv. Mater. 2009, 21, 665–669. [Google Scholar] [CrossRef]

- Nishimoto, S.; Bhushan, B. Bioinspired Self-Cleaning Surfaces with Superhydrophobicity, Superoleophobicity, and Superhydrophilicity. RSC Adv. 2012, 3, 671–690. [Google Scholar] [CrossRef]

- Si, Y.; Dong, Z.; Jiang, L. Bioinspired Designs of Superhydrophobic and Superhydrophilic Materials. ACS Cent. Sci. 2018, 4, 1102–1112. [Google Scholar] [CrossRef]

- Jiang, T.; Guo, Z.; Liu, W. Biomimetic Superoleophobic Surfaces: Focusing on Their Fabrication and Applications. J. Mater. Chem. A 2015, 3, 1811–1827. [Google Scholar] [CrossRef]

- Zhang, S.; Huang, J.; Chen, Z.; Lai, Y. Bioinspired Special Wettability Surfaces: From Fundamental Research to Water Harvesting Applications. Small 2017, 13, 1602992. [Google Scholar] [CrossRef]

- Park, K.-C.; Kim, P.; Grinthal, A.; He, N.; Fox, D.; Weaver, J.C.; Aizenberg, J. Condensation on Slippery Asymmetric Bumps. Nature 2016, 531, 78–82. [Google Scholar] [CrossRef]

- Yong, J.; Yang, Q.; Hou, X.; Chen, F. Emerging Separation Applications of Surface Superwettability. Nanomaterials 2022, 12, 688. [Google Scholar] [CrossRef]

- Bai, X.; Yuan, Z.; Lu, C.; Zhan, H.; Ge, W.; Li, W.; Liu, Y. Recent Advances in Superwetting Materials for Separation of Oil/Water Mixtures. Nanoscale 2023, 15, 5139–5157. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Gong, Q.; Zhan, S.; Jiang, L.; Zheng, Y. Robust Anti-Icing Performance of a Flexible Superhydrophobic Surface. Adv. Mater. 2016, 28, 7729–7735. [Google Scholar] [CrossRef]

- Darmanin, T.; Guittard, F. Superhydrophobic and Superoleophobic Properties in Nature. Mater. Today 2015, 18, 273–285. [Google Scholar] [CrossRef]

- Wang, D.-C.; Yang, X.; Yu, H.-Y.; Gu, J.; Qi, D.; Yao, J.; Ni, Q. Smart Nonwoven Fabric with Reversibly Dual-Stimuli Responsive Wettability for Intelligent Oil-Water Separation and Pollutants Removal. J. Hazard. Mater. 2020, 383, 121123. [Google Scholar] [CrossRef]

- Wang, Y.; Gong, X. Special Oleophobic and Hydrophilic Surfaces: Approaches, Mechanisms, and Applications. J. Mater. Chem. A 2017, 5, 3759–3773. [Google Scholar] [CrossRef]

- Yang, Y.; Guo, Z.; Liu, W. Special Superwetting Materials from Bioinspired to Intelligent Surface for On-Demand Oil/Water Separation: A Comprehensive Review. Small 2022, 18, 2204624. [Google Scholar] [CrossRef] [PubMed]

- Tie, L.; Li, J.; Liu, M.; Guo, Z.; Liang, Y.; Liu, W. Organic Media Superwettability: On-Demand Liquid Separation by Controlling Surface Chemistry. ACS Appl. Mater. Interfaces 2018, 10, 37634–37642. [Google Scholar] [CrossRef]

- Gupta, R.K.; Dunderdale, G.J.; England, M.W.; Hozumi, A. Oil/Water Separation Techniques: A Review of Recent Progresses and Future Directions. J. Mater. Chem. A 2017, 5, 16025–16058. [Google Scholar] [CrossRef]

- Zeng, X.; Yang, K.; Huang, C.; Yang, K.; Xu, S.; Wang, L.; Pi, P.; Wen, X. Novel pH-Responsive Smart Fabric: From Switchable Wettability to Controllable On-Demand Oil/Water Separation. ACS Sustain. Chem. Eng. 2019, 7, 368–376. [Google Scholar] [CrossRef]

- Mao, X.; Wang, Y.; Yan, X.; Huang, Z.; Gao, Z.; Wang, Y.; Huang, L.; Kipper, M.J.; Tang, J. A Review of Superwetting Membranes and Nanofibers for Efficient Oil/Water Separation. J. Mater. Sci. 2023, 58, 3–33. [Google Scholar] [CrossRef]

