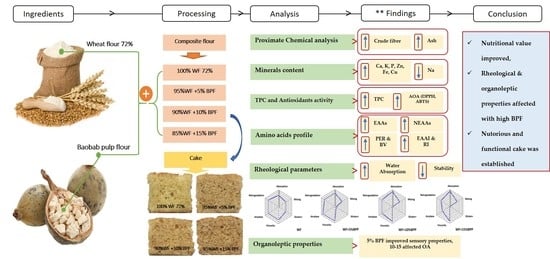

Nutritional and Rheological Characteristics of Composite Flour Substituted with Baobab (Adansonia digitata L.) Pulp Flour for Cake Manufacturing and Organoleptic Properties of Their Prepared Cakes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Baobab Pulp Flour and Cake Processing

2.2. Approximate Chemical Composition

2.3. Determination of Minerals

2.4. Total Phenolic Content and Antioxidant Activity

2.5. Determination of Amino Acids

2.6. Rheological Properties

2.7. Organoleptic Properties

2.8. Statistical Analysis

3. Results

3.1. Chemical Composition of WF, BPF, and Substituted WF with BPF

3.2. Mineral Content of WF, BPF, and Substituted WF with BPF

3.3. Total Phenolic Content and Antioxidant Capacity of WF, BPF and Substituted WF with BPF

3.4. Amino acids profile of WF, BPF, and substituted WF with BPF

3.5. Effect of WF Substitution with BPF on Rheological and Thermo-Mechanical Parameters Examined by MIXOLAB

3.6. The Organoleptic Properties of Cake Made from WF and Substituted WF with BPF

4. Discussion

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hafez, A.A. Physico-chemical and sensory properties of cakes supplemented with different concentration of marjoram. Aust. J. Basic Appl. Sci. 2012, 6, 463–470. [Google Scholar]

- Hussain, S.; Al-Oulabi, R. Studying the possibility of preparing an egg-free or egg-less cake. Int. J. Eng. Technol. 2009, 1, 324–329. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Song, Y.; Hu, X.; Liao, X.; Ni, Y.; Li, Q. Effects of sugars in batter formula and baking conditions on 5-hydroxymethylfurfural and furfural formation in sponge cake models. Food Res. Int. 2012, 49, 439–445. [Google Scholar] [CrossRef]

- Cappelli, A.; Bettaccini, L.; Cini, E. The kneading process: A systematic review of the effects on dough rheology and resulting bread characteristics, including improvement strategies. Trends Food Sci. Technol. 2020, 104, 91–101. [Google Scholar] [CrossRef]

- Cappelli, A.; Canessa, J.; Cini, E. Effects of CO2 snow addition during kneading on thermoregulation, dough rheological properties, and bread characteristics: A focus on ancient and modern wheat cultivars. Int. J. Refrig. 2020, 117, 52–60. [Google Scholar] [CrossRef]

- Jiang, X.L.; Tian, J.C.; Hao, Z.; Zhang, W.D. Protein Content and Amino Acid Composition in Grains of Wheat-Related Species. Agr. Sci. China. 2008, 7, 272–279. [Google Scholar] [CrossRef]

- Rahul, J.; Jain, M.K.; Singh, S.P.; Kamal, R.K.; Anuradha; Naz, A.; Gupta, A.K.; Mrityunjay, S.K. Adansonia digitata L. (baobab): A review of traditional information and taxonomic description. Asian Pac. J. Trop. Biomed. 2015, 5, 79–84. [Google Scholar]

- Kaboré, D.; Sawadogo-Lingani, H.; Diawara, B.; Compaoré, C.S.; Dicko, M.H.; Jakobsen, M. A review of baobab (Adansonia digitata) products: Effect of processing techniques, medicinal properties and uses. Afr. J. Food Sci. 2011, 5, 833–844. [Google Scholar]

- Osman, M.A. Chemical and nutrient analysis of baobab (Adansonia digitata) fruit and seed protein solubility. Plant Foods Hum. Nutr. 2004, 59, 29–33. [Google Scholar] [CrossRef]

- Yazzie, D.; VanderJagt, D.J.; Pastuszyn, A.; Okolo, A.; Glew, R.H. The amino acid and mineral content of baobab (Adansonia digitata L.) leaves. J. Food Compos. Anal. 1994, 7, 189–193. [Google Scholar] [CrossRef]

- De Caluwé, E.; Halamová, K.; Van Damme, P. Adansonia digitata L. A review of traditional uses, phytochemistry and pharmacology. Afr. Focus. 2010, 23, 11–51. [Google Scholar] [CrossRef]

- Muthai, K.U.; Karori, M.S.; Muchugi, A.; Indieka, A.S.; Dembele, C.; Mng’omba, S.; Jamnadass, R. Nutritional variation in baobab (Adansonia digitata L.) fruit pulp and seeds based on Africa geographical regions. Food Sci. Nutr. 2017, 5, 1116–1129. [Google Scholar] [CrossRef] [PubMed]

