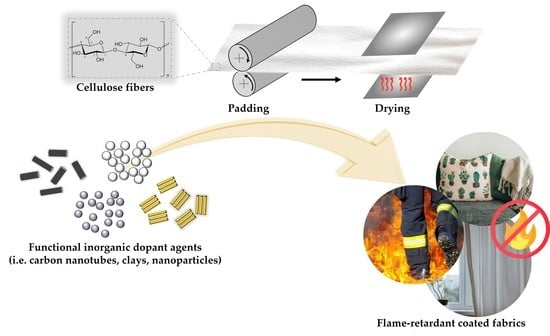

How to Address Flame-Retardant Technology on Cotton Fabrics by Using Functional Inorganic Sol–Gel Precursors and Nanofillers: Flammability Insights, Research Advances, and Sustainability Challenges

Abstract

:1. Introduction

- Gas phase. FRs following this mechanism act by diluting the gas phase and/or by chemical quenching of active radicals. The former effect is based on releasing non-combustible gases (e.g., H2O and CO2) that can dilute the oxygen or the fuel concentrations by lowering them under the flammability limit. Metal hydroxides and carbonates are generally believed to follow this mode of action due to their endothermic thermal decomposition and production of non-combustible gases. On the other side, because of the occurrence of radical reactions during combustion, the flame retardants decompose in radical species able to quench the high-energy free radicals formed during cellulose combustion (e.g., H• and •OH) by decreasing the burning rate of the combustible materials and, finally, interrupting the exothermic reactions of the combustion. However, the mechanism in the gas phase may be slightly different, depending on the used chemicals [21];

- Condensed phase. The thermal cracking reaction process of cellulose can be modified by flame retardants. Indeed, many reactions (e.g., dehydration, condensation, cross-linking, and cyclization) take place at lower temperatures by producing coherent carbon layers on the fabric surface, thus lowering both the evolution of combustible gases and the decomposition rate of the fabric. For more in detail, the depolymerization of fiber materials is observable under the action of the flame retardant, as well as a decrease in the melting temperature that leads to a higher temperature difference between the melting and ignition point [22]. According to the chemical structure of the employed FR, an intumescent effect can also be observable. Moreover, a certain amount of heat is absorbed by interrupting the feedback of the heat to the fibers and, finally, the combustion process. Inorganic finishes containing phosphorus, boron, sol–gel precursors, nanoclay, and metal-based finishes, as well as carbon nanotubes and graphene, are believed to follow this mode of action.

2. Mechanism of Cotton Combustion

- -

- a first stage (between 300 and 400 °C), corresponding to the pyrolysis that takes place through two competing decomposition reactions: dehydration and depolymerization [38]. The former produces anhydro-cellulose (dehydro-cellulose), which further decomposes at higher temperatures and produces various volatile products such as alcohols, alkanes, aldehydes, fuel gases, carbon monoxide, methane, ethylene, and non-flammable gases (carbon dioxide and water vapor), and an aliphatic char (char I). Otherwise, depolymerization by breaking of glycosidic linkages results in the formation of tar (condensed phase), which is mostly composed of levoglucosan and glycolaldehyde (hydrogen acetaldehyde);

- -

- a second stage (between 400 and 600 °C), corresponding to the competitive conversion of aliphatic char to aromatic and char oxidation [38]. In this stage, tar is further decomposed into small volatile flammable molecules and aromatic char (char II, stable up to 800 °C), while volatile compounds from Stage 1 are also oxidized to produce similar oxidized char and aromatic molecules;

- -

3. Flame Retardancy of Cotton Fabrics

- (a)

- by using fire-retardant materials that thermally decompose through strongly endothermic reactions to not easily achieve the heat required for thermal decomposition (temperature of pyrolysis (Tp) of the fiber should not be reached);

- (b)

- by applying a material that forms an insulating layer around a temperature below the fiber Tp;

- (c)

- by using phosphorous-containing fire retardants that modify the pyrolysis reaction (‘condensed phase’ mechanism) according to two mechanisms: (i) production of phosphoric acid through thermal decomposition, and cross-link with hydroxyl-containing polymers altering the pyrolysis pattern and yielding less-flammable byproducts; (ii) blocking of the primary hydroxyl group in the C-6 position of the cellulose units, preventing the formation of flammable byproducts (levoglucosan), and catalyzing the dehydration and char formation [46];

- (d)

- by preventing combustion through scavenging the generated free radicals (e.g., Br•/Cl• halogen-containing fire-retardant compounds), thus reducing the available heat (‘gas phase’ mechanism);

- (e)

- by enhancing the Tc (combustion temperature) [47];

- (f)

- by raising the initial decomposition temperature (i.e., Tp) for preventing/reducing the formation of flammable volatile species and increasing the formation of char and non-flammable gas.

4. Assessment of the Thermal Behavior and Flammability of Cotton Fabrics

4.1. Flammability Tests

| Mass Per Unit Area (g/m2) | Configuration of Flammability Test | Total Burning Time (s) | Total Burning Rate (mm/s) | After-Flame Time (s) | After-Glow Time (s) | Residue (%) | FlaPI (%/s) | Ref. |

|---|---|---|---|---|---|---|---|---|

| 145 | horizontal | 34 | - | - | - | 3.1 | - | [51] |

| 237 | horizontal | 149 | 0.67 | - | - | 0 | - | [60] |

| 331 | horizontal | 23 | - | - | 139 | 0 | 0 | [57] |

| 122 | Vertical | - | - | 15.8 | 20.7 | - | - | [12] |

| 129 | Vertical | - | - | 15 | 21 | - | - | [61] |

| 150 | Vertical | - | - | 15 | 26 | 0 | - | [62] |

| 184 | Vertical | - | - | 14.3 | 31.4 | 0 | - | [63] |

| 200 | Vertical | 45 | 2.2 | - | 27 | <2 | - | [64] |

| 210 | Vertical | 38 | - | - | - | 14 | 0.37 | [56] |

| 220 | Vertical | - | - | 7 | 21 | 0 | - | [65] |

| 237 | Vertical | 35 | 7.50 | - | - | - | - | [38] |

4.2. Cone Calorimetry Test

4.3. Microscale Combustion Calorimetry (MCC)

4.4. Pyrolysis Behavior of Cotton Fibers by Thermogravimetric Analysis

4.5. Differential Scanning Calorimetry

4.6. Study of Pyrolysis Products of Cellulose

5. Inorganic Chemicals Currently Used as Flame Retardants for Cotton

5.1. Inorganic Phosphorus-Based Flame Retardants

5.2. Boron-Based Flame Retardant

5.3. Flame-Retardant Finishing by Sol–Gel Technique

5.4. Flame-Retardant Finishing by Inorganic Nanoparticles

5.4.1. Nanoclays

Montmorillonite

Hydrotalcite

Vermiculite

5.4.2. Carbon Nanotubes

5.4.3. Graphene

5.4.4. Metal-Based Nanoparticles

Metal Oxides

Metal Hydroxides

Metal (Oxide/Hydroxide)

Zinc Carbonate

| Weight per Unit Area (g/m2) | Additive | Cone Calorimetry Tests | Thermal Behavior | Vertical Flame-Spread Tests | Ref. | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TTI (s) | FPI (sm2/kW) | PHRR (kW/m2) | TGA in Air | TGA in Nitrogen | Time to Ignite (s) | Flame-Spread Time (s) | |||||||

| Tonset5% (°C) | Tmax (°C) | Residue (%) | Tonset5% (°C) | Tmax (°C) | Residue (%) | ||||||||

| 98 | TiO2 (1 cycle) | 23 | - | 171 | - | - | - | 304 | 346 | 2.3 | - | - | [273] |

| 98 | TiO2 (3 cycles) | 20 | - | 132 | - | - | - | 292 | 339 | 8.0 | - | - | [273] |

| 98 | TiO2 (7 cycles) | 19 | - | 122 | - | - | - | 271 | 336 | 14.4 | - | - | [273] |

| 117 | MgO | - | - | - | 276 | 343 | 18.9 at 800 °C | 324 | 422 | 28.0 at 800 °C | - | - | [289] |

| 200 | SiO2 (by dipping) | 20 | - | 75 | - | - | - | - | - | - | 22 | - | [91] |

| 200 | SiO2 (by vertical spray) | 20 | - | 73 | - | - | - | - | - | - | 30 | - | [91] |

| 200 | SiO2 (by horizontal spray) | 28 | - | 66 | - | - | - | - | - | - | 30 | - | [91] |

| 139 | SiO2 | - | - | - | 224 | 541 | 40 at 400 °C | - | - | - | - | 13.6 | [278] |

| 139 | ZrO2 | - | - | - | 235 | 537 | 52 at 400 °C | - | - | - | - | 19.4 | [278] |

| 139 | MgO | - | - | - | 222 | 562 | 45 at 400 °C | - | - | - | - | 18.4 | [278] |

| 139 | TiO2 | - | - | - | 239 | 549 | 44 at 400 °C | - | - | - | - | 18.9 | [278] |

| 155 | 0.25% SiO2 + 0.25% ZnO | - | - | - | - | - | - | 330 b | 410 b | 8.9 b, at 600 °C | 4 b | 17 b | [276] |

| - | - | - | - | - | - | 333 a | 413 a | 7.6 a, at 600 °C | 3 a | 15 a | |||

| 155 | 0.5% SiO2 + 0.25% ZnO | - | - | - | - | - | - | 350 b | 428 b | 8.5 b, at 600 °C | 5 b | 21 b | [276] |

| - | - | - | - | - | - | 341 a | 418 a | 7.9 a, at 600 °C | 4 a | 19 a | |||

| 155 | 0.25% SiO2 + 0.5% ZnO | - | - | - | - | - | - | 340 b | 420 b | 8.6 b, at 600 °C | 5 b | 14 b | [276] |

| - | - | - | - | - | - | 336 a | 415 a | 7.8 a, at 600 °C | 4 a | 13 a | |||

| 210 | OS1 | 22 | 0.44 | 50 | 278 | 239 | 1 at 800 °C | - | - | - | - | - | [295] |

| 214 | SiO2 (30 min) | 17 | 0.17 | 99 | 296 | 500 | 25 at 400 °C | - | - | - | - | - | [229] |

| 214 | SiO2 (60 min) | 20 | 0.21 | 95 | 299 | 479 | 25 at 400 °C | - | - | - | - | - | [229] |

| - | TiO2 | - | - | - | - | - | - | 314 | - | 26.36 | - | 296 | [297] |

| 400 | ZnO microparticles | 13.0 | - | - | 340 | - | 350 | - | - | - | - | [19] | |

| 400 | ZnO + ZnS microparticles | 14.7 | - | - | 290 | - | - | - | - | - | - | [19] | |

6. Conclusions and Future Challenges

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Aldalbahi, A.; El-Naggar, M.; El-Newehy, M.; Rahaman, M.; Hatshan, M.; Khattab, T. Effects of Technical Textiles and Synthetic Nanofibers on Environmental Pollution. Polymers 2021, 13, 155. [Google Scholar] [CrossRef] [PubMed]

- Pandit, P.; Singha, K.; Kumar, V.; Maity, S. Advanced flame-retardant agents for protective textiles and clothing. In Advances in Functional and Protective Textiles; Elsevier: Amsterdam, The Netherlands, 2020; pp. 397–414. [Google Scholar]

- Sreenivasan, V.S.; Somasundaram, S.; Ravindran, D.; Manikandan, V.; Narayanasamy, R. Microstructural, physico-chemical and mechanical characterisation of Sansevieria cylindrica fibres—An exploratory investigation. Mater. Des. 2011, 32, 453–461. [Google Scholar] [CrossRef]

- Pavlović, Ž.; Vrljičak, Z. Comparing double jersey knitted fabrics made of Tencel and modal yarns, spun by different spinning methods. J. Eng. Fiber. Fabr. 2020, 15, 155892502091985. [Google Scholar] [CrossRef]

- Azman Mohammad Taib, M.N.; Hamidon, T.S.; Garba, Z.N.; Trache, D.; Uyama, H.; Hussin, M.H. Recent progress in cellulose-based composites towards flame retardancy applications. Polymer 2022, 244, 124677. [Google Scholar] [CrossRef]

