Measuring Circularity in Food Supply Chain Using Life Cycle Assessment; Refining Oil from Olive Kernel

Abstract

:1. Introduction

2. Materials and Methods

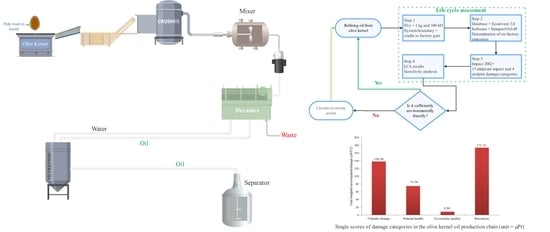

2.1. Refining Oil from Olive Kernel

2.2. Measuring Circularity Using LCA

3. Results and Discussion

3.1. Interpretation of Mid-Point LCA Results

3.2. Interpretation of End-Point Damage Assessment

3.3. Uncertainty of GWP’s Results

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Activity | Database | Category | Unit | Activity Uuid/Source |

|---|---|---|---|---|

| Electricity | Ecoinvent 3 | IR | kWh | 668baf12-38db-47b7-8517-c0a18aa122f4 |

| Natural gas | Ecoinvent 3 | GLO | M 3 | 65f221cf-b821-4da1-a2ed-a67994b10f42 |

| Transport | Ecoinvent 3 | GLO | t.km | 413c356e-677d-4676-b816-0c0b20768d7a_03bf1369-1eec-49d0-bc4b-8b29efa826b9.spold |

| Water-Unspecified origins | Input from nature | IR | M 3 | - |

| Emission | Coefficients [66,67] | Quantity (per on kg Produced Olive Kernel Oil) |

|---|---|---|

| Carbon dioxide (CO2) | 38.70 | 996.14 |

| Methane (CH4) | 7.40 × 10−4 | 1.90 × 10−2 |

| Dinitrogen monoxide (N2O) | 7.11 × 10−4 | 1.83 × 10−2 |

| Sulfur dioxide (SO2) | 1.93 × 10−4 | 4.97 × 10−3 |

| Nickel (Ni) | 6.78 × 10−7 | 1.75 × 10−5 |

| Lead | 1.61 × 10−7 | 4.14 × 10−6 |

| Zinc (Zn) | 9.37 × 10−6 | 2.41 × 10−4 |

| Benzo(a)pyrene | 3.87 × 10−9 | 9.96 × 10−8 |

| Selenium (Se) | 7.75 × 10−9 | 1.99 × 10−7 |

| Organic compound | 3.50 × 10−3 | 9.01 × 10−2 |

| Volatile organic compound (VOC) | 1.70 × 10−3 | 4.38 × 10−2 |

| Particulates (<2.5 μm) | 2.45 × 10−3 | 6.31 × 10−2 |

References

- Haupt, M.; Hellweg, S. Measuring the environmental sustainability of a circular economy. Environ. Sustain. Indic. 2019, 1, 100005. [Google Scholar] [CrossRef]

- Secondi, L. A Regression-Adjustment Approach with Control-Function for Estimating Economic Benefits of Targeted Circular Economy Practices: Evidence from European SMEs. Stud. Appl. Econ. 2020, 39. [Google Scholar] [CrossRef]

- Ruggieri, A.; Braccini, A.M.; Poponi, S.; Mosconi, E.M. A meta-model of inter-organisational cooperation for the transition to a circular economy. Sustainability 2016, 8, 1153. [Google Scholar] [CrossRef] [Green Version]

- Babbitt, C.W.; Gaustad, G.; Fisher, A.; Chen, W.Q.; Liu, G. Closing the loop on circular economy research: From theory to practice and back again. Resour. Conserv. Recycl. 2018, 135, 1–2. [Google Scholar] [CrossRef]

- Scheepens, A.E.; Vogtländer, J.G.; Brezet, J.C. Two life cycle assessment (LCA) based methods to analyse and design complex (regional) circular economy systems. Case: Making water tourism more sustainable. J. Clean. Prod. 2016, 114, 257–268. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Towards the Circular Economy: Economic and Business Rationale for Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2013. [Google Scholar]

- European Environment Agency. Signals: Well-Being and the Environment—Building a Resource-Efficient and Circular Economy in Europe Luxembourg; Publications Office of the European Union: Copenhagen, Denmark, 2014. [Google Scholar]

