Phytic Acid against Clostridium perfringens Type A: A Food Matrix Study

Abstract

:1. Introduction

2. Materials and Methods

2.1. Bacterial Strains and Reactivation

2.2. Spore Preparation and Purification

2.3. Vegetative Cells Preparation

2.4. Stock Solutions of the Tested Antimicrobials

2.5. Clostridium perfringens Spore Germination in the Presence of Phytic Acid and Sodium Sorbate

2.6. Clostridium perfringens Vegetative Cells Growth in the Presence of Phytic Acid and Sodium Sorbate

2.7. Application of Phytic Acid in the Inhibition of C. perfringens Spores in Cooked Meat Products

2.8. Statistical Analysis

3. Results and Discussion

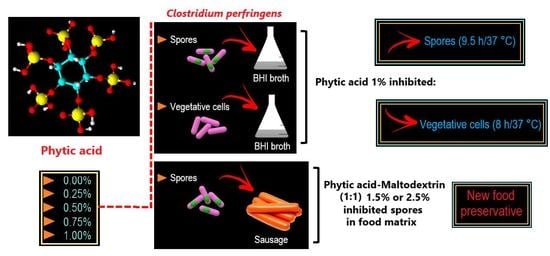

3.1. Germination of Clostridium perfringens Spores in the Presence of Phytic Acid and Sodium Sorbate

3.2. Clostridium perfringens Vegetative Cells in the Presence of Phytic Acid and Sodium Sorbate

3.3. Application of Phytic Acid in the Inhibition of C. perfringens Spores in Cooked Meat Products

4. Conclusions

5. Patents

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Briggs, D.C.; Naylor, C.E.; Smedley, J.G.; Lukoyanova, N.; Robertson, S.; Moss, D.S.; McClane, B.A.; Basak, A.K. Structure of the food-poisoning clostridium perfringens enterotoxin reveals similarity to the aerolysin-like pore-forming toxins. J. Mol. Biol. 2011, 413, 138–149. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Uzal, F.A.; McClane, B.A.; Cheung, J.K.; Theoret, J.; Garcia, J.P.; Moore, R.J.; Rood, J.I. Animal models to study the pathogenesis of human and animal Clostridium perfringens infections. Vet. Microbiol. 2015, 179, 23–33. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lindström, M.; Heikinheimo, A.; Lahti, P.; Korkeala, H. Novel insights into the epidemiology of Clostridium perfringens type A food poisoning. Food Microbiol. 2011, 28, 192–198. [Google Scholar] [CrossRef]

- Centers for Disease Control and Prevention (CDC). Surveillance for Foodborne Disease Outbreaks United States, 2017: Annual Report; U.S. Department of Health and Human Services, Ed.; Centers for Disease Control and Prevention (CDC): Atlanta, GA, USA, 2019.

- Kiu, R.; Caim, S.; Painset, A.; Pickard, D.; Swift, C.; Dougan, G.; Mather, A.E.; Amar, C.; Hall, L.J. Phylogenomic analysis of gastroenteritis-associated clostridium perfringens in england and wales over a 7-year period indicates distribution of clonal toxigenic strains in multiple outbreaks and extensive involvement of enterotoxin-encoding (Cpe) plasmids. Microb. Genom. 2019, 5. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; McClane, B.A. Comparative effects of osmotic, sodium nitrite-induced, and pH-induced stress on growth and survival of Clostridium perfringens type A isolates carrying chromosomal or plasmid-borne enterotoxin genes. Appl. Environ. Microbiol. 2006, 72, 7620–7625. [Google Scholar] [CrossRef] [Green Version]

- Jay, J.M. Microbiologia de Alimentos, 6th ed.; Artmed: Porto Alegre, Brazil, 2005. [Google Scholar]

- Sarker, M.R.; Shivers, R.P.; Sparks, S.G.; Juneja, V.K.; McClane, B.A. Comparative experiments to examine the effects of heating on vegetative cells and spores of Clostridium perfringens isolates carrying plasmid enterotoxin genes versus chromosomal enterotoxin genes. Appl. Environ. Microbiol. 2000, 66, 3234–3240. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Juneja, V.K.; Baker, D.A.; Thippareddi, H.; Snyder, O.P.; Mohr, T.B. Growth potential of clostridium perfringens from spores in acidified beef, pork, and poultry products during chilling. J. Food Prot. 2013, 76, 65–71. [Google Scholar] [CrossRef] [PubMed]