- Chakrabarty, A.; Teramoto, Y. Recent Advances in Nanocellulose Composites with Polymers: A Guide for Choosing Partners and How to Incorporate Them. Polymers 2018, 10, 517. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Pan, Y.-T.; Wang, X.; Acuña, P.; Zhu, P.; Wagenknecht, U.; Heinrich, G.; Zhang, X.-Q.; Wang, R.; Wang, D.-Y. Effect of phosphorus-containing inorganic–organic hybrid coating on the flammability of cotton fabrics: Synthesis, characterization and flammability. Chem. Eng. J. 2016, 294, 167–175. [Google Scholar] [CrossRef]

- Islam, M.S.; van de Ven, T.G.M. Cotton-based flame-retardant textiles: A review. BioResources 2021, 16, 4354–4381. [Google Scholar] [CrossRef]

- Siriviriyanun, A.; O’Rear, E.A.; Yanumet, N. Self-extinguishing cotton fabric with minimal phosphorus deposition. Cellulose 2008, 15, 731–737. [Google Scholar] [CrossRef]

- Lewin, M. Handbook of Fiber Chemistry; Wake, P.J., Ed.; CRC Press: Boca Raton, FL, USA, 2006; ISBN 9780824725655. [Google Scholar]

- Alongi, J.; Colleoni, C.; Rosace, G.; Malucelli, G. Thermal and fire stability of cotton fabrics coated with hybrid phosphorus-doped silica films. J. Therm. Anal. Calorim. 2012, 110, 1207–1216. [Google Scholar] [CrossRef]

- Wang, S.; Sun, L.; Li, Y.; Wang, H.; Liu, J.; Zhu, P.; Dong, C. Properties of flame-retardant cotton fabrics: Combustion behavior, thermal stability and mechanism of Si/P/N synergistic effect. Ind. Crops Prod. 2021, 173, 114157. [Google Scholar] [CrossRef]

- Zammarano, M.; Cazzetta, V.; Nazaré, S.; Shields, J.R.; Kim, Y.S.; Hoffman, K.M.; Maffezzoli, A.; Davis, R.D. Smoldering and Flame Resistant Textiles via Conformal Barrier Formation. Adv. Mater. Interfaces 2016, 3, 1600617. [Google Scholar] [CrossRef] [PubMed]

- Roberts, B.C.; Webber, M.E.; Ezekoye, O.A. Why and How the Sustainable Building Community Should Embrace Fire Safety. Curr. Sustain. Energy Rep. 2016, 3, 121–137. [Google Scholar] [CrossRef]

- Hall, J.R. Estimating Fires When a Product is the Primary Fuel But Not the First Fuel, With an Application to Upholstered Furniture. Fire Technol. 2015, 51, 381–391. [Google Scholar] [CrossRef]

- Salmeia, K.; Gaan, S.; Malucelli, G. Recent Advances for Flame Retardancy of Textiles Based on Phosphorus Chemistry. Polymers 2016, 8, 319. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Available online: www.ctif.org (accessed on 25 May 2023).

- Horrocks, A.R. Flame retardant challenges for textiles and fibres: New chemistry versus innovatory solutions. Polym. Degrad. Stab. 2011, 96, 377–392. [Google Scholar] [CrossRef]

- Wang, Y.-W.; Shen, R.; Wang, Q.; Vasquez, Y. ZnO Microstructures as Flame-Retardant Coatings on Cotton Fabrics. ACS Omega 2018, 3, 6330–6338. [Google Scholar] [CrossRef] [Green Version]

- Morgan, A.B.; Gilman, J.W. An overview of flame retardancy of polymeric materials: Application, technology, and future directions. Fire Mater. 2013, 37, 259–279. [Google Scholar] [CrossRef] [Green Version]

- Salmeia, K.; Fage, J.; Liang, S.; Gaan, S. An Overview of Mode of Action and Analytical Methods for Evaluation of Gas Phase Activities of Flame Retardants. Polymers 2015, 7, 504–526. [Google Scholar] [CrossRef] [Green Version]

- Shen, J.; Liang, J.; Lin, X.; Lin, H.; Yu, J.; Wang, S. The Flame-Retardant Mechanisms and Preparation of Polymer Composites and Their Potential Application in Construction Engineering. Polymers 2021, 14, 82. [Google Scholar] [CrossRef]

- Ling, C.; Guo, L.; Wang, Z. A review on the state of flame-retardant cotton fabric: Mechanisms and applications. Ind. Crops Prod. 2023, 194, 116264. [Google Scholar] [CrossRef]

- Hendrix, J.E.; Drake, G.L.; Barker, R.H. Pyrolysis and combustion of cellulose. III. Mechanistic basis for the synergism involving organic phosphates and nitrogenous bases. J. Appl. Polym. Sci. 1972, 16, 257–274. [Google Scholar] [CrossRef]

- Alongi, J.; Colleoni, C.; Rosace, G.; Malucelli, G. Phosphorus- and nitrogen-doped silica coatings for enhancing the flame retardancy of cotton: Synergisms or additive effects? Polym. Degrad. Stab. 2013, 98, 579–589. [Google Scholar] [CrossRef]

- Lewin, M. Synergism and catalysis in flame retardancy of polymers. Polym. Adv. Technol. 2001, 12, 215–222. [Google Scholar] [CrossRef]

- Horrocks, A.R.; Smart, G.; Nazaré, S.; Kandola, B.; Price, D. Quantification of Zinc Hydroxystannate** and Stannate** Synergies in Halogen-containing Flame-retardant Polymeric Formulations. J. Fire Sci. 2010, 28, 217–248. [Google Scholar] [CrossRef]

- Glogar, M.; Pušić, T.; Lovreškov, V.; Kaurin, T. Reactive Printing and Wash Fastness of Inherent Flame Retardant Fabrics for Dual Use. Materials 2022, 15, 4791. [Google Scholar] [CrossRef] [PubMed]

- Durrani, H.; Sharma, V.; Bamboria, D.; Shukla, A.; Basak, S.; Ali, W. Exploration of flame retardant efficacy of cellulosic fabric using in-situ synthesized zinc borate particles. Cellulose 2020, 27, 9061–9073. [Google Scholar] [CrossRef]

- van der Veen, I.; de Boer, J. Phosphorus flame retardants: Properties, production, environmental occurrence, toxicity and analysis. Chemosphere 2012, 88, 1119–1153. [Google Scholar] [CrossRef] [PubMed]

- De Smet, D.; Weydts, D.; Vanneste, M. Environmentally friendly fabric finishes. In Sustainable Apparel; Elsevier: Amsterdam, The Netherlands, 2015; pp. 3–33. [Google Scholar]

- Chivas, C.; Guillaume, E.; Sainrat, A.; Barbosa, V. Assessment of risks and benefits in the use of flame retardants in upholstered furniture in continental Europe. Fire Saf. J. 2009, 44, 801–807. [Google Scholar] [CrossRef]

- Höhn, W. Textile Industry Effluent. In Sustainable Textile and Fashion Value Chains; Springer International Publishing: Cham, Switzerland, 2021; pp. 123–149. [Google Scholar]

- Wang, X.; Hu, W.; Hu, Y. Polydopamine-Bridged Synthesis of Ternary h-BN@PDA@TiO2 as Nanoenhancers for Thermal Conductivity and Flame Retardant of Polyvinyl Alcohol. Front. Chem. 2020, 8, 587474. [Google Scholar] [CrossRef]

- Price, D. Fire Retardant Materials; Elsevier Science & Technology: Amsterdam, The Netherlands, 2001; ISBN 9781855734197. [Google Scholar]

- Horrocks, A.R.; Price, D. Fire Retardant Materials, 1st ed.; Woodhead Publishing Limited: Cambridge, UK, 2001; ISBN 1855734192. [Google Scholar]

- Little, R.W. Fundamentals of Flame Retardancy. Text. Res. J. 1951, 21, 901–908. [Google Scholar] [CrossRef]

- Alongi, J.; Colleoni, C.; Malucelli, G.; Rosace, G. Hybrid phosphorus-doped silica architectures derived from a multistep sol–gel process for improving thermal stability and flame retardancy of cotton fabrics. Polym. Degrad. Stab. 2012, 97, 1334–1344. [Google Scholar] [CrossRef]

- Horrocks, A.R. An Introduction to the Burning Behaviour of Cellulosic Fibres. J. Soc. Dye Colour. 1983, 99, 191–197. [Google Scholar] [CrossRef]

- Laoutid, F.; Bonnaud, L.; Alexandre, M.; Lopez-Cuesta, J.-M.; Dubois, P. New prospects in flame retardant polymer materials: From fundamentals to nanocomposites. Mater. Sci. Eng. R Rep. 2009, 63, 100–125. [Google Scholar] [CrossRef]

- Shafizadeh, F.; Fu, Y.L. Pyrolysis of cellulose. Carbohydr. Res. 1973, 29, 113–122. [Google Scholar] [CrossRef]

- Visakh, P.M.; Arao, Y. (Eds.) Flame Retardants; Engineering Materials; Springer International Publishing: Cham, Switzerland, 2015; ISBN 978-3-319-03466-9. [Google Scholar]

- Kaur, B.; Gur, I.S.; Bhatnagar, H.L. Thermal degradation studies of cellulose phosphates and cellulose thiophosphates. Die Angew. Makromol. Chem. 1987, 147, 157–183. [Google Scholar] [CrossRef]

- Merritt, M.J. Textile Fibres, Their Physical, Microscopic, and Chemical Properties, 6th ed.; John Wiley & Sons, Inc.: New York, NY, USA, 1954. [Google Scholar]

- Cabrales, L.; Abidi, N. Kinetics of Cellulose Deposition in Developing Cotton Fibers Studied by Thermogravimetric Analysis. Fibers 2019, 7, 78. [Google Scholar] [CrossRef] [Green Version]

- Xu, F.; Zhong, L.; Xu, Y.; Zhang, C.; Wang, P.; Zhang, F.; Zhang, G. Synthesis of three novel amino acids-based flame retardants with multiple reactive groups for cotton fabrics. Cellulose 2019, 26, 7537–7552. [Google Scholar] [CrossRef]

- Pal, A.; Samanta, A.K.; Bagchi, A.; Samanta, P.; Kar, T.R. A Review on Fire Protective Functional Finishing of Natural Fibre Based Textiles: Present Perspective. Curr. Trends Fash. Technol. Text. Eng. 2020, 7, 19–30. [Google Scholar] [CrossRef]

- Chang, S.; Slopek, R.P.; Condon, B.; Grunlan, J.C. Surface Coating for Flame-Retardant Behavior of Cotton Fabric Using a Continuous Layer-by-Layer Process. Ind. Eng. Chem. Res. 2014, 53, 3805–3812. [Google Scholar] [CrossRef]

- Lu, H.; Song, L.; Hu, Y. A review on flame retardant technology in China. Part II: Flame retardant polymeric nanocomposites and coatings. Polym. Adv. Technol. 2011, 22, 379–394. [Google Scholar] [CrossRef]

- Lomakin, S.M.; Zaikov, G.E.; Artsis, M.I. Advances in Nylon 6,6 Flame Retardancy. Int. J. Polym. Mater. 1996, 32, 173–202. [Google Scholar] [CrossRef]

- Faheem, S.; Baheti, V.; Tunak, M.; Wiener, J.; Militky, J. Flame resistance behavior of cotton fabrics coated with bilayer assemblies of ammonium polyphosphate and casein. Cellulose 2019, 26, 3557–3574. [Google Scholar] [CrossRef]

- Emsley, A.M.; Stevens, G.C. Kinetics and mechanisms of the low-temperature degradation of cellulose. Cellulose 1994, 1, 26–56. [Google Scholar] [CrossRef]

- UL-94; Standard for Tests for Flammability of Plastic Materials for Parts in Devices and Appliances. UL Solutions: Northbrook, IL, USA, 1996.