- Haupt, M.; Zschokke, M. How can LCA support the circular economy?—63rd discussion forum on life cycle assessment, Zurich, Switzerland, November 30, 2016. Int. J. Life Cycle Assess. 2017, 22, 832–837. [Google Scholar] [CrossRef]

- Patwa, N.; Sivarajah, U.; Seetharaman, A.; Sarkar, S.; Maiti, K.; Hingorani, K. Towards a circular economy: An emerging economies context. J. Bus. Res. 2021, 122, 725–735. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Bassi, F.; Dias, J.G. The use of circular economy practices in SMEs across the EU. Resour. Conserv. Recycl. 2019, 146, 523–533. [Google Scholar] [CrossRef]

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular economy: The concept and its limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation; Granta Design. An Approach Tomeasuring Circularity—Methodology; Ellen MacArthur Foundation: Cowes, UK, 2015. [Google Scholar]

- Di Maio, F.; Rem, P.C. A robust indicator for promoting circular economy through recycling. J. Environ. Protect. 2015, 6, 1095. [Google Scholar] [CrossRef] [Green Version]

- Linder, M.; Sarasini, S.; van Loon, P. A metric for quantifying product-level circularity. J. Ind. Ecol. 2017, 21, 545–558. [Google Scholar] [CrossRef] [Green Version]

- Vilariño, M.V.; Franco, C.; Quarrington, C. Food loss and waste reduction as an integral part of a circular economy. Front. Environ. Sci. 2017, 5, 21. [Google Scholar] [CrossRef] [Green Version]

- ISO (International Organization for Standardization). Environmental Management: Life Cycle Assessmente; Principles and Framework; British Standards Institution: London, UK, 2006; Volume 14040. [Google Scholar]

- ISO (International Organization for Standardization). Environmental Management: Life Cycle Assessment; Requirements and Guidelines; International Standard Organisation: Geneva, Switzerland, 2006. [Google Scholar]

- Corona, B.; Shen, L.; Reike, D.; Carreón, J.R.; Worrell, E. Towards sustainable development through the circular economy—A review and critical assessment on current circularity metrics. Resour. Conserv. Recycl. 2019, 151, 104498. [Google Scholar] [CrossRef]

- Lokesh, K.; Matharu, A.S.; Kookos, I.K.; Ladakis, D.; Koutinas, A.; Morone, P.; Clark, J. Hybridised sustainability metrics for use in life cycle assessment of bio-based products: Resource efficiency and circularity. Green Chem. 2020, 22, 803–813. [Google Scholar] [CrossRef] [Green Version]

- Dahiya, S.; Katakojwala, R.; Ramakrishna, S.; Mohan, S.V. Biobased Products and Life Cycle Assessment in the Context of Circular Economy and Sustainability. Mater. Circ. Econ. 2020, 2, 1–28. [Google Scholar] [CrossRef]

- Colangelo, F.; Navarro, T.G.; Farina, I.; Petrillo, A. Comparative LCA of concrete with recycled aggregates: A circular economy mindset in Europe. Int. J. Life Cycle Assess. 2020, 25, 1790–1804. [Google Scholar] [CrossRef]

- Pauer, E.; Wohner, B.; Heinrich, V.; Tacker, M. Assessing the environmental sustainability of food packaging: An extended life cycle assessment including packaging-related food losses and waste and circularity assessment. Sustainability 2019, 11, 925. [Google Scholar] [CrossRef] [Green Version]

- Sadhukhan, J.; Dugmore, T.I.; Matharu, A.; Martinez-Hernandez, E.; Aburto, J.; Rahman, P.K.; Lynch, J. Perspectives on “game changer” global challenges for sustainable 21st century: Plant-based diet, unavoidable food waste biorefining, and circular economy. Sustainability 2020, 12, 1976. [Google Scholar] [CrossRef] [Green Version]

- Dahiya, S.; Kumar, A.N.; Sravan, J.S.; Chatterjee, S.; Sarkar, O.; Mohan, S.V. Food waste biorefinery: Sustainable strategy for circular bioeconomy. Bioresour. Technol. 2018, 248, 2–12. [Google Scholar] [CrossRef] [PubMed]

- Shafiee-Jood, M.; Cai, X. Reducing food loss and waste to enhance food security and environmental sustainability. Environ. Sci. Technol. 2016, 50, 8432–8443. [Google Scholar] [CrossRef] [PubMed]