- Hyacinthe, T.; Charles, P.; Adama, K.; Diarra, C.S.; Dicko, M.H.; Svejgaard, J.J.; Diawara, B. Variability of vitamins B1, B2 and minerals content in baobab (Adansonia digitata) leaves in East and West Africa. Food Sci. Nutr. 2015, 3, 17–24. [Google Scholar] [CrossRef] [PubMed]

- Busson, F.; Deniel, P.; Toury, J. Amino acid composition of the leaves and fruit pulp of baobab (Adansonia digitata Linn.). Bull. Soc. Chim. Biol. 1958, 40, 711–714. [Google Scholar]

- Li, X.N.; Sun, J.; Shi, H.; Yu, L.L.; Ridge, C.D.; Mazzola, E.P.; Okunji, C.; Iwu, M.M.; Michel, T.K.; Chen, P. Profiling hydroxycinnamic acid glycosides, iridoid glycosides, and phenylethanoid glycosides in baobab fruit pulp (Adansonia digitata). Food Res. Int. 2017, 99, 755–761. [Google Scholar] [CrossRef] [PubMed]

- Irondi, E.A.; Akintunde, J.K.; Agboola, S.O.; Boligon, A.A.; Athayde, M.L. Blanching influences the phenolics composition, antioxidant activity, and inhibitory effect of Adansonia digitata leaves extract on alpha-amylase, alpha-glucosidase, and aldose reductase. Food Sci. Nutr. 2017, 5, 233–242. [Google Scholar] [CrossRef]

- Sokeng, A.J.T.; Sobolev, A.P.; Di Lorenzo, A.; Xiao, J.; Mannina, L.; Capitani, D.; Daglia, M. Metabolite characterization of powdered fruits and leaves from Adansonia digitata L. (baobab): A multi-methodological approach. Food Chem. 2019, 272, 93–108. [Google Scholar] [CrossRef] [PubMed]

- Ismail, B.B.; Pu, Y.; Guo, M.; Ma, X.; Liu, D. LC-MS/QTOF identification of phytochemicals and the effects of solvents on phenolic constituents and antioxidant activity of baobab (Adansonia digitata) fruit pulp. Food Chem. 2019, 277, 279–288. [Google Scholar] [CrossRef] [PubMed]

- Ismail, B.B.; Pu, Y.; Fan, L.; Dandago, M.A.; Guo, M.; Liu, D. Characterizing the phenolic constituents of baobab (Adansonia digitata) fruit shell by LC-MS/QTOF and their in vitro biological activities. Sci. Total Environ. 2019, 694, 133387. [Google Scholar] [CrossRef]

- Cicolari, S.; Dacrema, M.; Tsetegho Sokeng, A.J.; Xiao, J.; Atchan Nwakiban, A.P.; Di Giovanni, C.; Santarcangelo, C.; Magni, P.; Daglia, M. Hydromethanolic Extracts from Adansonia digitata L. Edible Parts Positively Modulate Pathophysiological Mechanisms Related to the Metabolic Syndrome. Molecules 2020, 25, 2858. [Google Scholar] [CrossRef]

- Coe, S.A.; Clegg, M.; Armengol, M.; Ryan, L. The polyphenol-rich baobab fruit (Adansonia digitata L.) reduces starch digestion and glycemic response in humans. Nutr. Res. 2013, 33, 888–896. [Google Scholar] [CrossRef] [PubMed]

- Suliman, H.M.; Osman, B.; Abdoon, I.H.; Saad, A.M.; Khalid, H. Ameliorative activity of Adansonia digitata fruit on high sugar/high fat diet-simulated Metabolic Syndrome model in male Wistar rats. Biomed. Pharm. 2020, 125, 109968. [Google Scholar] [CrossRef] [PubMed]

- Ntchapda, F.; Bonabe, C.; Atsamo, A.D.; Kemeta Azambou, D.R.; Bekono Fouda, Y.; Imar Djibrine, S.; Seke Etet, P.F.; Theophile, D. Effect of Aqueous Extract of Adansonia digitata Stem Bark on the Development of Hypertension in L-NAME-Induced Hypertensive Rat Model. Evid. Based Complement Altern. Med. 2020, 2020, 3678469. [Google Scholar] [CrossRef]

- Owoyele, B.V.; Bakare, A.O. Analgesic properties of aqueous bark extract of Adansonia digitata in Wistar rats. Biomed. Pharm. 2018, 97, 209–212. [Google Scholar] [CrossRef] [PubMed]

