Facile Synthesis of Hollow V2O5 Microspheres for Lithium-Ion Batteries with Improved Performance

Abstract

:1. Introduction

2. Results and Discussion

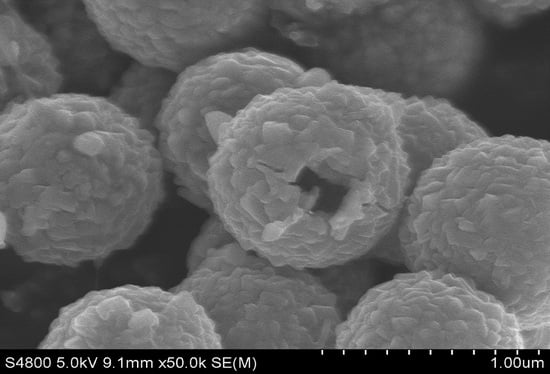

2.1. Morphologies of Materials

2.2. Structure of Materials

2.3. Electrochemical Performance of Materials

3. Materials and Methods

3.1. Synthesis of Materials

3.2. Characterizations of Materials

3.3. Electrochemical Tests of Hollow V2O5 Microspheres

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Guo, Y.; Wu, S.C.; He, Y.B.; Kang, F.Y.; Chen, L.Q.; Li, H.; Yang, Q.H. Solid-state lithium batteries: Safety and prospects. eScience 2023, 3, 138–163. [Google Scholar] [CrossRef]

- Liu, B.J.; Li, X.Y.; Zhao, Q.D.; Liu, J.; Liu, S.M.; Wang, S.B.; Tadè, M. Light into the mechanism of photocatalytic degradation of gaseous o-dichlorobenzene over flower-type V2O5 hollow spheres. J. Mater. Chem. A 2015, 3, 15163–15170. [Google Scholar] [CrossRef]

- McNulty, R.C.; Penston, K.; Amin, S.S.; Stal, S.; Lee, J.Y.; Samperi, M.; Pérez-García, L.; Cameron, J.M.; Johnson, L.R.; Amabilino, D.B.; et al. Self-assembled surfactant-polyoxovanadate soft materials as tuneable vanadium oxide cathode precursors for lithium-Ion batteries. Angew. Chem. Int. Ed. 2023, 62, e202216066. [Google Scholar] [CrossRef] [PubMed]

- Fei, H.L.; Zhou, H.J.; Wang, J.G.; Sun, P.C.; Ding, D.T.; Chen, T.H. Synthesis of hollow V2O5 microspheres and application to photocatalysis. Solid State Sci. 2008, 10, 1276–1284. [Google Scholar] [CrossRef]

- Córdobaa, R.; Kuhna, A.; Pérez-Floresa, J.C.; Moránb, E.; Gallardo-Amoresc, J.M.; García-Alvarado, F. Sodium insertion in high pressure β-V2O5: A new high capacity cathode material for sodium ion batteries. J. Power Sources 2019, 422, 42–48. [Google Scholar] [CrossRef]

- Zhu, Y.H.; Zhang, Q.; Yang, X.; Zhao, E.Y.; Sun, T.; Zhang, X.B.; Wang, S.; Yu, X.Q.; Yan, J.M.; Jiang, Q. Reconstructed orthorhombic V2O5 polyhedra for fast ion diffusion in K-ion batteries. Chem 2018, 5, 168–179. [Google Scholar] [CrossRef]

- Trócoli, R.; Parajuli, P.; Frontera, C.; Black, A.P.; Alexander, G.C.B.; Roy, I.; Dompablo, M.E.A.; Klie, R.F.; Cabana, J.; Palacínand, M.R. β-V2O5 as magnesium intercalation cathode. ACS Appl. Energy Mater. 2022, 5, 11964–11969. [Google Scholar] [CrossRef] [PubMed]

- Liu, F.J.; Zhu, Y.T.; Liu, L.Q.; Zhang, Z.; Yu, J.; Cai, J.X.; Yang, Z.Y. Defect-Rrich W/Mo-doped V2O5 microspheres as a catalytic host to boost sulfur redox kinetics for lithium−sulfur batteries. Inorg. Chem. 2023, 62, 5219–5228. [Google Scholar] [CrossRef]