- Wesana, J.; Gellynck, X.; Dora, M.K.; Pearce, D.; De Steur, H. Measuring Food Losses in the Supply Chain through Value Stream Mapping: A Case Study in the Dairy Sector. In Saving Food; Academic Press: New York, NY, USA, 2019; pp. 249–277. [Google Scholar]

- Strotmann, C.; Göbel, C.; Friedrich, S.; Kreyenschmidt, J.; Ritter, G.; Teitscheid, P. A participatory approach to minimizing food waste in the food industry—A manual for managers. Sustainability 2017, 9, 66. [Google Scholar] [CrossRef] [Green Version]

- Principato, L.; Ruini, L.; Guidi, M.; Secondi, L. Adopting the circular economy approach on food loss and waste: The case of Italian pasta production. Resour. Conserv. Recycl. 2019, 144, 82–89. [Google Scholar] [CrossRef]

- Muhammad, N.I.S.; Rosentrater, K.A. Comparison of global-warming potential impact of food waste fermentation to landfill disposal. SN Appl. Sci. 2020, 2, 261. [Google Scholar] [CrossRef] [Green Version]

- Ingrao, C.; Faccilongo, N.; Di Gioia, L.; Messineo, A. Food waste recovery into energy in a circular economy perspective: A comprehensive review of aspects related to plant operation and environmental assessment. J. Clean. Prod. 2018, 184, 869–892. [Google Scholar] [CrossRef]

- Negro, M.J.; Manzanares, P.; Ruiz, E.; Castro, E.; Ballesteros, M. The biorefinery concept for the industrial valorization of residues from olive oil industry. In Olive Mill Waste; Academic Press: New York, NY, USA, 2017; pp. 57–78. [Google Scholar]

- Khounani, Z.; Hosseinzadeh-Bandbafha, H.; Moustakas, K.; Talebi, A.F.; Goli, S.A.H.; Rajaeifar, M.A.; Khoshnevisan, B.; Jouzani, G.S.; Peng, W.; Kim, K.H.; et al. Environmental life cycle assessment of different biorefinery platforms valorizing olive wastes to biofuel, phosphate salts, natural antioxidant, and an oxygenated fuel additive (triacetin). J. Clean. Prod. 2021, 278, 123916. [Google Scholar] [CrossRef]

- Espadas-Aldana, G.; Vialle, C.; Belaud, J.P.; Vaca-Garcia, C.; Sablayrolles, C. Analysis and trends for Life Cycle Assessment of olive oil production. Sustain. Prod. Consum. 2019, 19, 216–230. [Google Scholar] [CrossRef] [Green Version]

- Nunes, M.A.; Pimentel, F.B.; Costa, A.S.; Alves, R.C.; Oliveira, M.B.P. Olive by-products for functional and food applications: Challenging opportunities to face environmental constraints. Innov. Food Sci. Emerg. Technol. 2016, 35, 139–148. [Google Scholar] [CrossRef]

- Gomez-Martin, A.; Chacartegui, R.; Ramirez-Rico, J.; Martinez-Fernandez, J. Performance improvement in olive stone’s combustion from a previous carbonization transformation. Fuel 2018, 228, 254–262. [Google Scholar] [CrossRef]

- Rodríguez, G.; Lama, A.; Rodríguez, R.; Jiménez, A.; Guillén, R.; Fernández-Bolanos, J. Olive stone an attractive source of bioactive and valuable compounds. Bioresour. Technol. 2008, 99, 5261–5269. [Google Scholar] [CrossRef] [PubMed]

- Batuecas, E.; Tommasi, T.; Battista, F.; Negro, V.; Sonetti, G.; Viotti, P.; Fino, D.; Mancini, G. Life Cycle Assessment of waste disposal from olive oil production: Anaerobic digestion and conventional disposal on soil. J. Environ. Manag. 2019, 237, 94–102. [Google Scholar] [CrossRef] [PubMed]

- Moghaddam, G.; Vander Heyden, Y.; Rabiei, Z.; Sadeghi, N.; Oveisi, M.R.; Jannat, B.; Araghi, V.; Hassani, S.; Behzad, M.; Hajimahmoodi, M. Characterization of different olive pulp and kernel oils. J. Food Compos. Anal. 2012, 28, 54–60. [Google Scholar] [CrossRef]