- Adeoye, A.O.; Olanlokun, J.O.; Tijani, H.; Lawal, S.O.; Babarinde, C.O.; Akinwole, M.T.; Bewaji, C.O. Molecular docking analysis of apigenin and quercetin from ethylacetate fraction of Adansonia digitata with malaria-associated calcium transport protein: An in silico approach. Heliyon 2019, 5, e02248. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Garvey, R.; Clegg, M.; Coe, S. The acute effects of baobab fruit (Adansonia digitata) on satiety in healthy adults. Nutr. Health 2017, 23, 83–86. [Google Scholar] [CrossRef] [PubMed]

- Hanafy, A.; Aldawsari, H.M.; Badr, J.M.; Ibrahim, A.K.; Abdel-Hady Sel, S. Evaluation of Hepatoprotective Activity of Adansonia digitata Extract on Acetaminophen-Induced Hepatotoxicity in Rats. Evid. Based. Complement Altern. Med. 2016, 2016, 4579149. [Google Scholar] [CrossRef] [Green Version]

- Ghoneim, M.A.; Hassan, A.I.; Mahmoud, M.G.; Asker, M.S. Protective Effect of Adansonia digitata against Isoproterenol-Induced Myocardial Injury in Rats. Anim. Biotechnol. 2016, 27, 84–95. [Google Scholar] [CrossRef]

- Ismail, B.B.; Yusuf, H.L.; Pu, Y.; Zhao, H.; Guo, M.; Liu, D. Ultrasound-assisted adsorption/desorption for the enrichment and purification of flavonoids from baobab (Adansonia digitata) fruit pulp. Ultrason. Sonochem. 2020, 65, 104980. [Google Scholar] [CrossRef]

- Debelo, H.; Ndiaye, C.; Kruger, J.; Hamaker, B.R.; Ferruzzi, M.G. African Adansonia digitata fruit pulp (baobab) modifies provitamin A carotenoid bioaccessibility from composite pearl millet porridges. J. Food Sci. Technol. 2020, 57, 1382–1392. [Google Scholar] [CrossRef]

- Kamanula, M.; Munthali, C.R.; Dziwapo, A.; Kamanula, J.F. Mineral and phytochemical composition of baobab (Adansonia digitata L.) root tubers from selected natural populations of Malawi. Malawi Med. J. 2018, 30, 250–255. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Braca, A.; Sinisgalli, C.; De Leo, M.; Muscatello, B.; Cioni, P.L.; Milella, L.; Ostuni, A.; Giani, S.; Sanogo, R. Phytochemical Profile, Antioxidant and Antidiabetic Activities of Adansonia digitata L. (Baobab) from Mali, as a Source of Health-Promoting Compounds. Mololecules 2018, 23, 3104. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Al-Juhaimi, F.; Babtain, I.A.; Mohamed Ahmed, I.A.; Alsawmahi, O.N.; Ghafoor, K.; Adiamo, O.Q.; Babiker, E.E. Assessment of oxidative stability and physicochemical, microbiological, and sensory properties of beef patties formulated with baobab seed (Adansonia digitata) extract. Meat Sci. 2020, 162, 108044. [Google Scholar] [CrossRef] [PubMed]

- Obizoba, I.C.; Anyika, J.U. Nutritive value of baobab milk (gubdi) and mixtures of baobab (Adansonia digitata L.) and hungry rice, acha (Digitaria exilis) flours. Plant Foods Hum. Nutr. 1994, 46, 157–165. [Google Scholar] [CrossRef] [PubMed]

- Fischer, S.; Jackering, L.; Kehlenbeck, K. The Baobab (Adansonia digitata L.) in Southern Kenya-A Study on Status, Distribution, Use and Importance in Taita-Taveta County. Environ. Manag. 2020, 66, 305–318. [Google Scholar] [CrossRef]

- Cappelli, A.; Oliva, N.; Cini, E.A. Systematic review of gluten-free dough and bread: Dough rheology, bread characteristics, and improvement strategies. Appl. Sci. 2020, 10, 6559. [Google Scholar] [CrossRef]

- Cappelli, A.; Mugnaini, M.; Cini, E. Improving roller milling technology using the break, sizing, and reduction systems for flour differentiation. LWT Food Sci. Technol. 2020, 133, 110067. [Google Scholar] [CrossRef]

- Galli, V.; Venturi, M.; Pini, N.; Granchi, L. Technological feature assessment of lactic acid bacteria isolated from cricket powder’s spontaneous fermentation as potential starters for cricket-wheat bread production. Foods 2020, 9, 1322. [Google Scholar] [CrossRef]

- Kowalczewski, P.Ł.; Walkowiak, K.; Masewicz, Ł.; Bartczak, O.; Lewandowicz, J.; Kubiak, P.; Baranowska, H.M. Gluten-free bread with cricket powder—mechanical properties and molecular water dynamics in dough and ready product. Foods 2019, 8, 240. [Google Scholar] [CrossRef] [Green Version]