- Zheng, W.; Huang, J.; Li, S.; Ge, M.; Teng, L.; Chen, Z.; Lai, Y. Advanced Materials with Special Wettability toward Intelligent Oily Wastewater Remediation. ACS Appl. Mater. Interfaces 2021, 13, 67–87. [Google Scholar] [CrossRef]

- Manouchehri, M. A Comprehensive Review on State-of-the-Art Antifouling Super(Wetting and Anti-Wetting) Membranes for Oily Wastewater Treatment. Adv. Colloid Interface Sci. 2024, 323, 103073. [Google Scholar] [CrossRef]

- Yong, J.; Yang, Q.; Guo, C.; Chen, F.; Hou, X. A Review of Femtosecond Laser-Structured Superhydrophobic or Underwater Superoleophobic Porous Surfaces/Materials for Efficient Oil/Water Separation. RSC Adv. 2019, 9, 12470–12495. [Google Scholar] [CrossRef]

- Qiu, L.; Sun, Y.; Guo, Z. Designing Novel Superwetting Surfaces for High-Efficiency Oil–Water Separation: Design Principles, Opportunities, Trends and Challenges. J. Mater. Chem. A 2020, 8, 16831–16853. [Google Scholar] [CrossRef]

- Ma, W.; Samal, S.K.; Liu, Z.; Xiong, R.; De Smedt, S.C.; Bhushan, B.; Zhang, Q.; Huang, C. Dual pH- and Ammonia-Vapor-Responsive Electrospun Nanofibrous Membranes for Oil-Water Separations. J. Membr. Sci. 2017, 537, 128–139. [Google Scholar] [CrossRef]

- Yong, J.; Chen, F.; Yang, Q.; Jiang, Z.; Hou, X. A Review of Femtosecond-Laser-Induced Underwater Superoleophobic Surfaces. Adv. Mater. Interfaces 2018, 5, 1701370. [Google Scholar] [CrossRef]

- Su, B.; Tian, Y.; Jiang, L. Bioinspired Interfaces with Superwettability: From Materials to Chemistry. J. Am. Chem. Soc. 2016, 138, 1727–1748. [Google Scholar] [CrossRef] [PubMed]

- Yong, J.; Chen, F.; Yang, Q.; Huo, J.; Hou, X. Superoleophobic Surfaces. Chem. Soc. Rev. 2017, 46, 4168–4217. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Huang, L.; Wang, D.; Zhou, S.; Sun, X.; Zhao, R.; Wang, G.; Yao, T.; Zhao, K.; Chen, R. A Review of 3D Superhydrophilic Porous Materials for Oil/Water Separation. Sep. Purif. Technol. 2023, 326, 124847. [Google Scholar] [CrossRef]

- Jung, Y.C.; Bhushan, B. Wetting Behavior of Water and Oil Droplets in Three-Phase Interfaces for Hydrophobicity/Philicity and Oleophobicity/Philicity. Langmuir 2009, 25, 14165–14173. [Google Scholar] [CrossRef] [PubMed]

- Wenzel, R.N. Resistance of solid surfaces to wetting by water. Ind. Eng. Chem. 1936, 28, 988–994. [Google Scholar] [CrossRef]

- Cassie, A.B.D.; Baxter, S. Large Contact Angles of Plant and Animal Surfaces. Nature 1945, 155, 21–22. [Google Scholar] [CrossRef]

- Yong, J.; Chen, F.; Yang, Q.; Zhang, D.; Farooq, U.; Du, G.; Hou, X. Bioinspired Underwater Superoleophobic Surface with Ultralow Oil-Adhesion Achieved by Femtosecond Laser Microfabrication. J. Mater. Chem. A 2014, 2, 8790–8795. [Google Scholar] [CrossRef]

- Cassie, A.B.D.; Baxter, S. Wettability of Porous Surfaces. Trans. Faraday Soc. 1944, 40, 546–551. [Google Scholar] [CrossRef]

- Gao, H.; Liu, Y.; Wang, G.; Li, S.; Han, Z.; Ren, L. Switchable Wettability Surface with Chemical Stability and Antifouling Properties for Controllable Oil–Water Separation. Langmuir 2019, 35, 4498–4508. [Google Scholar] [CrossRef]

- Popmintchev, T.; Chen, M.-C.; Popmintchev, D.; Arpin, P.; Brown, S.; Ališauskas, S.; Andriukaitis, G.; Balčiunas, T.; Mücke, O.D.; Pugzlys, A.; et al. Bright Coherent Ultrahigh Harmonics in the keV X-Ray Regime from Mid-Infrared Femtosecond Lasers. Science 2012, 336, 1287–1291. [Google Scholar] [CrossRef] [PubMed]

