The Use of Durum Wheat Oil in the Preparation of Focaccia: Effects on the Oxidative Stability and Physical and Sensorial Properties

Abstract

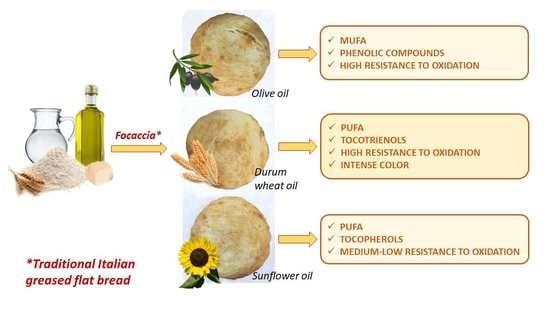

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Determination of the Resistance to Oxidation

2.4. Determination of Fatty Acid Composition

2.5. Lipid Extraction

2.6. Determination of Tocopherols and Tocotrienols

2.7. Determination of Polar Compounds of the Lipid Fraction of Focaccia

2.8. Determination of Antioxidant Activity

2.9. Determination of Volatile Compounds

2.10. Texture Profile Analysis

2.11. Color Determination

2.12. Determination of Dimensional Parameters

2.13. Determination of Sensory Properties

2.14. Statistical Analysis

3. Results and Discussion

3.1. Oxidation Stability, Fatty Acid Composition, and Tocols Content

3.2. Polar Compounds Content

3.3. Antioxidant Activity

3.4. Volatile Compounds

3.5. Physical Determinations

3.6. The Sensory Profile of Focaccia

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rosell, C.M.; Bajerska, J.; El Sheikha, A.F. Bread and Its Fortification: Nutrition and Health Benefits; CRC Press: Boca Raton, FL, USA, 2015; pp. 1–10. [Google Scholar]

- Pasqualone, A. Traditional flat breads spread from the Fertile Crescent: Production process and history of baking systems. J. Ethn. Foods 2018, 5, 10–19. [Google Scholar] [CrossRef]

- Boukid, F. Flatbread-a canvas for innovation: A review. Appl. Food Biotechnol. 2022, 2, 100071. [Google Scholar] [CrossRef]

- Research and Markets. Available online: https://www.researchandmarkets.com/reports/4987703/flatbread-market-to-2027-global-analysis-and#tag-pos-17 (accessed on 8 June 2022).

- Pasqualone, A.; Delcuratolo, D.; Gomes, T. Focaccia Italian flat fatty bread. In Flour and Breads and Their Fortification in Health and Disease Prevention; Academic Press: Oxford, UK, 2011; pp. 47–58. [Google Scholar]

- Pasqualone, A.; Vurro, F.; Summo, C.; Abd-El-Khalek, M.H.; Al-Dmoor, H.H.; Grgic, T.; Ruiz, M.; Magro, C.; Deligeorgakis, C.; Helou, C.; et al. The large and diverse family of Mediterranean flat breads: A database. Foods 2022, 11, 2326. [Google Scholar] [CrossRef] [PubMed]

- Italian Ministry of Agricultural and Forest Policies. Decreto Ministeriale n. 350. Regolamento recante norme per l’individuazione dei prodotti tradizionali di cui all’articolo 8, comma 1, del D. Lgs. 30 aprile 1998, n. 173. Ital. Off. J. 1999, 240, 30–31. [Google Scholar]

- Viganoni, L. Commercio e consumo nelle città che cambiano. In Napoli, Città Medie, Spazi Esterni; Franco Angeli: Milan, Italy, 2019; pp. 317–322. [Google Scholar]

- European Commission. Commission Regulation (EU) No 97/2010 of 4 February 2010 entering a name in the register of traditional specialties guaranteed [Pizza Napoletana (TSG)]. Off. J. Eur. Union 2010, L34, 7–16. [Google Scholar]

- Bernklau, I.; Neußer, C.; Moroni, A.V.; Gysler, C.; Spagnolello, A.; Chung, W.; Becker, T. Structural, textural and sensory impact of sodium reduction on long fermented pizza. Food Chem. 2017, 234, 398–407. [Google Scholar] [CrossRef]