- Birky, M.M.; Yeh, K.-N. Calorimetric study of flammable fabrics. I. Instrumentation and measurements. J. Appl. Polym. Sci. 1973, 17, 239–253. [Google Scholar] [CrossRef]

- Webster, C.T.; Wraight, H.G.H.; Thomas, P.H. 3—Heat-Transfer from Burning Fabrics. J. Text. Inst. Trans. 1962, 53, T29–T37. [Google Scholar] [CrossRef]

- Alongi, J.; Ciobanu, M.; Malucelli, G. Novel flame retardant finishing systems for cotton fabrics based on phosphorus-containing compounds and silica derived from sol–gel processes. Carbohydr. Polym. 2011, 85, 599–608. [Google Scholar] [CrossRef]

- Rosace, G.; Castellano, A.; Trovato, V.; Iacono, G.; Malucelli, G. Thermal and flame retardant behaviour of cotton fabrics treated with a novel nitrogen-containing carboxyl-functionalized organophosphorus system. Carbohydr. Polym. 2018, 196, 348–358. [Google Scholar] [CrossRef]

- Alongi, J.; Malucelli, G. Thermal stability, flame retardancy and abrasion resistance of cotton and cotton–linen blends treated by sol–gel silica coatings containing alumina micro- or nano-particles. Polym. Degrad. Stab. 2013, 98, 1428–1438. [Google Scholar] [CrossRef]

- Chang, S.; Condon, B.; Graves, E.; Uchimiya, M.; Fortier, C.; Easson, M.; Wakelyn, P. Flame retardant properties of triazine phosphonates derivative with cotton fabric. Fibers Polym. 2011, 12, 334–339. [Google Scholar] [CrossRef]

- Rosace, G.; Colleoni, C.; Trovato, V.; Iacono, G.; Malucelli, G. Vinylphosphonic acid/methacrylamide system as a durable intumescent flame retardant for cotton fabric. Cellulose 2017, 24, 3095–3108. [Google Scholar] [CrossRef]

- Liao, Y.; Chen, Y.; Wan, C.; Zhang, G.; Zhang, F. An eco-friendly N P flame retardant for durable flame-retardant treatment of cotton fabric. Int. J. Biol. Macromol. 2021, 187, 251–261. [Google Scholar] [CrossRef]

- Vishwakarma, A.; Singh, M.; Weclawski, B.; Reddy, V.J.; Kandola, B.K.; Manik, G.; Dasari, A.; Chattopadhyay, S. Construction of hydrophobic fire retardant coating on cotton fabric using a layer-by-layer spray coating method. Int. J. Biol. Macromol. 2022, 223, 1653–1666. [Google Scholar] [CrossRef]

- Hu, M.-Y.; Xiong, K.-K.; Li, J.-R.; Jing, X.-B.; Zhao, P.-H. Novel P/N/Si/S-containing Mononickel Complex as a Metal-based Intumescent Flame Retardant for Cotton Fabrics. Fibers Polym. 2019, 20, 1794–1802. [Google Scholar] [CrossRef]

- Manfredi, A.; Carosio, F.; Ferruti, P.; Alongi, J.; Ranucci, E. Disulfide-containing polyamidoamines with remarkable flame retardant activity for cotton fabrics. Polym. Degrad. Stab. 2018, 156, 1–13. [Google Scholar] [CrossRef]

- Li, P.; Wang, B.; Xu, Y.-J.; Jiang, Z.; Dong, C.; Liu, Y.; Zhu, P. Ecofriendly Flame-Retardant Cotton Fabrics: Preparation, Flame Retardancy, Thermal Degradation Properties, and Mechanism. ACS Sustain. Chem. Eng. 2019, 7, 19246–19256. [Google Scholar] [CrossRef]

- Li, D.; Wang, Z.; Zhu, Y.; You, F.; Zhou, S.; Li, G.; Zhang, X.; Zhou, C. Synergistically improved flame retardancy of the cotton fabric finished by silica-coupling agent-zinc borate hybrid sol. J. Ind. Text. 2022, 51, 8297S–8322S. [Google Scholar] [CrossRef]

- Cheng, X.; Shi, L.; Fan, Z.; Yu, Y.; Liu, R. Bio-based coating of phytic acid, chitosan, and biochar for flame-retardant cotton fabrics. Polym. Degrad. Stab. 2022, 199, 109898. [Google Scholar] [CrossRef]

- Gaan, S.; Sun, G. Effect of phosphorus flame retardants on thermo-oxidative decomposition of cotton. Polym. Degrad. Stab. 2007, 92, 968–974. [Google Scholar] [CrossRef]

- Camlibel, N.O.; Avinc, O.; Arik, B.; Yavas, A.; Yakin, I. The effects of huntite–hydromagnesite inclusion in acrylate-based polymer paste coating process on some textile functional performance properties of cotton fabric. Cellulose 2019, 26, 1367–1381. [Google Scholar] [CrossRef]

- Parmar, M.S.; Chakraborty, M. Thermal and Burning Behavior of Naturally Colored Cotton. Text. Res. J. 2001, 71, 1099–1102. [Google Scholar] [CrossRef]

- Alaybeyoglu, E.; Duran, K.; Körlü, A. Flammability Behaviours of Knitted Fabrics Containing PLA, Cotton, Lyocell, Chitosan Fibers. Mugla J. Sci. Technol. 2022, 8, 1–8. [Google Scholar] [CrossRef]

- Babrauskas, V. Upholstered Furniture Heat Release Rates: Measurements and Estimation. J. Fire Sci. 1983, 1, 9–32. [Google Scholar] [CrossRef]

- Babrauskas, V.; Baroudi, D.; Myllymäki, J.; Kokkala, M. The Cone Calorimeter Used for Predictions of the Full-scale Burning Behaviour of Upholstered Furniture. Fire Mater. 1997, 21, 95–105. [Google Scholar] [CrossRef]

- Hirschler, M.M. Polyurethane foam and fire safety. Polym. Adv. Technol. 2008, 19, 521–529. [Google Scholar] [CrossRef]

- Alongi, J.; Tata, J.; Carosio, F.; Rosace, G.; Frache, A.; Camino, G. A Comparative Analysis of Nanoparticle Adsorption as Fire-Protection Approach for Fabrics. Polymers 2014, 7, 47–68. [Google Scholar] [CrossRef] [Green Version]

- Tata, J.; Alongi, J.; Carosio, F.; Frache, A. Optimization of the procedure to burn textile fabrics by cone calorimeter: Part I. Combustion behavior of polyester. Fire Mater. 2011, 35, 397–409. [Google Scholar] [CrossRef]

- Tata, J.; Alongi, J.; Frache, A. Optimization of the procedure to burn textile fabrics by cone calorimeter: Part II. Results on nanoparticle-finished polyester. Fire Mater. 2012, 36, 527–536. [Google Scholar] [CrossRef]

- ISO 5659; Plastics—Smoke Generation—Part 1: Guidance on Optical-Density Testing 1996 + Part 2: Determination of Optical Density by a Single-Chamber Test 2002. International Organization for Standardization: Geneva, Switzerland, 2017.

- ISO 5660; Fire Test, Reaction to Fire—Part 1: Rate of Heat Release (Cone Calorimeter Method) + Part 2: Smoke Production Rate (Dynamic Measurement) + Part 3: Guidance on Measurement 2002 and 2003. International Organization for Standardization: Geneva, Switzerland, 2015.

- ISO 9239; Reaction to Fire Tests for Floorings—Part 1: Determination of the Burning Behaviour Using a Radiant Heat Source + Part 2: Determination of Flame Spread at a Heat Flux Level of 25 kW/m2 2002. International Organization for Standardization: Geneva, Switzerland, 2010.

- Nazaré, S.; Kandola, B.; Horrocks, A.R. Use of cone calorimetry to quantify the burning hazard of apparel fabrics. Fire Mater. 2002, 26, 191–199. [Google Scholar] [CrossRef]

- Babrauskas, V.; Peacock, R.D. Heat release rate: The single most important variable in fire hazard. Fire Saf. J. 1992, 18, 255–272. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, X.; Zhang, F.; Richard Horrocks, A. Estimation of heat release rate for polymer–filler composites by cone calorimetry. Polym. Test. 2004, 23, 225–230. [Google Scholar] [CrossRef]

- Quan, Y.; Zhang, Z.; Tanchak, R.N.; Wang, Q. A review on cone calorimeter for assessment of flame-retarded polymer composites. J. Therm. Anal. Calorim. 2022, 147, 10209–10234. [Google Scholar] [CrossRef]

- Gann, R.G.; Babrauskas, V.; Peacock, R.D.; Hall, J.R. Fire conditions for smoke toxicity measurement. Fire Mater. 1994, 18, 193–199. [Google Scholar] [CrossRef]

- Nazaré, S.; Kandola, B.K.; Horrocks, A.R. Smoke, CO, and CO2 Measurements and Evaluation using Different Fire Testing Techniques for Flame Retardant Unsaturated Polyester Resin Formulations. J. Fire Sci. 2008, 26, 215–242. [Google Scholar] [CrossRef]

- Hernandez, N.; Sonnier, R.; Giraud, S. Influence of grammage on heat release rate of polypropylene fabrics. J. Fire Sci. 2018, 36, 30–46. [Google Scholar] [CrossRef]

- Gou, T.; Wu, X.; Zhao, Q.; Chang, S.; Wang, P. Novel phosphorus/nitrogen-rich oligomer with numerous reactive groups for durable flame-retardant cotton fabric. Cellulose 2021, 28, 7405–7419. [Google Scholar] [CrossRef]

- Li, S.; Zhong, L.; Huang, S.; Wang, D.; Zhang, F.; Zhang, G. A novel flame retardant with reactive ammonium phosphate groups and polymerizing ability for preparing durable flame retardant and stiff cotton fabric. Polym. Degrad. Stab. 2019, 164, 145–156. [Google Scholar] [CrossRef]

- Wan, C.; Liu, S.; Chen, Y.; Zhang, F. Facile, one–pot, formaldehyde-free synthesis of reactive N P flame retardant for a biomolecule of cotton. Int. J. Biol. Macromol. 2020, 163, 1659–1668. [Google Scholar] [CrossRef] [PubMed]

- Alongi, J.; Carosio, F.; Frache, A.; Malucelli, G. Layer by Layer coatings assembled through dipping, vertical or horizontal spray for cotton flame retardancy. Carbohydr. Polym. 2013, 92, 114–119. [Google Scholar] [CrossRef]

- Guo, W.; Wang, X.; Huang, J.; Zhou, Y.; Cai, W.; Wang, J.; Song, L.; Hu, Y. Construction of durable flame-retardant and robust superhydrophobic coatings on cotton fabrics for water-oil separation application. Chem. Eng. J. 2020, 398, 125661. [Google Scholar] [CrossRef]

- Li, Z.-F.; Zhang, C.-J.; Cui, L.; Zhu, P.; Yan, C.; Liu, Y. Fire retardant and thermal degradation properties of cotton fabrics based on APTES and sodium phytate through layer-by-layer assembly. J. Anal. Appl. Pyrolysis 2017, 123, 216–223. [Google Scholar] [CrossRef]

- Alongi, J.; Malucelli, G. Cotton fabrics treated with novel oxidic phases acting as effective smoke suppressants. Carbohydr. Polym. 2012, 90, 251–260. [Google Scholar] [CrossRef]

- Alongi, J.; Cuttica, F.; Carosio, F.; Bourbigot, S. How much the fabric grammage may affect cotton combustion? Cellulose 2015, 22, 3477–3489. [Google Scholar] [CrossRef]

- Grancaric, A.M.; Colleoni, C.; Guido, E.; Botteri, L.; Rosace, G. Thermal behaviour and flame retardancy of monoethanolamine-doped sol-gel coatings of cotton fabric. Prog. Org. Coat. 2017, 103, 174–181. [Google Scholar] [CrossRef]

- Yang, C.Q.; He, Q.; Lyon, R.E.; Hu, Y. Investigation of the flammability of different textile fabrics using micro-scale combustion calorimetry. Polym. Degrad. Stab. 2010, 95, 108–115. [Google Scholar] [CrossRef]

- Laufer, G.; Carosio, F.; Martinez, R.; Camino, G.; Grunlan, J.C. Growth and fire resistance of colloidal silica-polyelectrolyte thin film assemblies. J. Colloid Interface Sci. 2011, 356, 69–77. [Google Scholar] [CrossRef]

- Ma, Z.; Zhang, Z.; Zhao, F.; Wang, Y. A multifunctional coating for cotton fabrics integrating superior performance of flame-retardant and self-cleaning. Adv. Compos. Hybrid Mater. 2022, 5, 2817–2833. [Google Scholar] [CrossRef]

- Xing, W.; Jie, G.; Song, L.; Hu, S.; Lv, X.; Wang, X.; Hu, Y. Flame retardancy and thermal degradation of cotton textiles based on UV-curable flame retardant coatings. Thermochim. Acta 2011, 513, 75–82. [Google Scholar] [CrossRef]