- Vorobyev, A.Y.; Guo, C. Direct Femtosecond Laser Surface Nano/Microstructuring and Its Applications. Laser Photonics Rev. 2013, 7, 385–407. [Google Scholar] [CrossRef]

- Bonse, J.; Krüger, J.; Höhm, S.; Rosenfeld, A. Femtosecond Laser-Induced Periodic Surface Structures. J. Laser Appl. 2012, 24, 042006. [Google Scholar] [CrossRef]

- Chapman, H.N.; Spence, J.C.H. Femtosecond X-ray Protein Nanocrystallography. Acta Crystallogr. A 2010, 66, 9. [Google Scholar] [CrossRef]

- Sugioka, K.; Cheng, Y. Ultrafast Lasers—Reliable Tools for Advanced Materials Processing. Light Sci. Appl. 2014, 3, e149. [Google Scholar] [CrossRef]

- Anisimov, S.I.; Luk’yanchuk, B.S. Selected Problems of Laser Ablation Theory. Phys. Uspekhi 2002, 45, 293–324. [Google Scholar] [CrossRef]

- Inogamov, N.A.; Zhakhovskii, V.V.; Ashitkov, S.I.; Petrov, Y.V.; Agranat, M.B.; Anisimov, S.I.; Nishihara, K.; Fortov, V.E. Nanospallation Induced by an Ultrashort Laser Pulse. J. Exp. Theor. Phys. 2008, 107, 1. [Google Scholar] [CrossRef]

- Zhigilei, L.V. Dynamics of the Plume Formation and Parameters of the Ejected Clusters in Short-Pulse Laser Ablation. Appl. Phys. A 2003, 76, 339–350. [Google Scholar] [CrossRef]

- Bulgakova, N.M.; Bourakov, I.M. Phase Explosion under Ultrashort Pulsed Laser Ablation: Modeling with Analysis of Metastable State of Melt. Appl. Surf. Sci. 2002, 197–198, 41–44. [Google Scholar] [CrossRef]

- Leveugle, E.; Ivanov, D.S.; Zhigilei, L.V. Photomechanical Spallation of Molecular and Metal Targets: Molecular Dynamics Study. Appl. Phys. A 2004, 79, 1643–1655. [Google Scholar] [CrossRef]

- Perez, D.; Lewis, L.J. Ablation of Solids under Femtosecond Laser Pulses. Phys. Rev. Lett. 2002, 89, 255504. [Google Scholar] [CrossRef] [PubMed]

- Malinauskas, M.; Žukauskas, A.; Hasegawa, S.; Hayasaki, Y.; Mizeikis, V.; Buividas, R.; Juodkazis, S. Ultrafast Laser Processing of Materials: From Science to Industry. Light Sci. Appl. 2016, 5, e16133. [Google Scholar] [CrossRef] [PubMed]

- Yan, H.; Abdul Rashid, M.R.B.; Khew, S.Y.; Li, F.; Hong, M. Wettability Transition of Laser Textured Brass Surfaces inside Different Mediums. Appl. Surf. Sci. 2018, 427, 369–375. [Google Scholar] [CrossRef]

- Trdan, U.; Hočevar, M.; Gregorčič, P. Transition from Superhydrophilic to Superhydrophobic State of Laser Textured Stainless Steel Surface and Its Effect on Corrosion Resistance. Corros. Sci. 2017, 123, 21–26. [Google Scholar] [CrossRef]

- Bai, X.; Yang, Q.; Fang, Y.; Zhang, J.; Yong, J.; Hou, X.; Chen, F. Superhydrophobicity-Memory Surfaces Prepared by a Femtosecond Laser. Chem. Eng. J. 2020, 383, 123143. [Google Scholar] [CrossRef]

- Li, J.; Zhou, Y.; Wang, W.; Xu, C.; Ren, L. Superhydrophobic Copper Surface Textured by Laser for Delayed Icing Phenomenon. Langmuir 2020, 36, 1075–1082. [Google Scholar] [CrossRef]

- Samanta, A.; Wang, Q.; Shaw, S.K.; Ding, H. Roles of Chemistry Modification for Laser Textured Metal Alloys to Achieve Extreme Surface Wetting Behaviors. Mater. Des. 2020, 192, 108744. [Google Scholar] [CrossRef]

