1. Introduction

The utilization of renewable energy sources, such as wind, solar, and tidal energies, is expected to alleviate the environmental pollution resulted from the combustion of fossil fuels. Due to the seasonal and regional factors, the storage of these energies with high efficiency, therefore, is of great significance to the wide application of these renewable energy sources. Among various energy storage systems, lithium ion batteries, due to their high energy density, are dominant in the markets of portable electronic devices and electric automobiles [

1,

2]. The safety issue and high cost of lithium ion batteries have driven us to search for alternative energy storage devices (ESDs) with comparable performance, but with a higher safety and lower cost. Aqueous ESDs, such as supercapacitor and nickel/metal hydride batteries, have been extensively investigated due to their excellent power densities and long lifespans. Unfortunately, the further application of these aqueous ESDs is restricted by the low energy density. Recently, aqueous zinc ion batteries (AZIBs) have drawn an exceptional amount of attention due to their environmental friendliness, high theoretical capacity of the Zn anode (820 mAh g

−1), and their abundancy in the Earth’s crust [

3,

4]. However, the application of AZIBs is restricted by the unsatisfying electrochemical performance of cathode materials. Currently, Mn- and V-based oxides are the most investigated cathode materials for AZIBs [

5,

6]. In addition to the low redox potential of V-based oxides, along with the dissolution problem of Mn-based oxides, their performance is also affected by the strong interaction between zinc ions and the crystal structure of oxides [

7]. Therefore, seeking new cathode materials is still of great significance to develop AZIBs with high energy densities and long lifespans.

Layered double hydroxides (LDHs), with tunable chemical compositions and 2D pore structures, exhibit excellent pseudocapacitive activities in battery/supercapacitor hybrid ESDs [

8,

9,

10]. Facilitated via the H

+ intercalation/deintercalation mechanism and the structural similarity, cobalt hydroxide (Co(OH)

2) has demonstrated an extraordinary performance in supercapacitors [

11]. Its atoms are very exposed on the surface of its unique 2D morphology, and the large interlayer spacings facilitates the charge transfer between the electrolyte and the active material. However, the interlayer spacings of Co(OH)

2 are usually occupied by the anion residues (

,

, organic anions, etc.) from the preparation to neutralize the positive charge of the Co-O layers [

12]. As a result, Zn ion storage is prohibited by either the interlayer species or the electrostatic repulsion from the positively charged Co-O layers. Our previous study has proven that the excellent pseudocapacitive behavior originates from the rapid transformation between Co(OH)

2 and CoOOH based on their structural similarity [

11]. Compared to Co(OH)

2, CoOOH not only preserves the morphology of Co(OH)

2, but also shows a higher level of thermal stability than Co(OH)

2, since each H atom is shared by two adjacent Co-O layers, and the positive charges are subsequently reduced, which presents CoOOH as a promising cathode material for AZIBs. Nevertheless, it remains uncertain to fabricate a high-performance CoOOH cathode for AZIBs, since no relevant study has been reported.

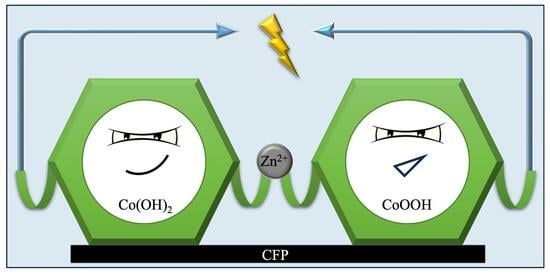

Herein, a mixed phase of Co(OH)2/CoOOH was synthesized via a two-step electrochemical preparation. As an AZIB cathode material, Co(OH)2/CoOOH showed a high average potential of 1.7 V vs. Zn2+/Zn, which is higher than most of the reported cathode materials for AZIBs. Correspondingly, the mixed phase of Co(OH)2/CoOOH can deliver a maximum capacity of 164 mAh g−1 at 0.05 A g−1 in 1 M ZnSO4 electrolyte. The Co(OH)2/CoOOH cathode also exhibited an excellent rate performance; a high capacity of 87 mAh g−1 was obtained at 1.6 A g−1. X-ray adsorption spectroscopy (XAS), along with theoretical simulations, indicated the high crystallinity and thermal stability of the mixed phase. The even distribution of CoOOH in the mixed phase suppresses the structure’s degradation. The reduced Co-Co and Co-O shells increased the mechanical strength of the mixed phase to accommodate Zn2+ ions and endure the electrostatic repulsion, resulting in an enhanced cycling stability. The mixed phase of Co(OH)2/CoOOH showed a stable cycle life of 200 cycles at 0.05 A g−1, with a capacity retention of 78%. The excellent performance of Co(OH)2/CoOOH has demonstrated the promising future of LDHs as cathode materials for AZIBs.