- Cappelli, A.; Oliva, N.; Bonaccorsi, G.; Lorini, C.; Cini, E. Assessment of the rheological properties and bread characteristics obtained by innovative protein sources (Cicer arietinum, Acheta domesticus, Tenebrio molitor): Novel food or potential improvers for wheat flour? LWT Food Sci. Technol. 2020, 118, 108867. [Google Scholar] [CrossRef]

- Valková, V.; Ďúranová, H.; Štefániková, J.; Miškeje, M.; Tokár, M.; Gabríny, L.; Kačániová, M. Wheat bread with grape seeds micropowder: Impact on dough rheology and bread properties. Appl. Rheol. 2020, 30, 138–150. [Google Scholar] [CrossRef]

- Adams, Z.S.; Manu, F.D.W.; Agbenorhevi, J.; Oduro, I. Improved Yam-Baobab-tamarind flour blends: Its potential use in extrusion cooking. Sci. Afr. 2019, 6, e00126. [Google Scholar] [CrossRef]

- A.A.C.C. Approved Methods of the American Association of Cereal Chemists; American Association of Cereal Chemists: St Paul, MN, USA, 2000; Volume 1, pp. 631–671. [Google Scholar]

- Khalifa, I.; Barakat, H.; El-Mansy, H.A.; Soliman, S.A. Physico-chemical, organolyptical and microbiological characteristics of substituted cupcake by potato processing residues. Food Nutr. Sci. 2015, 6, 83–100. [Google Scholar] [CrossRef] [Green Version]

- FAO. Food Energy e Methods of Analysis and Conversion Factors. In Food and Nutrition 2003; FAO: Rome, Italy, 2003; p. 77. [Google Scholar]

- A.O.A.C. Association of Official Analytical Chemists. Official Method of Analysis of AOAC International, 17th ed.; AOAC International: Gaithersburg, MD, USA, 2000; pp. 411–427. [Google Scholar]

- Borah, S.; Baruah, A.M.; Das, A.K.; Borah, J. Determination of mineral content in commonly consumed leafy vegetables. Food Anal. Method 2009, 2, 226–230. [Google Scholar] [CrossRef]

- Sudha, M.L.; Baskaran, V.; Leelavathi, K. Apple pomace as a source of dietary fiber and polyphenols and its effect on the rheological characteristics and cake making. Food Chem. 2007, 104, 686–692. [Google Scholar] [CrossRef]

- Lee, S.C.; Kim, J.H.; Jeong, S.M.; Kim, D.R.; Ha, J.U.; Nam, K.C.; Ahn, D.U. Effect of far-infrared radiation on the antioxidant activity of rice hulls. J. Agr. Food Chem. 2003, 51, 4400–4403. [Google Scholar] [CrossRef] [PubMed]

- Barakat, H.; Rohn, S. Effect of different cooking methods on bioactive compounds in vegetarian, broccoli-based bars. J. Funct. Food. 2014, 11, 407–416. [Google Scholar] [CrossRef]

- A.O.A.C. Official Methods of Analysis of the AOAC International No. 994.12, 19th ed.; A.O.A.C.: Gaithersburg, MD, USA, 2012; Chapter 4; pp. 18–19. [Google Scholar]

- Nosworthy, M.G.; Franczyk, A.; Zimoch-Korzycka, A.; Appah, P.; Utioh, A.; Neufeld, J.; House, J.D. Impact of processing on the protein quality of pinto bean (Phaseolus vulgaris) and buckwheat (Fagopyrum esculentum Moench) flours and blends, as determined by in vitro and in vivo methodologies. J. Agr. Food Chem. 2017, 65, 3919–3925. [Google Scholar] [CrossRef]

- Alsmeyer, R.H.; Cunningham, A.E.; Happich, M.L. Equations predict PER from amino acid analysis. Food Technol. 1974, 28, 34–40. [Google Scholar]

- WHO. Protein and Amino acid Requirements in Human Nutrition; World Health Organization: Geneva, Switzerland, 2007; Volume 935.

- Dubat, A. A New AACC International Approved Method to Measure Rheological Properties of a Dough Sample. Cereal Foods World 2010, 55, 150. [Google Scholar] [CrossRef]

- Steel, R.; Torrie, J.; Dickey, D. Principles and Procedures of Statistics: A Biometrical Approach, 3rd ed.; McGraw Hill, Inc. Book Co.: New York, NY, USA, 1997; pp. 352–358. [Google Scholar]

- Kahraman, K.; Sakıyan, O.; Ozturk, S.; Koksel, H.; Sumnu, G.; Dubat, A. Utilization of Mixolab® to predict the suitability of flours in terms of cake quality. Eur. Food Res. Technol. 2008, 227, 565–570. [Google Scholar] [CrossRef]

- Market Analysis Report. Cake Market Size, Share & Trends Analysis Report by Product (Cupcakes, Dessert Cakes, Sponge Cakes), By Distribution Channel, By Region, And Segment Forecasts, 2020—2027. July 2020, ID: GVR-4-68038-883-1. Available online: https://www.grandviewresearch.com/industry-analysis/cakes-market (accessed on 12 January 2021).

