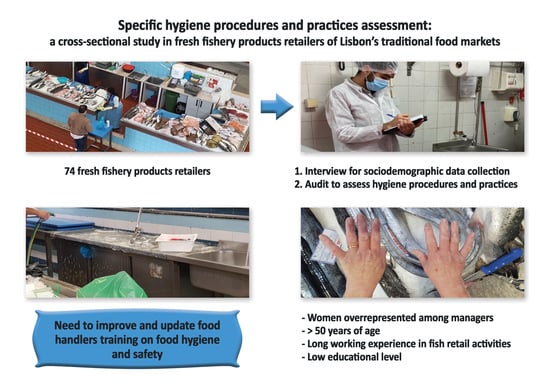

Specific Hygiene Procedures and Practices Assessment: A Cross-Sectional Study in Fresh Fishery Product Retailers of Lisbon’s Traditional Food Markets

Abstract

:1. Introduction

2. Materials and Methods

2.1. Study Design and Participants

2.2. Fresh Fishery Product Retailers’ Assessment

2.2.1. Interview for Socio-Demographic Data Collection

2.2.2. Auditing Hand Hygiene and Food Contact Surfaces Hygiene Procedures and Practices

2.3. Data Analysis

3. Results and Discussion

3.1. Fresh Fishery Product Retailers Socio-Demographic Data

3.2. Fresh Fishery Product Retailers Audit Assessment

3.2.1. Documental Assessment of Hand Hygiene and Food Contact Surfaces Hygiene

3.2.2. Hand Hygiene Procedures and Practices Verification

3.2.3. Food Contact Surfaces Hygiene Procedures and Practices Verification

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Sections | Questions |

| Documental assessment of procedures | Hand hygiene: Does the personal hygiene program include hand hygiene recommendations? Is there a recommended handwashing soap/sanitizer in the personal hygiene program? Are there technical and safety data sheets for in-use handwashing soap and sanitizer? Are handwashing instructions available and easily displayed while performing the procedure? Food contact surfaces hygiene: Does the hygiene program consider food contact surfaces hygiene? The existing hygiene program for food contact surfaces considers the following: (i) surfaces to be sanitized; (ii) detergents/sanitizers to be used; (iii) detailed cleaning and sanitizing procedures. Are there technical and safety data sheets for the detergent and sanitizer used in food contact surfaces? Are surfaces cleaning and sanitizing work instructions available and easily displayed while performing the procedure? |

| Hand hygiene practices | Hand presentation: Do food handlers present their hands and nails in a suitable condition for food handling? Do food handlers present hand and/or wrist adornments? Handwashing equipment: Is there an exclusive handwashing sink for handwashing? Is there an automatic/non-hand operated water supply in the handwashing sink? Handwashing procedure: Is running water used to pre-rinse hands? Is hot water used for handwashing purposes? Is soap used in the handwashing procedure? Are hands and wrists fully washed with soap during the handwashing procedure? Is running water used to remove soap? Is a hand sanitizer used? Does the handwashing procedure take 40–60 s? Is hand drying appropriately performed? Are the in-use soap and sanitizer appropriate and specific for the handwashing procedure? Glove wearing: Are gloves used during working hours? Are disposable gloves changed whenever necessary? Are reusable gloves sanitized after use? Is the sanitizing procedure used for reusable gloves appropriate? Are hands washed correctly before/after putting on gloves? |

| Food contact surfaces hygiene practices | Surfaces materials and maintenance: Are food contact surfaces made of suitable materials? Are food contact surfaces in good conservation conditions? Surfaces hygiene procedure: Is a pre-rinsing step applied? Is a cleaning step applied? In the cleaning step, is the recommended detergent application method fully observed? Is a sanitizing step applied? In the sanitizing step, is the recommended sanitizer application method fully observed? Is the detergent mixed with the sanitizer prior to their application on surfaces? Are food contact surfaces appropriately rinsed in the end of the hygienization procedures? Cleaning utensils and chemicals management: Are the cleaning utensils adequate? Are all chemicals stored away from food handling areas in a closed and properly identified place? Are chemical products properly stored in their original package? Are chemical products properly labeled? |

References

- World Health Organization (WHO). Available online: https://www.who.int/health-topics/foodborne-diseases#tab=tab_1 (accessed on 1 July 2021).