- Camacho Flinois, J.; Dando, R.; Padilla-Zakour, O.I. Yogurt acid whey utilization for production of baked goods: Pancakes and pizza crust. Foods 2019, 8, 615. [Google Scholar] [CrossRef]

- Pasqualone, A.; De Angelis, D.; Squeo, G.; Difonzo, G.; Caponio, F.; Summo, C. The effect of the addition of Apulian black chickpea flour on the nutritional and qualitative properties of durum wheat-based bakery products. Foods 2019, 8, 504. [Google Scholar] [CrossRef]

- Sagar, N.A.; Pareek, S. Dough rheology, antioxidants, textural, physicochemical characteristics, and sensory quality of pizza base enriched with onion (Allium cepa L.) skin powder. Sci. Rep. 2020, 10, 18669. [Google Scholar] [CrossRef]

- Pasqualone, A.; Costantini, M.; Faccia, M.; Difonzo, G.; Caponio, F.; Summo, C. The effectiveness of extruded-cooked lentil flour in preparing a gluten-free pizza with improved nutritional features and a good sensory quality. Foods 2022, 11, 482. [Google Scholar] [CrossRef]

- Kumar, R.; Chandrashekar, S.; Kathalsar, A.K.; Prabhasankar, P. Multi-Fabaceae flour for gluten-free pizza base: Rheology, processing, microstructural, and physico-sensory characteristics. J. Food Process. Preserv. 2022, 46, 16239. [Google Scholar]

- Delcuratolo, D.; Gomes, T.; Paradiso, V.M.; Nasti, R. Changes in the oxidative state of extra virgin olive oil used in baked Italian focaccia topped with different ingredients. Food Chem. 2008, 106, 222–226. [Google Scholar]

- Delcuratolo, D.; Paradiso, V.M.; Nasti, R.; Gomes, T. Comparative study and quality evaluation of Italian Focaccias seasoned with extra virgin olive oil. Int. J. Food Prop. 2011, 14, 988–995. [Google Scholar]

- Chen, J.; Zhang, L.; Li, Y.; Zhang, N.; Gao, Y.; Yu, X. The formation, determination and health implications of polar compounds in edible oils: Current status, challenges and perspectives. Food Chem. 2021, 364, 130451. [Google Scholar] [PubMed]

- Bavaro, A.R.; Di Biase, M.; Conte, A.; Lonigro, S.L.; Caputo, L.; Cedola, A.; Del Nobile, M.A.; Logrieco, A.F.; Lavermicocca, P.; Valerio, F. Weissella cibaria short-fermented liquid sourdoughs based on quinoa or amaranth flours as fat replacer in focaccia bread formulation. Int. J. Food Sci. Technol. 2021, 56, 3197–3208. [Google Scholar]

- Pasqualone, A. Italian Durum Wheat Breads; Nova Science Publisher Inc.: Hauppauge, NY, USA, 2012; pp. 57–79. [Google Scholar]

- European Commission and Council. Commission Regulation (EU) No. 1291/2003 of 18 July 2003 on the protection of geographical indications and designations of origin for agricultural products and foodstuffs [Pane di Altamura (PDO)]. Off. J. Eur. Union 2003, L181, 12–19. [Google Scholar]

- Brescia, M.A.; Sacco, D.; Sgaramella, A.; Pasqualone, A.; Simeone, R.; Peri, G.; Sacco, A. Characterisation of different typical Italian breads by means of traditional, spectroscopic and image analyses. Food Chem. 2007, 104, 429–438. [Google Scholar]

- Pasqualone, A.; Laddomada, B.; Centomani, I.; Paradiso, V.M.; Minervini, D.; Caponio, F.; Summo, C. Bread making aptitude of mixtures of re-milled semolina and selected durum wheat milling by-products. LWT 2017, 78, 151–159. [Google Scholar]

- Skendi, A.; Zinoviadou, K.G.; Papageorgiou, M.; Rocha, J.M. Advances on the valorisation and functionalization of by-products and wastes from cereal-based processing industry. Foods 2020, 9, 1243. [Google Scholar]

- Squeo, G.; Silletti, R.; Napoletano, G.; Greco Miani, M.; Difonzo, G.; Pasqualone, A.; Caponio, F. Characterization and effect of refining on the oil extracted from durum wheat by-products. Foods 2022, 11, 683. [Google Scholar]