- Martins, F.P.; Kiritsakis, A. Olives and Olive Oil as Functional Foods: Bioactivity, Chemistry and Processing, 1st ed.; Kiritsakis, A., Shahidi, F., Eds.; Wiley: Hoboken, NJ, USA, 2017; pp. 81–105. [Google Scholar]

- Kiritsakis, A.; Turkan, K.M.; Kiritsakis, K. Bailey’s Industrial Oil and Fat Products, 7th ed.; Shahidi, F., Ed.; Wiley: Hoboken, NJ, USA, 2020. [Google Scholar] [CrossRef]

- Cappelletti, G.M.; Ioppolo, G.; Nicoletti, G.M.; Russo, C. Energy requirement of extra virgin olive oil production. Sustainability 2014, 6, 4966–4974. [Google Scholar] [CrossRef] [Green Version]

- Sundaram, S.; Siew, K.; Martinez-Hernandez, E. Biorefineries and chemical processes: Design, integration and sustainability analysis. Green Process. Synth. 2015, 4, 65–66. [Google Scholar] [CrossRef]

- Jolliet, O.; Margni, M.; Charles, R.; Humbert, S.; Payet, J.; Rebitzer, G.; Rosenbaum, R. IMPACT 2002+: A new life cycle impact assessment methodology. Int. J. Life Cycle Assess. 2003, 8, 324. [Google Scholar] [CrossRef] [Green Version]

- Zargar-Ershadi, S.Z.; Heidari, M.D.; Dutta, B.; Dias, G.; Pelletier, N. Comparative life cycle assessment of technologies and strategies to improve nitrogen use efficiency in egg supply chains. Resour. Conserv. Recycl. 2021, 166, 105275. [Google Scholar] [CrossRef]

- Vásquez-Ibarra, L.; Rebolledo-Leiva, R.; Angulo-Meza, L.; González-Araya, M.C.; Iriarte, A. The joint use of life cycle assessment and data envelopment analysis methodologies for eco-efficiency assessment: A critical review, taxonomy and future research. Sci. Total Environ. 2020, 139538. [Google Scholar] [CrossRef]

- Fathollahi, H.; Mousavi-Avval, S.H.; Akram, A.; Rafiee, S. Comparative energy, economic and environmental analyses of forage production systems for dairy farming. J. Clean. Prod. 2018, 182, 852–862. [Google Scholar] [CrossRef]

- Cherubini, E.; Franco, D.; Zanghelini, G.M.; Soares, S.R. Uncertainty in LCA case study due to allocation approaches and life cycle impact assessment methods. Int. J. Life Cycle Assess. 2018, 23, 2055–2070. [Google Scholar] [CrossRef]

- Noya, I.; González-García, S.; Bacenetti, J.; Fiala, M.; Moreira, M.T. Environmental impacts of the cultivation-phase associated with agricultural crops for feed production. J. Clean. Prod. 2018, 172, 3721–3733. [Google Scholar] [CrossRef]

- Rezaei, M.; Soheilifard, F.; Keshvari, A. Impact of agrochemical emission models on the environmental assessment of paddy rice production using life cycle assessment approach. Energy Sources 2021, 1–16. [Google Scholar] [CrossRef]

- Paramesh, V.; Arunachalam, V.; Nikkhah, A.; Das, B.; Ghnimi, S. Optimization of energy consumption and environmental impacts of arecanut production through coupled data envelopment analysis and life cycle assessment. J. Clean. Prod. 2018, 203, 674–684. [Google Scholar] [CrossRef]

- Dekker, E.; Zijp, M.C.; van de Kamp, M.E.; Temme, E.H.; van Zelm, R. A taste of the new ReCiPe for life cycle assessment: Consequences of the updated impact assessment method on food product LCAs. Int. J. Life Cycle Assess. 2019, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Guinée, J.B.; Lindeijer, E. Handbook on Life Cycle Assessment—Operational Guide to the ISO Standards. In Handbook on Life Cycle Assessment: Operational Guide to the ISO Standards Series: Eco-Efficiency in Industry and Science; Guinée, J.B., Ed.; Springer: Dordrecht, The Netherlands, 2002. [Google Scholar]

- Hauschild, M.Z.; Wenzel, H. Environmental Assessment of Products, Volume 2: Scientific Background; Springer: New York, NY, USA, 1998. [Google Scholar]

