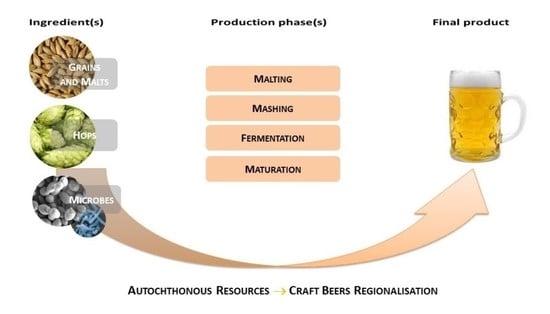

Autochthonous Biological Resources for the Production of Regional Craft Beers: Exploring Possible Contributions of Cereals, Hops, Microbes, and Other Ingredients

Abstract

:1. Introduction

2. Ingredients

2.1. Grains and Malted Cereals

2.2. Hops

2.3. Microbes

2.4. Adjuncts

3. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Allied Market Research. Available online: https://www.alliedmarketresearch.com/beer-market (accessed on 21 May 2021).

- Aquilani, B.; Laureti, T.; Poponi, S.; Secondi, L. Beer Choice and Consumption Determinants When Craft Beers Are Tasted: An Exploratory Study of Consumer Preferences. Food Qual. Prefer. 2015, 41, 214–224. [Google Scholar] [CrossRef]

- Parker, D.K. 6-Beer: Production, sensory characteristics and sensory analysis. In Alcoholic Beverages; Piggott, J., Ed.; Woodhead Publishing Series in Food Science, Technology and Nutrition; Woodhead Publishing: Sawston, UK, 2012; pp. 133–158. ISBN 978-0-85709-051-5. [Google Scholar]

- Briggs, D.E.; Brookes, P.A.; Stevens, R.; Boulton, C.A. Brewing: Science and Practice; Elsevier: Amsterdam, The Netherlands, 2004. [Google Scholar]

- Omari, I.O.; Charnock, H.M.; Fugina, A.L.; Thomson, E.L.; McIndoe, J.S. Magnesium-Accelerated Maillard Reactions Drive Differences in Adjunct and All-Malt Brewing. J. Am. Soc. Brew. Chem. 2020, 79, 145–155. [Google Scholar] [CrossRef]

- Bastgen, N.; Becher, T.; Titze, J. Influencing Factors on Hop Isomerization Beyond the Conventional Range. J. Am. Soc. Brew. Chem. 2019, 77, 126–133. [Google Scholar] [CrossRef]

- Palmer, J.; Kaminski, C. Water: A Comprehensive Guide for Brewers; Brewers Publications: Boulder, CO, USA, 2013. [Google Scholar]

- Wunderlich, S.; Back, W. 1-Overview of Manufacturing Beer: Ingredients, Processes, and Quality Criteria. In Beer in Health and Disease Prevention; Preedy, V.R., Ed.; Academic Press: San Diego, CA, USA, 2009; pp. 3–16. ISBN 978-0-12-373891-2. [Google Scholar]

- Herb, D.; Filichkin, T.; Fisk, S.; Helgerson, L.; Hayes, P.; Benson, A.; Vega, V.; Carey, D.; Thiel, R.; Cistue, L. Malt Modification and Its Effects on the Contributions of Barley Genotype to Beer Flavor. J. Am. Soc. Brew. Chem. 2017, 75, 354–362. [Google Scholar] [CrossRef] [Green Version]

- Herb, D.; Filichkin, T.; Fisk, S.; Helgerson, L.; Hayes, P.; Meints, B.; Jennings, R.; Monsour, R.; Tynan, S.; Vinkemeier, K. Effects of Barley (Hordeum vulgare L.) Variety and Growing Environment on Beer Flavor. J. Am. Soc. Brew. Chem. 2017, 75, 345–353. [Google Scholar] [CrossRef] [Green Version]

- Berbegal, C.; Spano, G.; Tristezza, M.; Grieco, F.; Capozzi, V. Microbial Resources and Innovation in the Wine Production Sector. South Afr. J. Enol. Vitic. 2017, 38, 156–166. [Google Scholar] [CrossRef]

- Mallett, J. Malt: A Practical Guide from Field to Brewhouse; Brewers Publications: Boulder, CO, USA, 2014; Volume 4. [Google Scholar]

- Hieronymus, S. Brewing with Wheat: The’wit’and’weizen’of World Wheat Beer Styles; Brewers Publications: Boulder, CO, USA, 2010. [Google Scholar]

- Cela, N.; Condelli, N.; Caruso, M.C.; Perretti, G.; Di Cairano, M.; Tolve, R.; Galgano, F. Gluten-Free Brewing: Issues and Perspectives. Fermentation 2020, 6, 53. [Google Scholar] [CrossRef]

- Kordialik-Bogacka, E.; Bogdan, P.; Diowksz, A. Malted and Unmalted Oats in Brewing. J. Inst. Brew. 2014, 120, 390–398. [Google Scholar] [CrossRef]

- Goode, D.L.; Arendt, E.K. 3-Developments in the supply of adjunct materials for brewing. In Brewing; Bamforth, C.W., Ed.; Woodhead Publishing Series in Food Science, Technology and Nutrition; Woodhead Publishing: Sawston, UK, 2006; pp. 30–67. ISBN 978-1-84569-003-8. [Google Scholar]

- Maier, P.; Klein, O.; Schumacher, K.P. Ecological Benefits through Alternative Food Networks? Prospects of Regional Barley-Malt-Beer Value Chains in Bavaria, Germany. J. Clean. Prod. 2020, 265, 121848. [Google Scholar] [CrossRef]

- Mascia, I.; Fadda, C.; Dostálek, P.; Olšovská, J.; Caro, A.D. Preliminary Characterization of an Italian Craft Durum Wheat Beer. J. Inst. Brew. 2014, 120, 495–499. [Google Scholar] [CrossRef]

- Cooper, R. Re-Discovering Ancient Wheat Varieties as Functional Foods. J. Tradit. Complement. Med. 2015, 5, 138–143. [Google Scholar] [CrossRef] [Green Version]

- Fogarasi, A.-L.; Kun, S.; Tankó, G.; Stefanovits-Bányai, É.; Hegyesné-Vecseri, B. A Comparative Assessment of Antioxidant Properties, Total Phenolic Content of Einkorn, Wheat, Barley and Their Malts. Food Chem. 2015, 167, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Mayer, H.; Marconi, O.; Perretti, G.; Sensidoni, M.; Fantozzi, P. Investigation of the Suitability of Hulled Wheats for Malting and Brewing. J. Am. Soc. Brew. Chem. 2011, 69, 116–120. [Google Scholar] [CrossRef]

- Zdaniewicz, M.; Pater, A.; Szczepanik, O.; Duliński, R.; Cioch-Skoneczny, M. Tritordeum Malt: An Innovative Raw Material for Beer Production. J. Cereal Sci. 2020, 96, 103095. [Google Scholar] [CrossRef]

- Cioch-Skoneczny, M.; Zdaniewicz, M.; Pater, A.; Skoneczny, S. Impact of Triticale Malt Application on Physiochemical Composition and Profile of Volatile Compounds in Beer. Eur. Food Res. Technol. 2019, 245, 1431–1437. [Google Scholar] [CrossRef] [Green Version]

- Ceppi, E.L.M.; Brenna, O.V. Brewing with Rice Malt—A Gluten-Free Alternative. J. Inst. Brew. 2010, 116, 275–279. [Google Scholar] [CrossRef]