- Ur Rehman, Z.; Huh, S.-H.; Ullah, Z.; Pan, Y.-T.; Churchill, D.G.; Koo, B.H. LBL generated fire retardant nanocomposites on cotton fabric using cationized starch-clay-nanoparticles matrix. Carbohydr. Polym. 2021, 274, 118626. [Google Scholar] [CrossRef]

- Chang, S.; Condon, B.; Nam, S. Development of Flame-Resistant Cotton Fabrics with Casein Using Pad-dry-cure and Supercritical Fluids Methods. Int. J. Mater. Sci. Appl. 2020, 9, 53. [Google Scholar] [CrossRef]

- Kaurin, T.; Pušić, T.; Dekanić, T.; Flinčec Grgac, S. Impact of Washing Parameters on Thermal Characteristics and Appearance of Proban®—Flame Retardant Material. Materials 2022, 15, 5373. [Google Scholar] [CrossRef]

- Krishnasamy, S.; Thiagamani, S.M.K.; Muthu Kumar, C.; Nagarajan, R.; Shahroze, R.M.; Siengchin, S.; Ismail, S.O.; Devi, I. Recent advances in thermal properties of hybrid cellulosic fiber reinforced polymer composites. Int. J. Biol. Macromol. 2019, 141, 1–13. [Google Scholar] [CrossRef]

- Neto, J.; Queiroz, H.; Aguiar, R.; Lima, R.; Cavalcanti, D.; Doina Banea, M. A Review of Recent Advances in Hybrid Natural Fiber Reinforced Polymer Composites. J. Renew. Mater. 2022, 10, 561–589. [Google Scholar] [CrossRef]

- Price, D.; Horrocks, A.R.; Akalin, M.; Faroq, A.A. Influence of flame retardants on the mechanism of pyrolysis of cotton (cellulose) fabrics in air. J. Anal. Appl. Pyrolysis 1997, 40–41, 511–524. [Google Scholar] [CrossRef]

- Alongi, J.; Colleoni, C.; Rosace, G.; Malucelli, G. Sol–gel derived architectures for enhancing cotton flame retardancy: Effect of pure and phosphorus-doped silica phases. Polym. Degrad. Stab. 2014, 99, 92–98. [Google Scholar] [CrossRef]

- Alongi, J.; Carosio, F.; Malucelli, G. Influence of ammonium polyphosphate-/poly(acrylic acid)-based layer by layer architectures on the char formation in cotton, polyester and their blends. Polym. Degrad. Stab. 2012, 97, 1644–1653. [Google Scholar] [CrossRef]

- Montava-Jordà, S.; Torres-Giner, S.; Ferrandiz-Bou, S.; Quiles-Carrillo, L.; Montanes, N. Development of Sustainable and Cost-Competitive Injection-Molded Pieces of Partially Bio-Based Polyethylene Terephthalate through the Valorization of Cotton Textile Waste. Int. J. Mol. Sci. 2019, 20, 1378. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, S.; Liu, J.; Sun, L.; Wang, H.; Zhu, P.; Dong, C. Preparation of flame-retardant/dyed cotton fabrics: Flame retardancy, dyeing performance and flame retardant/dyed mechanism. Cellulose 2020, 27, 10425–10440. [Google Scholar] [CrossRef]

- Sánchez-Jiménez, P.E.; Pérez-Maqueda, L.A.; Crespo-Amorós, J.E.; López, J.; Perejón, A.; Criado, J.M. Quantitative Characterization of Multicomponent Polymers by Sample-Controlled Thermal Analysis. Anal. Chem. 2010, 82, 8875–8880. [Google Scholar] [CrossRef] [Green Version]

- Šimkovic, I. TG/DTG/DTA evaluation of flame retarded cotton fabrics and comparison to cone calorimeter data. Carbohydr. Polym. 2012, 90, 976–981. [Google Scholar] [CrossRef]

- Davies, D.; Horrocks, A.R.; Greenhalgh, M. Ignition studies on cotton cellulose by DTA. Thermochim. Acta 1983, 63, 351–362. [Google Scholar] [CrossRef]

- Shafizadeh, F.; Bradbury, A.G.W.; DeGroot, W.F.; Aanerud, T.W. Role of inorganic additives in the smoldering combustion of cotton cellulose. Ind. Eng. Chem. Prod. Res. Dev. 1982, 21, 97–101. [Google Scholar] [CrossRef]

- Ghanadpour, M.; Carosio, F.; Wågberg, L. Ultrastrong and flame-resistant freestanding films from nanocelluloses, self-assembled using a layer-by-layer approach. Appl. Mater. Today 2017, 9, 229–239. [Google Scholar] [CrossRef]

- Li, J.; Jiang, W. Synthesis of a novel P-N flame retardant for preparing flame retardant and durable cotton fabric. Ind. Crops Prod. 2021, 174, 114205. [Google Scholar] [CrossRef]

- Li, Q.-L.; Huang, F.-Q.; Wei, Y.-J.; Wu, J.-Z.; Zhou, Z.; Liu, G. A Phosphorus-Nitrogen Flame-retardant: Synthesis and Application in Cotton Fabrics. Mater. Sci. 2018, 24, 448–452. [Google Scholar] [CrossRef] [Green Version]

- Gaan, S.; Sun, G. Effect of phosphorus and nitrogen on flame retardant cellulose: A study of phosphorus compounds. J. Anal. Appl. Pyrolysis 2007, 78, 371–377. [Google Scholar] [CrossRef]

- Lawler, T.E.; Drews, M.J.; Barker, R.H. Pyrolysis and combustion of cellulose. VIII. Thermally initiated reactions of phosphonomethyl amide flame retardants. J. Appl. Polym. Sci. 1985, 30, 2263–2277. [Google Scholar] [CrossRef]

- Teli, M.; Pandit, P. Development of thermally stable and hygienic colored cotton fabric made by treatment with natural coconut shell extract. J. Ind. Text. 2018, 48, 87–118. [Google Scholar] [CrossRef] [Green Version]

- El Messoudi, M.; Boukhriss, A.; Bentis, A.; El Bouchti, M.; Ait Chaoui, M.; El Kouali, M.; Gmouh, S. Flame retardant finishing of cotton fabric based on ionic liquid compounds containing boron prepared with the sol-gel method. J. Coat. Technol. Res. 2022, 19, 1609–1619. [Google Scholar] [CrossRef]

- Zhu, P.; Sui, S.; Wang, B.; Sun, K.; Sun, G. A study of pyrolysis and pyrolysis products of flame-retardant cotton fabrics by DSC, TGA, and PY–GC–MS. J. Anal. Appl. Pyrolysis 2004, 71, 645–655. [Google Scholar] [CrossRef]

- Bourbigot, S.; Chlebicki, S.; Mamleev, V. Thermal degradation of cotton under linear heating. Polym. Degrad. Stab. 2002, 78, 57–62. [Google Scholar] [CrossRef]

- Tian, C.M.; Shi, Z.H.; Zhang, H.Y.; Xu, J.Z.; Shi, J.R.; Guo, H.Z. Thermal degradation of cotton cellulose. J. Therm. Anal. Calorim. 1999, 55, 93–98. [Google Scholar] [CrossRef]

- Nakanishi, S.; Masuko, F.; Hori, K.; Hashimoto, T. Pyrolytic Gas Generation of Cotton Cellulose With and Without Flame Retardants at Different Stages of Thermal Degradation: Effects of Nitrogen, Phosphorus, and Halogens. Text. Res. J. 2000, 70, 574–583. [Google Scholar] [CrossRef]

- Gaan, S.; Sun, G. Effect of nitrogen additives on thermal decomposition of cotton. J. Anal. Appl. Pyrolysis 2009, 84, 108–115. [Google Scholar] [CrossRef]

- Kang, M.; Chen, S.; Yang, R.; Li, D.; Zhang, W. Fabrication of an Eco-Friendly Clay-Based Coating for Enhancing Flame Retardant and Mechanical Properties of Cotton Fabrics via LbL Assembly. Polymers 2022, 14, 4994. [Google Scholar] [CrossRef] [PubMed]

- Weil, E.D.; Levchik, S. Current Practice and Recent Commercial Developments in Flame Retardancy of Polyamides. J. Fire Sci. 2004, 22, 251–264. [Google Scholar] [CrossRef]

- Granzow, A. Flame retardation by phosphorus compounds. Acc. Chem. Res. 1978, 11, 177–183. [Google Scholar] [CrossRef]

- MOSTASHARI, S.M.; FAYYAZ, F. A Thermogravimetric Study of Cotton Fabric Flame-Retardancy by Means of Impregnation with Red Phosphorus. Chin. J. Chem. 2008, 26, 1030–1034. [Google Scholar] [CrossRef]

- Mostashari, S.M.; Baie, S. TG studies of synergism between red phosphorus (RP)–calcium chloride used in flame-retardancy for a cotton fabric favorable to green chemistry. J. Therm. Anal. Calorim. 2010, 99, 431–436. [Google Scholar] [CrossRef]

- Mostashari, S.M.; Fayyaz, F. A Combination of Red Phosphorus-Zinc Chloride for Flame-Retardancy of a Cotton Fabric. Int. J. Polym. Mater. 2007, 57, 125–131. [Google Scholar] [CrossRef]

- Mngomezulu, M.E.; John, M.J.; Jacobs, V.; Luyt, A.S. Review on flammability of biofibres and biocomposites. Carbohydr. Polym. 2014, 111, 149–182. [Google Scholar] [CrossRef]

- Lee, H.C.; Lee, S. Flame retardancy for cotton cellulose treated with H3PO3. J. Appl. Polym. Sci. 2018, 135, 46497. [Google Scholar] [CrossRef]

- Lin, D.; Zeng, X.; Li, H.; Lai, X.; Wu, T. One-pot fabrication of superhydrophobic and flame-retardant coatings on cotton fabrics via sol-gel reaction. J. Colloid Interface Sci. 2019, 533, 198–206. [Google Scholar] [CrossRef]

- Wang, D.; Ma, J.; Liu, J.; Tian, A.; Fu, S. Intumescent flame-retardant and ultraviolet-blocking coating screen-printed on cotton fabric. Cellulose 2021, 28, 2495–2504. [Google Scholar] [CrossRef]

- Lu, S.-Y.; Hamerton, I. Recent developments in the chemistry of halogen-free flame retardant polymers. Prog. Polym. Sci. 2002, 27, 1661–1712. [Google Scholar] [CrossRef]

- Zhang, Q.-H.; Zhang, W.; Chen, G.-Q.; Xing, T.-L. Combustion properties of cotton fabric treated by boron doped silica sol. Therm. Sci. 2015, 19, 1345–1348. [Google Scholar] [CrossRef]

- Zhu, W.; Yang, M.; Huang, H.; Dai, Z.; Cheng, B.; Hao, S. A phytic acid-based chelating coordination embedding structure of phosphorus–boron–nitride synergistic flame retardant to enhance durability and flame retardancy of cotton. Cellulose 2020, 27, 4817–4829. [Google Scholar] [CrossRef]

- Nine, M.J.; Tran, D.N.H.; Tung, T.T.; Kabiri, S.; Losic, D. Graphene-Borate as an Efficient Fire Retardant for Cellulosic Materials with Multiple and Synergetic Modes of Action. ACS Appl. Mater. Interfaces 2017, 9, 10160–10168. [Google Scholar] [CrossRef]

- Mostashari, S.M.; Fayyaz, F. TG of a cotton fabric impregnated by sodium borate decahydrate (Na2B4O7·10H2O) as a flame-retardant. J. Therm. Anal. Calorim. 2008, 93, 933–936. [Google Scholar] [CrossRef]

- Tawiah, B.; Yu, B.; Yang, W.; Yuen, R.K.K.; Fei, B. Facile flame retardant finishing of cotton fabric with hydrated sodium metaborate. Cellulose 2019, 26, 4629–4640. [Google Scholar] [CrossRef]

- Akarslan, F. Investigation on Fire Retardancy Properties of Boric Acid Doped Textile Materials. Acta Phys. Pol. A 2015, 128, B-403–B-405. [Google Scholar] [CrossRef]

- Liu, H.; Du, Y.; Lei, S.; Liu, Z. Flame-retardant activity of modified boron nitride nanosheets to cotton. Text. Res. J. 2020, 90, 512–522. [Google Scholar] [CrossRef]

- Bentis, A.; Boukhriss, A.; Gmouh, S. Flame-retardant and water-repellent coating on cotton fabric by titania–boron sol–gel method. J. Sol-Gel Sci. Technol. 2020, 94, 719–730. [Google Scholar] [CrossRef]

- Shen, K.K. Review of Recent Advances on the Use of Boron-based Flame Retardants. In Polymer Green Flame Retardants; Elsevier: Amsterdam, The Netherlands, 2014; pp. 367–388. [Google Scholar]

- Global Organic Textile Standard (GOTS) 2020. Version 6.0. Available online: https://www.global-standard.org (accessed on 25 May 2023).