- Yong, J.; Chen, F.; Li, M.; Yang, Q.; Fang, Y.; Huo, J.; Hou, X. Remarkably Simple Achievement of Superhydrophobicity, Superhydrophilicity, Underwater Superoleophobicity, Underwater Superoleophilicity, Underwater Superaerophobicity, and Underwater Superaerophilicity on Femtosecond Laser Ablated PDMS Surfaces. J. Mater. Chem. A 2017, 5, 25249–25257. [Google Scholar] [CrossRef]

- Yang, Z.; Tian, Y.L.; Yang, C.J.; Wang, F.J.; Liu, X.P. Modification of Wetting Property of Inconel 718 Surface by Nanosecond Laser Texturing. Appl. Surf. Sci. 2017, 414, 313–324. [Google Scholar] [CrossRef]

- Bonse, J.; Gräf, S. Maxwell Meets Marangoni—A Review of Theories on Laser-Induced Periodic Surface Structures. Laser Photonics Rev. 2020, 14, 2000215. [Google Scholar] [CrossRef]

- Ngo, C.-V.; Chun, D.-M. Fast Wettability Transition from Hydrophilic to Superhydrophobic Laser-Textured Stainless Steel Surfaces under Low-Temperature Annealing. Appl. Surf. Sci. 2017, 409, 232–240. [Google Scholar] [CrossRef]

- Ma, Q.; Tong, Z.; Wang, W.; Dong, G. Fabricating Robust and Repairable Superhydrophobic Surface on Carbon Steel by Nanosecond Laser Texturing for Corrosion Protection. Appl. Surf. Sci. 2018, 455, 748–757. [Google Scholar] [CrossRef]

- Sun, K.; Yang, H.; Xue, W.; He, A.; Zhu, D.; Liu, W.; Adeyemi, K.; Cao, Y. Anti-Biofouling Superhydrophobic Surface Fabricated by Picosecond Laser Texturing of Stainless Steel. Appl. Surf. Sci. 2018, 436, 263–267. [Google Scholar] [CrossRef]

- Zhan, Y.L.; Ruan, M.; Li, W.; Li, H.; Hu, L.Y.; Ma, F.M.; Yu, Z.L.; Feng, W. Fabrication of Anisotropic PTFE Superhydrophobic Surfaces Using Laser Microprocessing and Their Self-Cleaning and Anti-Icing Behavior. Colloids Surf. Physicochem. Eng. Asp. 2017, 535, 8–15. [Google Scholar] [CrossRef]

- Fang, Y.; Yong, J.; Chen, F.; Huo, J.; Yang, Q.; Zhang, J.; Hou, X. Bioinspired Fabrication of Bi/Tridirectionally Anisotropic Sliding Superhydrophobic PDMS Surfaces by Femtosecond Laser. Adv. Mater. Interfaces 2018, 5, 1701245. [Google Scholar] [CrossRef]

- Song, Y.; Wang, C.; Dong, X.; Yin, K.; Zhang, F.; Xie, Z.; Chu, D.; Duan, J. Controllable Superhydrophobic Aluminum Surfaces with Tunable Adhesion Fabricated by Femtosecond Laser. Opt. Laser Technol. 2018, 102, 25–31. [Google Scholar] [CrossRef]

- Yang, Z.; Liu, X.; Tian, Y. Insights into the Wettability Transition of Nanosecond Laser Ablated Surface under Ambient Air Exposure. J. Colloid Interface Sci. 2019, 533, 268–277. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Liu, B.; Luo, Z.; Ding, K.; Duan, J. Fabrication of Microholes Array on Titanium Foil by a Femtosecond Laser and a Surface’s Wettability Switching. Chin. Opt. Lett. 2021, 19, 082201. [Google Scholar] [CrossRef]

- Weber, F.R.; Kunz, C.; Gräf, S.; Rettenmayr, M.; Müller, F.A. Wettability Analysis of Water on Metal/Semiconductor Phases Selectively Structured with Femtosecond Laser-Induced Periodic Surface Structures. Langmuir 2019, 35, 14990–14998. [Google Scholar] [CrossRef] [PubMed]

- Wood, M.J.; Servio, P.; Kietzig, A.-M. The Tuning of LIPSS Wettability during Laser Machining and through Post-Processing. Nanomaterials 2021, 11, 973. [Google Scholar] [CrossRef]

- Chen, L.; Minakawa, A.; Mizutani, M.; Kuriyagawa, T. Study of Laser-Induced Periodic Surface Structures on Different Coatings Exhibit Super Hydrophilicity and Reduce Friction. Precis. Eng. 2022, 78, 215–232. [Google Scholar] [CrossRef]