- European Food Safety Authority and European Centre for Disease Prevention and Control. The European Union One Health 2019 Zoonoses Report. EFSA J. 2021, 19, 6406. Available online: https://www.ecdc.europa.eu/sites/default/files/documents/zoonoses-EU-one-health-2019-report.pdf (accessed on 2 June 2021).

- European Commission. Commission Regulation (EC) No 852/2004 of 29 April 2004 on the hygiene of foodstuffs. Off. J. Eur. Union 2004, 47, L139. Available online: http://data.europa.eu/eli/reg/2004/852/oj (accessed on 1 July 2021).

- European Commission. Commission Regulation (EC) No 853/2004 of 29 April 2004 laying down specific hygiene rules for food of animal origin. Off. J. Eur. Union 2004, 139, 55–206. Available online: http://data.europa.eu/eli/reg/2004/853/oj (accessed on 1 July 2021).

- European Commission. Commission Notice 2016/C 278/01 of 30 July 2016 on the implementation of food safety management systems covering prerequisite programs and procedures based on the HACCP principles, including the facilitation/flexibility of the implementation in certain food businesses. Off. J. Eur. Union 2016, 278, 1–32. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52016XC0730%2801%29 (accessed on 1 July 2021).

- Bucking, M.; Haugen, J.E. Improving hygiene control by sensors. In Handbook of Hygiene Control in the Food Industry, 2nd ed.; Lelieveld, H.L.M., Mostert, M.A., Holah, J., Eds.; Woodhead Publishing Ltd.: Cambridge, UK, 2016; pp. 312–334. ISBN 978-0-0810-01554. [Google Scholar]

- van Asselt, A.J.; Giffel, M.C. Pathogen resistance to sanitisers. In Handbook of Hygiene Control in the Food Industry, 2nd ed.; Lelieveld, H.L.M., Mostert, M.A., Holah, J., Eds.; Woodhead Publishing Ltd.: Cambridge, UK, 2016; pp. 69–92. ISBN 978-0-0810-01554. [Google Scholar]

- Luning, P.A.; Jacxsens, L.; Rovira, J.; Osés, S.M.; Uyttendaele, M.; Marcelis, W.J. A concurrent diagnosis of microbiological food safety output and food safety management system performance: Cases from meat processing industries. Food Control 2011, 22, 555–565. [Google Scholar] [CrossRef]

- Lahou, E.; Jacxsens, L.; Daelman, J.; Van Landeghem, F.; Uyttendaele, M. Microbiological Performance of a Food Safety Management System in a Food Service Operation. J. Food Prot. 2012, 75, 706–716. [Google Scholar] [CrossRef]

- Notermans, S.; Powell, S.C.; Hoornstra, E. Introduction. In Handbook of Hygiene Control in the Food Industry, 2nd ed.; Lelieveld, H.L.M., Mostert, M.A., Holah, J., Eds.; Woodhead Publishing Ltd.: Cambridge, UK, 2016; pp. 1–28. ISBN 978-0-0810-01554. [Google Scholar]

- Santos, A.; Cardoso, M.F.; Costa, J.; Gomes-Neves, E. Meat Safety: An Evaluation of Portuguese Butcher Shops. J. Food Prot. 2017, 80, 1159–1166. [Google Scholar] [CrossRef]

- Maillard, J.-Y. Testing the effectiveness of disinfectants and sanitisers. In Handbook of Hygiene Control in the Food Industry, 2nd ed.; Lelieveld, H.L.M., Mostert, M.A., Holah, J., Eds.; Woodhead Publishing Ltd.: Cambridge, UK, 2016; pp. 641–671. ISBN 978-0-0810-01554. [Google Scholar]

- World Health Organization (WHO). WHO Guidelines on Hand Hygiene in Health Care—16 First Global Patient Safety Challenge—Clean Care Is Safer Care. Available online: https://www.who.int/gpsc/5may/tools/who_guidelines-handhygiene_summary.pdf (accessed on 21 June 2021).