- Mayer, H.; Marconi, O.; Regnicoli, G.F.; Perretti, G.; Fantozzi, P. Production of a Saccharifying Rice Malt for Brewing Using Different Rice Varieties and Malting Parameters. J. Agric. Food Chem. 2014, 62, 5369–5377. [Google Scholar] [CrossRef]

- Mayer, H.; Ceccaroni, D.; Marconi, O.; Sileoni, V.; Perretti, G.; Fantozzi, P. Development of an All Rice Malt Beer: A Gluten Free Alternative. LWT-Food Sci. Technol. 2016, 67, 67–73. [Google Scholar] [CrossRef]

- Ceccaroni, D.; Marconi, O.; Sileoni, V.; Wray, E.; Perretti, G. Rice Malting Optimization for the Production of Top-Fermented Gluten-Free Beer. J. Sci. Food Agric. 2019, 99, 2726–2734. [Google Scholar] [CrossRef] [PubMed]

- Ceccaroni, D.; Sileoni, V.; Marconi, O.; De Francesco, G.; Lee, E.G.; Perretti, G. Specialty Rice Malt Optimization and Improvement of Rice Malt Beer Aspect and Aroma. LWT 2019, 99, 299–305. [Google Scholar] [CrossRef]

- Klose, C.; Mauch, A.; Wunderlich, S.; Thiele, F.; Zarnkow, M.; Jacob, F.; Arendt, E.K. Brewing with 100% Oat Malt. J. Inst. Brew. 2011, 117, 411–421. [Google Scholar] [CrossRef]

- Diakabana, P.; Mvoulatsieri, M.; Dhellot, J.; Kobawila, S.; Louembé, D. Physico-Chemical Characterization of Brew during the Brewing Corn Malt in the Production of Maize Beer in Congo. Adv. J. Food Sci. Technol. 2013, 5, 671–677. [Google Scholar] [CrossRef]

- Flores-Calderón, A.M.D.; Luna, H.; Escalona-Buendía, H.B.; Verde-Calvo, J.R. Chemical Characterization and Antioxidant Capacity in Blue Corn (Zea mays L.) Malt Beers. J. Inst. Brew. 2017, 123, 506–518. [Google Scholar] [CrossRef] [Green Version]

- Romero-Medina, A.; Estarrón-Espinosa, M.; Verde-Calvo, J.R.; Lelièvre-Desmas, M.; Escalona-Buendía, H.B. Renewing Traditions: A Sensory and Chemical Characterisation of Mexican Pigmented Corn Beers. Foods 2020, 9, 886. [Google Scholar] [CrossRef] [PubMed]

- Lyumugabe, F.; Gros, J.; Nzungize, J.; Bajyana, E.; Thonart, P. Characteristics of African Traditional Beers Brewed with Sorghum Malt: A Review. Biotechnol. Agron. Société Et Environ. 2012, 16, 509–530. [Google Scholar]

- Taylor, J.R.N.; Dlamini, B.C.; Kruger, J. 125th Anniversary Review: The Science of the Tropical Cereals Sorghum, Maize and Rice in Relation to Lager Beer Brewing. J. Inst. Brew. 2013, 119, 1–14. [Google Scholar] [CrossRef]

- Espinosa-Ramírez, J.; Pérez-Carrillo, E.; Serna-Saldívar, S.O. Production of Brewing Worts from Different Types of Sorghum Malts and Adjuncts Supplemented with β-Amylase or Amyloglucosidase. J. Am. Soc. Brew. Chem. 2013, 71, 49–56. [Google Scholar] [CrossRef]

- Espinosa-Ramírez, J.; Pérez-Carrillo, E.; Serna-Saldívar, S.O. Maltose and Glucose Utilization during Fermentation of Barley and Sorghum Lager Beers as Affected by β-Amylase or Amyloglucosidase Addition. J. Cereal Sci. 2014, 60, 602–609. [Google Scholar] [CrossRef]

- Heredia-Olea, E.; Cortés-Ceballos, E.; Serna-Saldívar, S.O. Malting Sorghum with Aspergillus oryzae Enhances Gluten-Free Wort Yield and Extract. J. Am. Soc. Brew. Chem. 2017, 75, 116–121. [Google Scholar] [CrossRef]

- Kordialik-Bogacka, E.; Bogdan, P.; Pielech-Przybylska, K.; Michałowska, D. Suitability of Unmalted Quinoa for Beer Production. J. Sci. Food Agric. 2018, 98, 5027–5036. [Google Scholar] [CrossRef]

- Langenaeken, N.A.; De Schutter, D.P.; Courtin, C.M. Arabinoxylan from Non-Malted Cereals Can Act as Mouthfeel Contributor in Beer. Carbohydr. Polym. 2020, 239, 116257. [Google Scholar] [CrossRef]

- Di Ghionno, L.; Sileoni, V.; Marconi, O.; De Francesco, G.; Perretti, G. Comparative Study on Quality Attributes of Gluten-Free Beer from Malted and Unmalted Teff [Eragrostis Tef (Zucc.) Trotter]. LWT 2017, 84, 746–752. [Google Scholar] [CrossRef]

- Leoncini, E.; Prata, C.; Malaguti, M.; Marotti, I.; Segura-Carretero, A.; Catizone, P.; Dinelli, G.; Hrelia, S. Phytochemical Profile and Nutraceutical Value of Old and Modern Common Wheat Cultivars. PLoS ONE 2012, 7, e45997. [Google Scholar] [CrossRef] [Green Version]

- Dinelli, G.; Segura-Carretero, A.; Di Silvestro, R.; Marotti, I.; Arráez-Román, D.; Benedettelli, S.; Ghiselli, L.; Fernadez-Gutierrez, A. Profiles of Phenolic Compounds in Modern and Old Common Wheat Varieties Determined by Liquid Chromatography Coupled with Time-of-Flight Mass Spectrometry. J. Chromatogr. A 2011, 1218, 7670–7681. [Google Scholar] [CrossRef]

- Migliorini, P.; Spagnolo, S.; Torri, L.; Arnoulet, M.; Lazzerini, G.; Ceccarelli, S. Agronomic and Quality Characteristics of Old, Modern and Mixture Wheat Varieties and Landraces for Organic Bread Chain in Diverse Environments of Northern Italy. Eur. J. Agron. 2016, 79, 131–141. [Google Scholar] [CrossRef]

- Yu, W.; Quek, W.P.; Li, C.; Gilbert, R.G.; Fox, G.P. Effects of the Starch Molecular Structures in Barley Malts and Rice Adjuncts on Brewing Performance. Fermentation 2018, 4, 103. [Google Scholar] [CrossRef] [Green Version]

- Hayashida, F.M. Ancient Beer and Modern Brewers: Ethnoarchaeological Observations of Chicha Production in Two Regions of the North Coast of Peru. J. Anthropol. Archaeol. 2008, 27, 161–174. [Google Scholar] [CrossRef]

- Vargas-Yana, D.; Aguilar-Morón, B.; Pezo-Torres, N.; Shetty, K.; Ranilla, L.G. Ancestral Peruvian Ethnic Fermented Beverage “Chicha” Based on Purple Corn (Zea mays L.): Unraveling the Health-Relevant Functional Benefits. J. Ethn. Foods 2020, 7, 1–12. [Google Scholar] [CrossRef]

- Sakamoto, K.; Konings, W.N. Beer Spoilage Bacteria and Hop Resistance. Int. J. Food Microbiol. 2003, 89, 105–124. [Google Scholar] [CrossRef]

- Van Opstaele, F.; De Rouck, G.; De Clippeleer, J.; Aerts, G.; De Cooman, L. Analytical and Sensory Assessment of Hoppy Aroma and Bitterness of Conventionally Hopped and Advanced Hopped Pilsner Beers. J. Inst. Brew. 2010, 116, 445–458. [Google Scholar] [CrossRef]

- Česlová, L.; Holčapek, M.; Fidler, M.; Drštičková, J.; Lísa, M. Characterization of Prenylflavonoids and Hop Bitter Acids in Various Classes of Czech Beers and Hop Extracts Using High-Performance Liquid Chromatography–Mass Spectrometry. J. Chromatogr. A 2009, 1216, 7249–7257. [Google Scholar] [CrossRef]

- Hornsey, I.S. A History of Beer and Brewing; Royal Society of Chemistry: London, UK, 2003; Volume 34. [Google Scholar]

- FAO. FAOSTAT Statistical Database. Available online: http://www.fao.org/faostat/en/#compare (accessed on 1 June 2021).