- Xing, Y.; Wu, Z.; Yang, J.; Wang, X.; Liu, L. LIPSS Combined with ALD MoS2 Nano-Coatings for Enhancing Surface Friction and Hydrophobic Performances. Surf. Coat. Technol. 2020, 385, 125396. [Google Scholar] [CrossRef]

- Gnilitskyi, I.; Alnusirat, W.; Sorgato, M.; Orazi, L.; Lucchetta, G. Effects of Anisotropic and Isotropic LIPSS on Polymer Filling Flow and Wettability of Micro Injection Molded Parts. Opt. Laser Technol. 2023, 158, 108795. [Google Scholar] [CrossRef]

- Gaudiuso, C.; Fanelli, F.; Mezzapesa, F.P.; Volpe, A.; Ancona, A. Tailoring the Wettability of Surface-Textured Copper Using Sub-THz Bursts of Femtosecond Laser Pulses. Appl. Surf. Sci. 2023, 638, 158032. [Google Scholar] [CrossRef]

- Martínez-Calderon, M.; Rodríguez, A.; Dias-Ponte, A.; Morant-Miñana, M.C.; Gómez-Aranzadi, M.; Olaizola, S.M. Femtosecond Laser Fabrication of Highly Hydrophobic Stainless Steel Surface with Hierarchical Structures Fabricated by Combining Ordered Microstructures and LIPSS. Appl. Surf. Sci. 2016, 374, 81–89. [Google Scholar] [CrossRef]

- Khan, S.A.; Ialyshev, V.; Kim, V.V.; Iqbal, M.; Al Harmi, H.; Boltaev, G.S.; Ganeev, R.A.; Alnaser, A.S. Expedited Transition in the Wettability Response of Metal Meshes Structured by Femtosecond Laser Pulses for Oil-Water Separation. Front. Chem. 2020, 8, 768. [Google Scholar] [CrossRef] [PubMed]

- Dong, Z.; Sun, X.; Kong, D.; Chu, D.; Hu, Y.; Duan, J.-A. Spatial Light Modulated Femtosecond Laser Ablated Durable Superhydrophobic Copper Mesh for Oil-Water Separation and Self-Cleaning. Surf. Coat. Technol. 2020, 402, 126254. [Google Scholar] [CrossRef]

- Yong, J.; Fang, Y.; Chen, F.; Huo, J.; Yang, Q.; Bian, H.; Du, G.; Hou, X. Femtosecond Laser Ablated Durable Superhydrophobic PTFE Films with Micro-through-Holes for Oil/Water Separation: Separating Oil from Water and Corrosive Solutions. Appl. Surf. Sci. 2016, 389, 1148–1155. [Google Scholar] [CrossRef]

- Bakhtiari, N.; Azizian, S.; Mohazzab, B.F.; Jaleh, B. One-Step Fabrication of Brass Filter with Reversible Wettability by Nanosecond Fiber Laser Ablation for Highly Efficient Oil/Water Separation. Sep. Purif. Technol. 2021, 259, 118139. [Google Scholar] [CrossRef]

- Qin, Z.; Xiang, H.; Liu, J.; Zeng, X. High-Performance Oil-Water Separation Polytetrafluoroethylene Membranes Prepared by Picosecond Laser Direct Ablation and Drilling. Mater. Des. 2019, 184, 108200. [Google Scholar] [CrossRef]

- Ma, Z.; Lu, M.; Wang, W.; Hong, Z.; Chen, Z.; Zhang, W.; Pan, S.; Shui, L.; Zhang, C. Sucrose Solution Assisted Femtosecond Laser Ablation of Aluminum Film to Induce Nanospikes for Efficient and Stable Oil-Water Separation. Surf. Coat. Technol. 2021, 417, 127182. [Google Scholar] [CrossRef]

- Ettel, D.; Havelka, O.; Isik, S.; Silvestri, D.; Wacławek, S.; Urbánek, M.; Padil, V.V.T.; Černík, M.; Yalcinkaya, F.; Torres-Mendieta, R. Laser-Synthesized Ag/TiO Nanoparticles to Integrate Catalytic Pollutant Degradation and Antifouling Enhancement in Nanofibrous Membranes for Oil–Water Separation. Appl. Surf. Sci. 2021, 564, 150471. [Google Scholar] [CrossRef]

- Yu, P.; Lian, Z.; Xu, J.; Yu, Z.; Ren, W.; Yu, H. Fabrication of Superhydrophilic and Underwater Superoleophobic Metal Mesh by Laser Treatment and Its Application. Mater. Res. Express 2018, 5, 045013. [Google Scholar] [CrossRef]