- Dislich, H. Glassy and crystalline systems from gels, chemical basis and technical application. J. Non. Cryst. Solids 1984, 63, 237–241. [Google Scholar] [CrossRef]

- Segal, D.L. Sol-gel processing: Routes to oxide ceramics using colloidal dispersions of hydrous oxides and alkoxide intermediates. J. Non. Cryst. Solids 1984, 63, 183–191. [Google Scholar] [CrossRef]

- Brinker, C.J.; Scherer, G.W. The Physics and Chemistry of Sol–Gel Processing; Academic Press: New York, NY, USA, 1990. [Google Scholar]

- Sfameni, S.; Hadhri, M.; Rando, G.; Drommi, D.; Rosace, G.; Trovato, V.; Plutino, M.R. Inorganic Finishing for Textile Fabrics: Recent Advances in Wear-Resistant, UV Protection and Antimicrobial Treatments. Inorganics 2023, 11, 19. [Google Scholar] [CrossRef]

- Sfameni, S.; Del Tedesco, A.; Rando, G.; Truant, F.; Visco, A.; Plutino, M.R. Waterborne Eco-Sustainable Sol–Gel Coatings Based on Phytic Acid Intercalated Graphene Oxide for Corrosion Protection of Metallic Surfaces. Int. J. Mol. Sci. 2022, 23, 12021. [Google Scholar]

- Innocenzi, P. The Precursors of the Sol-Gel Process. In The Sol-to-Gel Transition. SpringerBriefs in Materials; Springer: Cham, Switzerland, 2019; pp. 7–19. [Google Scholar]

- Ielo, I.; Giacobello, F.; Castellano, A.; Sfameni, S.; Rando, G.; Plutino, M.R. Development of Antibacterial and Antifouling Innovative and Eco-Sustainable Sol–Gel Based Materials: From Marine Areas Protection to Healthcare Applications. Gels 2022, 8, 26. [Google Scholar]

- Giacobello, F.; Ielo, I.; Belhamdi, H.; Plutino, M.R. Geopolymers and Functionalization Strategies for the Development of Sustainable Materials in Construction Industry and Cultural Heritage Applications: A Review. Materials 2022, 15, 1725. [Google Scholar] [CrossRef]

- Sfameni, S.; Rando, G.; Marchetta, A.; Scolaro, C.; Cappello, S.; Urzì, C.; Visco, A.; Plutino, M.R. Development of Eco-Friendly Hydrophobic and Fouling-Release Coatings for Blue-Growth Environmental Applications: Synthesis, Mechanical Characterization and Biological Activity. Gels 2022, 8, 528. [Google Scholar] [CrossRef]

- Figueira, R.B.; Silva, C.J.R.; Pereira, E.V. Organic–inorganic hybrid sol–gel coatings for metal corrosion protection: A review of recent progress. J. Coat. Technol. Res. 2014, 12, 1–35. [Google Scholar] [CrossRef]

- Mahltig, B.; Textor, T. Nanosols and Textiles; World Scientific Publishing Co. Pte. Ltd.: Singapore, 2008. [Google Scholar]

- Sfameni, S.; Rando, G.; Plutino, M.R. Sustainable Secondary-Raw Materials, Natural Substances and Eco-Friendly Nanomaterial-Based Approaches for Improved Surface Performances: An Overview of What They Are and How They Work. Int. J. Mol. Sci. 2023, 24, 5472. [Google Scholar] [CrossRef]

- Sakka, S. (Ed.) Sol-Gel Science and Technology: Topics and Fundamental Research and Applications; Kluwer Academic Publishers: Norwell, Australia, 2003; ISBN 978-1402072918. [Google Scholar]

- Colleoni, C.; Guido, E.; Migani, V.; Rosace, G. Hydrophobic behaviour of non-fluorinated sol-gel based cotton and polyester fabric coatings. J. Ind. Text. 2015, 44, 815–834. [Google Scholar] [CrossRef]

- Sfameni, S.; Lawnick, T.; Rando, G.; Visco, A.; Textor, T.; Plutino, M.R. Super-Hydrophobicity of Polyester Fabrics Driven by Functional Sustainable Fluorine-Free Silane-Based Coatings. Gels 2023, 9, 109. [Google Scholar] [CrossRef] [PubMed]

- Guido, E.; Colleoni, C.; De Clerck, K.; Plutino, M.R.; Rosace, G. Influence of catalyst in the synthesis of a cellulose-based sensor: Kinetic study of 3-glycidoxypropyltrimethoxysilane epoxy ring opening by Lewis acid. Sens. Actuators B Chem. 2014, 203, 213–222. [Google Scholar] [CrossRef]

- Min, L.; Xiaoli, Z.; Shuilin, C. Enhancing the wash fastness of dyeings by a sol-gel process. Part 1; Direct dyes on cotton. Color. Technol. 2003, 119, 297–300. [Google Scholar] [CrossRef]

- Schramm, C.; Binder, W.H.; Tessadri, R. Durable Press Finishing of Cotton Fabric with 1,2,3,4-Butanetetracarboxylic Acid and TEOS/GPTMS. J. Sol-Gel Sci. Technol. 2004, 29, 155–165. [Google Scholar] [CrossRef]

- Haufe, H.; Muschter, K.; Siegert, J.; Böttcher, H. Bioactive textiles by sol–gel immobilised natural active agents. J. Sol-Gel Sci. Technol. 2008, 45, 97–101. [Google Scholar] [CrossRef]

- El-Hady, M.M.A.; Farouk, A.; Sharaf, S. Flame retardancy and UV protection of cotton based fabrics using nano ZnO and polycarboxylic acids. Carbohydr. Polym. 2013, 92, 400–406. [Google Scholar] [CrossRef]

- Colleoni, C.; Massafra, M.R.; Rosace, G. Photocatalytic properties and optical characterization of cotton fabric coated via sol–gel with non-crystalline TiO2 modified with poly(ethylene glycol). Surf. Coat. Technol. 2012, 207, 79–88. [Google Scholar] [CrossRef]

- Sfameni, S.; Lawnick, T.; Rando, G.; Visco, A.; Textor, T.; Plutino, M.R. Functional Silane-Based Nanohybrid Materials for the Development of Hydrophobic and Water-Based Stain Resistant Cotton Fabrics Coatings. Nanomaterials 2022, 12, 3404. [Google Scholar] [CrossRef] [PubMed]

- Sfameni, S.; Rando, G.; Plutino, M.R. Perspective Chapter: Functional Sol–Gel Based Coatings for Innovative and Sustainable Applications; Singh, D.J.P., Acharya, D.S.S., Kumar, D.S., Dixit, D.S.K., Eds.; IntechOpen: Rijeka, Croatia, 2023; p. Ch. 3. ISBN 978-1-80355-415-0. [Google Scholar]

- Poli, R.; Colleoni, C.; Calvimontes, A.; Polášková, H.; Dutschk, V.; Rosace, G. Innovative sol–gel route in neutral hydroalcoholic condition to obtain antibacterial cotton finishing by zinc precursor. J. Sol-Gel Sci. Technol. 2015, 74, 151–160. [Google Scholar] [CrossRef]

- Alongi, J.; Malucelli, G. Cotton flame retardancy: State of the art and future perspectives. RSC Adv. 2015, 5, 24239–24263. [Google Scholar] [CrossRef]

- Hench, L.L.; West, J.K. The sol-gel process. Chem. Rev. 1990, 90, 33–72. [Google Scholar] [CrossRef]

- Pierre, A. Introduction to Sol-Gel Processing; The Kluwer International Series in Sol-Gel Processing: Technology and Applications; Springer: Boston, MA, USA, 1998; ISBN 978-0-7923-8121-1. [Google Scholar]

- Malucelli, G.; Carosio, F.; Alongi, J.; Fina, A.; Frache, A.; Camino, G. Materials engineering for surface-confined flame retardancy. Mater. Sci. Eng. R Rep. 2014, 84, 1–20. [Google Scholar] [CrossRef]

- Alongi, J.; Ciobanu, M.; Malucelli, G. Thermal stability, flame retardancy and mechanical properties of cotton fabrics treated with inorganic coatings synthesized through sol–gel processes. Carbohydr. Polym. 2012, 87, 2093–2099. [Google Scholar] [CrossRef]

- Cireli, A.; Onar, N.; Ebeoglugil, M.F.; Kayatekin, I.; Kutlu, B.; Culha, O.; Celik, E. Development of flame retardancy properties of new halogen-free phosphorous doped SiO2 thin films on fabrics. J. Appl. Polym. Sci. 2007, 105, 3748–3756. [Google Scholar] [CrossRef]

- Alongi, J.; Ciobanu, M.; Tata, J.; Carosio, F.; Malucelli, G. Thermal stability and flame retardancy of polyester, cotton, and relative blend textile fabrics subjected to sol-gel treatments. J. Appl. Polym. Sci. 2011, 119, 1961–1969. [Google Scholar] [CrossRef]

- Colleoni, C.; Donelli, I.; Freddi, G.; Guido, E.; Migani, V.; Rosace, G. A novel sol-gel multi-layer approach for cotton fabric finishing by tetraethoxysilane precursor. Surf. Coat. Technol. 2013, 235, 192–203. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, Z.; Zhou, S.; You, F.; Li, D.; Zhou, C.; Pan, Y.; Wang, J. Enhanced flame retardancy level of a cotton fabric treated by an ammonium pentaborate doped silica-KH570 sol. J. Ind. Text. 2022, 52, 152808372211165. [Google Scholar] [CrossRef]

- Alongi, J.; Ciobanu, M.; Malucelli, G. Sol–gel treatments for enhancing flame retardancy and thermal stability of cotton fabrics: Optimisation of the process and evaluation of the durability. Cellulose 2011, 18, 167–177. [Google Scholar] [CrossRef]

- Alongi, J.; Malucelli, G. Thermal Degradation of Cellulose and Cellulosic Substrates; Wiley: Hoboken, NJ, USA, 2015. [Google Scholar]

- Alongi, J.; Ciobanu, M.; Malucelli, G. Sol–gel treatments on cotton fabrics for improving thermal and flame stability: Effect of the structure of the alkoxysilane precursor. Carbohydr. Polym. 2012, 87, 627–635. [Google Scholar] [CrossRef] [PubMed]

- Birnbaum, L.S.; Staskal, D.F. Brominated flame retardants: Cause for concern? Environ. Health Perspect. 2004, 112, 9–17. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Barcelo, D.; Kostianoy, A.G. Handbook environmental chemistry. In Brominated Flame Retardants; Heidelberg, S.-V.B., Ed.; Springer: New York, NY, USA, 2011; Volume 16. [Google Scholar]

- Alongi, J.; Carosio, F. All-inorganic intumescent nanocoating containing montmorillonite nanoplatelets in ammonium polyphosphate matrix capable of preventing cotton ignition. Polymers 2016, 8, 430. [Google Scholar] [CrossRef]

- Kiliaris, P.; Papaspyrides, C.D. Polymer/layered silicate (clay) nanocomposites: An overview of flame retardancy. Prog. Polym. Sci. 2010, 35, 902–958. [Google Scholar] [CrossRef]

- Alongi, J.; Carosio, F.; Kiekens, P. Recent Advances in the Design of Water Based-Flame Retardant Coatings for Polyester and Polyester-Cotton Blends. Polymers 2016, 8, 357. [Google Scholar] [CrossRef]

- Carosio, F.; Alongi, J. Ultra-Fast Layer-by-Layer Approach for Depositing Flame Retardant Coatings on Flexible PU Foams within Seconds. ACS Appl. Mater. Interfaces 2016, 8, 6315–6319. [Google Scholar] [CrossRef]