- Vurro, F.; Greco Miani, M.; Summo, C.; Caponio, F.; Pasqualone, A. Effect of durum wheat oil on the physico-chemical and sensory features of biscuits. Foods 2022, 11, 1282. [Google Scholar] [PubMed]

- Glauben, T.; Svanidze, M.; Götz, L.; Prehn, S.; Jamali Jaghdani, T.; Đurić, I.; Kuhn, L. The war in Ukraine, agricultural trade and risks to global food security. Intereconomics 2022, 57, 157–163. [Google Scholar]

- Statista 2022. Available online: https://www.statista.com/statistics/263937/vegetable-oils-global-consumption/ (accessed on 8 June 2022).

- Ali, B.M.; van der Werf, W.; Lansink, A.O. Assessment of the environmental impacts of Xylella fastidiosa subsp. Pauca in Puglia. J. Crop Prot. 2021, 142, 105519. [Google Scholar]

- AOCS. Official Methods and Recommended Practices of the American Oil Chemist’s Society Cd 12c-16 “Accelerated Oxidation Test for the Determination of the Oxidation Stability of Foods, Oils and Fats Using the Oxitest Oxidation Test Reactor”; AOCS: Urbana, IL, USA, 2017. [Google Scholar]

- Difonzo, G.; Pasqualone, A.; Silletti, R.; Cosmai, L.; Summo, C.; Paradiso, V.M.; Caponio, F. Use of olive leaf extract to reduce lipid oxidation of baked snacks. Food Res. Int. 2018, 108, 48–56. [Google Scholar]

- Troilo, M.; Difonzo, G.; Paradiso, V.M.; Pasqualone, A.; Caponio, F. Grape Pomace as Innovative Flour for the Formulation of Functional Muffins: How Particle Size Affects the Nutritional, Textural and Sensory Properties. Foods 2022, 11, 1799. [Google Scholar] [PubMed]

- Difonzo, G.; Russo, A.; Trani, A.; Paradiso, V.M.; Ranieri, M.; Pasqualone, A.; Summo, C.; Tamma, G.; Silletti, R.; Caponio, F. Green extracts from Coratina olive cultivar leaves: Antioxidant characterization and biological activity. J. Funct. Foods 2017, 31, 63–70. [Google Scholar]

- ISO 13299; Sensory Analysis. Methodology. General Guidance for Establishing a Sensory Profile. ISO: Geneva, Switzerland, 2016.

- ISO 11132; Sensory Analysis. Methodology. Guidelines for the Measurement of the Performance of a Quantitative Descriptive Sensory Panel. ISO: Geneva, Switzerland, 2021.

- ISO 8589; Sensory Analysis. General Guidance for the Design of Test Rooms. ISO: Geneva, Switzerland, 2007.

- Caruso, M.C.; Galgano, F.; Colangelo, M.A.; Condelli, N.; Scarpa, T.; Tolve, R.; Favati, F. Evaluation of the oxidative stability of bakery products by OXITEST method and sensory analysis. Eur. Food Res. Technol. 2017, 243, 1183–1191. [Google Scholar]

- Saini, R.K.; Prasad, P.; Sreedhar, R.V.; Akhilender Naidu, K.; Shang, X.; Keum, Y.S. Omega-3 Polyunsaturated Fatty Acids (PUFAs): Emerging plant and microbial sources, oxidative stability, bioavailability, and health benefits—A Review. Antioxidants 2021, 10, 1627. [Google Scholar]

- Codex Standards for Fats and Oils from Vegetable Sources. Available online: https://www.fao.org/3/y2774e/y2774e04.htm#bm4.2 (accessed on 22 July 2022).