- Ahlawat, S.; Singh, A.; Mukhopadhyay, P.K.; Singh, R.; Bindra, K.S. Nanosecond Laser Induced Glass Particle Deposition over Steel Mesh for Long-Term Superhydrophilicity and Gravity Driven Oil Water Separation. Mater. Chem. Phys. 2021, 263, 124343. [Google Scholar] [CrossRef]

- Li, B.; Lian, Z.; Yu, H.; Xu, J.; Shi, G.; Yu, Z.; Wang, Z. Underwater Superoleophobic Stainless Steel Mesh Fabricated by Laser Cladding a Copper Foil for Oil–Water Separation. Mater. Res. Express 2018, 5, 075014. [Google Scholar] [CrossRef]

- Li, G.; Fan, H.; Ren, F.; Zhou, C.; Zhang, Z.; Xu, B.; Wu, S.; Hu, Y.; Zhu, W.; Li, J.; et al. Multifunctional Ultrathin Aluminum Foil: Oil/Water Separation and Particle Filtration. J. Mater. Chem. A 2016, 4, 18832–18840. [Google Scholar] [CrossRef]

- Yong, J.; Yang, Q.; Hou, X.; Chen, F. Endowing Metal Surfaces with Underwater Superoleophobicity by Femtosecond Laser Processing for Oil-Water Separation Application. Front. Phys. 2020, 8, 305. [Google Scholar] [CrossRef]

- Yu, H.; Lian, Z.; Xu, J.; Wan, Y.; Wang, Z.; Li, Y.; Yu, Z.; Weng, Z. Mechanically Durable Underwater Superoleophobic Surfaces Based on Hydrophilic Bulk Metals for Oil/Water Separation. Appl. Surf. Sci. 2018, 437, 400–409. [Google Scholar] [CrossRef]

- Khew, S.Y.; Tan, C.F.; Yan, H.; Lin, S.; Thian, E.S.; Zhou, R.; Hong, M. Nanosecond Laser Ablation for Enhanced Adhesion of CuO Nanowires on Copper Substrate and Its Application for Oil-Water Separation. Appl. Surf. Sci. 2019, 465, 995–1002. [Google Scholar] [CrossRef]

- Xia, L.; Chen, F.; Chao, J.; Zhang, D.; Tian, Y.; Zhang, D. Femtosecond Laser Engineered Eggshell Membrane for Durable Oil/Water Separation under Harsh Conditions. J. Membr. Sci. 2023, 668, 121242. [Google Scholar] [CrossRef]

- Wang, J.; Xu, J.; Chen, G.; Lian, Z.; Yu, H. Reversible Wettability between Underwater Superoleophobicity and Superhydrophobicity of Stainless Steel Mesh for Efficient Oil–Water Separation. ACS Omega 2021, 6, 77–84. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Gu, X.; Yuan, Z.; Li, Y.; Wang, B.; Yan, J.; Zhao, D.; Liu, J.; Liu, X. PDMS Mesh with Reversible Super-Wettability for Oil/Water Separation. Colloids Surf. Physicochem. Eng. Asp. 2022, 641, 128462. [Google Scholar] [CrossRef]

- Wang, J.; Xu, J.; Lian, Z.; Wang, J.; Chen, G.; Li, Y.; Yu, H. Facile and Green Fabrication of Robust Microstructured Stainless Steel Mesh for Efficient Oil/Water Separation via Waterjet-Assisted Laser Ablation. Colloids Surf. Physicochem. Eng. Asp. 2022, 643, 128703. [Google Scholar] [CrossRef]

- Lian, Z.; Xu, J.; Wang, Z.; Yu, Z.; Weng, Z.; Yu, H. Nanosecond Laser-Induced Underwater Superoleophobic and Underoil Superhydrophobic Mesh for Oil/Water Separation. Langmuir 2018, 34, 2981–2988. [Google Scholar] [CrossRef] [PubMed]

- Zhou, R.; Lin, S.; Shen, F.; Khew, S.Y.; Hong, M. A Universal Copper Mesh with On-Demand Wettability Fabricated by Pulsed Laser Ablation for Oil/Water Separation. Surf. Coat. Technol. 2018, 348, 73–80. [Google Scholar] [CrossRef]