- Carosio, F.; Alongi, J.; Malucelli, G. Flammability and combustion properties of ammonium polyphosphate-/poly(acrylic acid)- based layer by layer architectures deposited on cotton, polyester and their blends. Polym. Degrad. Stab. 2013, 98, 1626–1637. [Google Scholar] [CrossRef]

- Alongi, J.; Han, Z.; Bourbigot, S. Intumescence: Tradition versus novelty. A comprehensive review. Prog. Polym. Sci. 2015, 51, 28–73. [Google Scholar] [CrossRef]

- Hall, P.L. The application of electron spin resonance spectroscopy to studies of clay minerals: I. Isomorphous substitutions and external surface properties. Clay Miner. 1980, 15, 321–335. [Google Scholar] [CrossRef]

- Murray, H.H. Chapter 2 Structure and Composition of the Clay Minerals and their Physical and Chemical Properties. In Developments in Clay Science; Elsevier: Amsterdam, The Netherlands, 2006; pp. 7–31. [Google Scholar]

- Bergaya, F.; Lagaly, G. Chapter 1 General Introduction: Clays, Clay Minerals, and Clay Science. In Developments in Clay Science; Elsevier: Amsterdam, The Netherlands, 2006; pp. 1–18. [Google Scholar]

- Rando, G.; Sfameni, S.; Galletta, M.; Drommi, D.; Cappello, S.; Plutino, M.R. Functional Nanohybrids and Nanocomposites Development for the Removal of Environmental Pollutants and Bioremediation. Molecules 2022, 27, 4856. [Google Scholar] [CrossRef]

- Kotal, M.; Bhowmick, A.K. Polymer nanocomposites from modified clays: Recent advances and challenges. Prog. Polym. Sci. 2015, 51, 127–187. [Google Scholar] [CrossRef] [Green Version]

- Murray, H.H. Overview—Clay mineral applications. Appl. Clay Sci. 1991, 5, 379–395. [Google Scholar] [CrossRef]

- Kloprogge, J.T. Synthesis of Smectites and Porous Pillared Clay Catalysts: A Review. J. Porous Mater. 1998, 5, 5–41. [Google Scholar] [CrossRef]

- Ielo, I.; Galletta, M.; Rando, G.; Sfameni, S.; Cardiano, P.; Sabatino, G.; Drommi, D.; Rosace, G.; Plutino, M.R. Design, synthesis and characterization of hybrid coatings suitable for geopolymeric-based supports for the restoration of cultural heritage. IOP Conf. Ser. Mater. Sci. Eng. 2020, 777, 012003. [Google Scholar] [CrossRef]

- Masini, J.C.; Abate, G. Guidelines to Study the Adsorption of Pesticides onto Clay Minerals Aiming at a Straightforward Evaluation of Their Removal Performance. Minerals 2021, 11, 1282. [Google Scholar] [CrossRef]

- Perelomov, L.; Mandzhieva, S.; Minkina, T.; Atroshchenko, Y.; Perelomova, I.; Bauer, T.; Pinsky, D.; Barakhov, A. The Synthesis of Organoclays Based on Clay Minerals with Different Structural Expansion Capacities. Minerals 2021, 11, 707. [Google Scholar] [CrossRef]

- Undabeytia, T.; Shuali, U.; Nir, S.; Rubin, B. Applications of Chemically Modified Clay Minerals and Clays to Water Purification and Slow Release Formulations of Herbicides. Minerals 2020, 11, 9. [Google Scholar] [CrossRef]

- Jacquet, A.; Geatches, D.; Clark, S.; Greenwell, H. Understanding Cationic Polymer Adsorption on Mineral Surfaces: Kaolinite in Cement Aggregates. Minerals 2018, 8, 130. [Google Scholar] [CrossRef] [Green Version]

- Lazorenko, G.; Kasprzhitskii, A.; Yavna, V. Comparative Study of the Hydrophobicity of Organo-Montmorillonite Modified with Cationic, Amphoteric and Nonionic Surfactants. Minerals 2020, 10, 732. [Google Scholar] [CrossRef]

- Li, A.; Wang, A.-Q.; Chen, J.-M. Preparation and Properties of Poly (acrylic acid-potassium acrylate)/Attapulgite Superabsorbent Composite. J. Funct. Polym. 2004, 17, 200–206. [Google Scholar]

- Taylor, R.K.; Smith, T.J. The engineering geology of clay minerals: Swelling, shrinking and mudrock breakdown. Clay Miner. 1986, 21, 235–260. [Google Scholar] [CrossRef]

- Chi, M. Cation Exchange Capacity of Kaolinite. Clays Clay Miner. 1999, 47, 174–180. [Google Scholar] [CrossRef]

- Theng, B.K.G. Formation and Properties of Clay-Polymer Complexes; Elsevier: Amsterdam, The Netherlands, 2012; ISBN 9780080885278. [Google Scholar]

- Rezaei, A.; Daeihamed, M.; Capanoglu, E.; Tomas, M.; Akbari-Alavijeh, S.; Shaddel, R.; Khoshnoudi-Nia, S.; Boostani, S.; Rostamabadi, H.; Falsafi, S.R.; et al. Possible health risks associated with nanostructures in food. In Safety and Regulatory Issues of Nanoencapsulated Food Ingredients; Elsevier: Amsterdam, The Netherlands, 2021; pp. 31–118. [Google Scholar]

- Churchman, G.J.; Lowe, D.J. Alteration, formation, and occurrence of minerals in soils. In Handbook of Soil Sciences: Properties and Processes; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Chalasani, R.; Gupta, A.; Vasudevan, S. Engineering New Layered Solids from Exfoliated Inorganics: A Periodically Alternating Hydrotalcite—Montmorillonite Layered Hybrid. Sci. Rep. 2013, 3, 3498. [Google Scholar] [CrossRef] [Green Version]

- Kausar, A.; Ahmad, I.; Maaza, M.; Eisa, M.H. State-of-the-Art Nanoclay Reinforcement in Green Polymeric Nanocomposite: From Design to New Opportunities. Minerals 2022, 12, 1495. [Google Scholar] [CrossRef]

- Shan, G.; Jin, W.; Chen, H.; Zhao, M.; Surampalli, R.; Ramakrishnan, A.; Zhang, T.; Tyagi, R.D. Flame-Retardant Polymer Nanocomposites and Their Heat-Release Rates. J. Hazard. Toxic Radioact. Waste 2015, 19, 04015006. [Google Scholar] [CrossRef]

- Kang, D.J.; Park, G.U.; Park, H.Y.; Park, J.-U.; Im, H.-G. A high-performance transparent moisture barrier using surface-modified nanoclay composite for OLED encapsulation. Prog. Org. Coat. 2018, 118, 66–71. [Google Scholar] [CrossRef]

- Król-Morkisz, K.; Pielichowska, K. Thermal Decomposition of Polymer Nanocomposites With Functionalized Nanoparticles. In Polymer Composites with Functionalized Nanoparticles; Elsevier: Amsterdam, The Netherlands, 2019; pp. 405–435. [Google Scholar]

- Jayrajsinh, S.; Shankar, G.; Agrawal, Y.K.; Bakre, L. Montmorillonite nanoclay as a multifaceted drug-delivery carrier: A review. J. Drug Deliv. Sci. Technol. 2017, 39, 200–209. [Google Scholar] [CrossRef]

- Shunmugasamy, V.C.; Xiang, C.; Gupta, N. Clay/Polymer Nanocomposites: Processing, Properties, and Applications. In Hybrid and Hierarchical Composite Materials; Springer International Publishing: Cham, Switzerland, 2015; pp. 161–200. [Google Scholar]

- Khalid, M.; Walvekar, R.; Ketabchi, M.R.; Siddiqui, H.; Hoque, M.E. Rubber/Nanoclay Composites: Towards Advanced Functional Materials. In Nanoclay Reinforced Polymer Composites; Springer: Berlin/Heidelberg, Germany, 2016; pp. 209–224. [Google Scholar]

- Zare, Y.; Garmabi, H.; Sharif, F. Optimization of mechanical properties of PP/Nanoclay/CaCO3 ternary nanocomposite using response surface methodology. J. Appl. Polym. Sci. 2011, 122, 3188–3200. [Google Scholar] [CrossRef]

- Zare, Y.; Garmabi, H. Modeling of interfacial bonding between two nanofillers (montmorillonite and CaCO3) and a polymer matrix (PP) in a ternary polymer nanocomposite. Appl. Surf. Sci. 2014, 321, 219–225. [Google Scholar] [CrossRef]

- de Oliveira, C.R.S.; Batistella, M.A.; Lourenço, L.A.; de Souza, S.M.d.A.G.U.; de Souza, A.A.U. Cotton fabric finishing based on phosphate/clay mineral by direct-coating technique and its influence on the thermal stability of the fibers. Prog. Org. Coat. 2021, 150, 105949. [Google Scholar] [CrossRef]

- Furtana, S.; Mutlu, A.; Dogan, M. Thermal stability and flame retardant properties of calcium- and magnesium-hypophosphite-finished cotton fabrics and the evaluation of interaction with clay and POSS nanoparticles. J. Therm. Anal. Calorim. 2020, 139, 3415–3425. [Google Scholar] [CrossRef]

- He, H.; Tao, Q.; Zhu, J.; Yuan, P.; Shen, W.; Yang, S. Silylation of clay mineral surfaces. Appl. Clay Sci. 2013, 71, 15–20. [Google Scholar] [CrossRef]

- Romanzini, D.; Piroli, V.; Frache, A.; Zattera, A.J.; Amico, S.C. Sodium montmorillonite modified with methacryloxy and vinylsilanes: Influence of silylation on the morphology of clay/unsaturated polyester nanocomposites. Appl. Clay Sci. 2015, 114, 550–557. [Google Scholar] [CrossRef]

- Illy, N.; Fache, M.; Ménard, R.; Negrell, C.; Caillol, S.; David, G. Phosphorylation of bio-based compounds: The state of the art. Polym. Chem. 2015, 6, 6257–6291. [Google Scholar] [CrossRef] [Green Version]

- Tang, G.; Huang, X.; Ding, H.; Wang, X.; Jiang, S.; Zhou, K.; Wang, B.; Yang, W.; Hu, Y. Combustion properties and thermal degradation behaviors of biobased polylactide composites filled with calcium hypophosphite. RSC Adv. 2014, 4, 8985. [Google Scholar] [CrossRef]

- Costantino, U.; Nocchetti, M.; Sisani, M.; Vivani, R. Recent progress in the synthesis and application of organically modified hydrotalcites. Z. Für Krist. 2009, 224, 273–281. [Google Scholar] [CrossRef]

- Forano, C.; Hibino, T.; Leroux, F.; Taviot-Guého, C. Chapter 13.1 Layered Double Hydroxides. In Developments in Clay Science; Elsevier: Amsterdam, The Netherlands, 2006; pp. 1021–1095. [Google Scholar]

- Alongi, J.; Tata, J.; Frache, A. Hydrotalcite and nanometric silica as finishing additives to enhance the thermal stability and flame retardancy of cotton. Cellulose 2011, 18, 179–190. [Google Scholar] [CrossRef]

- Ishihara, S.; Sahoo, P.; Deguchi, K.; Ohki, S.; Tansho, M.; Shimizu, T.; Labuta, J.; Hill, J.P.; Ariga, K.; Watanabe, K.; et al. Dynamic Breathing of CO2 by Hydrotalcite. J. Am. Chem. Soc. 2013, 135, 18040–18043. [Google Scholar] [CrossRef]

- Wang, S.; Gainey, L.; Mackinnon, I.D.R.; Allen, C.; Gu, Y.; Xi, Y. Thermal behaviors of clay minerals as key components and additives for fired brick properties: A review. J. Build. Eng. 2023, 66, 105802. [Google Scholar] [CrossRef]

- Shmuradko, V.T.; Panteleenko, F.I.; Reut, O.P.; Panteleenko, E.F.; Kirshina, N.V. Composition, structure, and property formation of heat insulation fire- and heat-reflecting materials based on vermiculite for industrial power generation. Refract. Ind. Ceram. 2012, 53, 254–258. [Google Scholar] [CrossRef]

- Addison, J. Vermiculite: A Review of the Mineralogy and Health Effects of Vermiculite Exploitation. Regul. Toxicol. Pharmacol. 1995, 21, 397–405. [Google Scholar] [CrossRef] [PubMed]