- Wang, Z.Q.; Zhou, M.; Qin, L.P.; Chen, M.H.; Chen, Z.X.; Guo, S.; Wang, L.B.; Fang, G.Z.; Liang, S.Q. Simultaneous regulation of cations and anions in an electrolyte for high-capacity, high-stability aqueous zinc–vanadium batteries. eScience 2022, 2, 209–218. [Google Scholar] [CrossRef]

- Zhang, N.; Dong, Y.; Jia, M.; Bian, X.; Wang, Y.Y.; Qiu, M.D.; Xu, J.Z.; Liu, Y.C.; Jiao, L.F.; Cheng, F.Y. Rechargeable aqueous Zn−V2O5 battery with high energy density and long cycle life. ACS Energy Lett. 2018, 3, 1366–1372. [Google Scholar] [CrossRef]

- De, P.; Halder, J.; Priya, S.; Srivastava, A.K.; Chandra, A. Two-dimensional V2O5 nanosheets as an advanced cathode material for realizing low–cost aqueous aluminum-ion batteries. ACS Appl. Energy Mater. 2023, 6, 753–762. [Google Scholar] [CrossRef]

- Kuchena, S.F.; Wang, Y. V2O5 intercalated with polyaniline for improved kinetics in aqueous ammonium-ion batteries. Electrochim. Acta 2022, 425, 140751. [Google Scholar] [CrossRef]

- Minakshi, M. Examining manganese dioxide electrode in KOH electrolyte using TEM technique. J. Electroanal. Chem. 2008, 616, 99–106. [Google Scholar] [CrossRef]

- Hembram, K.P.S.S.; Kumar, J. Ironation mechanism in vanadium pentoxide (V2O5) for iron battery application. J. Phys. Chem. Solids 2023, 183, 11640. [Google Scholar] [CrossRef]

- Liu, N.B.; Zhao, X.Y.; Wang, X.H.; Li, Q.Q.; Wang, L.B. A V2O5 cathode for aqueous rechargeable Pb-ion batteries. Chem. Commun. 2023, 59, 12719. [Google Scholar] [CrossRef]

- Yuan, B.H.; Yuan, X.; Zhang, B.E.; An, Z.; Luo, S.J.; Chen, L.L. Lithium ion batteries cathode material: V2O5. Chin. Phys. B 2022, 31, 038203. [Google Scholar] [CrossRef]

- Pan, A.Q.; Wu, H.B.; Yu, L.; Lou, X.W. Template-free synthesis of VO2 hollow microspheres with various interiors and their conversion into V2O5 for lithium-ion batteries. Angew. Chem. Int. Ed. 2013, 52, 2226–2230. [Google Scholar] [CrossRef]

- Fei, H.L.; Li, Z.W.; Feng, W.J.; Liu, X. Stable anode performance of vanadium oxide hydrate semi-microspheres and their graphene based composite microspheres in sodium-ion batteries. Dalton Trans. 2015, 44, 146–150. [Google Scholar] [CrossRef]

- Uchaker, E.; Zhou, N.; Li, Y.W.; Cao, G.Z. Polyol-mediated solvothermal synthesis and electrochemical performance of nanostructured V2O5 hollow microspheres. J. Phys. Chem. C 2013, 117, 1621–1626. [Google Scholar] [CrossRef]

- Dong, X.L.; Dong, F.Y.; Zhu, K.K.; Li, H.B.; Zeng, S.Y.; Cui, C.S.; Fu, C.G.; Wang, L. Facile preparation of V2O5 hollow microspheres with mesoporous on the shell and their electrochemical properties for lithium-ion batteries. J. Electrochem. Soc. 2023, 170, 170050505. [Google Scholar] [CrossRef]

- Zheng, Y.Z.; Ding, H.Y.; Uchaker, E.; Tao, X.; Chen, J.F.; Zhang, Q.F.; Cao, G.Z. Nickel-mediated polyol synthesis of hierarchical V2O5 hollow microspheres with enhanced lithium storage properties. J. Mater. Chem. A 2015, 3, 1979–1985. [Google Scholar] [CrossRef]

- Yan, B.; Li, X.F.; Bai, Z.M.; Zhao, Y.; Dong, L.; Song, X.S.; Li, D.J.; Langford, C.; Sun, X.L. Crumpled reducedgrapheneoxideconformallyencapsulatedhollow V2O5 nano/microsphere achieving brilliant lithium storage performance. Nano Energy 2016, 24, 32–44. [Google Scholar] [CrossRef]