2. Results

The mixed phase of Co(OH)

2/CoOOH was synthesized via a two-step electrochemical preparation, as illustrated in

Figure 1A. Firstly, Co(OH)

2 was electrodeposited on the carbon fiber paper (CFP) as the substrate in a three-electrode system, in which a CFP, a platinum plate, a saturated calomel electrode, and a 1 M Co(NO

3)

2 solution served as the working electrode, counter electrode, reference electrode, and electrolyte, respectively. As the supercapacitor electrode, Co(OH)

2 loses one H atom and is then oxidized to CoOOH to store charges in alkaline media. Accordingly, the as-prepared Co(OH)

2 electrode was placed into a 1 M KOH solution for a cyclic voltammetry (CV) treatment to prepare the mixed phase of Co(OH)

2/CoOOH. The CV potential was set in the range of −0.1~0.45 V. To acquire the structural information, X-ray diffraction (XRD) was conducted on each step of the preparation.

Figure 1B depicts the XRD patterns of the CFP after the electrodeposition, alkaline media contact, and the CV treatment, in which α, β, and C stand for α-Co(OH)

2, β-Co(OH)

2, and CoOOH, respectively. Two peaks were observed at 33° and 59°, which can be indexed to the (100) and (110) planes of α-Co(OH)

2 (PDF card No.460605). Compared to the pure CFP (

Figure S1), the feature peak of the carbon materials (002) at 26° was far more reduced, indicating the well coating of α-Co(OH)

2 on the CFP. The α-Co(OH)

2 is known for its large interlayer spacing due to either anion or molecule insertion from the electrolyte. Our previous work has manifested that the electrochemically deposited α-Co(OH)

2 was unstable, which could easily transform into β-Co(OH)

2 in alkaline media by removing the

species from the structure. The same phenomenon was also observed in this work. After being soaked in a 1 M KOH solution, the (001), (100), (101), (102), (110), and (111) planes of β-Co(OH)

2, with a high level of crystallinity, were detected in the red line (PDF card No.300443), while no signs of α-Co(OH)

2 were detected in the XRD patterns, indicating the transformation from α-Co(OH)

2 into β-Co(OH)

2. After the CV treatment, three new peaks were detected at 20°, 38°, and 65°, which can be indexed to the (001), (012), and (018) planes of CoOOH (PDF card No.070159), respectively, indicating the co-existence of β-Co(OH)

2 and CoOOH.

The morphology evolution of Co(OH)

2 was analyzed via scanning electron spectroscopy (SEM) and transmission electron spectroscopy (TEM). As shown in

Figure 2A, the as-prepared α-Co(OH)

2 displayed a petal-like morphology, with an average thickness of 200 nm. With a closer scrutiny, each petal was loosely stacked, consisting of multiple Co(OH)

2 layers with large interlayer spacings (

Figure 2B). After being soaked in a 1 M KOH solution, the morphology of Co(OH)

2 changed dramatically from the loosely stacked petals to the hexagonal platelets, corresponding to the change in the XRD pattern (

Figure 2C). In the hexagonal platelets, no obvious void was observed, suggesting a decreased interlayer spacing. In addition, TEM images also confirmed the morphology evolution from α- to β-Co(OH)

2. The porous structure was observed in α-Co(OH)

2 (

Figure 2D), which disappeared and changed to the compact stack of Co(OH)

2 layers (

Figure 2E), when the electrode was put into alkaline media. No obvious pores were identified. These results indicate that the actual reactant was β-Co(OH)

2. In addition, the space group of hexagonal β-Co(OH)

2 was R3m. The (010) and (100) crystal planes exhibited an acute angle of 60° (

Figure 2F), also suggesting the formation of β-Co(OH)

2. After the CV treatment, the morphology of the mixed phase of β-Co(OH)

2 and CoOOH was quite similar to β-Co(OH)

2 (

Figures S2 and S3), showing a morphology of well-shaped hexagonal platelets, which resulted from the similar structural parameters of β-Co(OH)

2 and CoOOH.