- Van Holle, A.; Van Landschoot, A.; Roldán-Ruiz, I.; Naudts, D.; De Keukeleire, D. The Brewing Value of Amarillo Hops (Humulus lupulus L.) Grown in Northwestern USA: A Preliminary Study of Terroir Significance. J. Inst. Brew. 2017, 123, 312–318. [Google Scholar] [CrossRef] [Green Version]

- Morcol, T.B.; Negrin, A.; Matthews, P.D.; Kennelly, E.J. Hop (Humulus lupulus L.) Terroir Has Large Effect on a Glycosylated Green Leaf Volatile but Not on Other Aroma Glycosides. Food Chem. 2020, 321, 126644. [Google Scholar] [CrossRef] [PubMed]

- Forster, A.; Gahr, A. A Comparison of the Analytical and Brewing Characteristics of Cascade and Comet Hop Varieties as Grown in Yakima (USA) and Hallertau (Germany). Brew. Sci. 2014, 67, 137–148. [Google Scholar]

- Forteschi, M.; Porcu, M.C.; Fanari, M.; Zinellu, M.; Secchi, N.; Buiatti, S.; Passaghe, P.; Bertoli, S.; Pretti, L. Quality Assessment of Cascade Hop (Humulus lupulus L.) Grown in Sardinia. Eur. Food Res. Technol. 2019, 245, 863–871. [Google Scholar] [CrossRef]

- Mozzon, M.; Foligni, R.; Mannozzi, C. Brewing Quality of Hop Varieties Cultivated in Central Italy Based on Multivolatile Fingerprinting and Bitter Acid Content. Foods 2020, 9, 541. [Google Scholar] [CrossRef] [PubMed]

- Steyer, D.; Clayeux, C.; Laugel, B. Characterization of the Terpenoids Composition of Beers Made with the French Hop Varieties: Strisselspalt, Aramis, Triskel and Bouclier. Brew. Sci. 2013, 66, 192–197. [Google Scholar]

- Krofta, K.; Patzak, J.; Sedlák, T.; Mikyška, A.; Štěrba, K.; Jurková, M. Kazbek–The First Czech Aroma “Flavor Hops” Variety: Characteristics and Utilization. KVASNY PRUMYSL 2019, 65, 72–83. [Google Scholar] [CrossRef]

- Sanekata, A.; Tanigawa, A.; Takoi, K.; Nakayama, Y.; Tsuchiya, Y. Identification and Characterization of Geranic Acid as a Unique Flavor Compound of Hops (Humulus lupulus L.) Variety Sorachi Ace. J. Agric. Food Chem. 2018, 66, 12285–12295. [Google Scholar] [CrossRef] [PubMed]

- Mongelli, A.; Rodolfi, M.; Ganino, T.; Marieschi, M.; Dall’Asta, C.; Bruni, R. Italian Hop Germplasm: Characterization of Wild Humulus lupulus L. Genotypes from Northern Italy by Means of Phytochemical, Morphological Traits and Multivariate Data Analysis. Ind. Crop. Prod. 2015, 70, 16–27. [Google Scholar] [CrossRef]

- Patzak, J.P.; Nesvadba, V.N.; Krofta, K.K.; Henychova, A.H.; Marzoev, A.I.M.I.; Richards, K.R. Evaluation of Genetic Variability of Wild Hops (Humulus lupulus L.) in Canada and the Caucasus Region by Chemical and Molecular Methods. Genome 2010, 53, 545–557. [Google Scholar] [CrossRef] [PubMed]

- da Rosa Almeida, A.; Maciel, M.V.D.O.B.; Cardoso Gasparini Gandolpho, B.; Machado, M.H.; Teixeira, G.L.; Bertoldi, F.C.; Noronha, C.M.; Vitali, L.; Block, J.M.; Barreto, P.L.M. Brazilian Grown Cascade Hop (Humulus lupulus L.): LC-ESI-MS-MS and GC-MS Analysis of Chemical Composition and Antioxidant Activity of Extracts and Essential Oils. J. Am. Soc. Brew. Chem. 2020, 79, 156–166. [Google Scholar] [CrossRef]

- Larroque, M.N.; Carrau, F.; Fariña, L.; Boido, E.; Dellacassa, E.; Medina, K. Effect of Saccharomyces and Non-Saccharomyces Native Yeasts on Beer Aroma Compounds. Int. J. Food Microbiol. 2021, 337, 108953. [Google Scholar] [CrossRef] [PubMed]

- Takoi, K.; Koie, K.; Itoga, Y.; Katayama, Y.; Shimase, M.; Nakayama, Y.; Watari, J. Biotransformation of Hop-Derived Monoterpene Alcohols by Lager Yeast and Their Contribution to the Flavor of Hopped Beer. J. Agric. Food Chem. 2010, 58, 5050–5058. [Google Scholar] [CrossRef]

- Takoi, K.; Itoga, Y.; Koie, K.; Takayanagi, J.; Kaneko, T.; Watanabe, T.; Matsumoto, I.; Nomura, M. Systematic Analysis of Behaviour of Hop-Derived Monoterpene Alcohols during Fermentation and New Classification of Geraniol-Rich Flavour Hops. BrewingScience 2017, 70, 177–186. [Google Scholar]

- Ohashi, Y.; Huang, S.; Maeda, I. Biosyntheses of Geranic Acid and Citronellic Acid from Monoterpene Alcohols by Saccharomyces Cerevisiae. Biosci. Biotechnol. Biochem. 2021, 85, 1530–1535. [Google Scholar] [CrossRef]

- Capozzi, V.; Russo, P.; Spano, G. Microbial Information Regimen in EU Geographical Indications. World Pat. Inf. 2012, 34, 229–231. [Google Scholar] [CrossRef]

- Petruzzi, L.; Corbo, M.R.; Sinigaglia, M.; Bevilacqua, A. Brewer’s Yeast in Controlled and Uncontrolled Fermentations, with a Focus on Novel, Nonconventional, and Superior Strains. Food Rev. Int. 2016, 32, 341–363. [Google Scholar] [CrossRef]

- Spitaels, F.; Wieme, A.D.; Janssens, M.; Aerts, M.; Daniel, H.-M.; Van Landschoot, A.; De Vuyst, L.; Vandamme, P. The Microbial Diversity of Traditional Spontaneously Fermented Lambic Beer. PLoS ONE 2014, 9, e95384. [Google Scholar] [CrossRef] [PubMed]

- Shayevitz, A.; Harrison, K.; Curtin, C.D. Barrel-Induced Variation in the Microbiome and Mycobiome of Aged Sour Ale and Imperial Porter Beer. J. Am. Soc. Brew. Chem. 2021, 79, 33–40. [Google Scholar] [CrossRef]