- Liu, Y.-Q.; Han, D.-D.; Jiao, Z.-Z.; Liu, Y.; Jiang, H.-B.; Wu, X.-H.; Ding, H.; Zhang, Y.-L.; Sun, H.-B. Laser-Structured Janus Wire Mesh for Efficient Oil–Water Separation. Nanoscale 2017, 9, 17933–17938. [Google Scholar] [CrossRef]

| Fabrication Methods | Manufacturing Materials | Laser Pulse Duration | Frequency | Energy per Pulse/Laser Power | Scanning Speed (mm/s) | Chemical Modification | Types of Oil | Separation Efficiency (%) | Oil Flux (OF, Lm−2h−1) | Characteristics | Refs. |

|---|---|---|---|---|---|---|---|---|---|---|---|

| UL processing | Stainless-steel mesh, copper mesh | 36 fs | 50 kHz | 0.1 mJ 5.0 W | 100~1200 100, 300 | - | n-Hexane | >98 | 50 | Environmentally friendly, chemical free, highly efficient | [106] |

| UL processing | Copper mesh, PTFE | 120 fs | 1 kHz | - | 0.05 | - | Edible oil | ~98.3 | ~46 | Fast, efficient, self-cleaning ability | [107] |

| Glycerol | ~97.9 | ~25 | |||||||||

| Diesel | ~95.8 | ~20 | |||||||||

| UL processing, mechanical drilling | PTFE | 50 fs | 1 kHz | 20 mW | 5 | - | Petroleum ether | - | 132,840 | Simple, durable, stable | [108] |

| UL processing | Brass sheet | 100 ns | 20 kHz | 0.9 mJ 18 W | 500 | - | Gasoline | ~85 | 2880 | Facile, economical, environmentally friendly | [109] |

| Diesel fuel | ~75 | 2160 | |||||||||

| n-Heptane | ~90 | 3240 | |||||||||

| n-Hexane | ~85 | 2880 | |||||||||

| n-Decane | ~82 | 2520 | |||||||||

| Kerosene | ~90 | 3240 | |||||||||

| UL processing | PTFE | - | 200 kHz | 4.0 W 20.0 W | 1500 150 | - | Chloroform | ~99.5 | ~129,960 | Facile, rapid, excellent stability and applicability | [110] |

| Hexadecane | ~99.4 | ||||||||||

| Silicon oil | ~99.2 | ||||||||||

| Petroleum ether | ~99.3 | ||||||||||

| Gasoline | ~99.5 | ||||||||||

| Soybean oil | ~99.3 | ||||||||||

| Sucrose solution assisted UL | Al film | 100 fs | 1 kHz | 280 µJ 4~16 µJ | 0.2 1 | PDMS | Dichloroethane | >99.61 | 19,008 | Highly efficient, recyclable, strongly environmental stability | [111] |

| Needleless electrospinning, reactive laser ablation in liquids | PVDF, PET, Ti foil, AgNO3 | 400 fs | 1 MHz | 1.5 µJ 150 mW | 2000 | KOH | Kitchen oil | 97.9 | - | Emulsion separation, eco-friendly | [112] |

| n-Hexane | 92.3 |

| Fabrication Methods | Manufacturing Materials | Laser Pulse Duration | Frequency | Energy per Pulse/Laser Power | Scanning Speed (mm/s) | Types of Oil | Separation Efficiency (%) | Water Flux (WF, Lm−2h−1) | Characteristics | Refs. |

|---|---|---|---|---|---|---|---|---|---|---|

| UL processing | Stainless-steel mesh | 100 ns | 50 kHz | 12 W | 500 | Kerosene | ~97.7 | >63,000 | Simple, economical, high efficiency | [113] |

| Peanut oil | ~97.3 | |||||||||

| UL processing | Stainless-steel mesh, soda lime glass | 200 ns | 18 kHz | 1~2.5 W | 5 | Mustard oil | ~97.5 | ~145,000 | Simple, high efficiency, stable | [114] |

| Kerosene | ~97 | |||||||||

| Petrol | ~97.1 | |||||||||

| UL processing | Stainless-steel mesh, Cu foil | 100 ns | 20 kHz | 10 W | 500 | Kerosene | ~98.5 | ~118,800 | Fast, efficient, self-cleaning | [115] |

| Soybean oil | ~96.8 | |||||||||

| Hexadecane | ~97.5 | |||||||||

| Dodecane | ~97.3 | |||||||||

| Silicone oil | ~96.6 | |||||||||

| UL processing | Al foil | 104 fs | 1 kHz | 50 µJ | - | 1,2-Dichloroethane | 99 | 77,000 | High speed, efficient | [116] |

| Normal octane | ||||||||||

| UL processing, mechanical drilling | Iron sheet | 50 fs | 1 kHz | 30 mW | 6 | 1,2-Dichloroethane | >97.8 | - | Widely applicable | [117] |

| UL processing | Al alloy, Ti alloy, stainless steel | 100 ns | 20 kHz | 14 W | 500 | Kerosene | ~97.8 | - | Large area, durable | [118] |