- Michaels, B. Understanding the Glove Risk Paradigm: Part I. Food Saf. Mag. 2004, 10, 24–27. [Google Scholar]

- Vitória, A.G.; Oliveira, J.S.C.; Almeida Pereira, L.C.; Faria, C.P.; São José, J.F.B. Food safety knowledge, attitudes and practices of food handlers: A cross-sectional study in school kitchens in Espírito Santo, Brazil. BMC Public Health 2021, 21, 349. [Google Scholar] [CrossRef] [PubMed]

- Raaska, L. Managing contamination risks from food packaging materials. In Handbook of Hygiene Control in the Food Industry, 2nd ed.; Lelieveld, H.L.M., Mostert, M.A., Holah, J., Eds.; Woodhead Publishing Ltd.: Cambridge, UK, 2016; pp. 378–395. ISBN 978-0-0810-01554. [Google Scholar]

- World Health Organization and Food and Agriculture Organization of the United Nations. Codex Alimentarius: Food Hygiene (Basic Texts), 4th ed.; FAO: Rome, Italy, 2009; pp. 1–35. [Google Scholar]

- Associação dos Comerciantes de Pescado. Guia de Boas Práticas de Higiene para Produtos da Pesca Frescos, Grossistas e Retalhistas; Imagem Digital Gráfica: Lisbon, Portugal, 2012. [Google Scholar]

- European Commission. Commission recommendation 2003/361/EC of 6 May 2003 concerning the definition of micro, small and medium-sized enterprises. Off. J. Eur. Union 2003, 20, 36–41. [Google Scholar]

- Cunha, D.T.; Stedefeldt, E.; Rosso, V.V. The role of theoretical food safety training on Brazilian food handlers’ knowledge, attitude and practice. Food Control 2014, 43, 167–174. [Google Scholar] [CrossRef]

- Tan, S.L.; Bakar, F.A.; Karim, M.S.A.; Lee, H.Y.; Mahyudin, N.A. Hand hygiene knowledge, attitudes and practices among food handlers at primary schools in Hulu Langat district, Selangor (Malaysia). Food Control 2013, 34, 428–435. [Google Scholar] [CrossRef]

- Sibanyoni, J.J.; Tshabalala, P.A.; Tabit, F.T. Food safety knowledge and awareness of food handlers in school feeding programmes in Mpumalanga, South Africa. Food Control 2016, 73, 1397–1406. [Google Scholar] [CrossRef]

- De Silva, D.A.M. Faces of Women in Global Fishery Value Chains: Female Involvement, Impact and Importance in the Fisheries of Developed and Developing Countries, 1st ed.; Norwegian Agency for Development Cooperation/Food and Agriculture Organization Value Chain Project: Geneva, Switzerland, 2011; pp. 1–68. [Google Scholar]

- de Lisboa, C.M. Plano Municipal dos Mercados de Lisboa 2016–2020; CML: Lisbon, Portugal, 2016. [Google Scholar]

- Barreta, J. Organização e Gestão dos Mercados Municipais. Mudar e Inovar para Competir, 1st ed.; GEPE: Lisbon, Portugal, 2002; pp. 15–30. [Google Scholar]

- Soares, L.S.; Almeida, C.; Cerqueira, E.; Carvalho, J.; Nunes, I. Knowledge, attitudes and practices in food safety and the presence of coagulase-positive staphylococci on hands of food handlers in the schools of Camaçari, Brazil. Food Control 2012, 27, 206–213. [Google Scholar] [CrossRef] [Green Version]

- Liu, S.; Liu, Z.; Zhang, H.; Lu, L.; Liang, J.; Huang, Q. Knowledge, attitude and practices of food safety amongst food handlers in the coastal resort of Guangdong, China. Food Control 2015, 47, 457–461. [Google Scholar] [CrossRef]

- Lee, H.; Abdul Halim, H.; Thong, K.; Chai, L. Assessment of Food Safety Knowledge, Attitude, Self-Reported Practices, and Microbiological Hand Hygiene of Food Handlers. Int. J. Environ. Res. Public Health 2017, 14, 55. [Google Scholar] [CrossRef] [Green Version]