- Cain, A.A.; Plummer, M.G.B.; Murray, S.E.; Bolling, L.; Regev, O.; Grunlan, J.C. Iron-containing, high aspect ratio clay as nanoarmor that imparts substantial thermal/flame protection to polyurethane with a single electrostatically-deposited bilayer. J. Mater. Chem. A 2014, 2, 17609–17617. [Google Scholar] [CrossRef]

- Suvorov, S.A.; Skurikhin, V.V. Vermiculite—A promising material for high-temperature heat insulators. Refract. Ind. Ceram. 2003, 44, 186–193. [Google Scholar] [CrossRef]

- Ortelli, S.; Malucelli, G.; Cuttica, F.; Blosi, M.; Zanoni, I.; Costa, A.L. Coatings made of proteins adsorbed on TiO2 nanoparticles: A new flame retardant approach for cotton fabrics. Cellulose 2018, 25, 2755–2765. [Google Scholar] [CrossRef]

- Ortelli, S.; Malucelli, G.; Blosi, M.; Zanoni, I.; Costa, A.L. NanoTiO2@DNA complex: A novel eco, durable, fire retardant design strategy for cotton textiles. J. Colloid Interface Sci. 2019, 546, 174–183. [Google Scholar] [CrossRef] [PubMed]

- Apaydin, K.; Laachachi, A.; Ball, V.; Jimenez, M.; Bourbigot, S.; Ruch, D. Layer-by-layer deposition of a TiO2-filled intumescent coating and its effect on the flame retardancy of polyamide and polyester fabrics. Colloids Surfaces A Physicochem. Eng. Asp. 2015, 469, 1–10. [Google Scholar] [CrossRef]

- Qin, S.; Pour, M.G.; Lazar, S.; Köklükaya, O.; Gerringer, J.; Song, Y.; Wågberg, L.; Grunlan, J.C. Super Gas Barrier and Fire Resistance of Nanoplatelet/Nanofibril Multilayer Thin Films. Adv. Mater. Interfaces 2019, 6, 1801424. [Google Scholar] [CrossRef]

- Ali, Z.A. A Seq to Seq Machine Translation from Urdu to Chinese. J. Auton. Intell. 2021, 4, 1. [Google Scholar] [CrossRef]

- Beyer, G. Short communication: Carbon nanotubes as flame retardants for polymers. Fire Mater. 2002, 26, 291–293. [Google Scholar] [CrossRef]

- Coleman, J.N.; Khan, U.; Blau, W.J.; Gun’ko, Y.K. Small but strong: A review of the mechanical properties of carbon nanotube–polymer composites. Carbon 2006, 44, 1624–1652. [Google Scholar] [CrossRef]

- Moniruzzaman, M.; Winey, K.I. Polymer Nanocomposites Containing Carbon Nanotubes. Macromolecules 2006, 39, 5194–5205. [Google Scholar] [CrossRef]

- Zare, Y.; Garmabi, H. Attempts to Simulate the Modulus of Polymer/Carbon Nanotube Nanocomposites and Future Trends. Polym. Rev. 2014, 54, 377–400. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, X.; Qi, K.; Xin, J.H. Functionalization of cotton with carbon nanotubes. J. Mater. Chem. 2008, 18, 3454. [Google Scholar] [CrossRef]

- Kashiwagi, T.; Du, F.; Douglas, J.F.; Winey, K.I.; Harris, R.H.; Shields, J.R. Nanoparticle networks reduce the flammability of polymer nanocomposites. Nat. Mater. 2005, 4, 928–933. [Google Scholar] [CrossRef] [Green Version]

- Ye, L.; Wu, Q.; Qu, B. Synergistic effects and mechanism of multiwalled carbon nanotubes with magnesium hydroxide in halogen-free flame retardant EVA/MH/MWNT nanocomposites. Polym. Degrad. Stab. 2009, 94, 751–756. [Google Scholar] [CrossRef]

- Janas, D.; Rdest, M.; Koziol, K.K.K. Flame-retardant carbon nanotube films. Appl. Surf. Sci. 2017, 411, 177–181. [Google Scholar] [CrossRef]

- Araby, S.; Philips, B.; Meng, Q.; Ma, J.; Laoui, T.; Wang, C.H. Recent advances in carbon-based nanomaterials for flame retardant polymers and composites. Compos. Part B Eng. 2021, 212, 108675. [Google Scholar] [CrossRef]

- Cho, C.; Song, Y.; Allen, R.; Wallace, K.L.; Grunlan, J.C. Stretchable electrically conductive and high gas barrier nanocomposites. J. Mater. Chem. C 2018, 6, 2095–2104. [Google Scholar] [CrossRef]

- Rizkalla, S.; Dawood, M.; Schnerch, D. Development of a carbon fiber reinforced polymer system for strengthening steel structures. Compos. Part A Appl. Sci. Manuf. 2008, 39, 388–397. [Google Scholar] [CrossRef]

- He, W.; Gao, J.; Liao, S.; Wang, X.; Qin, S.; Song, P. A facile method to improve thermal stability and flame retardancy of polyamide 6. Compos. Commun. 2019, 13, 143–150. [Google Scholar] [CrossRef]

- Lazar, S.T.; Kolibaba, T.J.; Grunlan, J.C. Flame-retardant surface treatments. Nat. Rev. Mater. 2020, 5, 259–275. [Google Scholar] [CrossRef]

- Montazer, M.; Harifi, T. Flame-retardant textile nanofinishes. In Nanofinishing of Textile Materials; Elsevier: Amsterdam, The Netherlands, 2018; pp. 163–181. [Google Scholar]

- Gonçalves, A.G.; Jarrais, B.; Pereira, C.; Morgado, J.; Freire, C.; Pereira, M.F.R. Functionalization of textiles with multi-walled carbon nanotubes by a novel dyeing-like process. J. Mater. Sci. 2012, 47, 5263–5275. [Google Scholar] [CrossRef]

- Motaghi, Z.; Shahidi, S. Improvement the Conductivity and Flame Retardant Properties of Carboxylated Single-Walled Carbon Nanotube/Cotton Fabrics Using Citric Acid and Sodium Hypophosphite. J. Nat. Fibers 2018, 15, 353–362. [Google Scholar] [CrossRef]

- Xu, J.; Niu, Y.; Xie, Z.; Liang, F.; Guo, F.; Wu, J. Synergistic flame retardant effect of carbon nanohorns and ammonium polyphosphate as a novel flame retardant system for cotton fabrics. Chem. Eng. J. 2023, 451, 138566. [Google Scholar] [CrossRef]

- Liu, H.; Du, Y.; Yang, G.; Zhu, G.; Gao, Y.; Ding, W. Flame retardance of modified graphene to pure cotton fabric. J. Fire Sci. 2018, 36, 111–128. [Google Scholar] [CrossRef]

- Norouzi, M.; Zare, Y.; Kiany, P. Nanoparticles as Effective Flame Retardants for Natural and Synthetic Textile Polymers: Application, Mechanism, and Optimization. Polym. Rev. 2015, 55, 531–560. [Google Scholar] [CrossRef]

- Cinausero, N.; Azema, N.; Lopez-Cuesta, J.-M.; Cochez, M.; Ferriol, M. Synergistic effect between hydrophobic oxide nanoparticles and ammonium polyphosphate on fire properties of poly(methyl methacrylate) and polystyrene. Polym. Degrad. Stab. 2011, 96, 1445–1454. [Google Scholar] [CrossRef]

- Rault, F.; Pleyber, E.; Campagne, C.; Rochery, M.; Giraud, S.; Bourbigot, S.; Devaux, E. Effect of manganese nanoparticles on the mechanical, thermal and fire properties of polypropylene multifilament yarn. Polym. Degrad. Stab. 2009, 94, 955–964. [Google Scholar] [CrossRef]

- Coyle, S.; Wu, Y.; Lau, K.-T.; De Rossi, D.; Wallace, G.; Diamond, D. Smart Nanotextiles: A Review of Materials and Applications. MRS Bull. 2007, 32, 434–442. [Google Scholar] [CrossRef] [Green Version]

- Sundarrajan, S.; Chandrasekaran, A.R.; Ramakrishna, S. An Update on Nanomaterials-Based Textiles for Protection and Decontamination. J. Am. Ceram. Soc. 2010, 93, 3955–3975. [Google Scholar] [CrossRef]

- Yadav, A.; Prasad, V.; Kathe, A.A.; Raj, S.; Yadav, D. Functional finishing in cotton fabrics using zinc oxide nanoparticles. Bull. Mater. Sci. 2006, 29, 641–645. [Google Scholar] [CrossRef]

- Xue, C.-H.; Yin, W.; Jia, S.-T.; Ma, J.-Z. UV-durable superhydrophobic textiles with UV-shielding properties by coating fibers with ZnO/SiO2 core/shell particles. Nanotechnology 2011, 22, 415603. [Google Scholar] [CrossRef] [PubMed]

- Dastjerdi, R.; Montazer, M. A review on the application of inorganic nano-structured materials in the modification of textiles: Focus on anti-microbial properties. Colloids Surf. B Biointerfaces 2010, 79, 5–18. [Google Scholar] [CrossRef]

- El-Nahhal, I.M.; Zourab, S.M.; Kodeh, F.S.; Selmane, M.; Genois, I.; Babonneau, F. Nanostructured copper oxide-cotton fibers: Synthesis, characterization, and applications. Int. Nano Lett. 2012, 2, 14. [Google Scholar] [CrossRef] [Green Version]

- Selvam, S.; Rajiv Gandhi, R.; Suresh, J.; Gowri, S.; Ravikumar, S.; Sundrarajan, M. Antibacterial effect of novel synthesized sulfated β-cyclodextrin crosslinked cotton fabric and its improved antibacterial activities with ZnO, TiO2 and Ag nanoparticles coating. Int. J. Pharm. 2012, 434, 366–374. [Google Scholar] [CrossRef] [PubMed]

- Esmail, W.A.; Darwish, A.M.Y.; Ibrahim, O.A.; Abadir, M.F. The effect of magnesium chloride hydrates on the fire retardation of cellulosic fibers. J. Therm. Anal Calorim. 2001, 63, 831−838. [Google Scholar] [CrossRef]

- Gulrajani, M.L.; Deepti, G. Emerging techniques for functional finishing of textile. Indian J. Fibre Text. Res. 2011, 36, 388−397. [Google Scholar]

- Moafi, H.F.; Shojaie, A.F.; Zanjanchi, M.A. Flame-retardancy and photocatalytic properties of cellulosic fabric coated by nano-sized titanium dioxide. J. Therm. Anal. Calorim. 2011, 104, 717–724. [Google Scholar] [CrossRef]

- Jolles, Z.E.; Jolles, G.I. Some notes on flame-retardant mechanisms in polymers. Plast Polym. 1972, 40, 319. [Google Scholar]

- Shen, R.; Fan, T.; Quan, Y.; Ma, R.; Zhang, Z.; Li, Y.; Wang, Q. Thermal stability and flammability of cotton fabric with TiO2 coatings based on biomineralization. Mater. Chem. Phys. 2022, 282, 125986. [Google Scholar] [CrossRef]

- Fallah, M.H.; Fallah, S.A.; Zanjanchi, M.A. Synthesis and Characterization of Nano-sized Zinc Oxide Coating on Cellulosic Fibers: Photoactivity and Flame-retardancy Study. Chin. J. Chem. 2011, 29, 1239–1245. [Google Scholar] [CrossRef]

- Prilla, K.A.V.; Jacinto, J.M.; Ricardo, L.J.O.; Box, J.T.S.; Lim, A.B.C.; Francisco, E.F.; De Vera, G.I.N.; Yaya, J.A.T.; Natividad, V.V.M.; Awi, E.N.; et al. Flame Retardant and Uv-Protective Cotton Fabrics Functionalized with Copper (II) Oxide Nanoparticles. Antorcha 2020, 7, 11–16. [Google Scholar]

- Saleemi, S.; Naveed, T.; Riaz, T.; Memon, H.; Awan, J.A.; Siyal, M.I.; Xu, F.; Bae, J. Surface Functionalization of Cotton and PC Fabrics Using SiO2 and ZnO Nanoparticles for Durable Flame Retardant Properties. Coatings 2020, 10, 124. [Google Scholar] [CrossRef] [Green Version]