- Dong, Y.J.; Wei, H.Y.; Liu, W.; Liu, Q.J.; Zhang, W.J.; Yang, Y.Z. Template-free synthesis of V2O5 hierarchical nanosheet-assembled microspheres with excellent cycling stability. J. Power Sources 2015, 285, 538–542. [Google Scholar] [CrossRef]

- Wang, H.E.; Chen, D.S.; Cai, Y.; Zhang, R.J.; Xu, J.M.; Deng, Z.; Zheng, X.F.; Li, Y.; Bello, I.; Su, B.L. Facile synthesis of hierarchical and porous V2O5 microspheres as cathode materials for lithium ion batteries. J. Colloid Interf. Sci. 2014, 418, 74–80. [Google Scholar] [CrossRef] [PubMed]

- Pan, A.Q.; Wu, H.B.; Zhang, L.; Lou, X.W. Uniform V2O5 nanosheet-assembled hollow microflowers with excellent lithium storage properties. Energy Environ. Sci. 2013, 6, 1476–1479. [Google Scholar] [CrossRef]

- Li, H.K.; Wang, J.X.; Liu, X.; Sun, Q.; Djurisi, A.B.; Xie, M.H.; Mei, Y.; Tang, C.Y.; Shih, K. Template-free synthesis of hierarchical hollow V2O5 microspheres with highly stable lithium storage capacity. RSC Adv. 2017, 7, 2480–2485. [Google Scholar] [CrossRef]

- Liang, X.; Gao, G.H.; Du, Y.C.; Wang, J.C.; Sun, W.; Liu, Y.D.; Zhang, K.; Wu, G.M. Synthesis and characterization of various V2O5 microsphere structures and their electrochemical performance. J. Alloys Cmpd. 2018, 757, 177–187. [Google Scholar] [CrossRef]

- Shan, Y.L.; Xu, L.; Hu, Y.J.; Jiang, H.; Li, C.Z. Internal-diffusion controlled synthesis of V2O5 hollow microspheres for superior lithium-ion full batteries. Chem. Eng. Sci. 2019, 200, 38–45. [Google Scholar] [CrossRef]

- Qin, H.G.; Chen, L.L.; Wang, L.M.; Chen, X.; Yang, Z.H. V2O5 hollow spheres as high rate and long life cathode for aqueous rechargeable zinc ion batteries. Electrochim. Acta 2019, 306, 307–316. [Google Scholar] [CrossRef]

- Wang, S.Q.; Lu, Z.D.; Wang, D.; Li, C.G.; Chen, C.H.; Yin, Y.D. Porous monodisperse V2O5 microspheres as cathode materials for lithium-ion batteries. J. Mater. Chem. 2011, 21, 6365–6369. [Google Scholar] [CrossRef]

- Cao, A.M.; Hu, J.S.; Liang, H.P.; Wan, L.J. Self-assembled vanadium pentoxide (V2O5) hollow microspheres from nanorods and their application in lithium-ion batterie. Angew. Chem. Int. Ed. 2005, 44, 4391–4395. [Google Scholar] [CrossRef] [PubMed]

- Xue, L.C.; Li, Y.Q.; Lin, W.T.; Chen, F.M.; Chen, G.C.; Chen, D.J. Electrochemical properties and facile preparation of hollow porous V2O5 microspheres for lithium-ion batteries. J. Colloid Interf. Sci. 2023, 638, 231–241. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.; Lee, M.J. Template-assisted solvothermal assembly of size-controlled hierarchical V2O5 hollow microspheres with tunable nanoscale building blocks and their enhanced lithium storage properties. Electrochim. Acta 2017, 258, 942–950. [Google Scholar] [CrossRef]

- Sasidharan, M.; Gunawardhana, N.; Yoshio, M.; Nakashima, K. V2O5 hollow nanospheres: A lithium intercalation host with good rate capability and capacity retention. J. Electrochem. Soc. 2012, 159, A618–A621. [Google Scholar] [CrossRef]

- Shao, J.; Li, X.Y.; Wan, Z.M.; Zhang, L.F.; Ding, Y.L.; Zhang, L.; Qu, Q.T.; Zheng, H.H. Low-cost synthesis of hierarchical V2O5 microspheres as high performance cathode for lithium-ion batteries. ACS Appl. Mater. Interf. 2013, 5, 7671–7675. [Google Scholar] [CrossRef]