- Agüeria, D.A.; Terni, C.; Baldovino, V.M.; Civit, D. Food safety knowledge, practices and attitudes of fishery workers in Mar del Plata, Argentina. Food Control 2018, 91, 5–11. [Google Scholar] [CrossRef]

- Praia, E.F.; Henriques, A.R. Assessing the implementation of food defense requirements in industrial meat-based food processors. Braz. J. Food Technol. 2021, 24, e2020201. [Google Scholar] [CrossRef]

- Visser, T.; van Scheers, L. Can family business managers manage family business risks? J. Contemp. Manag. Issues 2018, 23, 123–137. [Google Scholar] [CrossRef] [Green Version]

- Osaili, T.M.; Jamous, D.O.; Obeidat, B.A.; Bawadi, H.A.; Tayyem, R.F.; Subih, H.S. Food safety knowledge among food workers in restaurants in Jordan. Food Control 2013, 31, 145–150. [Google Scholar] [CrossRef]

- Akabanda, F.; Hlortsi, E.H.; Owusu-kwarteng, J. Food safety knowledge, attitudes and practices of institutional food-handlers in Ghana. BMC Public Health 2017, 17, 40. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- De Oliveira, C.A.; da Cruz, A.G.; Tavolaro, P.; Corassin, C.H. Food Safety: Good manufacturing practices (GMP), sanitation standard operating procedures (SSOP), hazard analysis and critical control point (HACCP). In Antimicrobial Food Packaging, 1st ed.; Barros-Velazquez, J., Ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2016; pp. 129–139. [Google Scholar]

- Askarian, M.; Kabir, G.; Aminbaig, M.; Memish, Z.; Jafari, P. Knowledge, Attitudes, and Practices of Food Service Staff Regarding Food Hygiene in Shiraz, Iran. Infect. Control Hosp. Epidemiol. 2004, 25, 16–20. [Google Scholar] [CrossRef] [PubMed]

- Aarnisalo, K.; Tallavaara, K.; Wirtanen, G.; Maijala, R.; Raaska, L. The hygienic working practices of maintenance personnel and equipment hygiene in the Finnish food industry. Food Control 2006, 17, 1001–1011. [Google Scholar] [CrossRef]

- Powell, D.A.; Jacob, C.J.; Chapman, B.J. Enhancing food safety culture to reduce rates of foodborne illness. Food Control 2011, 22, 817–822. [Google Scholar] [CrossRef]

- European Parliament. Regulation (EC) No 1907/2006 of 18 December 2006 concerning the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH), establishing a European Chemicals Agency, amending Directive 1999/45/EC and repealing Council Regulation (EEC) No 793/93 and Commission Regulation (EC) No 1488/94 as well as Council Directive 76/769/EEC and Commission Directives 91/155/EEC, 93/67/EEC, 93/105/EC and 2000/21/EC. Off. J. Eur. Union 2006, 396, 1–849. [Google Scholar]

- Ramos-Peralonso, M.J. Chemical Hazard Communication and Safety Data Sheets. In Encyclopedia of Toxicology, 3rd ed.; Wexler, P., Ed.; Academic Press: Cambridge, MA, USA, 2014; pp. 787–792. [Google Scholar]

- Dzwolak, W. Assessment of HACCP plans in standardized food safety management systems—The case of small-sized Polish food businesses. Food Control 2019, 106, 106716. [Google Scholar] [CrossRef]

- Al Suwaidi, A.H.E.; Hussein, H.; Al Faisal, W.; El Sawaf, E.; Wasfy, A. Hygienic Practices Among Food Handlers in Dubai. Int. J. Prev. Med. Res. 2015, 1, 101–108. [Google Scholar]

- Garayoa, R.; Vitas, A.I.; Díez-Leturia, M.; García-Jalón, I. Food safety and the contract catering companies: Food handlers, facilities and HACCP evaluation. Food Control 2019, 22, 2006–2012. [Google Scholar] [CrossRef]

- Mattick, K.; Durham, K.; Hendrix, M.; Slader, J.; Griffith, C.; Sen, M.; Humphrey, T. The microbiological quality of washing-up water and the environment in domestic and commercial kitchens. J. Appl. Microbiol. 2003, 94, 842–848. [Google Scholar] [CrossRef]