- Cappelli, A.; Guerrini, L.; Cini, E.; Parenti, A. Improving whole wheat dough tenacity and extensibility: A new kneading process. J. Cereal Sci. 2019, 90, 102852. [Google Scholar] [CrossRef]

- Serra-Majem, L. Vitamin and mineral intakes in European children. Is food fortification needed? Public Health Nutr. 2001, 4, 101–107. [Google Scholar] [CrossRef] [Green Version]

- Hunt, J.; Dwyer, J. Position of the American Dietetic Association: Food fortification and dietary supplements. J. Am. Diet. Assoc. 2001, 101, 115–125. [Google Scholar]

- Compaoré, W.; Nikièma, P.; Bassolé, H.; Savadogo, A.; Mouecoucou, J. Chemical composition and antioxidative properties of seeds of Moringa oleifera and pulps of Parkia biglobosa and Adansonia digitata commonly used in food fortification in Burkina Faso. Curr. Res. J. Biol. Sci. 2011, 3, 64–72. [Google Scholar]

- Fagbohun, A.A.; Ikokoh, P.P.; Afolayan, M.O.; Olajide, O.O.; Fatokun, O.A.; Akanji, F.T. Chemical composition and antioxidant capacity of the fruit pulp of Adansonia digitata L. Int. J. Appl. Chem. 2012, 8, 165–172. [Google Scholar]

- Nour, A.A.; Magboul, B.I.; Kheiri, N.H. Chemical composition of baobab fruit. Adansonia Digit. 1980, 22, 383–388. [Google Scholar]

- Adubiaro, H.; Olaofe, O.; Akintayo, E.; Babalola, O. Chemical composition, cacium, zinc and phytate interrelationships in baobab (Adansonia digitata) seed flour. Adv. J. Food Sci. Technol. 2011, 3, 228–232. [Google Scholar]

- Lu, T.; Lee, C.Y.; Mau, J.; Lin, S. Quality and antioxidant property of green tea sponge cake. Food Chem. 2010, 119, 1090–1095. [Google Scholar] [CrossRef]

- Ahmed, A.R. Influence of Chemical Properties of Wheat-Lupine Flour Blends on Cake Quality. Am. J. Food Sci. Technol. 2014, 2, 67–75. [Google Scholar] [CrossRef] [Green Version]

- Glew, R.H.; VanderJagt, D.J.; Lockett, C.; Grivetti, L.E.; Smith, G.C.; Pastuszyn, A.; Millson, M. Amino acid, fatty acid, and mineral composition of 24 indigenous plants of Burkina Faso. J. Food Compos. Anal. 1997, 10, 205–217. [Google Scholar] [CrossRef]

- Nie, C.; He, T.; Zhang, W.; Zhang, G.; Ma, X. Branched chain amino acids: Beyond nutrition metabolism. Int. J. Mol. Sci. 2018, 19, 954. [Google Scholar] [CrossRef] [Green Version]

- Saito, K.; Jin, D.-H.; Ogawa, T.; Muramoto, K.; Hatakeyama, E.; Yasuhara, T.; Nokihara, K. Antioxidative properties of tripeptide libraries prepared by the combinatorial chemistry. J. Agr. Food Chem. 2003, 51, 3668–3674. [Google Scholar] [CrossRef] [PubMed]

- Song, W.; Kong, X.; Hua, Y.; Li, X.; Zhang, C.; Chen, Y. Antioxidant and antibacterial activity and in vitro digestion stability of cottonseed protein hydrolysates. LWT 2020, 118, 108724. [Google Scholar] [CrossRef]

- Singh, T.P.; Sogi, D.S. Comparative study of structural and functional characterization of bran protein concentrates from superfine, fine and coarse rice cultivars. Int. J. Biol. Macromol. 2018, 111, 281–288. [Google Scholar] [CrossRef] [PubMed]

- Mariotti, F. Vegetarian and Plant-Based Diets in Health and Disease Prevention; Academic Press: Cambridge, MA, USA, 2017; pp. 621–642. [Google Scholar]

- Ozturk, S.; Kahraman, K.; Tiftik, B.; Koksel, H. Predicting the cookie quality of flours by using Mixolab®. Eur. Food Res Technol. 2008, 227, 1549–1554. [Google Scholar] [CrossRef]