- Yin, Z.D.; Xu, J.; Ge, Y.L.; Jiang, Q.Y.; Zhang, Y.L.; Yang, Y.W.; Sun, Y.P.; Hou, S.Y.; Shang, Y.Y.; Zhang, Y.J. Synthesis of V2O5 microspheres by spray pyrolysis as cathode material for supercapacitors. Mater. Res. Express 2018, 5, 5036306. [Google Scholar] [CrossRef]

- Hu, P.; Zhu, T.; Ma, J.X.; Cai, C.C.; Hu, G.W.; Wang, X.P.; Liu, Z.; Zhou, L.; Mai, L.Q. Porous V2O5 microspheres: A high-capacity cathode material for aqueous zinc-ion batteries. Chem. Commun. 2019, 55, 8486–8489. [Google Scholar] [CrossRef]

- Wilkins, P.C.; Johnson, M.D.; Holder, A.A.; Crans, D.C. Reduction of vanadium (V) by L-ascorbic acid at low and neutral pH: Kinetic, mechanistic, and spectroscopic characterization. Inorg. Chem. 2006, 45, 1471–1479. [Google Scholar] [CrossRef]

- Fei, H.L. Synthesis of hollow nontransparent VO2 microspheres as stable electrode materials for lithium-ion batteries. Int. J. Electrochem. Sci. 2021, 16, 210631. [Google Scholar] [CrossRef]

- Sharma, P.; Minakshi, M.; Whale, J.; Jean-Fulcrand, A.; Garnweitner, G. Effect of the anionic counterpart: Molybdate vs. tungstate in energy storage for Pseudo-capacitor applications. Nanomaterials 2021, 11, 580. [Google Scholar] [CrossRef]

| Ref. | Morphologies | Discharge Current Density mAg−1 | Capacity (Cycle Number) mAhg−1 |

|---|---|---|---|

| [18] | 3.0 µm hollow spheres of aggregated 77 nm nanoparticles andan inner diameter of approximately 750 nm | 300 | 190 |

| [20] | 4 µm hollow Ni-doped V2O5 microspheres | 300 | 238 (50) |

| [21] | 1 µm microspheres built with rod-like nanoparticles | 100 | 282 |

| [27] | 4.9 µm hollow microspheres with cuboid-shaped building blocks | 44.5 | 287 (40) |

| [27] | 1.3 µm hollow microspheres with nanoplatelet-like building blocks | 44.5 | 130 (40) |

| [22] | 22 µm hierarchical nanosheet-assembled microspheres | 300 | 243 (200) |

| [26] | 1.4–1.6 µm yolk-shell microspheres with 65 nm thick shells | 100 | 194 |

| [34] | 400 nm spheres with 65 nm thick shells built with platelike structures | 300 | 266 |

| [29] | 7 µm porous microspheres | 45 | 160 |

| [24] | 1 µm hollow microflowers assembled from nanosheets | 300 | 211 (100) |

| [33] | Approximately 28 nm hollow nanospheres with hollow cavity size of approximately 18 nm | 150 | 181 (50) |

| This work | 1.0 μm hollow microspheres built with small rodlike nanoparticles | 50 | 256.4 (2) |

| 750 | 151.5 (2) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fei, H.; Wu, P.; He, L.; Li, H. Facile Synthesis of Hollow V2O5 Microspheres for Lithium-Ion Batteries with Improved Performance. Inorganics 2024, 12, 37. https://doi.org/10.3390/inorganics12020037

Fei H, Wu P, He L, Li H. Facile Synthesis of Hollow V2O5 Microspheres for Lithium-Ion Batteries with Improved Performance. Inorganics. 2024; 12(2):37. https://doi.org/10.3390/inorganics12020037

Chicago/Turabian StyleFei, Hailong, Peng Wu, Liqing He, and Haiwen Li. 2024. "Facile Synthesis of Hollow V2O5 Microspheres for Lithium-Ion Batteries with Improved Performance" Inorganics 12, no. 2: 37. https://doi.org/10.3390/inorganics12020037

APA StyleFei, H., Wu, P., He, L., & Li, H. (2024). Facile Synthesis of Hollow V2O5 Microspheres for Lithium-Ion Batteries with Improved Performance. Inorganics, 12(2), 37. https://doi.org/10.3390/inorganics12020037