- Todd, E.; Michaels, B.S.; Smith, D.; Greig, J.D.; Bartleson, C.A. Outbreaks Where Food Workers Have Been Implicated in the Spread of Foodborne Disease. Part 9. Washing and Drying of Hands To Reduce Microbial Contamination. J Food Prot. 2010, 73, 1937–1955. [Google Scholar] [CrossRef]

- United States of America Centers for Disease Control and Prevention. Available online: https://www.cdc.gov/fdoss/pdf/2016_FoodBorneOutbreaks_508.pdf (accessed on 28 June 2021).

- Hedberg, C.W. Explaining the Risk of Foodborne Illness Associated with Restaurants: The Environmental Health Specialists Network (EHS-Net). J. Food Prot. 2013, 76, 2124–2125. [Google Scholar] [CrossRef]

- Sprenger, R.A. Hygiene for Management a Text for Food Hygiene Courses, 19th ed.; Highfield Publications: Doncaster, UK, 2017; pp. 63–70. [Google Scholar]

- Baş, M.; Ersun, A.S.; Kıvanç, G. The evaluation of food hygiene knowledge, attitudes, and practices of food handlers’ in food businesses in Turkey. Food Control 2006, 17, 317–322. [Google Scholar] [CrossRef]

- Valero, A.; Rodríguez, M.-Y.; Posada-Izquierdo, G.D.; Pérez-Rodríguez, F.; Carrasco, E.; García-Gimeno, R.M. Risk Factors Influencing Microbial Contamination in Food Service Centers. In Significance, Prevention and Control of Food Related Diseases; Makun, H.A., Ed.; IntechOpen: London, UK, 2016; ISBN 978-9-5351-22777. [Google Scholar]

- Green, L.R.; Radke, V.; Manson, R.; Bushnell, L.; Reimann, D.W.; Mack, J.C.; Motsinger, M.D.; Stigger, T.; Selman, C.A. Factors Related to Food Worker Hand Hygiene Practices. J. Food Prot. 2007, 70, 661–666. [Google Scholar] [CrossRef]

- Freitas, J.F.; Calazans, D.; Alchieri, J. Food handlers’ occupational and professional training characterization. J. Nutr. Food Sci. 2014, 4, 1000325. [Google Scholar] [CrossRef] [Green Version]

- Brown, L.G.; Le, B.; Wong, M.R.; Reimann, D.; Nicholas, D.; Faw, B.; Davis, E.; Selman, A.C. Restaurant manager and worker food safety certification and knowledge. Foodborne Pathog. Dis. 2014, 11, 835–843. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zanin, L.M.; Da Cunha, D.T.; De Rosso, V.V.; Dias Capriles, V.; Stedefeldt, E. Knowledge, attitudes and practices of food handlers in food safety: An integrative review. Food Res. Int. 2017, 100, 53–62. [Google Scholar] [CrossRef]

- Jullien, C.; Bénézech, T.; Carpentier, B.; Lebret, V.; Faille, C. Identification of surface characteristics relevant to the hygienic status of stainless steel for the food industry. J. Food Eng. 2003, 56, 77–87. [Google Scholar] [CrossRef]

- Gkana, E.; Lianou, A.; Nychas, E. Transfer of Salmonella enterica Serovar Typhimurium from Beef to Tomato through Kitchen Equipment and the Efficacy of Intermediate Decontamination Procedures. J. Food Prot. 2016, 79, 1252–1258. [Google Scholar] [CrossRef] [PubMed]

- Holah, J.T.; Thorpe, R.H. Cleanability in relation to bacterial retention on unused and abraded domestic sink materials. J. Appl. Bacteriol. 1990, 69, 599–608. [Google Scholar] [CrossRef]

- Boulangé-Petermann, L. Processes of bioadhesion on stainless steel surfaces and cleanability: A review with special reference to the food industry. Biofouling 1996, 10, 275–300. [Google Scholar] [CrossRef] [PubMed]