- Giakoumis, E.G. Analysis of 22 vegetable oils’ physico-chemical properties and fatty acid composition on a statistical basis, and correlation with the degree of unsaturation. Renew. Energy 2018, 126, 403–419. [Google Scholar]

- Dorni, C.; Sharma, P.; Saikia, G.; Longvah, T. Fatty acid profile of edible oils and fats consumed in India. Food Chem. 2018, 238, 9–15. [Google Scholar]

- Peh, H.Y.; Tan, W.D.; Liao, W.; Wong, W.F. Vitamin E therapy beyond cancer: Tocopherol versus tocotrienol. Pharmacol. Ther. 2016, 162, 152–169. [Google Scholar] [PubMed]

- Tan, S.M.Q.; Chiew, Y.; Ahmad, B.; Kadir, K.A. Tocotrienol-rich vitamin E from palm oil (tocovid) and its effects in diabetes 608 and diabetic nephropathy: A pilot phase II clinical trial. Nutrients 2018, 10, 1315. [Google Scholar]

- Rossi, M.; Alamprese, C.; Ratti, S. Tocopherols and tocotrienols as free radical-scavengers in refined vegetable oils and their 610 stability during deep-fat frying. Food Chem. 2007, 102, 812–817. [Google Scholar]

- Mignogna, R.; Fratianni, A.; Niro, S.; Panfili, G. Tocopherol and tocotrienol analysis as a tool to discriminate different fat ingredients in bakery products. Food Control 2015, 54, 31–38. [Google Scholar]

- Chen, H.; Chen, Y.; Wan, C.; Deng, Q. Free-radical-mediated formation mechanism of polar polymeric triglycerides in vegetable oil studied by electron spin resonance and high-performance liquid chromatography. J. Agric. Food Chem. 2021, 69, 9034–9042. [Google Scholar]

- Atehli, D.; Wang, J.; Yu, J.; Ali, F.; Wang, Y. Effects of mono-and diglycerides of fatty acids on the milk fat globule membrane after heat treatment. Int. J. Dairy Technol. 2020, 73, 667–673. [Google Scholar]

- Azizi, M.H.; Rajabzadeh, N.; Riahi, E. Effect of mono-diglyceride and lecithin on dough rheological characteristics and quality of flat bread. LWT-Food Sci. Technol. 2003, 36, 189–193. [Google Scholar]

- Tebben, L.; Shen, Y.; Li, Y. Improvers and functional ingredients in whole wheat bread: A review of their effects on dough properties and bread quality. Trends Food Sci. Technol. 2018, 81, 10–24. [Google Scholar]

- Xiao, F.; Xu, T.; Lu, B.; Liu, R. Guidelines for antioxidant assays for food components. Food Front. 2020, 1, 60–69. [Google Scholar]

- Liu, R.; Lu, M.; Zhang, T.; Zhang, Z.; Jin, Q.; Chang, M.; Wang, X. Evaluation of the antioxidant properties of micronutrients in different vegetable oils. Eur. J. Lipid Sci. Technol. 2020, 122, 1900079. [Google Scholar]

- Durmaz, G.; Gökmen, V. Effect of refining on bioactive composition and oxidative stability of hazelnut oil. Int. Food Res. J. 2019, 116, 586–591. [Google Scholar] [CrossRef] [PubMed]

- Dong, Y.; Karboune, S. A review of bread qualities and current strategies for bread bioprotection: Flavor, sensory, rheological, and textural attributes. Compr. Rev. Food Sci. Food Saf. 2021, 20, 1937–1981. [Google Scholar] [CrossRef] [PubMed]

- Pico, J.; Bernal, J.; Gómez, M. Wheat bread aroma compounds in crumb and crust: A review. Food Res. Int. 2015, 75, 200–215. [Google Scholar] [CrossRef]

- Pasqualone, A.; Bianco, A.M.; Paradiso, V.M.; Summo, C.; Gambacorta, G.; Caponio, F.; Blanco, A. Production and characterization of functional biscuits obtained from purple wheat. Food Chem. 2015, 180, 64–70. [Google Scholar] [CrossRef]

- Zamora, R.; Hidalgo, F.J. Coordinate contribution of lipid oxidation and Maillard reaction to the nonenzymatic food browning. Crit. Rev. Food Sci. Nutr. 2005, 45, 49–59. [Google Scholar] [CrossRef]

- Emektar, K.; Kantekin-Erdogan, M.N.; Tekin, A. Furan formation in some vegetable oils during heat treatments. Food Chem. 2022, 386, 132744. [Google Scholar] [CrossRef]