| Soybean oil | ~97.5 | |||||||||

| UL processing | Cu foil | 5 ns | 90 kHz | - | 5 | Sesame oil | ~98 | ~16,000 | Simple, efficient, scalable | [119] |

| Hexane | ||||||||||

| Toluene | ||||||||||

| UL processing | Eggshell membrane | - | 25 kHz | 0.193 W 1.32 W | 800 | Peanut oil | ~98.7 | ~12,500 | Green, anti-corrosion, robust, self-cleaning | [120] |

| Toluene | ~99.2 | ~16,500 | ||||||||

| Petroleum ether | ~98.7 | ~22,500 | ||||||||

| Paraffin oil | ~98.6 | ~11,000 |

| Fabrication Methods | Manufacturing Materials | Laser Pulse Duration | Frequency | Energy per Pulse/Laser Power | Scanning Speed (mm/s) | Wettability Transformation Methods | Types of Oil | Separation Efficiency (%) | Oil–Water Flux (Lm−2h−1) | Characteristics | Refs. |

|---|---|---|---|---|---|---|---|---|---|---|---|

| UL processing | Stainless-steel mesh | 100 ns | - | 12 W | 500 | Ethanol soaking, natural drying | Kerosene | ~96 | WF ≈ 102,600 | Facile, economical, environmentally friendly | [121] |

| Lubricating oil | ~96.7 | ||||||||||

| Dichloromethane | ~97 | ||||||||||

| Dichloroethane | ~96.3 | ||||||||||

| UL processing | PDMS, curing agent, Al sheets | - | - | 6 W | 800 | APPJ treatment, heating treatment | Dichloromethane | ~96 | OF ≈ 15,000 WF ≈ 18,000 | Environmentally friendly, low cost, high efficiency | [122] |

| Peanut oil | ~97.5 | ||||||||||

| Diesel | ~99 | ||||||||||

| Hexadecane | ~97.3 | ||||||||||

| Lubricating oil | ~98 | ||||||||||

| Waterjet-assisted laser ablation, UL processing | Stainless-steel mesh | 100 ns | - | 18 W | 200 | - | Kerosene | ~97.6 | - | Simple, environmentally friendly, excellent mechanical property | [123] |

| Soybean oil | ~96.9 | ||||||||||

| n-Heptane | ~98.3 | ||||||||||

| Dichloromethane | ~97.5 | ||||||||||

| 1,2-Dichloroethane | ~97.5 | ||||||||||

| UL processing | Brass mesh | 100 ns | 20 kHz | 10 W | 500 | - | Kerosene | ~98.5 | WF > 134,280 OF > 76,680 | Simple, high efficiency, stable | [124] |

| Soybean oil | ~96.4 | ||||||||||

| Dodecane | ~97 | ||||||||||

| 1,2-Dichloroethane | ~96.3 | ||||||||||

| Chloroform | ~98 | ||||||||||

| UL processing | Copper sheet | 100 ns | - | 24 W | 1000 | - | Kerosene | >98 | WF > 32,000 OF > 37,500 | Superior environmental stability | [125] |

| Isooctane | |||||||||||

| Heptane | |||||||||||

| 1,2-Dichloroethane | |||||||||||

| Dichloromethane | |||||||||||

| UL processing, chemical modification | Cu wire mesh, fluorosilane, GO | - | - | 100 mW | 2 | - | Bean oil | - | - | Asymmetric wettability | [126] |

| n-Heptane | |||||||||||

| Methylbenzene | |||||||||||

| Perchlormethane | |||||||||||

| Trichloromethane |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiong, W.; Zhu, L.; Jiang, R.; Chen, C. Laser Manufacturing of Superwetting Oil–Water Separation Materials: A Review. Separations 2024, 11, 126. https://doi.org/10.3390/separations11040126

Xiong W, Zhu L, Jiang R, Chen C. Laser Manufacturing of Superwetting Oil–Water Separation Materials: A Review. Separations. 2024; 11(4):126. https://doi.org/10.3390/separations11040126

Chicago/Turabian StyleXiong, Wei, Linfeng Zhu, Ruisong Jiang, and Chaolang Chen. 2024. "Laser Manufacturing of Superwetting Oil–Water Separation Materials: A Review" Separations 11, no. 4: 126. https://doi.org/10.3390/separations11040126

APA StyleXiong, W., Zhu, L., Jiang, R., & Chen, C. (2024). Laser Manufacturing of Superwetting Oil–Water Separation Materials: A Review. Separations, 11(4), 126. https://doi.org/10.3390/separations11040126