- Huijbregts, M.A.; Hellweg, S.; Frischknecht, R.; Hungerbühler, K.; Hendriks, A.J. Ecological footprint accounting in the life cycle assessment of products. Ecol. Econ. 2008, 64, 798–807. [Google Scholar] [CrossRef]

- EN 15804, BS EN 15804:2012. Standards Publication Sustainability of Construction Works-Environmental Product Declarations-Core Rules for the Product Category of Construction Products; European Committee for Standardization: Brussels, Belgium, 2014; Volume 70. [Google Scholar]

- De Bruyn, S.; Ahdour, S.; Bijleveld, M.; De Graaff, L.; Schep, E.; Schroten, A.; Vergeer, R. Environmental Prices Handbook 2017-Methods and Numbers for Valuation of Environmental Impacts. 2018. Available online: https://www.cedelft.eu/en/publications/2113/envionmental-prices-handbook-2017 (accessed on 12 January 2021).

- PRE. SimaPro Database Manual Methods Library. 2019. Available online: https://simapro.com/ (accessed on 28 January 2021).

- Chomkhamsri, K.; Wolf, M.A.; Pant, R. International reference life cycle data system (ILCD) handbook: Review schemes for life cycle assessment. Towards Life Cycle Sustain. Manag. 2011, 107–117. [Google Scholar] [CrossRef]

- Herrmann, I.T.; Moltesen, A. Does it matter which Life Cycle Assessment (LCA) tool you choose?–a comparative assessment of SimaPro and GaBi. J. Clean. Prod. 2015, 86, 163–169. [Google Scholar] [CrossRef]

- Hiloidhari, M.; Banerjee, R.; Rao, A.B. Life cycle assessment of sugar and electricity production under different sugarcane cultivation and cogeneration scenarios in India. J. Clean. Prod. 2020, 290, 125170. [Google Scholar] [CrossRef]

- Salomone, R.; Cappelletti, G.M.; Malandrino, O.; Mistretta, M.; Neri, E.; Nicoletti, G.M.; Notarnicola, B.; Pattara, C.; Russo, C.; Saija, G. Life Cycle Assessment in the Olive Oil Sector. In Life Cycle Assessment in the Agri-food Sector; Springer: Cham, Switzerland, 2015; pp. 57–121. [Google Scholar]

- El Hanandeh, A. Carbon abatement via treating the solid waste from the Australian olive industry in mobile pyrolysis units: LCA with uncertainty analysis. Waste Manag. Res. 2013, 31, 341–352. [Google Scholar] [CrossRef]

- Intini, F.; Kuhtz, S.; Rospi, G. Life cycle assessment (LCA) of an energy recovery plant in the olive oil industries. Int. J. Energy Environ. 2012, 3, 541–552. [Google Scholar]

- Martinez-Hernandez, E.; Martinez-Herrera, J.; Campbell, G.M.; Sadhukhan, J. Process integration, energy and GHG emission analyses of Jatropha-based biorefinery systems. Biomass Convers. Biorefinery 2014, 4, 105–124. [Google Scholar] [CrossRef]

- EPA-Environmental Protection Agency Emission Factor Documentation for AP-42 Section 1.4-Natural Gas Combustion, Technical Support Division, Office of Air Quality Planning and Standards, Research Triangle Park, NC, USA, 1998. Available online: http://www3.epa.gov/ttnchie1/ap42/ch01/bgdocs/b01s04.pdf (accessed on 8 January 2021).

- Farahani, S.S.; Soheilifard, F.; Raini, M.G.N.; Kokei, D. Comparison of different tomato puree production phases from an environmental point of view. Int. J. Life Cycle Assess. 2019, 24, 1817–1827. [Google Scholar] [CrossRef]