- Matthewson, L.; Heacock, H. Methods for cleaning & sanitizing food contact surfaces (countertops) to prevent cross contamination in restaurant kitchens. BCIT Environ. Public Health J. 2017. [Google Scholar] [CrossRef]

- Hernández-Navarrete, M.J.; Celorrio-Pascual, J.M.; Lapresta Moros, C.; Solano Bernad, V.M. Fundamentos de antisepsia, desinfección y esterilización. Enferm. Infecc. Microbiol. Clínica 2014, 32, 681–688. [Google Scholar] [CrossRef] [PubMed]

- Andrade, J.C.; João, A.L.; Alonso, C.d.S.; Barreto, A.S.; Henriques, A.R. Genetic Subtyping, Biofilm-Forming Ability and Biocide Susceptibility of Listeria monocytogenes Strains Isolated from a Ready-to-Eat Food Industry. Antibiotics 2020, 9, 416. [Google Scholar] [CrossRef] [PubMed]

- Henriques, A.R.; Fraqueza, M.J. Listeria monocytogenes and ready-to-eat meat-based food products: Incidence and control. In Listeria Monocytogenes: Incidence, Growth Behavior and Control, 1st ed.; Viccario, T., Ed.; Nova Science Publishers Inc.: New York, NY, USA, 2015; pp. 71–103. ISBN 978-1-6348-3765-1. [Google Scholar]