- Dhineshbabu, N.R.; Manivasakan, P.; Yuvakkumar, R.; Prabu, P.; Rajendran, V. Enhanced Functional Properties of ZrO2/SiO2 Hybrid Nanosol Coated Cotton Fabrics. J. Nanosci. Nanotechnol. 2013, 13, 4017–4024. [Google Scholar] [CrossRef] [PubMed]

- Rajendran, V.; Dhineshbabu, N.R.; Kanna, R.R.; Kaler, K.V.I.S. Enhancement of Thermal Stability, Flame Retardancy, and Antimicrobial Properties of Cotton Fabrics Functionalized by Inorganic Nanocomposites. Ind. Eng. Chem. Res. 2014, 53, 19512–19524. [Google Scholar] [CrossRef]

- Frąckowiak, A.; Skibiński, P.; Gaweł, W.; Zaczyńska, E.; Czarny, A.; Gancarz, R. Synthesis of glycoside derivatives of hydroxyanthraquinone with ability to dissolve and inhibit formation of crystals of calcium oxalate. Potential compounds in kidney stone therapy. Eur. J. Med. Chem. 2010, 45, 1001–1007. [Google Scholar] [CrossRef] [PubMed]

- Małecka, B.; Drożdż-Cieśla, E.; Małecki, A. Mechanism and kinetics of thermal decomposition of zinc oxalate. Thermochim. Acta 2004, 423, 13–18. [Google Scholar] [CrossRef]

- Echigo, T.; Kimata, M.; Kyono, A.; Shimizu, M.; Hatta, T. Re-investigation of the crystal structure of whewellite [Ca(C2O4)·H2O] and the dehydration mechanism of caoxite [Ca(C2O4)·3H2O]. Mineral. Mag. 2005, 69, 77–88. [Google Scholar] [CrossRef]

- Majumdar, R.; Sarkar, P.; Ray, U.; Roy Mukhopadhyay, M. Secondary catalytic reactions during thermal decomposition of oxalates of zinc, nickel and iron(II). Thermochim. Acta 1999, 335, 43–53. [Google Scholar] [CrossRef]

- Gabal, M.; El-Bellihi, A.; El-Bahnasawy, H. Non-isothermal decomposition of zinc oxalate–iron(II) oxalate mixture. Mater. Chem. Phys. 2003, 81, 174–182. [Google Scholar] [CrossRef]

- Mohamed, M.A.; Galwey, A.K.; Halawy, S.A. A comparative study of the thermal reactivities of some transition metal oxalates in selected atmospheres. Thermochim. Acta 2005, 429, 57–72. [Google Scholar] [CrossRef]

- Vlaev, L.; Nedelchev, N.; Gyurova, K.; Zagorcheva, M. A comparative study of non-isothermal kinetics of decomposition of calcium oxalate monohydrate. J. Anal. Appl. Pyrolysis 2008, 81, 253–262. [Google Scholar] [CrossRef]

- Donkova, B.; Mehandjiev, D. Mechanism of decomposition of manganese(II) oxalate dihydrate and manganese(II) oxalate trihydrate. Thermochim. Acta 2004, 421, 141–149. [Google Scholar] [CrossRef]

- Weil, E.D.; Levchik, S.; Moy, P. Flame and Smoke Retardants in Vinyl Chloride Polymers—Commercial Usage and Current Developments. J. Fire Sci. 2006, 24, 211–236. [Google Scholar] [CrossRef]

- Holdsworth, A.F.; Horrocks, A.R.; Kandola, B.K.; Price, D. The potential of metal oxalates as novel flame retardants and synergists for engineering polymers. Polym. Degrad. Stab. 2014, 110, 290–297. [Google Scholar] [CrossRef]

- Ji, W.; Wang, H.; Yao, Y.; Wang, R. Mg(OH)2 and PDMS-coated cotton fabrics for excellent oil/water separation and flame retardancy. Cellulose 2019, 26, 6879–6890. [Google Scholar] [CrossRef]

- Plentz, R.S.; Miotto, M.; Schneider, E.E.; Forte, M.M.C.; Mauler, R.S.; Nachtigall, S.M.B. Effect of a macromolecular coupling agent on the properties of aluminum hydroxide/PP composites. J. Appl. Polym. Sci. 2006, 101, 1799–1805. [Google Scholar] [CrossRef]

- Sabet, M.; Hassan, A.; Ratnam, C.T. Flammability and Thermal Characterization of Aluminum Hydroxide Filled with LDPE. Int. Polym. Process. 2013, 28, 393–397. [Google Scholar] [CrossRef]

- Lee, M.-Y.; Yen, F.-S.; Hsiang, H.-I. Generating Self-Shaped 2D Aluminum Oxide Nanopowders. Nanomaterials 2022, 12, 2955. [Google Scholar] [CrossRef]

- Esposito Corcione, C.; Frigione, M.; Maffezzoli, A.; Malucelli, G. Photo—DSC and real time—FT-IR kinetic study of a UV curable epoxy resin containing o-Boehmites. Eur. Polym. J. 2008, 44, 2010–2023. [Google Scholar] [CrossRef]

- Grand, A.F.; Wilkie, C.A. (Eds.) Fire Retardancy of Polymeric Materials; Marcel Dekker: New York, NY, USA, 2000; Chapter 9. [Google Scholar]

- Alongi, J.; Brancatelli, G.; Rosace, G. Thermal properties and combustion behavior of POSS- and bohemite-finished cotton fabrics. J. Appl. Polym. Sci. 2012, 123, 426–436. [Google Scholar] [CrossRef]

- Sharma, V.; Basak, S.; Rishabh, K.; Umaria, H.; Ali, S.W. Synthesis of zinc carbonate nanoneedles, a potential flame retardant for cotton textiles. Cellulose 2018, 25, 6191–6205. [Google Scholar] [CrossRef]

- de Paiva Teixeira, M.H.; Lourenço, L.A.; Artifon, W.; de Castro Vieira, C.J.; Gómez González, S.Y.; Hotza, D. Eco-Friendly Manufacturing of Nano-TiO2 Coated Cotton Textile with Multifunctional Properties. Fibers Polym. 2020, 21, 90–102. [Google Scholar] [CrossRef]

| Fiber | Tg (°C) | Tm (°C) | Td (°C) | Tc (°C) | LOI (%) |

|---|---|---|---|---|---|

| Cotton | - | - | 350 | 350 | 18.4 |

| Viscose | - | - | 350 | 420 | 18.9 |

| Wool | - | - | 245 | 600 | 25 |

| Polyamide 6 | 50 | 215 | 431 | 450 | 20–21.5 |

| Polyester | 80–90 | 255 | 420–447 | 480 | 20–21.5 |

| Mass per Unit Area of the Sample (g/m2) | TTI (s) | THR (MJ/m2) | HRR | FIGRA (kW/m2 s) | TSR (m2/m2) | CO2/CO Peak | Residue (%) | Ref | |

|---|---|---|---|---|---|---|---|---|---|

| Peak (kW/m2) | Time (s) | ||||||||

| 110 | - | 2.35 | 179.2 | 15 | 11.94 | - | 71.5 | 2.6 | [88] |

| 115 | 6 | 2.84 | 196 | 20 | 10 | - | 77 | 7.5 | [89] |

| 118 | 7 | 2.68 | 181.55 | 25 | 7.26 | - | 77.05 | 0.93 | [90] |

| 122 | 2 | 6.3 | 232.1 | 35 | 6.6 | - | 22.1 | 4.3 | [12] |

| 129 | 7 | 2.8 | 181.5 | 22 | 8.3 | 5.3 | 88.7 | 0.9 | [61] |

| 145 | 48 | 2.1 | 147 | - | - | - | - | 2 | [51] |

| 150 | 8 | 1.2 | 97 | 23 | 4.2 | - | - | 3.4 | [62] |

| 200 | 22 | 2.0 | 83 | - | - | 4.3 | - | 0.01 | [91] |

| 220 | 4 | 4.6 | 269 | 7.7 | 34.9 | - | - | 0 | [92] |

| 237 | 18 | 4.6 | 143 | 58 | - | 26 | 0.024 | 4 | [38] |

| 280 | 45 | 19.2 | 223 | 55 | 4.05 | - | - | 0.6 | [93] |

| 290 | 18 | 3.8 | 131 | - | - | 24 | - | <1 | [94] |

| 331 | 43 | 3.9 | 154.2 | - | - | - | 142.86 | 1 | [57] |

| Mass per Unit Area (g/m2) | TPHRR (or Tmax) (°C) | PHRR (or Qmax) (W/g) | HRC (or ηc) (J/g·K) | THR (kJ/g) | Ref. |

|---|---|---|---|---|---|

| 119 | 381 | 285 | - | 12.8 | [98] |

| 121 | 379.2 | 343.5 | 341.1 | 14.9 | [99] |

| 156 | 371 | 183.0 | 181.0 | 8.8 | [100] |

| 180 | 377.92 | 241.8 | 520.7 | 15.2 | [101] |

| 184 | - | 224.3 | 235.6 | 14.1 | [63] |

| 240 | 383.9 | 253.7 | 250.3 | 12.0 | [96] |

| 258 | 390.0 | 269.4 | 270.0 | 12.0 | [102] |

| 347 | 314.1 | 62.5 | 61.0 | - | [103] |

| Mass per Unit Area (g/m2) | Atm. | Tonset10% (°C) | T50% (°C) | Tmax1 (°C) | R@Tmax1 (%) | Tmax2 (°C) | R@Tmax2 (%) | R > 600 °C (%) | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| 115 | N2 | 331 | 372 | 368 | - | - | - | 5.9 | [89] |

| O2 | 327 | 378 | 352 | - | - | - | 1.1 | ||

| 122 | N2 | 338 | - | 374 | 40 | - | - | 4 | [12] |

| O2 | 327 | - | 353 | 42 | - | - | 1 | ||

| 129 | N2 | 358.4 | - | 376.1 | 31.5 | - | - | 4.7 | [61] |

| O2 | 345.6 | - | 349.2 | 43.1 | 489.5 | 4.5 | 0 | ||

| 150 | N2 | 311 | - | 346 | 23.3 | - | - | 0.9 | [62] |

| O2 | 297 | - | 327 | 49.7 | - | - | 0.6 | ||

| 200 | N2 | - | - | 366 | 42 | - | - | 13 | [58] |

| O2 | - | - | 341 | 52.5 | 482 | 6.0 | <2.0 | ||

| 220 | N2 | - | - | 365.7 | - | - | - | - | [92] |

| O2 | - | - | 346.6 | - | 463.9 | - | 1.8 | ||

| 237 | N2 | 336 | 360 | 362 | 50.3 | - | - | 8.3 | [60] |

| O2 | 330 | 349 | 351 | 41.7 | 471 | 5.6 | 1.6 | ||

| 290 | N2 | 316 | - | 366 | 42.3 | - | - | 13.4 | [94] |

| O2 | 309 | - | 344 | 50.0 | 485 | 5 | 1.4 |

| Inorganic Flame Retardant | Action Mechanism | Mode of Action | Effect |

|---|---|---|---|

| Red Phosphorous | Condensed Phase Gas Phase |

|

|

| Boron-based FRs | Condensed Phase |

|

|

| Sol–gel-based FRs | Condensed Phase |

|

|

| Nanoclays | Condensed Phase |

|

|

| CNTs | Condensed Phase |

|

|

| Graphene | Condensed Phase |

|

|

| Metal-based NPs | Condensed Phase Gas Phase |

|

|

| Weight per Unit Area (g/m2) | Precursor (Molar Ratio of Precursor:H2O) | Cone Calorimeter Tests | Thermal Behavior | Vertical Flame-Spread Tests | Ref. | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TTI (s) | THR (MJ/m2) | PHRR (kW/m2) | TGA in Air | TGA in Nitrogen | Total Burning Time (s) | Total Burning Rate (mm/s) | Residue (%) | ||||||

| Tmax1 (°C) | Tmax2 (°C) | Residue at T > 600 °C (%) | Tmax (°C) | Residue at >600 °C (%) | |||||||||

| - | TEOS1 (1:1) | 16 | 2 | 39 | 338 | 507 * | 24 | 361 | 37 | - | - | - | [178] |

| - | TEOS2 (2:1) | 9 | 3 | 38 | 338 | 507 * | 24 | 361 | 32 | - | - | - | [178] |

| - | TEOS3 (3:1) | 18 | 3 | 37 | 338 | 507 * | 18 | 361 | 32 | - | - | - | [178] |