- Bokulich, N.A.; Bamforth, C.W.; Mills, D.A. Brewhouse-Resident Microbiota Are Responsible for Multi-Stage Fermentation of American Coolship Ale. PLoS ONE 2012, 7, e35507. [Google Scholar] [CrossRef] [PubMed]

- Roos, J.D.; Vuyst, L.D. Microbial Acidification, Alcoholization, and Aroma Production during Spontaneous Lambic Beer Production. J. Sci. Food Agric. 2019, 99, 25–38. [Google Scholar] [CrossRef] [Green Version]

- Dysvik, A.; Rosa, S.L.L.; Rouck, G.D.; Rukke, E.-O.; Westereng, B.; Wicklund, T. Microbial Dynamics in Traditional and Modern Sour Beer Production. Appl. Environ. Microbiol. 2020, 86. [Google Scholar] [CrossRef] [PubMed]

- De Keersmaecker, J. The Mystery of Lambic Beer. Sci. Am. 1996, 275, 74–80. [Google Scholar] [CrossRef]

- Grieco, F.; Tristezza, M.; Vetrano, C.; Bleve, G.; Panico, E.; Mita, G.; Logrieco, A. Exploitation of Autochthonous Micro-Organism Potential to Enhance the Quality of Apulian Wines. Ann. Microbiol. 2011, 61, 67–73. [Google Scholar] [CrossRef]

- Tristezza, M.; Fantastico, L.; Vetrano, C.; Bleve, G.; Corallo, D.; Grieco, F.; Mita, G.; Grieco, F. Molecular and Technological Characterization of Saccharomyces cerevisiae Strains Isolated from Natural Fermentation of Susumaniello Grape Must in Apulia, Southern Italy. Int. J. Microbiol. 2014, 2014, e897428. [Google Scholar] [CrossRef] [PubMed]

- Tufariello, M.; Chiriatti, M.A.; Grieco, F.; Perrotta, C.; Capone, S.; Rampino, P.; Tristezza, M.; Mita, G. Influence of Autochthonous Saccharomyces cerevisiae Strains on Volatile Profile of Negroamaro Wines. LWT-Food Sci. Technol. 2014, 58, 35–48. [Google Scholar] [CrossRef]

- Capozzi, V.; Garofalo, C.; Chiriatti, M.A.; Grieco, F.; Spano, G. Microbial Terroir and Food Innovation: The Case of Yeast Biodiversity in Wine. Microbiol. Res. 2015, 181, 75–83. [Google Scholar] [CrossRef]

- Iattici, F.; Catallo, M.; Solieri, L. Designing New Yeasts for Craft Brewing: When Natural Biodiversity Meets Biotechnology. Beverages 2020, 6, 3. [Google Scholar] [CrossRef] [Green Version]

- Cubillos, F.A.; Gibson, B.; Grijalva-Vallejos, N.; Krogerus, K.; Nikulin, J. Bioprospecting for Brewers: Exploiting Natural Diversity for Naturally Diverse Beers. Yeast 2019, 36, 383–398. [Google Scholar] [CrossRef] [PubMed]

- Canonico, L.; Comitini, F.; Ciani, M. Dominance and Influence of Selected Saccharomyces cerevisiae Strains on the Analytical Profile of Craft Beer Refermentation. J. Inst. Brew. 2014, 120, 262–267. [Google Scholar] [CrossRef]

- Mascia, I.; Fadda, C.; Dostálek, P.; Karabín, M.; Zara, G.; Budroni, M.; Caro, A.D. Is It Possible to Create an Innovative Craft Durum Wheat Beer with Sourdough Yeasts? A Case Study. J. Inst. Brew. 2015, 121, 283–286. [Google Scholar] [CrossRef]

- Marongiu, A.; Zara, G.; Legras, J.-L.; Del Caro, A.; Mascia, I.; Fadda, C.; Budroni, M. Novel Starters for Old Processes: Use of Saccharomyces cerevisiae Strains Isolated from Artisanal Sourdough for Craft Beer Production at a Brewery Scale. J. Ind. Microbiol. Biotechnol. 2015, 42, 85–92. [Google Scholar] [CrossRef]

- Mascia, I.; Fadda, C.; Karabín, M.; Dostálek, P.; Del Caro, A. Aging of Craft Durum Wheat Beer Fermented with Sourdough Yeasts. LWT-Food Sci. Technol. 2016, 65, 487–494. [Google Scholar] [CrossRef]

- Catallo, M.; Iattici, F.; Randazzo, C.; Caggia, C.; Krogerus, K.; Magalhães, F.; Gibson, B.; Solieri, L. Hybridization of Saccharomyces Cerevisiae Sourdough Strains with Cryotolerant Saccharomyces bayanus NBRC1948 as a Strategy to Increase Diversity of Strains Available for Lager Beer Fermentation. Microorganisms 2020, 9, 514. [Google Scholar] [CrossRef] [PubMed]

- Bourbon-Melo, N.; Palma, M.; Rocha, M.P.; Ferreira, A.; Bronze, M.R.; Elias, H.; Sá-Correia, I. Use of Hanseniaspora Guilliermondii and Hanseniaspora opuntiae to Enhance the Aromatic Profile of Beer in Mixed-Culture Fermentation with Saccharomyces Cerevisiae. Food Microbiol. 2021, 95, 103678. [Google Scholar] [CrossRef] [PubMed]

- Johansson, L.; Nikulin, J.; Juvonen, R.; Krogerus, K.; Magalhães, F.; Mikkelson, A.; Nuppunen-Puputti, M.; Sohlberg, E.; de Francesco, G.; Perretti, G.; et al. Sourdough Cultures as Reservoirs of Maltose-Negative Yeasts for Low-Alcohol Beer Brewing. Food Microbiol. 2021, 94, 103629. [Google Scholar] [CrossRef] [PubMed]

- Bellut, K.; Michel, M.; Hutzler, M.; Zarnkow, M.; Jacob, F.; Schutter, D.P.D.; Daenen, L.; Lynch, K.M.; Zannini, E.; Arendt, E.K. Investigation into the Potential of Lachancea fermentati Strain KBI 12.1 for Low Alcohol Beer Brewing. J. Am. Soc. Brew. Chem. 2019, 77, 157–169. [Google Scholar] [CrossRef]

- Zdaniewicz, M.; Satora, P.; Pater, A.; Bogacz, S. Low Lactic Acid-Producing Strain of Lachancea thermotolerans as a New Starter for Beer Production. Biomolecules 2020, 10, 256. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- De Francesco, G.; Sannino, C.; Sileoni, V.; Marconi, O.; Filippucci, S.; Tasselli, G.; Turchetti, B. Mrakia gelida in Brewing Process: An Innovative Production of Low Alcohol Beer Using a Psychrophilic Yeast Strain. Food Microbiol. 2018, 76, 354–362. [Google Scholar] [CrossRef]

- De Francesco, G.D.; Turchetti, B.; Sileoni, V.; Marconi, O.; Perretti, G. Screening of New Strains of Saccharomycodes judwigii and Zygosaccharomyces Rouxii to Produce Low-alcohol Beer. J. Inst. Brew. 2015, 121, 113–121. [Google Scholar] [CrossRef]

- Canonico, L.; Comitini, F.; Ciani, M. Torulaspora delbrueckii Contribution in Mixed Brewing Fermentations with Different Saccharomyces Cerevisiae Strains. Int. J. Food Microbiol. 2017, 259, 7–13. [Google Scholar] [CrossRef] [PubMed]

- Canonico, L.; Agarbati, A.; Comitini, F.; Ciani, M. Torulaspora Delbrueckii in the Brewing Process: A New Approach to Enhance Bioflavour and to Reduce Ethanol Content. Food Microbiol. 2016, 56, 45–51. [Google Scholar] [CrossRef] [PubMed]