Fourier transform infrared spectroscopy (FTIR) and X-ray photoemission spectroscopy (XPS) analyses were conducted to probe the surface state of the Co(OH)

2/CoOOH mixed phase.

Figure 3A shows the FTIR spectra of the as-prepared Co(OH)

2 and the Co(OH)

2 after their immersion in the alkaline media. There was a sharp absorption band observed at 1383 cm

−1 in the spectrum of α-Co(OH)

2, representing the N-O vibration from the inserted

species [

13]. The intensity of the N-O vibration was substantially reduced after diving the as-prepared Co(OH)

2 in the KOH solution, indicating the removal of

. In addition, an intense band appeared at 3572 cm

−1 in the spectrum of β-Co(OH)

2, which is the typical feature of OH groups. The transformation from α- to β-Co(OH)

2 could be explained by the

replacement of OH

− with a smaller size, leading to the compact arrangement of the Co-O layers. According to the FTIR analysis, α-Co(OH)

2 is quite unstable in the alkaline media, which can rapidly transform into β-Co(OH)

2. So, the actual reactant is β-Co(OH)

2, rather than α-Co(OH)

2, to store Zn

2+ ions.

Figure 3B depicts the XPS spectrum of C 1s of α-Co(OH)

2 on the CFP. In addition to the typical signals of the sp

2 carbon and some surface function groups, such as C-O, C=O, and COOH, strong Co-O-C interactions were generated between the CFP and Co(OH)

2 at 294 eV and 298 eV, which can provide a robust bonding between the active material and the substrate to prevent their pulverization [

14]. X-ray adsorption spectroscopy (XAS) measurements were also conducted to evaluate the structural evolution from Co(OH)

2 to CoOOH. X-ray absorption near-edge structure (XANES) spectra of β-Co(OH)

2 and the mixed phase of Co(OH)

2/CoOOH are shown in

Figure 3C. The intensity of the Co(OH)

2/CoOOH mixed phase was much higher than that of β-Co(OH)

2, indicating a decreased disorder in the local environment and stronger Co-Co shells [

15,

16]. The K-edge of the Co(OH)

2/CoOOH mixed phase shows a positive shift compared to β-Co(OH)

2 in the inset of

Figure 3C, which demonstrates an increased Co valence in the mixed phase. In addition, the overall oscillation patterns of β-Co(OH)

2 and the mixed phase were quite similar, suggesting similar coordination environments of the Co atom in β-Co(OH)

2 and the mixed phase. The extended X-ray absorption fine structure (EXAFS) spectra of β-Co(OH)

2 and the mixed phase are displayed in

Figure 3D. The similar patterns also suggest similar coordination environments in β-Co(OH)

2 and the mixed phase. Moreover, two peaks were also observed, standing for the Co-O and Co-Co shells. The increased intensities of both peaks in the mixed phase were detected, which indicate a decreased structural disorder in the mixed phase [

17,

18]. Furthermore, negative shifts of the Co-O and Co-Co shells were also observed in the mixed phase, which suggests the reduced Co-O and Co-Co bond lengths due to the existence of CoOOH. Compared to Co(OH)

2, each H atom is shared by the two adjacent Co-O layers in CoOOH. The density functional theory (DFT) calculation simulated the transformation from Co(OH)

2 into CoOOH, and its computed energy file is provided in

Figure 4. CoOOH (a = b = 3.036 Å; c = 8.862 Å) was obtained by losing one H atom per formula unit from Co(OH)

2 (a = b = 3.176 Å; c = 9.358 Å). We found that the energy difference between CoOOH and Co(OH)

2 was 0.6 eV, and that the activation energy from CoOOH to Co(OH)

2 was higher than for the opposite process, indicating that the mixed phase is more stable than pure Co(OH)

2.