- Mortzfeld, F.B.; Hashem, C.; Vranková, K.; Winkler, M.; Rudroff, F. Pyrazines: Synthesis and industrial application of these valuable flavor and fragrance compounds. Biotechnol. J. 2020, 15, 2000064. [Google Scholar] [CrossRef]

- Negroni, M.; D’Agostin, A.; Arnoldi, A. Effects of olive, canola, and sunflower oils on the formation of volatiles from the Maillard reaction of lysine with xylose and glucose. J. Agric. Food Chem. 2001, 49, 439–445. [Google Scholar] [CrossRef]

- De Luca, L.; Aiello, A.; Pizzolongo, F.; Blaiotta, G.; Aponte, M.; Romano, R. Volatile organic compounds in breads prepared with different sourdoughs. Appl. Sci. 2021, 11, 1330. [Google Scholar] [CrossRef]

- Melini, V.; Melini, F.; Acquistucci, R. Nutritional characterization of an Italian traditional bread from ancient grains: The case study of the durum wheat bread “Pane di Monreale”. Eur. Food Res. Technol. 2021, 247, 193–200. [Google Scholar] [CrossRef]

- Debonne, E.; De Leyn, I.; Verwaeren, J.; Moens, S.; Devlieghere, F.; Eeckhout, M.; Van Bockstaele, F. The influence of natural oils of blackcurrant, black cumin seed, thyme and wheat germ on dough and bread technological and microbiological quality. LWT-Food Sci. 2018, 93, 212–219. [Google Scholar] [CrossRef]

- Pycia, K.; Kapusta, I.; Jaworska, G. Walnut oil and oilcake affect selected the physicochemical and antioxidant properties of wheat bread enriched with them. J. Food Process. Preserv. 2020, 44, 14573. [Google Scholar] [CrossRef]

- Funami, T.; Nakauma, M. Instrumental food texture evaluation in relation to human perception. Food Hydroc. 2022, 124, 107253. [Google Scholar] [CrossRef]

- Keskin, S.Ö.; Sumnu, G.; Sahin, S. Usage of enzymes in a novel baking process. Food/Nahrung 2004, 48, 156–160. [Google Scholar] [CrossRef] [PubMed]