- Udompijitkul, P.; Alnoman, M.; Sarker, M.R. Inactivation strategy for Clostridium perfringens spores adhered to food contact surfaces. Food Microbiol. 2013, 34, 328–336. [Google Scholar] [CrossRef]

- Alnoman, M.; Udompijitkul, P.; Paredes-Sabja, D.; Sarker, M.R. The inhibitory effects of sorbate and benzoate against Clostridium perfringens type A isolates. Food Microbiol. 2015, 48, 89–98. [Google Scholar] [CrossRef]

- De Oliveira, T.L.C.; de Araújo Soares, R.; Ramos, E.M.; das Graças Cardoso, M.; Alves, E.; Piccoli, R.H. Antimicrobial activity of Satureja montana L. essential oil against Clostridium perfringens type A inoculated in mortadella-type sausages formulated with different levels of sodium nitrite. Int. J. Food Microbiol. 2011, 144, 546–555. [Google Scholar] [CrossRef] [Green Version]

- Radaelli, M.; da Silva, B.P.; Weidlich, L.; Hoehne, L.; Flach, A.; da Costa, L.A.M.A.; Ethur, E.M. Antimicrobial activities of six essential oils commonly used as condiments in Brazil against clostridium perfringens. Braz. J. Microbiol. 2016, 47, 424–430. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nieto-Lozano, J.C.; Reguera-Useros, J.I.; Peláez-Martínez, M.D.C.; De La Torre, A.H. Effect of a bacteriocin produced by Pediococcus acidilactici against Listeria monocytogenes and Clostridium perfringens on Spanish raw meat. Meat Sci. 2006, 72, 57–61. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nieto-Lozano, J.C.; Reguera-Useros, J.I.; Peláez-Martínez, M.D.C.; Sacristán-Pérez-Minayo, G.; Gutiérrez-Fernández, Á.J.; de la Torre, A.H. The effect of the pediocin PA-1 produced by Pediococcus acidilactici against Listeria monocytogenes and Clostridium perfringens in Spanish dry-fermented sausages and frankfurters. Food Control 2010, 21, 679–685. [Google Scholar] [CrossRef]

- Garde, S.; Gómez-Torres, N.; Hernández, M.; Ávila, M. Susceptibility of Clostridium perfringens to antimicrobials produced by lactic acid bacteria: Reuterin and nisin. Food Control 2014, 44, 22–25. [Google Scholar] [CrossRef]

- Ávila, M.; Gómez-Torres, N.; Hernández, M.; Garde, S. Inhibitory activity of reuterin, nisin, lysozyme and nitrite against vegetative cells and spores of dairy-related Clostridium species. Int. J. Food Microbiol. 2014, 172, 70–75. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Q.; Zhao, Y.; Dang, H.; Tang, Y.; Zhang, B. Antibacterial effects of phytic acid against foodborne pathogens and investigation of its mode of action. J. Food Prot. 2019, 82, 826–833. [Google Scholar] [CrossRef] [PubMed]

- Canan, C.; Bloot, A.P.M.; Baraldi, I.J.; Colla, E.; Feltrin, V.P.; Corso, M.P.; Habu, S.; Nogues, D.R.N.; Kalschne, D.L.; Da Silva-Buzanello, R.A. Composição Antimicrobiana a Base de Fitato, e seu. U.S. Patent Registration Number: BR1020180062280, 27 March 2018. [Google Scholar]

- Kim, N.H.; Rhee, M.S. Phytic acid and sodium chloride show marked synergistic bactericidal effects against nonadapted and acid-adapted Escherichia coli O157:H7 strains. Appl. Environ. Microbiol. 2016, 82, 1040–1049. [Google Scholar] [CrossRef] [Green Version]

- Bloot, A.P.M.; Kalschne, D.L.; Amaral, J.A.S.; Baraldi, I.J.; Canan, C. A Review of Phytic Acid Sources, Obtention, and Applications. Food Rev. Int. 2021, 1–20. [Google Scholar] [CrossRef]

- Inatsu, Y.; Weerakkody, K.; Bari, M.L.; Hosotani, Y.; Nakamura, N.; Kawasaki, S. The efficacy of combined (NaClO and organic acids) washing treatments in controlling Escherichia coli O157:H7, Listeria monocytogenes and spoilage bacteria on shredded cabbage and bean sprout. LWT Food Sci. Technol. 2017, 85, 1–8. [Google Scholar] [CrossRef]