- Canonico, L.; Ciani, E.; Galli, E.; Comitini, F.; Ciani, M. Evolution of Aromatic Profile of Torulaspora delbrueckii Mixed Fermentation at Microbrewery Plant. Fermentation 2020, 6, 7. [Google Scholar] [CrossRef] [Green Version]

- Dysvik, A.; La Rosa, S.L.; Liland, K.H.; Myhrer, K.S.; Østlie, H.M.; De Rouck, G.; Rukke, E.-O.; Westereng, B.; Wicklund, T. Co-Fermentation Involving Saccharomyces cerevisiae and Lactobacillus Species Tolerant to Brewing-Related Stress Factors for Controlled and Rapid Production of Sour Beer. Front. Microbiol. 2020, 11, 279. [Google Scholar] [CrossRef] [PubMed]

- Dysvik, A.; La Rosa, S.L.; Buffetto, F.; Liland, K.H.; Myhrer, K.S.; Rukke, E.-O.; Wicklund, T.; Westereng, B. Secondary Lactic Acid Bacteria Fermentation with Wood-Derived Xylooligosaccharides as a Tool To Expedite Sour Beer Production. J. Agric. Food Chem. 2020, 68, 301–314. [Google Scholar] [CrossRef] [PubMed]

- Peyer, L.C.; Zarnkow, M.; Jacob, F.; Schutter, D.P.D.; Arendt, E.K. Sour Brewing: Impact of Lactobacillus amylovorus FST2.11 on Technological and Quality Attributes of Acid Beers. J. Am. Soc. Brew. Chem. 2017, 75, 207–216. [Google Scholar] [CrossRef]

- Kim, M.; Choi, E.; Kim, J.; Ahn, H.; Han, H.; Kim, W.J. Effect of Bacteriocin-Producing Pediococcus acidilactici K10 on Beer Fermentation. J. Inst. Brew. 2016, 122, 422–429. [Google Scholar] [CrossRef] [Green Version]

- Kim, D.-Y.; Kim, J.; Kim, J.H.; Kim, W.J. Malt and Wort Bio-Acidification by Pediococcus acidilactici HW01 as Starter Culture. Food Control 2021, 120, 107560. [Google Scholar] [CrossRef]

- Ahn, H.; Kim, J.; Kim, W.J. Isolation and Characterization of Bacteriocin-Producing Pediococcus acidilactici HW01 from Malt and Its Potential to Control Beer Spoilage Lactic Acid Bacteria. Food Control 2017, 80, 59–66. [Google Scholar] [CrossRef]

- Rossi, S.; Turchetti, B.; Sileoni, V.; Marconi, O.; Perretti, G. Evaluation of Saccharomyces cerevisiae Strains Isolated from Non-Brewing Environments in Beer Production. J. Inst. Brew. 2018, 124, 381–388. [Google Scholar] [CrossRef] [Green Version]

- Catallo, M.; Nikulin, J.; Johansson, L.; Krogerus, K.; Laitinen, M.; Magalhães, F.; Piironen, M.; Mikkelson, A.; Randazzo, C.L.; Solieri, L. Sourdough Derived Strains of Saccharomyces cerevisiae and Their Potential for Farmhouse Ale Brewing. J. Inst. Brew. 2020, 126, 168–175. [Google Scholar] [CrossRef] [Green Version]

- Ripari, V.; Tomassetti, M.; Cecchi, T.; Enrico, B. Recipe, Volatiles Profile, Sensory Analysis, Physico-Chemical and Microbial Characterization of Acidic Beers from Both Sourdough Yeasts and Lactic Acid Bacteria. Eur. Food Res. Technol. 2018, 244, 2027–2040. [Google Scholar] [CrossRef]

- Ripari, V.; Tomassetti, M.; Cecchi, T.; Berardi, E. First Study of Sourdough Beer Aging Via the Chemical Fingerprint of Volatile Markers. Food Anal. Methods 2019, 12, 2459–2468. [Google Scholar] [CrossRef]

- Ciani, M.; Comitini, F.; Mannazzu, I.; Domizio, P. Controlled Mixed Culture Fermentation: A New Perspective on the Use of Non-Saccharomyces Yeasts in Winemaking. FEMS Yeast Res. 2010, 10, 123–133. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Capece, A.; Romaniello, R.; Siesto, G.; Romano, P. Conventional and Non-Conventional Yeasts in Beer Production. Fermentation 2018, 4, 38. [Google Scholar] [CrossRef] [Green Version]

- Serra Colomer, M.; Funch, B.; Forster, J. The Raise of Brettanomyces Yeast Species for Beer Production. Curr. Opin. Biotechnol. 2019, 56, 30–35. [Google Scholar] [CrossRef] [PubMed]

- Holt, S.; Mukherjee, V.; Lievens, B.; Verstrepen, K.J.; Thevelein, J.M. Bioflavoring by Non-Conventional Yeasts in Sequential Beer Fermentations. Food Microbiol. 2018, 72, 55–66. [Google Scholar] [CrossRef]

- Tataridis, P.; Kanelis, A.; Logotetis, S.; Nerancis, E. Use of Non-Saccharomyces Torulaspora delbrueckii Yeast Strains in Winemaking and Brewing. Zb. Matice Srp. Za Prir. Nauk. 2013, 124, 415–426. [Google Scholar] [CrossRef]

- Domizio, P.; House, J.F.; Joseph, C.M.L.; Bisson, L.F.; Bamforth, C.W. Lachancea thermotolerans as an Alternative Yeast for the Production of Beer. J. Inst. Brew. 2016, 122, 599–604. [Google Scholar] [CrossRef] [Green Version]

- Osburn, K.; Amaral, J.; Metcalf, S.R.; Nickens, D.M.; Rogers, C.M.; Sausen, C.; Caputo, R.; Miller, J.; Li, H.; Tennessen, J.M.; et al. Primary Souring: A Novel Bacteria-Free Method for Sour Beer Production. Food Microbiol. 2018, 70, 76–84. [Google Scholar] [CrossRef]

- Bossaert, S.; Crauwels, S.; De Rouck, G.; Lievens, B. The Power of Sour-a Review: Old Traditions, New Opportunities. BrewingScience 2019, 72, 78–88. [Google Scholar]

- Dysvik, A.; Liland, K.H.; Myhrer, K.S.; Westereng, B.; Rukke, E.-O.; De Rouck, G.; Wicklund, T. Pre-Fermentation with Lactic Acid Bacteria in Sour Beer Production. J. Inst. Brew. 2019, 125, 342–356. [Google Scholar] [CrossRef]

- Strong, G.; England, K. Beer Judge Certification Program: 2015 Style Guidelines. Brew. Assoc. 2015, 47. Available online: https://www.bjcp.org/docs/2015_Guidelines_Beer.pdf (accessed on 1 June 2021).