| Ingredients | SO (g) | OO (g) | DWO (g) |

|---|---|---|---|

| Wheat flour type 0 | 600 | 600 | 600 |

| Water | 420 | 420 | 420 |

| Sunflower oil | 85 | - | - |

| Olive oil | - | 85 | - |

| Durum wheat oil | - | - | 85 |

| Salt | 15 | 15 | 15 |

| Yeast | 5 | 5 | 5 |

| Sample | Induction Time (min) |

|---|---|

| Focaccia | |

| OO | 134 ± 2.06 a |

| SO | 66.3 ± 4.81 c |

| DWO | 86.2 ± 2.53 b |

| Oils | |

| Olive oil | 59.5 ± 0.07 a |

| Sunflower oil | 30.7 ± 0.64 c |

| Durum wheat oil | 39.8 ± 0.26 b |

| Fatty Acids (%) | Olive Oil | Durum Wheat Oil | Sunflower Oil |

|---|---|---|---|

| C14:0 | 0.02 ± 0.00 c | 0.07 ± 0.00 b | 0.08 ± 0.00 a |

| C16:0 | 12.9 ± 0.06 b | 14.84 ± 0.04 a | 6.48 ± 0.01 c |

| C18:0 | 3.24 ± 0.04 b | 1.38 ± 0.01 c | 3.82 ± 0.01 a |

| C18:1 | 71.0 ± 0.11 a | 22.2 ± 0.05 c | 30.3 ± 0.00 b |

| C18:2 | 9.42 ± 0.08 c | 55.1 ± 0.05 b | 57.5 ± 0.01 a |

| C18:3 | 0.90 ± 0.01 b | 5.06 ± 0.03 a | 0.23 ± 0.01 c |

| ∑SFA | 16.9 ± 0.03 b | 17.0 ± 0.00 a | 10.8 ± 0.01 c |

| ∑MUFA | 72.5 ± 0.11 a | 22.6 ± 0.06 c | 30.5 ± 0.00 b |

| ∑PUFA | 10.6 ± 0.08 c | 60.5 ± 0.06 a | 58.7 ± 0.01 b |

| Focaccia Type | ABTS (µmol TE/g) | DPPH (µmol TE/g) |

|---|---|---|

| OO | 0.64 ± 0.03 ab | 0.46 ± 0.01 ab |

| DWO | 0.70 ± 0.04 a | 0.55 ± 0.02 a |

| SO | 0.56 ± 0.04 b | 0.38 ± 0.03 b |

| Volatile Compounds (µg/g) | Focaccia Type | ||

|---|---|---|---|

| OO | DWO | SO | |

| Aldehydes | |||

| Hexanal | 15.7 ± 0.01 c | 22.2 ± 0.0 b | 25.8 ± 1.07 a |

| Heptanal | 1.00 ± 0.08 b | 1.85 ± 0.02 a | 2.01 ± 0.24 a |

| Nonanal | 4.91 ± 0.33 b | 4.83 ± 0.15 b | 7.20 ± 0.01 a |

| 2-Methylbutanal | 12.0 ± 0.45 c | 17.7 ± 0.64 b | 20.5 ± 0.31 a |

| 3-Methylbutanal | 16.3 ± 0.63 c | 25.5 ± 0.66 a | 22.7 ± 0.08 b |

| Octanal | 1.35 ± 0.02 ab | 0.87 ± 0.16 b | 1.71 ± 0.12 a |

| 2-Heptenal | 5.00 ± 0.01 b | 4.63 ± 0.11 c | 9.75 ± 0.15 a |

| 2,4-Heptadienal | 0.78 ± 0.06 c | 1.56 ± 0.08 b | 3.28 ± 0.11 a |

| Benzacetaldheyde | 2.57 ± 0.04 b | 4.58 ± 0.09 a | 1.83 ± 0.08 c |

| Benzaldehyde | 6.18 ± 0.55 b | 7.55 ± 0.36 a | 7.28 ± 0.18 a |

| Alcohols | |||

| Ethyl alcohol | 2.29 ± 0.32 a | 2.10 ± 0.46 a | 2.67 ± 0.22 a |

| 2-Phenylethanol | 8.54 ± 0.16 a | 4.73 ± 0.12 c | 7.57 ± 0.23 b |

| 1-Hexanol | 6.14 ± 0.00 b | 2.82 ± 0.13 c | 10.8 ± 0.08 a |

| Carboxylic acid | |||

| Acetic acid | 2.95 ± 0.00 a | 1.41 ± 0.09 c | 1.73 ± 0.05 b |

| Ketones | |||

| Methyl ethyl ketone | 1.72 ± 0.28 a | 1.73 ± 0.17 a | 1.48 ± 0.04 a |

| Furan compounds | |||

| 2-Furanmethanol | 1.28 ± 0.25 c | 9.67 ± 0.90 a | 6.59 ± 0.27 b |

| Furan-2-pentyl | 2.25 ± 0.26 c | 4.80 ± 0.35 a | 3.83 ± 0.09 b |

| 2-Furancarboxaldehyde, 5-methyl- | 0.50 ± 0.10 c | 1.44 ± 0.07 a | 0.63 ± 0.04 b |

| 2-Furancarboxaldehyde (furfural) | 1.46 ± 0.01 c | 5.32 ± 0.06 a | 5.15 ± 0.06 b |