| Inputs and Outputs | Unit | Quantity | |

|---|---|---|---|

| Per 1 kg Produced Oil | Per 100 MJ Produced Oil | ||

| Inputs | |||

| —Olive kernel | kg | 47.72 | 150.83 |

| —Water consumption | m3 | 0.05 | 0.14 |

| —Natural gas | m3 | 0.52 | 1.65 |

| —Electricity | kWh | 0.10 | 0.31 |

| —Human labor | h | 0.16 | 0.50 |

| —Transportation of the produced oil | ton × km | 0.34 | 1.07 |

| Outputs | |||

| —Olive kernel oil | 1 kg | 100 MJ | |

| —Efficiency (oil/olive kernel) | % | 2.09 | 2.09 |

| Impact Category | Unit | Quantity | |

|---|---|---|---|

| Per 1 kg Produced Oil | Per 100 MJ Produced Energy | ||

| Global warming | kg CO2eq | 1.37 | 4.32 |

| Non-renewable energy | MJ primary | 26.40 | 83.44 |

| Mineral extraction | MJ surplus | 0.005 | 0.02 |

| Ozone layer depletion | kg CFC-11eq | 1.57 × 10−7 | 4.97 × 10−7 |

| Non-carcinogens | kg C2H3Cl eq | 0.02 | 0.05 |

| Carcinogens | kg C2H3Cl eq | 0.08 | 0.24 |

| Ionizing radiation | Bq C-14 eq | 1.94 | 6.14 |

| Respiratory organics | kg C2H4 eq | 3.84 × 10−4 | 1.39 × 10−3 |

| Respiratory inorganics | kg PM2.5eq | 4.40 × 10−4 | 1.21 × 10−3 |

| Aquatic ecotoxicity | kg TEG water | 68.07 | 215.16 |

| Terrestrial ecotoxicity | kg TEG soil | 12.71 | 40.16 |

| Aquatic eutrophication | kg PO4 P-lim | 3.28 × 10−5 | 1.04 × 10−4 |

| Terrestrial acid/nutri | kg SO2eq | 0.007 | 0.02 |

| Land occupation | m2org.arable | 0.009 | 0.03 |

| Aquatic acidification | kg SO2eq | 0.002 | 0.01 |

| Off-Site | On-Site | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Electricity | Natural Gas | Transportation | On-Factory | |||||||||

| Damage Category | Damage Assessment | Normalized | Weighted | Damage Assessment | Normalized | Weighted | Damage Assessment | Normalized | Weighted | Damage Assessment | Normalized | Weighted |

| Human health | 3.78 × 10−8 DALY | 2.53 × 10−6 | 5.23 | 3.20 × 10−7 DALY | 4.51 × 10−5 | 45.07 | 1.28 × 10−7 DALY | 1.80 × 10−5 | 17.98 | 4.46 × 10−8 DALY | 6.29 × 10−6 | 6.29 |

| Ecosystem quality | 3.95 × 10−3 PDF.m2.yr | 2.8 × 10−7 | 0.29 | 3.46 × 10−2 PDF.m2.yr | 2.53 × 10−6 | 2.53 | 8.08 × 10−2 PDF.m2.yr | 5.89 × 10−6 | 5.89 | 2.02 × 10−3 PDF.m2.yr | 1.47 × 10−7 | 0.15 |

| Climate change | 0.06 kg CO2eq | 6.28 × 10−6 | 6.28 | 0.13 kg CO2eq | 1.35 × 10−5 | 13.48 | 0.17 kg CO2eq | 1.75 × 10−5 | 17.52 | 1.00 kg CO2eq | 1.01 × 10−4 | 100.91 |

| Resource depletion | 1.08 MJ | 7.12 × 10−6 | 7.12 | 22.57 MJ | 1.49 × 10−4 | 148.52 | 2.75 MJ | 1.81 × 10−5 | 18.09 | 0 | 0 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nikkhah, A.; Firouzi, S.; Dadaei, K.; Van Haute, S. Measuring Circularity in Food Supply Chain Using Life Cycle Assessment; Refining Oil from Olive Kernel. Foods 2021, 10, 590. https://doi.org/10.3390/foods10030590

Nikkhah A, Firouzi S, Dadaei K, Van Haute S. Measuring Circularity in Food Supply Chain Using Life Cycle Assessment; Refining Oil from Olive Kernel. Foods. 2021; 10(3):590. https://doi.org/10.3390/foods10030590

Chicago/Turabian StyleNikkhah, Amin, Saeed Firouzi, Keyvan Dadaei, and Sam Van Haute. 2021. "Measuring Circularity in Food Supply Chain Using Life Cycle Assessment; Refining Oil from Olive Kernel" Foods 10, no. 3: 590. https://doi.org/10.3390/foods10030590

APA StyleNikkhah, A., Firouzi, S., Dadaei, K., & Van Haute, S. (2021). Measuring Circularity in Food Supply Chain Using Life Cycle Assessment; Refining Oil from Olive Kernel. Foods, 10(3), 590. https://doi.org/10.3390/foods10030590