- Nardini, M.; Garaguso, I. Characterization of Bioactive Compounds and Antioxidant Activity of Fruit Beers. Food Chem. 2020, 305, 125437. [Google Scholar] [CrossRef] [PubMed]

- Garavaglia, C. The Emergence of Italian Craft Breweries and the Development of Their Local Identity. In The Geography of Beer: Culture and Economics; Hoalst-Pullen, N., Patterson, M.W., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 135–147. ISBN 978-3-030-41654-6. [Google Scholar]

- Martínez, A.; Vegara, S.; Martí, N.; Valero, M.; Saura, D. Physicochemical Characterization of Special Persimmon Fruit Beers Using Bohemian Pilsner Malt as a Base. J. Inst. Brew. 2017, 123, 319–327. [Google Scholar] [CrossRef] [Green Version]

- Carvalho, G.B.; Silva, D.P.; Bento, C.V.; Vicente, A.A.; Teixeira, J.A.; Maria das Graças, A.F.; e Silva, J.B.A. Banana as Adjunct in Beer Production: Applicability and Performance of Fermentative Parameters. Appl. Biochem. Biotechnol. 2009, 155, 53–62. [Google Scholar] [CrossRef] [Green Version]

- Kawa-Rygielska, J.; Adamenko, K.; Kucharska, A.Z.; Prorok, P.; Piórecki, N. Physicochemical and Antioxidative Properties of Cornelian Cherry Beer. Food Chem. 2019, 281, 147–153. [Google Scholar] [CrossRef]

- Adamenko, K.; Kawa-Rygielska, J.; Kucharska, A.Z. Characteristics of Cornelian Cherry Sour Non-Alcoholic Beers Brewed with the Special Yeast Saccharomycodes ludwigii. Food Chem. 2020, 312, 125968. [Google Scholar] [CrossRef]

- Adadi, P.; Kovaleva, E.G.; Glukhareva, T.V.; Shatunova, S.A.; Petrov, A.S. Production and Analysis of Non-Traditional Beer Supplemented with Sea Buckthorn. Agron. Res. 2017, 15, 1831–1845. [Google Scholar]

- Gasiński, A.; Kawa-Rygielska, J.; Szumny, A.; Gąsior, J.; Głowacki, A. Assessment of Volatiles and Polyphenol Content, Physicochemical Parameters and Antioxidant Activity in Beers with Dotted Hawthorn (Crataegus punctata). Foods 2020, 9, 775. [Google Scholar] [CrossRef]

- Velić, N.; Mujić, I.; Krstanović, V.; Velić, D.; Franić, M.; Zec Sombol, S.; Mastanjević, K. Chestnut in Beer Production: Applicability and Effect on Beer Quality Parameters. Acta Hortic 1220 2018, 209–214. [Google Scholar] [CrossRef]

- Nunes, C.S.O.; da Silva, M.L.C.; Camilloto, G.P.; Machado, B.A.S.; Hodel, K.V.S.; Koblitz, M.G.B.; Carvalho, G.B.M.; Uetanabaro, A.P.T. Potential Applicability of Cocoa Pulp (Theobroma cacao L) as an Adjunct for Beer Production. Sci. World J. 2020, 2020, e3192585. [Google Scholar] [CrossRef]

- Nunes, C.D.S.O.; de Carvalho, G.B.M.; da Silva, M.L.C.; da Silva, G.P.; Machado, B.A.S.; Uetanabaro, A.P.T. Cocoa Pulp in Beer Production: Applicability and Fermentative Process Performance. PLoS ONE 2017, 12, e0175677. [Google Scholar] [CrossRef] [Green Version]

- Alves, M.D.M.; Rosa, M.D.S.; SANTOS, P.P.A.D.; PAZ, M.F.D.; Morato, P.N.; Fuzinatto, M.M. Artisanal Beer Production and Evaluation Adding Rice Flakes and Soursop Pulp (Annona muricata L.). Food Sci. Technol. 2020, 40, 545–549. [Google Scholar] [CrossRef]

- Schuina, G.L.; Quelhas, J.O.F.; de Carvalho, G.B.M.; Bianchi, V.L.D. Use of Carqueja (Baccharis Trimera (Less.) DC. Asteraceae) as a Total Substitute for Hops in the Production of Lager Beer. J. Food Process. Preserv. 2020, 44, e14730. [Google Scholar] [CrossRef]

- Schuina, G.L.; Quelhas, J.O.F.; CASTILHOS, M.B.M.D.; CARVALHO, G.B.M.D.; Del Bianchi, V.L. Alternative Production of Craft Lager Beers Using Artichoke (Cynara scolymus L.) as a Hops Substitute. Food Sci. Technol. 2020, 40, 157–161. [Google Scholar] [CrossRef] [Green Version]

- Panda, S.K.; Panda, S.H.; Swain, M.R.; Ray, R.C.; Kayitesi, E. Anthocyanin-Rich Sweet Potato (Ipomoea batatas L.) Beer: Technology, Biochemical and Sensory Evaluation. J. Food Process. Preserv. 2015, 39, 3040–3049. [Google Scholar] [CrossRef]

- Guglielmotti, M.; Passaghe, P.; Buiatti, S. Use of Olive (Olea europaea L.) Leaves as Beer Ingredient, and Their Influence on Beer Chemical Composition and Antioxidant Activity. J. Food Sci. 2020, 85, 2278–2285. [Google Scholar] [CrossRef] [PubMed]

- Horincar, G.; Enachi, E.; Bolea, C.; Râpeanu, G.; Aprodu, I. Value-Added Lager Beer Enriched with Eggplant (Solanum melongena L.) Peel Extract. Molecules 2020, 25, 731. [Google Scholar] [CrossRef] [Green Version]

- Pereira, I.M.C.; Matos, J.D.; Figueiredo, R.W.; Carvalho, J.D.G.; Figueiredo, E.A.T.D.; Menezes, N.V.S.D.; Gaban, S.V.F. Physicochemical Characterization, Antioxidant Activity, and Sensory Analysis of Beers Brewed with Cashew Peduncle (Anacardium occidentale) and Orange Peel (Citrus Sinensis). Food Sci. Technol. 2020, 40, 749–755. [Google Scholar] [CrossRef] [Green Version]

- Baiano, A. Craft beer: An overview. Compr. Rev. Food Sci. Food Saf. 2021, 20, 1829–1856. [Google Scholar] [CrossRef] [PubMed]

- Donadini, G.; Porretta, S. Uncovering patterns of consumers’ interest for beer: A case study with craft beers. Food Res. Int. 2017, 91, 183–198. [Google Scholar] [CrossRef]

- Atallah, S.S.; Bazzani, C.; Ha, K.A.; Nayga, R.M. Does the Origin of Inputs and Processing Matter? Evidence from Consumers’ Valuation for Craft Beer. Food Qual. Prefer. 2021, 89, 104146. [Google Scholar] [CrossRef]

- Melewar, T.C.; Skinner, H. Territorial Brand Management: Beer, Authenticity, and Sense of Place. J. Bus. Res. 2020, 116, 680–689. [Google Scholar] [CrossRef]

- Gutiérrez-Gamboa, G.; Liu, S.-Y.; Pszczólkowski, P. Resurgence of Minority and Autochthonous Grapevine Varieties in South America: A Review of Their Oenological Potential. J. Sci. Food Agric. 2020, 100, 465–482. [Google Scholar] [CrossRef] [PubMed]

- Garofalo, C.; El Khoury, M.; Lucas, P.; Bely, M.; Russo, P.; Spano, G.; Capozzi, V. Autochthonous Starter Cultures and Indigenous Grape Variety for Regional Wine Production. J. Appl. Microbiol. 2015, 118, 1395–1408. [Google Scholar] [CrossRef]

- Capozzi, V.; Fragasso, M.; Russo, P. Microbiological Safety and the Management of Microbial Resources in Artisanal Foods and Beverages: The Need for a Transdisciplinary Assessment to Conciliate Actual Trends and Risks Avoidance. Microorganisms 2020, 8, 306. [Google Scholar] [CrossRef] [Green Version]

- Lucini, L.; Rocchetti, G.; Trevisan, M. Extending the concept of terroir from grapes to other agricultural commodities: An overview. Curr. Opin. Food Sci. 2020, 31, 88–95. [Google Scholar] [CrossRef]