- Sun, X.; Hong, H.; Jia, S.; Liu, Y.; Luo, Y. Effects of phytic acid and lysozyme on microbial composition and quality of grass carp (Ctenopharyngodon idellus) fillets stored at 4%C. Food Microbiol. 2020, 86, 103313. [Google Scholar] [CrossRef]

- Boukhris, I.; Smaoui, S.; Ennouri, K.; Morjene, N.; Farhat-Khemakhem, A.; Blibech, M.; Alghamdi, O.A.; Chouayekh, H. Towards understanding the antagonistic activity of phytic acid against common foodborne bacterial pathogens using a general linear model. PLoS ONE 2020, 15, e0231397. [Google Scholar] [CrossRef] [PubMed]

- Graf, E.; Eaton, J.W. Antioxidant functions of phytic acid. Free Radic. Biol. Med. 1990, 8, 61–69. [Google Scholar] [CrossRef]

- Canan, C.; Delaroza, F.; Casagrande, R.; Baracat, M.M.; Shimokomaki, M.; Ida, E.I. Antioxidant capacity of phytic acid purified from rice bran. Acta Sci.—Technol. 2012, 34, 457–463. [Google Scholar] [CrossRef] [Green Version]

- Canan, C.; Lahis, D.; Gabriela, K.; Ongaratto, C.; Donizeti, O.; Ana, L.; Trindade, C.; Eder, C.; De Moraes, L.; Ida, E.I. Antioxidant effect of rice bran purified phytic acid on mechanically deboned chicken meat. J. Food Processing Preserv. 2021, 45, e15716. [Google Scholar] [CrossRef]

- FDA (Food and Drug Administration). GRN n. 381—Phytic Acid; U.S. Food and Drug Administration: Silver Spring, MD, USA, 2012; p. 1.

- Nita, L.E.; Chiriac, A.P.; Ghilan, A.; Rusu, A.G.; Tudorachi, N.; Timpu, D. Alginate enriched with phytic acid for hydrogels preparation. Int. J. Biol. Macromol. 2021, 181, 561–571. [Google Scholar] [CrossRef] [PubMed]

- Paredes-Sabja, D.; Torres, J.A.; Setlow, P.; Sarker, M.R. Clostridium perfringens spore germination: Characterization of germinants and their receptors. J. Bacteriol. 2008, 190, 1190–1201. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Duncan, C.L.; Strong, D.H. Improved medium for enumeration of Clostridium perfringens. Appl. Microbiol. 1968, 16, 82–89. [Google Scholar] [CrossRef]

- Geitenes, S.; de Oliveira, M.F.B.; Kalschne, D.L.; Sarmento, C.M.P. Growth Modeling of Lactic Acid Bacteria and Microbiological Analysis in Two Types of Sliced Vacuum Package Cooked Ham. Rev. Ciências Exatas e Nat.—RECEN 2013, 15, 113–133. [Google Scholar] [CrossRef]

- Kalschne, D.L.; Geitenes, S.; Veit, M.R.; Sarmento, C.M.P.; Colla, E. Growth inhibition of lactic acid bacteria in ham by nisin: A model approach. Meat Sci. 2014, 98, 744–752. [Google Scholar] [CrossRef]

- Juneja, V.K.; Novak, J.S.; Labbe, R.J. Clostridium perfringens. In Pathogens and Toxins in Foods: Challenges and Interventions; Juneja, V.K., Sofos, J.N., Eds.; ASM Press: Washington, DC, USA, 2010; pp. 53–70. ISBN 9781555814595. [Google Scholar]

- Li, J.; Paredes-sabja, D.; Sarker, M.R.; Mcclane, B.A. Clostridium perfringens Sporulation and Sporulation-Associated Toxin Production. Microbiol. Spectr. 2016, 4, 4.3.08. [Google Scholar] [CrossRef] [Green Version]

- Ando, Y. Spore lytic enzyme released from Clostridium perfringens spores during germination. J. Bacteriol. 1979, 140, 59–64. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Carpenter, C.E.; Reddy, D.S.A.; Cornforth, D.P. Inactivation of clostridial ferredoxin and pyruvate-ferredoxin oxidoreductase by sodium nitrite. Appl. Environ. Microbiol. 1987, 53, 549–552. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Franco, B.D.G.M.; Landgraf, M.; Destro, M.T. Controle do Desenvolvimento Microbiano nos Alimentos; Artmed: São Paulo, Brazil, 1996. [Google Scholar]