- Bucsella, B.; Takacs, A.; Vizer, V.; Schwendener, U.; Tomoskozi, S. Comparison of the effects of different heat treatment processes on rheological properties of cake and bread wheat flours. Food Chem. 2016, 190, 990–996. [Google Scholar] [CrossRef]

- Chen, F.; Li, H.; Li, X.; Dong, Z.; Zuo, A.; Shang, X.; Cui, D. Alveograph and Mixolab parameters associated with Puroindoline-D1 genes in Chinese winter wheats. J. Sci. Food Agri. 2013, 93, 2541–2548. [Google Scholar] [CrossRef]

- Zou, W.; Schulz, B.L.; Tan, X.; Sissons, M.; Warren, F.J.; Gidley, M.J.; Gilbert, R.G. The role of thermostable proteinaceous α-amylase inhibitors in slowing starch digestion in pasta. Food Hydrocoll. 2019, 90, 241–247. [Google Scholar] [CrossRef]

- Mounjouenpou, P.; Eyenga, S.N.N.N.; Kamsu, E.J.; Kari, P.B.; Ehabe, E.E.; Ndjouenkeu, R. Effect of fortification with baobab (Adansonia digitata L.) pulp flour on sensorial acceptability and nutrient composition of rice cookies. Sci. Afr. 2018, 1, e00002. [Google Scholar] [CrossRef]

| Ingredients | WF | WF + 5% BPF | WF + 10% BPF | WF + 15% BPF |

|---|---|---|---|---|

| Soft wheat flour (72% extraction) | 250.0 | 237.5 | 225 | 212.5 |

| Baobab pulp flour (BPF) | - | 12.5 | 25 | 37.5 |

| Sucrose powder | 125.0 | 125.0 | 125.0 | 125.0 |

| Salt | 3.50 | 3.50 | 3.50 | 3.50 |

| Skimmed milk powder | 25.0 | 25.0 | 25.0 | 25.0 |

| Shortening | 53.50 | 53.50 | 53.50 | 53.50 |

| Fresh whole egg | 110.0 | 110.0 | 110.0 | 110.0 |

| Baking powder | 12.50 | 12.50 | 12.50 | 12.50 |

| Vanilla | 2.0 | 2.0 | 2.0 | 2.0 |

| Chemical Composition | Cake Formulas | ||||

|---|---|---|---|---|---|

| BPF | WF | WF + 5% BPF | WF + 10% BPF | WF + 15% BPF | |

| Moisture | 13.28 ± 0.26 a | 11.70 ± 0.59 b | 11.80 ± 0.35 b | 11.84 ± 0.47 b | 11.97 ± 0.42 b |

| Crud protein * | 12.54 ± 0.14 a | 12.93 ± 0.65 a | 12.93 ± 0.39 a | 12.87 ± 0.51 a | 12.90 ± 0.45 a |

| Ash * | 6.52 ± 0.05 a | 0.83 ± 0.04 e | 1.13 ± 0.03 d | 1.38 ± 0.06 c | 1.71 ± 0.06 b |

| Crude fat * | 0.45 ± 0.05 c | 0.95 ± 0.05 a | 0.95 ± 0.03 a | 0.88 ± 0.04 b | 0.91 ± 0.03 a |

| Crude fiber * | 4.65 ± 0.23 a | 0.88 ± 0.04 e | 1.09 ± 0.03 d | 1.24 ± 0.05 c | 1.48 ± 0.05 b |

| Available carbohydrate * | 75.84 ± 0.15 b | 84.41 ± 4.22 a | 84.00 ± 2.52 a | 83.53 ± 3.34 a | 83.15 ± 2.91 a |

| Energy value (Kcal 100 g−1) | 357.57 ± 9.21 a | 351.75 ± 17.59 a | 349.86 ± 10.50 a | 347.30 ± 13.89 a | 345.75 ± 12.10 a |

| Minerals (mg 100 g−1) * | Cake Formulas | ||||

|---|---|---|---|---|---|

| BPF | WF | WF + 5% BPF | WF + 10% BPF | WF + 15% BPF | |

| Macroelements | - | - | - | - | - |

| Na | 36.02 ± 1.08 e | 186.54 ± 4.46 a | 177.51 ± 3.04 b | 171.85 ± 3.73 c | 162.10 ± 2.87 b |

| Ca | 237.03 ± 7.11 a | 35.89 ± 1.44 e | 47.96 ± 1.63 d | 58.37 ± 2.28 c | 65.70 ± 2.50 b |

| K | 987.51 ± 29.63 a | 165.47 ± 6.62 e | 214.79 ± 7.30 d | 257.55 ± 10.04 c | 287.12 ± 7.16 b |

| P | 124.08 ± 3.72 a | 86.15 ± 3.45 b | 88.43 ± 3.01 b | 91.18 ± 3.56 b | 90.98 ± 3.46 b |