The electrochemical performance of the Co(OH)

2/CoOOH mixed phase as the cathode for AZIBs was investigated in a coin cell, in which the Co(OH)

2/CoOOH mixed phase, a Zn foil, and 1 M ZnSO

4 solution were used as the cathode, anode, and electrolyte, respectively (

Figure 5A). The mixed phase of Co(OH)

2/CoOOH exhibited a maximum capacity of 164 mAh g

−1 at 0.05 A g

−1, as well as a high energy density of 275 Wh kg

−1 (

Figure 5B). Moreover, no obvious decay in capacity was observed in the first five cycles, suggesting a good stability of the mixed phase of Co(OH)

2/CoOOH. The differential capacity (dQ/dV) curve is depicted in

Figure 5C, and two discharge peaks located at 1.6 eV and 1.8 V vs. Zn

2+/Zn were observed. The average discharge voltage of 1.7 V vs. Zn

2+/Zn was higher than for most of the reported cathode materials, such as V

2O

5 (0.6 V vs. Zn

2+/Zn) and MnO

2 (1.4 V vs. Zn

2+/Zn).

Figure 5D shows the Nyquist plot of the mixed phase. The inset is the electrical equivalent circuit, in which R

ct, R

s, W, and CPE stand for the charge-transfer resistance, the equivalent series resistance, the Warburg impedance, and the constant phase element, respectively. According to the fitting results (

Table S2), R

ct was calculated to be 2.1 Ω, and such a small charge-transfer resistance indicates an excellent electron transfer rate in the mixed phase of β-Co(OH)

2 and CoOOH.

Figure 5E displays the CV curves of the mixed phase of Co(OH)

2/CoOOH at different scan rates, and the reaction kinetics were evaluated based on the scan rate and the corresponding current. The capacity contribution of the diffusion- and surface-controlled processes can be deconvoluted according to the following equation [

19]:

in which

and

stand for the surface- and diffusion-controlled processes, respectively. As the scan rate increased from 0.1 mV s

−1 to 5 mV s

−1, the contribution ratio of the diffusion-controlled capacity was stabilized at ~70%, indicating that both surface and diffusion synergically regulate the electrode reaction. As a result, the mixed phase of Co(OH)

2/CoOOH exhibited an excellent rate performance. Its capacity can reach 164, 124, 108, 103, 98, and 87 mAh g

−1 at 0.05, 0.1, 0.2, 0.4, 0.8, and 1.6 A g

−1, respectively (

Figure 5G,H). In contrast, β-Co(OH)

2 only showed a maximum capacity of 48.8 mAh g

−1 at 0.1 A g

−1 (

Figure S4), along with an inferior rate performance (

Figure S5). Compared to recently reported cathode materials for AZIBs, such as PBA (99.7 mAh g

−1 at 0.05 A g

−1) [

20], FeHCF (76 mAh g

−1 at 1 A g

−1) [

21], and Na

3V

2(PO

4)

2F

3 (65 mAh g

−1 at 0.08 A g

−1) [

22], the mixed phase of Co(OH)

2/CoOOH exhibited an increased capacity, an improved rate performance, and a higher discharge voltage of 1.7 V (

Table 1). The mixed phased also delivered a good stability at the current density of 0.05 A g

−1. After 200 cycles, a capacity retention of 78% was retained, with high Coulombic efficiencies (

Figure 5I). However, the capacity of β-Co(OH)

2 rapidly dropped to 38% after 50 cycles at the current density of 0.1 A g

−1 (

Figure S6). Both Co(OH)

2 and CoOOH are amphoteric materials, which could be dissolved in acidic media. The pH value of the 1 M ZnSO

4 electrolyte is about 4~4.5, meaning that the dissolution of the active material is responsible for the capacity loss. On the other hand, the interaction between the Zn

2+ ions and the Co-O layer was enhanced after the removal of

species, which neutralize the positive charge of the Co-O layers. However, the high thermal stability and the shortened Co-Co and Co-O shells, according our XAS analysis and DFT calculation, increased the mechanical strength of the mixed phase to accommodate Zn

2+ ions and endure the electrostatic repulsion.