- Buiatti, S.; Guglielmotti, M.; Passaghe, P. 1-Industrial beer versus craft beer: Definitions and nuances. In Case Studies in the Beer Sector; Capitello, R., Maehle, N., Eds.; Woodhead Publishing Series in Consumer Sci & Strat Market; Woodhead Publishing: Sawston, UK, 2021; pp. 329–340. ISBN 978-0-12-817734-1. [Google Scholar]

- Richter, T.M.; Silcock, P.; Algarra, A.; Eyres, G.T.; Capozzi, V.; Bremer, P.J.; Biasioli, F. Evaluation of PTR-ToF-MS as a tool to track the behavior of hop-derived compounds during the fermentation of beer. Food Res. Int. 2018, 111, 582–589. [Google Scholar] [CrossRef]

- Van Holle, A.V.; Muylle, H.; Haesaert, G.; Naudts, D.; Keukeleire, D.D.; Roldán-Ruiz, I.; Landschoot, A.V. Relevance of Hop Terroir for Beer Flavour. J. Inst. Brew. 2021. [Google Scholar] [CrossRef]

- Albanese, L.; Ciriminna, R.; Meneguzzo, F.; Pagliaro, M. Innovative beer-brewing of typical, old and healthy wheat varieties to boost their spreading. J. Clean. Prod. 2018, 171, 297–311. [Google Scholar] [CrossRef]

- Basso, R.F.; Alcarde, A.R.; Portugal, C.B. Could non-Saccharomyces yeasts contribute on innovative brewing fermentations? Food Res. Int. 2016, 86, 112–120. [Google Scholar] [CrossRef]

- Aka, S.; Dridi, B.; Bolotin, A.; Yapo, E.A.; Koussemon-Camara, M.; Bonfoh, B.; Renault, P. Characterization of lactic acid bacteria isolated from a traditional Ivoirian beer process to develop starter cultures for safe sorghum-based beverages. Int. J. Food Microbiol. 2020, 322, 108547. [Google Scholar] [CrossRef] [PubMed]

- Tufariello, M.; Fragasso, M.; Pico, J.; Panighel, A.; Castellarin, S.D.; Flamini, R.; Grieco, F. Influence of non-Saccharomyces on wine chemistry: A focus on aroma-related compounds. Molecules 2021, 26, 644. [Google Scholar] [CrossRef]

- Capozzi, V.; Tufariello, M.; De Simone, N.; Fragasso, M.; Grieco, F. Biodiversity of Oenological Lactic Acid Bacteria: Species- and Strain-Dependent Plus/Minus Effects on Wine Quality and Safety. Fermentation. Fermentation 2021, 7, 24. [Google Scholar] [CrossRef]

- Berbegal, C.; Khomenko, I.; Russo, P.; Spano, G.; Fragasso, M.; Biasioli, F.; Capozzi, V. PTR-ToF-MS for the Online Monitoring of Alcoholic Fermentation in Wine: Assessment of VOCs Variability Associated with Different Combinations of Saccharomyces/Non-Saccharomyces as a Case-Study. Fermentation 2020, 6, 55. [Google Scholar] [CrossRef]

- Dank, A.; van Mastrigt, O.; Yang, Z.; Dinesh, V.M.; Lillevang, S.K.; Weij, C.; Smid, E.J. The Cross-over Fermentation Concept and Its Application in a Novel Food Product: The Dairy Miso Case Study. LWT 2021, 142, 111041. [Google Scholar] [CrossRef]

- Gatrell, J.; Reid, N.; Steiger, T.L. Branding Spaces: Place, Region, Sustainability and the American Craft Beer Industry. Appl. Geogr. 2018, 90, 360–370. [Google Scholar] [CrossRef]

- Ness, B. Beyond the Pale (Ale): An Exploration of the Sustainability Priorities and Innovative Measures in the Craft Beer Sector. Sustainability 2018, 10, 4108. [Google Scholar] [CrossRef] [Green Version]

- Capozzi, V.; Fragasso, M.; Bimbo, F. Microbial Resources, Fermentation and Reduction of Negative Externalities in Food Systems: Patterns toward Sustainability and Resilience. Fermentation 2021, 7, 54. [Google Scholar] [CrossRef]

- Maqueda, M.; Pérez-Nevado, F.; Regodón, J.A.; Zamora, E.; Alvarez, M.L.; Rebollo, J.E.; Ramírez, M. A low-cost procedure for production of fresh autochthonous wine yeast. J. Ind. Microbiol. Biotechnol. 2011, 38, 459–469. [Google Scholar] [CrossRef] [PubMed]

- Borsellino, V.; Schimmenti, E.; El Bilali, H. Agri-Food Markets towards Sustainable Patterns. Sustainability 2020, 12, 2193. [Google Scholar] [CrossRef] [Green Version]

| Grains | Regions | Impact on Beer Quality | Ref. |

|---|---|---|---|

| Durum wheat (cv. Senatore Cappelli) | Sardinia (IT) | High polyphenol content, balanced taste, low sweetness. | [18] |

| Einkorn, emmer and spelt | Italy, Hungary | Higher antioxidant activity and polyphenol content, more fibre, lower gluten content, and low extract yields. | [19,20,21] |

| Tritordeum (cv. Bulel) | Spain | Addition of slight acidity and higher free amino nitrogen. | [22] |

| Triticale (cv. Remiko) | Poland | Higher acidity, lower esters and isoamyl alcohol content. | [23] |

| Rice (cv. Loto) | Italy | Acceptable alcoholic content (3.5–4.5% vol.), good foam stability, rather poor in body and mouthfeel. | [24] |

| Rice (cv. Centauro) | Italy | Pale colour, not persistent foam, flat sensory characteristics. Optimisation of malt production improves colour and flavour. | [25,26,27,28] |

| Oat (cv. Koneser) | Finland | Increased protein content in the wort and prolonged filtration time. | [15] |

| Oat (cv. Raisio) | Finland | High pH and low alcohol content, strong berry flavour and low amount of staling compounds during ageing. | [29] |

| Corn (cv. Nzaka-nzaka) | Congo | Poor foam stability, saccharification needs of exogenous α-amylase. | [30] |

| Pigmented Corn (cv. Chalqueño) | Mexico | Low-alcohol beer with polyphenols and anthocyanins with antioxidant properties. | [31,32] |

| Sorghum | African countries | Slight alcoholic (3.6%), brown colour, and acid pH (4.15 on average) due to the alcoholic and lactic co-fermentation. Incomplete saccharification, residue of insoluble materials, increased viscosity. | [33,34] |

| Red Sorghum (cv. DKS-74) | Mexico | Exogenous enzymes treatment yields glucose and alcohol content similar to barley-malt beer. | [34,35,36,37] |

| Quinoa | Bolivia | Higher foam stability, lower level of soluble nitrogen, and more than twice the amount of fat; positive effect on the overall sensorial quality. | [38] |

| Rye (cv. Dukato) | Belgium | Increased beer viscosity, higher palate-fullness. | [39] |

| Teff (cv. Witkop) | South Africa | Higher content of glucose and a lower content of maltose, higher sweetness, fruity aroma, with little body. | [40] |

| Hops’ Varieties | Region | Impact on Beer Quality | Ref. |

|---|---|---|---|

| Kazbek | Czech Republic | Low content of alpha acids, citrus-like aroma due to geranyl esters content of essential oil fraction. | [58] |

| Aramis | France | Terpenoid profile similar to the parental variety Strisselspalt, gives spicy and herbal notes to the beer. | [57] |

| Triskel | France | High concentration of monoterpenoids, especially linalool, which bring a floral note to beer. | [57] |