| Market | No. FFPR | Food Handlers | ||

|---|---|---|---|---|

| Total | Minimum–Maximum Range | Median | ||

| A | 6 | 11 | 1 | 1 |

| B | 1 | 1 | 1 | |

| C | 4 | 6 | 1 | 2 |

| D | 10 | 20 | 1 | 2 |

| E | 1 | 2 | 2 | |

| F | 2 | 2 | 1 | |

| G | 6 | 16 | 1 | 2 |

| H | 6 | 9 | 1 | 1 |

| I | 2 | 5 | 1 | 3 |

| J | 1 | 1 | 1 | |

| K | 2 | 2 | 1 | |

| L | 14 | 30 | 1 | 2 |

| M | 11 | 32 | 1 | 2 |

| N | 3 | 5 | 1 | 2 |

| O | 1 | 1 | 1 | |

| P | 1 | 1 | 1 | |

| Q | 2 | 2 | 1 | |

| R | 1 | 1 | 1 | |

| Total | 74 | 147 | 1–7 | 1 |

| Characteristics | N (%) |

|---|---|

| Sex | |

| Male | 18 (24.3) |

| Female | 56 (75.7) |

| Age | |

| 30–39 | 7 (9.5) |

| 40–49 | 17 (23) |

| 50–59 | 21 (28.3) |

| 60–69 | 18 (24.3) |

| 70 or more | 11 (14.9) |

| Nationality | |

| Portuguese | 72 (97.3) |

| Other | 2 (2.7) |

| Primary language | |

| Portuguese | 74 (100) |

| Other | 0 |

| Education level | |

| Illiterate | 5 (6.8) |

| 1st cycle | 22 (29.7) |

| 2nd cycle | 12 (16.2) |

| 3rd cycle | 21 (28.4) |

| High School | 11 (14.9) |

| University level | 3 (4) |

| Years working in fresh fishery products retail | |

| 0–5 | 3 (4) |

| 6–10 | 2 (2.7) |

| 11–15 | 5 (6.8) |

| 16–20 | 7 (9.4) |

| 21–25 | 10 (13.5) |

| 26–30 | 11 (14.9) |

| 31–35 | 9 (12.2) |

| 36–40 | 10 (13.5) |

| 41–45 | 8 (10.8) |

| >46 | 9 (12.2) |

| Food handlers working in their fresh fishery products retail business | |

| 1 to 2 | 57 (77) |

| 3 to 5 | 12 (16.2) |

| >5 | 5 (6.8) |

| Contract with a food safety consultancy company | |

| Yes | 21 (28.4) |

| No | 53 (71.6) |

| Last training course on food hygiene, safety, and HACCP- based procedures | |

| Never had | 5 (6.8) |

| Last 2 years | 20 (27) |

| Between 2 to 5 years | 27 (36.5) |

| Between 6 to 10 years | 20 (27) |

| More than 10 years | 2 (2.7) |

| Ongoing food safety management system supported by documents | |

| Yes | 11 (14.9) |

| No | 63 (85.1) |

| Requisites | Compliance | |

|---|---|---|

| % | n | |

| Personal hygiene program includes hand hygiene recommendations | 6.8 | 5 |

| Personal hygiene program mentions appropriate hand soap/sanitizer | 2.7 | 2 |

| Hand soap/sanitizer technical and safety data sheets included | 5.4 | 4 |

| Handwashing instructions displayed | 9.5 | 7 |

| Hygiene program includes food contact surfaces | 8.1 | 6 |

| Hygiene program considers: | ||

| Specific food contact surfaces to be sanitized | 8.1 | 6 |

| Detergents/sanitizers to be used | 2.7 | 2 |

| Specific cleaning and sanitizing instructions | 4.1 | 3 |

| Detergent/sanitizer technical and safety data sheets included | 2.7 | 2 |

| Requisites | Compliance | |

|---|---|---|

| % | n | |

| Hands and nails in adequate condition for food handling | 58.1 | 43 |

| Absence of hand and/or wrist adornments | 28.4 | 21 |

| Exclusive handwashing sink | 25.7 | 19 |

| Handwashing sink with touchless faucet | 5.4 | 4 |

| Handwashing performed with hot water | 2.7 | 2 |

| Hands are pre-rinsed with water | 66.2 | 49 |

| Hands are washed and rubbed with soap | 1.4 | 1 |

| Hand soap removal with running water | 1.4 | 1 |

| Appropriate handwashing duration | 0 | 0 |

| Hands dried with disposable paper towels | 18.9 | 14 |

| Use of sanitizer after handwashing | 0 | 0 |

| Disposable gloves used | 8.1 | 6 |

| Reusable gloves used | 39.2 | 29 |

| Reusable gloves sanitized after use | 0 | 0 |

| Correct handwashing before/after putting on/removing gloves | 0 | 0 |

| Requisites | Compliance | |

|---|---|---|

| % | n | |

| Suitable materials in food contact surfaces | 100 | 74 |

| Food contact surfaces maintained in good conditions | 48.7 | 36 |

| Pre-rinsing step applied | 90.5 | 67 |

| Recommended detergent application method | 79.7 | 59 |

| Sanitizing step applied | 68.9 | 51 |

| Recommended sanitizer application method | 27 | 20 |

| Arbitrary mix of detergent and sanitizer | 47.3 | 35 |

| Proper final rinsing | 82.4 | 61 |

| Adequate cleaning utensils | 27 | 20 |

| Chemicals stored in closed and identified place | 29.7 | 22 |

| Chemicals stored in original package | 81.1 | 60 |

| Chemicals properly labelled | 70.3 | 52 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oliveira, R.S.; Rodrigues, M.J.; Henriques, A.R. Specific Hygiene Procedures and Practices Assessment: A Cross-Sectional Study in Fresh Fishery Product Retailers of Lisbon’s Traditional Food Markets. Foods 2021, 10, 1805. https://doi.org/10.3390/foods10081805

Oliveira RS, Rodrigues MJ, Henriques AR. Specific Hygiene Procedures and Practices Assessment: A Cross-Sectional Study in Fresh Fishery Product Retailers of Lisbon’s Traditional Food Markets. Foods. 2021; 10(8):1805. https://doi.org/10.3390/foods10081805

Chicago/Turabian StyleOliveira, Rafael Sousa, Maria José Rodrigues, and Ana Rita Henriques. 2021. "Specific Hygiene Procedures and Practices Assessment: A Cross-Sectional Study in Fresh Fishery Product Retailers of Lisbon’s Traditional Food Markets" Foods 10, no. 8: 1805. https://doi.org/10.3390/foods10081805

APA StyleOliveira, R. S., Rodrigues, M. J., & Henriques, A. R. (2021). Specific Hygiene Procedures and Practices Assessment: A Cross-Sectional Study in Fresh Fishery Product Retailers of Lisbon’s Traditional Food Markets. Foods, 10(8), 1805. https://doi.org/10.3390/foods10081805