| Mg | 102.01 ± 3.06 a | 84.54 ± 3.10 b | 85.59 ± 2.37 b | 87.31 ± 2.70 b | 86.32 ± 1.89 b |

| Microelements | - | - | - | - | - |

| Zn | 2.04 ± 0.06 a | 0.66 ± 0.05 d | 0.74 ± 0.03 c | 0.82 ± 0.05 bc | 0.86 ± 0.07 b |

| Fe | 9.03 ± 0.27 a | 1.21 ± 0.04 e | 1.68 ± 0.05 d | 2.08 ± 0.07 c | 2.37 ± 0.08 b |

| Cu | 1.53 ± 0.05 a | 0.28 ± 0.01 d | 0.35 ± 0.03 c | 0.42 ± 0.02 b | 0.46 ± 0.04 b |

| Organoleptic Attributes | Cake Formulas | |||

|---|---|---|---|---|

| WF | WF + 5% BPF | WF + 10% BPF | WF + 15% BPF | |

| Total phenolic compounds (mg GAE g−1 dw) | 3.15 ± 0.13 e | 3.55 ± 0.18 d | 3.96 ± 0.10 c | 4.36 ± 0.20 b |

| Antioxidant activity, DPPH (mg TE g−1 dw) | 5.47 ± 0.22 e | 6.45 ± 0.32 d | 7.44 ± 0.21 c | 8.42 ± 0.38 b |

| Antioxidant activity, ABTS (mg TE g−1 dw) | 6.48 ± 0.26 e | 7.89 ± 0.49 d | 9.31 ± 0.31 c | 10.72 ± 0.49 b |

| Amino Acid | Amino Acid (AA) mg/g Protein | ||||

|---|---|---|---|---|---|

| BPF | WF | WF + 5% BPF | WF + 10% BPF | WF + 15% BPF | |

| EAA | |||||

| Therionine | 30.30 | 25.68 | 25.88 | 26.19 | 26.30 |

| Valine | 50.24 | 39.75 | 40.25 | 40.88 | 41.23 |

| Isoleucine | 35.89 | 31.86 | 32.03 | 32.32 | 32.38 |

| Leucine | 63.80 | 57.54 | 57.78 | 58.27 | 58.32 |

| Phenylalanine | 49.44 | 45.94 | 46.02 | 46.39 | 46.32 |

| Lysine | 52.63 | 24.90 | 26.37 | 27.74 | 29.05 |

| Hisitidine | 23.92 | 21.81 | 21.89 | 22.07 | 22.08 |

| Cystine | 24.72 | 18.72 | 19.03 | 19.35 | 19.60 |

| Methonine | 19.14 | 20.26 | 20.17 | 20.18 | 20.03 |

| NEAA | |||||

| Aspartic | 90.11 | 48.26 | 50.45 | 52.61 | 54.53 |

| Serine | 46.25 | 37.28 | 37.70 | 38.25 | 38.53 |

| Glutamic | 240.03 | 229.54 | 229.73 | 230.96 | 230.41 |

| Proline | 38.28 | 120.65 | 115.97 | 112.40 | 107.62 |

| Glycine | 43.06 | 36.50 | 36.80 | 37.23 | 37.39 |

| Alanine | 48.64 | 31.86 | 32.72 | 33.63 | 34.34 |

| Tyrosine | 29.51 | 34.18 | 33.87 | 33.76 | 33.36 |

| Argenine | 107.66 | 42.85 | 46.29 | 49.54 | 52.65 |

| EAAs | 350.08 | 286.47 | 289.42 | 293.38 | 295.30 |

| NEAAs | 643.54 | 581.13 | 583.54 | 588.37 | 588.83 |

| TAA | 993.62 | 867.59 | 872.96 | 881.75 | 884.13 |

| Parameters | BPF | WF | WF + 5% BPF | WF + 10% BPF | WF + 15% BPF |

|---|---|---|---|---|---|

| Total BCAAs (mg/g protein) | 149.92 | 129.16 | 130.07 | 131.47 | 131.93 |

| Total BAAs (mg/g protein) | 184.21 | 89.56 | 94.55 | 99.35 | 103.78 |

| Total uncharged polar AAs | 173.84 | 152.36 | 153.28 | 154.77 | 155.18 |

| PER | 26.61 | 19.88 | 20.21 | 20.60 | 20.85 |

| BV | 44.54 | 20.29 | 21.23 | 22.48 | 23.11 |

| EAAI | 54.34 | 44.68 | 45.20 | 45.86 | 46.19 |

| Requirement index (Infants) | 116.41 | 95.72 | 96.84 | 98.24 | 98.96 |

| Requirement index (Preschool child) | 126.43 | 103.96 | 105.18 | 106.70 | 107.48 |