- Tompkim, R.P. Nitrite. In Antimicrobials in Food; Davidson, P.M., Sofos, J.N., Branen, A.L., Eds.; CRC Press: Boca Raton, FL, USA, 2005; pp. 169–236. [Google Scholar]

- Chabrière, E.; Charon, M.; Volbeda, A.; Pieulle, L.; Hatchikian, E.C. Crystal structures of the key anaerobic enzyme pyruvate: Ferredoxin oxidoreductase, free and in complex with pyruvate. Nature 1999, 6, 182–190. [Google Scholar]

- Yoch, D.C.; Carithers, R.P. Bacterial iron-sulfur proteins. Microbiol. Rev. 1979, 43, 384–421. [Google Scholar] [CrossRef]

- Brazil Collegiate Board Resolution n. 272, 14 March 2019. Available online: https://www.in.gov.br/web/guest/materia/-/asset_publisher/Kujrw0TZC2Mb/content/id/67378977/do1-2019-03-18-resolucao-da-diretoria-colegiada-rdc-n-272-de-14-de-marco-de-2019-67378770 (accessed on 15 December 2021).

- FDA. Food Additives Permitted for Direct Addition to Food for Human Consumption; 21CFR172.175; FDA: Silver Spring, MD, USA, 2020.

- Nakahima, S.M.K.; André, C.D.S.; Franco, B.D.G.M. Review: Basic Aspects of Predictive Microbiology. Braz. J. Food Technol. 2000, 3, 41–51. [Google Scholar]

- Canan, C.; Cruz, F.T.L.; Delaroza, F.; Casagrande, R.; Sarmento, C.P.M.; Shimokomaki, M.; Ida, E.I. Studies on the extraction and purification of phytic acid from rice bran. J. Food Compos. Anal. 2011, 24, 1057–1063. [Google Scholar] [CrossRef] [Green Version]

| Formulations | λ | A | μ | MSE | BF | AF | R2 |

|---|---|---|---|---|---|---|---|

| SA1 (NC) | 0 | 8.26 | 0.38 | 0.069 | 1.001 | 1.057 | 0.99 |

| SA2 (PA-MD 1.50%) | 0 | 7.34 | 0.27 | 0.102 | 1.032 | 1.082 | 0.98 |

| SA3 (PA-MD 2.50%) | 0 | 7.29 | 0.26 | 0.161 | 1.011 | 1.092 | 0.98 |

| SA4 (SS 10%-PC) | 0 | 5.78 | 0.23 | 0.045 | 1.003 | 1.061 | 0.99 |

| SA5 (NO2 0.015%-PC) | 0 | 8.19 | 0.31 | 0.109 | 1.008 | 1.069 | 0.99 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bloot, A.P.M.; Kalschne, D.L.; Nogues, D.R.N.; Amaral, J.S.; Flores, E.L.M.; Colla, E.; Habu, S.; Baraldi, I.J.; Canan, C. Phytic Acid against Clostridium perfringens Type A: A Food Matrix Study. Foods 2022, 11, 406. https://doi.org/10.3390/foods11030406

Bloot APM, Kalschne DL, Nogues DRN, Amaral JS, Flores ELM, Colla E, Habu S, Baraldi IJ, Canan C. Phytic Acid against Clostridium perfringens Type A: A Food Matrix Study. Foods. 2022; 11(3):406. https://doi.org/10.3390/foods11030406

Chicago/Turabian StyleBloot, Ana Paula Marinho, Daneysa Lahis Kalschne, Diego Ricardo Nunes Nogues, Joana S. Amaral, Eder Lisandro Moraes Flores, Eliane Colla, Sascha Habu, Ilton José Baraldi, and Cristiane Canan. 2022. "Phytic Acid against Clostridium perfringens Type A: A Food Matrix Study" Foods 11, no. 3: 406. https://doi.org/10.3390/foods11030406

APA StyleBloot, A. P. M., Kalschne, D. L., Nogues, D. R. N., Amaral, J. S., Flores, E. L. M., Colla, E., Habu, S., Baraldi, I. J., & Canan, C. (2022). Phytic Acid against Clostridium perfringens Type A: A Food Matrix Study. Foods, 11(3), 406. https://doi.org/10.3390/foods11030406