| Amarillo | Idaho (US) | Lower citrusy and floral notes, but higher fruity, spicy, and resinous odour descriptions. | [52] |

| Cascade | Hallertau (DE) | Higher content of polyphenols and esters, such as isobutyl-isobutyrate and 2-methylbutyl-2-methylpropanoate. | [54] |

| Cascade | Washington (US) | Higher linalool contents with respect to those grown in Hallertau (DE). | [54] |

| Cascade | Sardinia (IT) | Essential oil and the α-/β-acids in the same range of those cultivated in the US. | [55] |

| Cascade | Brazil | Higher content of farnesene and selinene, but lower levels of humulene and myrcene respect to the US grown crops. | [62] |

| Sorachi Ace | Hokkaido (JP) | It contains a unique volatile compound, geranic acid, which enhances the aroma contribution of terpenoids at sub-threshold levels. | [59] |

| Wild hops | Italy | Selinenes, α-acids, trans-β-farnesene, and α-caryophyllene/β-humulene ratio are the main contributors and have a higher content of xanthohumol and α-acids among European wild hops. | [60] |

| Wild hops | Canada | High content of myrcene and low contents of humulene, farnesene, and selinenes. | [61] |

| Wild hops | Caucasus | Significantly lower cohumulone content. | [61] |

| Species/Strains | Source | Region | Impact on the Beer Quality | Ref. | |

|---|---|---|---|---|---|

| Saccharomyces spp. | S. cerevisiae | Wine | Italy | Higher fruity and flowery aroma compounds in bottle re-fermentation. | [81] |

| S. cerevisiae S-42 | Sourdough | Sardinia (IT) | Similar sensorial profile, higher acidity, higher ethanol and esters content. | [82,83,84] | |

| S. bayanus × S. cerevisiae | De novo hybridisation | Italy | Efficient consumption of maltotriose, appreciable level of aroma compounds. | [85] | |

| Non- Saccharomyces | Hanseniaspora guilliermondii IST315 | Grape | Portugal | Increasing eight times the content of phenylethyl acetate, associated with rose and honey aroma. | [86] |

| Hanseniaspora vineae T02/05 | Grape | Uruguay | High ester production, fruity aroma suitable for low-alcohol beer production. | [63] | |

| Kazachstania servazzii | Rye malt Sourdough | Finland | Clean flavour profile and tolerance to low-temperature conditions. | [87] | |

| Lachancea fermentati KBI 12.1 | Kombucha | Ireland | Lactic acid production, lower alcohol level, fruity aroma. | [88] | |

| Lachancea thermotolerans MN477031 | Grape must | Slovakia | Low lactic acid production with a minor impact on pH of the beer. | [89] | |

| Mrakia gelida DBVPG 5952 | Glacial melting water | Italy | Low alcohol production and low diacetyl, and appreciable organoleptic characteristics. | [90] | |

| Pichia fermentans | Sourdough | Finland | Production of the spice/clove aroma 4-vinylguaiacol, suitable for low-alcohol wheat beers. | [87] | |

| Saccharomycodes ludwigii DBVPG 3010 | Grape must | Italy | Production of low-alcohol beer, higher content of esters, and lower amount of diacetyl. | [91] | |

| Torulaspora delbrueckii DiSVA 254 | Papaya leaves | Cameron | Increase of aromatic compounds, emphasised fruity/citric and fruity/esters notes. | [92,93,94] | |

| Lactic Acid Bacteria | L. brevis BSO 464 | Collection strain | Not reported | High flavour intensity, acidic taste, and astringency in co-fermentation. | [95,96] |

| Lactobacillus amylovorus FST2.11 | Brewing environment | Ireland | High sensitive to hops, acidification of unhopped wort until 5–6 g/L of lactic acid. | [97] | |

| Pediococcus acidilactici K10 | Kimchi | Korea | Starter for malt acidification; provides bioprotection against spoilage bacteria. | [98] | |

| P. acidilactici HW01 | Malt | Korea | In malt acidification, improves microbiological stability, viscosity, and filtration time. | [99,100] |

| Adjuncts | Regions | Impact on Beer Quality | Ref. | |

|---|---|---|---|---|

| Fruits | Banana (cv. Prata) | Brazil | Increasing of fermentable sugars and ethanol production. | [118] |

| Persimmon (cv. Rojo Brillante) | Spain | Addition of malic and citric acid, light orange colour by solubilisation of carotenoids, increase of fermentable sugars. | [117] | |

| Hawthorn fruit (cv. Aurea) | Not reported | Increase of antioxidant activity, polyphenols, and volatile aroma compounds. | [122] | |

| Cornelian cherry (cv. Podolski) | Poland | Increase of polyphenols and antioxidant activity, addition of anthocyanins and sour taste. | [119,120] | |

| Chestnut | Croatia | Slightly higher alcohol content, higher colour index. | [123] | |

| Cocoa (VP 1151) | Brazil | Increasing of wort viscosity, higher mineral, glucose and fructose content, higher ethanol production. | [124,125] | |

| Soursop | Brazil | Lesser variation in beer standard parameters, good acceptance in sensorial attribute. | [126] | |

| Vegetables | Carqueja (Baccharis trimera) | Brazil | Addition of bittering compounds, total substitution of hop has shown no negative effects, sensorial acceptance similar to commercial beers. | [127] |

| Artichoke | Brazil | Bittering effect, suitable for total hop substitution, good sensorial acceptance. | [128] | |

| Purple sweet potato (ST-13) | India | High content of anthocyanins and antioxidant compounds, peculiar pink colour. | [129] | |

| Birch-derived Xylooligosaccharides | Norway | Promoting secondary fermentation by LAB in sour beer. | [96] | |

| Olive leaves | Italy | Increase polyphenol content but not antioxidant activity, sour/astringent taste and herbal aroma at 10 g/L, pleasant sensory profile at 5 g/L. | [130] | |

| Eggplant (cv. Classic) peel extract | Romania | Increase of antioxidant activity, phenolics, and flavonoids content, reddish colour due to the release of anthocyanins. | [131] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Simone, N.; Russo, P.; Tufariello, M.; Fragasso, M.; Solimando, M.; Capozzi, V.; Grieco, F.; Spano, G. Autochthonous Biological Resources for the Production of Regional Craft Beers: Exploring Possible Contributions of Cereals, Hops, Microbes, and Other Ingredients. Foods 2021, 10, 1831. https://doi.org/10.3390/foods10081831

De Simone N, Russo P, Tufariello M, Fragasso M, Solimando M, Capozzi V, Grieco F, Spano G. Autochthonous Biological Resources for the Production of Regional Craft Beers: Exploring Possible Contributions of Cereals, Hops, Microbes, and Other Ingredients. Foods. 2021; 10(8):1831. https://doi.org/10.3390/foods10081831

Chicago/Turabian StyleDe Simone, Nicola, Pasquale Russo, Maria Tufariello, Mariagiovanna Fragasso, Michele Solimando, Vittorio Capozzi, Francesco Grieco, and Giuseppe Spano. 2021. "Autochthonous Biological Resources for the Production of Regional Craft Beers: Exploring Possible Contributions of Cereals, Hops, Microbes, and Other Ingredients" Foods 10, no. 8: 1831. https://doi.org/10.3390/foods10081831

APA StyleDe Simone, N., Russo, P., Tufariello, M., Fragasso, M., Solimando, M., Capozzi, V., Grieco, F., & Spano, G. (2021). Autochthonous Biological Resources for the Production of Regional Craft Beers: Exploring Possible Contributions of Cereals, Hops, Microbes, and Other Ingredients. Foods, 10(8), 1831. https://doi.org/10.3390/foods10081831