4. Materials and Methods

Synthesis of α-Co(OH)2. The α-Co(OH)2 was electrochemically deposited on the carbon fiber paper (CFP) as the substrate. A 1 M Co(NO3)2 solution (analytical reagent (AR), Xilong Chemical Co., Ltd., Guangzhou, China) was used as the electrolyte. Before the electrodeposition, the CFP was washed with acetone, ethanol, and distilled water for 30 min each, and the CFP was dried in a 60 degree oven overnight. Then, the α-Co(OH)2 thin film was electrodeposited on the CFP in a conventional three-electrode electrolytic cell, in which the CFP, a platinum plate, and a saturated calomel electrode (SCE) served as the working, counter, and reference electrode, respectively. The electrodeposition was conducted using a CHI660E potentiostat, and the voltage was maintained at −1 V for 30 min. The formation of α-Co(OH)2 can be expressed as follows: + 7H2O + 8e− → + 10 OH−, Co2+ + 2OH− → Co(OH)2. Following the electrodeposition, the prepared electrode was washed with distilled water for several times and dried in a 60 degree vacuum oven overnight.

Synthesis of the mixed phase of Co(OH)2/CoOOH. The as-prepared α-Co(OH)2 was utilized as the precursor to obtain the mixed phase of Co(OH)2 and CoOOH via an electrochemical method in a conventional three-electrode electrolytic cell for a CV treatment, in which the as-prepared α-Co(OH)2, a platinum plate, a saturated calomel electrode (SCE), and a 1 M KOH solution served as the working electrode, counter electrode, reference electrode, and the electrolyte, respectively. The CV treatment was conducted using a CHI660E potentiostat. The potential range of the CV treatment was set from −0.1 V to 0.45 V, and the scan rate was 25 mV s−1 for 50 cycles. The electrochemical process was expressed as follows: Co(OH)2 + OH− → CoOOH + H2O + e−. After the CV treatment, the electrode was washed using the distilled water for several times to wash off the alkaline residues and dried in a 60 degree vacuum oven overnight.

Physical characterization. The morphologies of α-Co(OH)2, β-Co(OH)2, and the mixed phase of Co(OH)2/CoOOH were characterized via scanning electron microscopy (SEM, Hitach SU8000 scanning electron microscope, Hitachi High-Tech, Tokoy, Japan) and transmission electron microscopy (TEM, JEM ARM 1300S for high-resolution TEM images, Thermo Fisher, Shanghai, China). The structural evolution from α-Co(OH)2 to the mixed phase of Co(OH)2/CoOOH was probed via X-ray diffraction (XRD, RIGAKU D/MAX2500, Rigaku, Tokoy, Japan). Fourier transform infrared spectra were conducted using a JW-BK132F from the JWGB SCI. & TECH instrument (Beijing, China), and X-ray photoelectron spectroscopy (XPS) spectra were obtained using the ESCALAB-250 instrument with a monochromatic Al Kα radiation source and a hemisphere detector with an energy resolution of 0.1 eV. The X-ray absorption (XAS) spectra were obtained on the beamline 1W1B at the Beijing Synchrotron Facility (BSRF), with an electron of 2.2 GeV and a beam current of 250 mA.

Electrochemical evaluation. The electrochemical performances of β-Co(OH)2 and the mixed phase were carried out in a coin cell, in which Zn foil and 1 M ZnSO4 served as the anode and the electrolyte, respectively. The cathode and anode were separated via a glass microfiber filter (CAT No. 1823-125). The galvanostatic profiles, dQ/dV plot, and cycling performance were conducted using a Neware battery testing system. The CV curves and Nyquist plot were obtained using a CHI660E potentiostat.

DFT simulations. The Perdew–Burke–Ernzerhof (PBE) functional and supercell approach were utilized as implemented in the Vienna ab initio simulation package (VASP) to perform the spin-polarized DFT calculations. Co (3s, 3p, 3d, and 4s) and O (2s and 2p) electrons were treated as valence states, with a cut-off energy of 520 eV in plane waves, and PBE-based projector-augmented wave potentials were used to replace the other electrons. All energies were computed using the DFT + U method. Co2O4H2 (two formula units) was used as a unit cell, and the equilibrium lattice constants were simulated with cell shape, a lattice vector, and atomic position using a residual force of 0.02 eV Å−1. These conditions ensured a convergence in the equilibrium distance. As for the transition state, the considered phase transformation was located using the elastic band algorithm.