| Pyrazines | |||

| Methyl-pyrazine | 2.72 ± 0.11 c | 10.4 ± 0.82 a | 8.20 ± 0.85 b |

| Ethyl-pyrazine | 1.42 ± 0.12 c | 2.66 ± 0.07 a | 2.42 ± 0.02 b |

| Focaccia Type | |||

|---|---|---|---|

| OO | DWO | SO | |

| Color | |||

| Crumb | |||

| a* | 0.40 ± 0.08 b | 0.87 ± 0.11 a | 0.67 ± 0.08 a |

| b* | 18.2 ± 0.31 a | 18.99 ± 0.46 a | 21.0 ± 0.38 a |

| L* | 72.8 ± 1.37 ab | 71.15 ± 1.58 b | 74.5 ± 0.13 a |

| ∆E | - | 1.88 | 3.28 |

| Crust | |||

| a* | 7.15 ± 0.34 b | 10.1 ± 1.77 a | 9.31 ± 0.66 ab |

| b* | 32.0 ± 1.14 a | 33.4 ± 2.02 a | 33.2 ± 2.39 a |

| L* | 67.5 ± 0.82 a | 62.7 ± 1.89 b | 64.7 ± 1.99 ab |

| ∆E | - | 5.82 | 3.71 |

| Texture | |||

| Hardness (N) | 7.69 ± 1.06 b | 8.67 ± 1.13 b | 12.1 ± 1.13 a |

| Springiness | 0.94 ± 0.01 a | 0.94 ± 0.02 a | 0.95 ± 0.01 a |

| Chewiness (N) | 5.73 ± 0.84 b | 6.39 ± 0.44 b | 9.80 ± 0.48 a |

| Cohesiveness | 0.79 ± 0.01 a | 0.82 ± 0.07 a | 0.82 ± 0.01 a |

| Dimensional variations during baking | |||

| Diameter variation (%) | −0.73 ± 0.01 a | −0.73 ± 0.01 a | −0.75 ± 0.01 a |

| Thickness variation (%) | 117 ± 9.91 a | 110 ± 11.7 a | 118 ± 8.08 a |

| Focaccia Type | |||

|---|---|---|---|

| Sensory Descriptor | OO | DWO | SO |

| Surface color | 3.80 ± 0.35 b | 5.55 ± 0.28 a | 4.22 ± 0.30 b |

| Inner color | 0.58 ± 0.12 b | 0.85 ± 0.05 a | 0.75 ± 0.00 a |

| Crumb porosity | 4.27 ± 0.35 b | 5.53 ± 0.12 a | 3.57 ± 0.25 b |

| Focaccia odor | 6.50 ± 0.05 b | 7.67 ± 0.25 a | 6.75 ± 0.05 b |

| Oxidized odor | 0.00 ± 0.00 b | 0.00 ± 0.00 b | 0.63 ± 0.10 a |

| Roasted odor | 1.15 ± 0.15 b | 1.67 ± 0.22 a | 1.13 ± 0.15 b |

| Crumb elasticity | 5.38 ± 0.06 a | 5.17 ± 0.38 a | 5.60 ± 0.22 a |

| Softness | 6.18 ± 0.29 b | 7.08 ± 0.08 a | 5.77 ± 0.08 b |

| Crumb moisture | 5.55 ± 0.05 a | 5.55 ± 0.79 a | 5.48 ± 0.08 a |

| Greasiness | 6.07 ± 0.19 a | 5.12 ± 0.43 b | 5.93 ± 0.19 a |

| Sweetness | 1.15 ± 0.13 a | 1.22 ± 0.28 a | 1.42 ± 0.08 a |

| Saltiness | 5.03 ± 0.20 a | 4.37 ± 0.25 b | 4.90 ± 0.09 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vurro, F.; Summo, C.; Squeo, G.; Caponio, F.; Pasqualone, A. The Use of Durum Wheat Oil in the Preparation of Focaccia: Effects on the Oxidative Stability and Physical and Sensorial Properties. Foods 2022, 11, 2679. https://doi.org/10.3390/foods11172679

Vurro F, Summo C, Squeo G, Caponio F, Pasqualone A. The Use of Durum Wheat Oil in the Preparation of Focaccia: Effects on the Oxidative Stability and Physical and Sensorial Properties. Foods. 2022; 11(17):2679. https://doi.org/10.3390/foods11172679

Chicago/Turabian StyleVurro, Francesca, Carmine Summo, Giacomo Squeo, Francesco Caponio, and Antonella Pasqualone. 2022. "The Use of Durum Wheat Oil in the Preparation of Focaccia: Effects on the Oxidative Stability and Physical and Sensorial Properties" Foods 11, no. 17: 2679. https://doi.org/10.3390/foods11172679

APA StyleVurro, F., Summo, C., Squeo, G., Caponio, F., & Pasqualone, A. (2022). The Use of Durum Wheat Oil in the Preparation of Focaccia: Effects on the Oxidative Stability and Physical and Sensorial Properties. Foods, 11(17), 2679. https://doi.org/10.3390/foods11172679