| Requirement index (Schoolchild) | 138.35 | 113.76 | 115.09 | 116.76 | 117.62 |

| Requirement index (Adult) | 145.50 | 119.63 | 121.04 | 122.79 | 123.69 |

| Composite Flour * | Mixolab Parameters | |||||

|---|---|---|---|---|---|---|

| Water Absorption (% b14) ** | Stability (min) | C2 (Nm) | C3 (Nm) | C4 (Nm) | C5 (Nm) | |

| WF 72% | 59.1 ± 0.9 c | 8.82 ± 0.41 a | 0.504 ± 0.012 a | 1.942 ± 0.034 b | 1.780 ± 0.057 c | 2.750 ± 0.035 b |

| WF + 5%BPF | 60.3 ± 0.7 c | 7.78 ± 0.52 a | 0.348 ± 0.024 b | 2.157 ± 0.047 a | 2.006 ± 0.078 a | 2.978 ± 0.027 a |

| WF + 10%BPF | 62.4 ± 0.6 b | 5.35 ± 0.19 b | 0.299 ± 0.017 c | 2.148 ± 0.057 a | 1.903 ± 0.024 b | 2.711 ± 0.045 b |

| WF + 15%BPF | 64.6 ± 0.5 a | 4.45 ± 0.67 c | 0.275 ± 0.032 c | 2.040 ± 0.071 a | 1.803 ± 0.057 c | 2.570 ± 0.052 c |

| Organoleptic Attributes | Cake Formulas | ||||

|---|---|---|---|---|---|

| WF | WF + 5% BPF | WF + 10% BPF | WF + 15% BPF | ||

| Crust color (10) | 8.83 ± 0.40 a | 8.33 ± 0.16 a | 7.50 ± 0.21 b | 7.08 ± 0.50 b | |

| Odor (10) | 9.00 ± 0.30 a | 8.50 ± 0.29 a | 8.00 ± 0.33 a,b | 8.17 ± 0.44 a,b | |

| Taste (10) | 8.25 ± 0.88 a | 8.92 ± 0.25 a | 8.08 ± 0.25 a,b | 7.83 ± 0.35 b | |

| Crumb cells (40) | Thickness (10) | 8.75 ± 0.38 a | 8.58 ± 0.21 a | 7.92 ± 0.28 b,c | 7.50 ± 0.42 b,c |

| Size (10) | 9.00 ± 0.30 a | 8.42 ± 0.28 a | 7.50 ± 0.37 b | 6.42 ± 0.39 c | |

| Uniformity (10) | 8.75 ± 0.33 a | 7.92 ± 0.28 b | 7.17 ± 0.30 c | 6.50 ± 0.37 d | |

| Color (10) | 8.25 ± 0.51 a | 8.00 ± 0.19 a | 7.5 ± 0.37 a,b | 6.75 ± 0.47 b,c | |

| Texture (30) | Softness (10) | 8.75 ± 0.41 a | 8.42 ± 0.25 a,b | 8.00 ± 0.30 a,b | 7.67 ± 0.43 b,c |

| Tenderness (10) | 9.00 ± 0.30 a | 8.17 ± 0.33 b | 7.83 ± 0.30 b | 7.42 ± 0.34 b,c | |

| Moistness (10) | 8.75 ± 0.38 a | 8.17 ± 0.33 a,b | 7.92 ± 0.37 b | 7.58 ± 0.53 b | |

| Overall acceptability (100) | 86.33 ± 3.41 a | 82.92 ± 1.76 a | 77.67 ± 1.61 b | 73.33 ± 2.82 b | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barakat, H. Nutritional and Rheological Characteristics of Composite Flour Substituted with Baobab (Adansonia digitata L.) Pulp Flour for Cake Manufacturing and Organoleptic Properties of Their Prepared Cakes. Foods 2021, 10, 716. https://doi.org/10.3390/foods10040716

Barakat H. Nutritional and Rheological Characteristics of Composite Flour Substituted with Baobab (Adansonia digitata L.) Pulp Flour for Cake Manufacturing and Organoleptic Properties of Their Prepared Cakes. Foods. 2021; 10(4):716. https://doi.org/10.3390/foods10040716

Chicago/Turabian StyleBarakat, Hassan. 2021. "Nutritional and Rheological Characteristics of Composite Flour Substituted with Baobab (Adansonia digitata L.) Pulp Flour for Cake Manufacturing and Organoleptic Properties of Their Prepared Cakes" Foods 10, no. 4: 716. https://doi.org/10.3390/foods10040716

APA StyleBarakat, H. (2021). Nutritional and Rheological Characteristics of Composite Flour Substituted with Baobab (Adansonia digitata L.) Pulp Flour for Cake Manufacturing and Organoleptic Properties of Their Prepared Cakes. Foods, 10(4), 716. https://doi.org/10.3390/foods10040716