Folate Enrichment of Whole-Meal Spaghetti Using Durum Wheat Debranning Fractions

Abstract

:1. Introduction

2. Materials and Methods

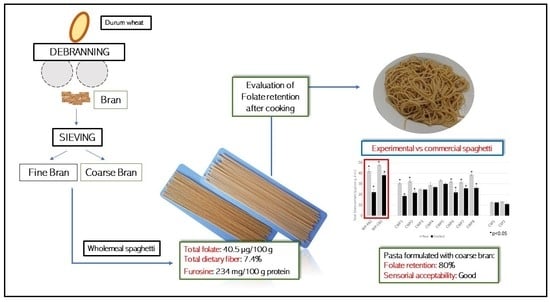

2.1. Debranning/Milling

2.2. Particle Size Distribution

2.3. Pasta Making

2.4. Commercial Pasta Sampling

2.5. Spaghetti Cooking

2.6. Color

2.7. Chemical Analysis

2.8. Total Folate Content and Apparent Folate Retention Determination

2.9. Furosine Determination

2.10. Cooking Quality and Sensory Evaluation

2.11. Statistical Analysis

3. Results

3.1. Particle Size Distribution and Folate Content of Durum Wheat Debranning Fractions

3.2. Chemical–Nutritional Composition and Colorimetric Indices of Experimental Whole-Meal Pasta

3.3. Total Folate Content in Raw Experimental and Commercial Pasta Samples

3.4. Folate Content and Retention in Experimental and Commercial Pasta Samples after Cooking

3.5. Sensorial Properties of Cooked Spaghetti Samples

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- van der Kamp, J.W.; Jones, J.M.; Miller, K.B.; Ross, A.B.; Seal, C.J.; Tan, B.; Beck, E.J. Consensus, global definitions of whole grain as a food ingredient and of whole-grain foods presented on behalf of the Whole Grain Initiative. Nutrients 2022, 14, 138. [Google Scholar] [CrossRef]

- Barrett, E.M.; Foster, S.I.; Beck, E.J. Whole grain and high-fibre grain foods: How do knowledge, perceptions and attitudes affect food choice? Appetite 2020, 149, 104630. [Google Scholar] [CrossRef]

- Onipe, O.O.; Jideani, A.I.O.; Beswa, D. Composition and functionality of wheat bran and its application in some cereal food products. Int. J. Food Sci. Technol. 2015, 50, 2509–2518. [Google Scholar] [CrossRef]

- Stevenson, L.; Phillips, F.; O’Sullivan, K.; Walton, J. Wheat bran: Its composition and benefits to health, a European perspectives. Int. J. Food Sci. Nut. 2012, 63, 1001–1013. [Google Scholar] [CrossRef]

- Cheng, W.; Sun, Y.; Fan, M.; Li, Y.; Wang, L.; Qian, H. Wheat bran, as the resource of dietary fiber: A review. Crit. Rev. Food Sci. Nut. 2022, 62, 7269–7281. [Google Scholar] [CrossRef]

- Lu, Z.; Walker, K.; Muir, J.; O’Dea, K. Arabinoxylan fibre improves metabolic control in people with Type II diabetes. Eur. J. Clin. Nutr. 2004, 58, 621–628. [Google Scholar] [CrossRef]

- De Munter, J.S.; Hu, F.B.; Spiegelman, D.; Franz, M.; van Dam, R.M. Whole grain, bran, and germ intake and risk of type 2 diabetes: A prospective cohort study and systematic review. PLoS Med. 2007, 4, e261. [Google Scholar] [CrossRef]

- Ciccoritti, R.; Taddei, F.; Nicoletti, I.; Gazza, L.; Corradini, D.; D’Egidio, M.G.; Martini, D. Use of bran fractions and debranned kernels for the development of pasta with high nutritional and healthy potential. Food Chem. 2017, 225, 77–86. [Google Scholar] [CrossRef]

- De Arcangelis, E.; Angelicola, M.; Trivisonno, M.C.; Iacovino, S.; Falasca, L.; Lafiandra, L.; Sestili, F.; Messia, M.C.; Marconi, E. High-amylose bread wheat and its effects on cooking quality and nutritional properties of pasta. Int. J. Food Sci. Technol. 2022, 57, 6785–6794. [Google Scholar] [CrossRef]

- Di Pede, G.; Dodi, R.; Scarpa, C.; Brighenti, F.; Dall’Asta, M.; Scazzina, F. Glycemic index values of pasta products: An overview. Foods 2021, 10, 2541. [Google Scholar] [CrossRef]

- Iafelice, G.; Caboni, M.F.; Cubadda, R.; Di Criscio, T.; Trivisonno, M.C.; Marconi, E. Development of functional spaghetti enriched in long chain omega-3 fatty acids. Cereal Chem. 2008, 85, 146–151. [Google Scholar] [CrossRef]

- De Paula, R.; Abdel-Aal, E.-S.M.; Messia, M.C.; Rabalski, I.; Marconi, E. Effect of processing on the beta-glucan physicochemical properties in barley and semolina pasta. J. Cereal Sci. 2017, 75, 124–131. [Google Scholar] [CrossRef]

- EFSA. Scientific Opinion on Dietary Reference Values for folate. EFSA J. 2014, 12, 3893. [Google Scholar]

- Pounis, G.; Di Castelnuovo, A.F.; de Lorgeril, M.; Krogh, V.; Siani, A.; Arnout, J.; Cappuccio, F.P.; van Dongen, M.; Zappacosta, B.; Donati, M.B.; et al. European Collaborative Groups of the IMMIDIET project Folate intake and folate serum levels in men and women from two European populations: The IMMIDIET project. Nutrition 2014, 30, 822–830. [Google Scholar] [CrossRef]

- Rogers, L.M.; Cordero, A.M.; Pfeiffer, C.M.; Hausman, D.B.; Tsang, B.L.; De-Regil, L.M.; Rosenthal, J.; Razzaghi, H.; Wong, E.; Weakland, A.P.; et al. Global folate status in women of reproductive age: A systematic review with emphasis on methodological issues. Ann. N. Y. Acad. Sci. 2018, 1431, 35–57. [Google Scholar] [CrossRef]

- Safi, J.; Joyeux, L.; Chalouhi, G.E. Periconceptional Folate Deficiency and Implications in Neural Tube Defects. J. Pregnancy 2012, 2012, 295083. [Google Scholar] [CrossRef]

- Obeid, R.; Oexle, K.; Pietrzik, K.; Koletzko, B. Folate status and health: Challenges and opportunities. J. Perinat. Med. 2016, 44, 261–268. [Google Scholar] [CrossRef]

- Clarke, R.; Halsey, J.; Lewington, S.; Lonn, E.; Armitage, J.; Man-son, J.E.; Bonaa, K.H.; Spence, J.D.; Nygard, O.; Jamison, R.; et al. Effects of lowering homocysteine levels with B vitamins on cardiovascular disease, cancer, and cause-specific mortality: Meta-analysis of 8 randomized trials involving 37485 individuals. Arch. Intern. Med. 2010, 170, 1622–1631. [Google Scholar]

- Wang, Z.; Zhu, W.; Xing, Y.; Jia, J.; Tang, Y. B vitamins and prevention of cognitive decline and incident dementia: A systematic review and meta-analysis. Nutri. Rev. 2022, 80, 931–949. [Google Scholar] [CrossRef]

- Piironen, V.; Edelmann, M.; Kariluoto, S.; Bedo, Z. Folate in wheat genotypes in the HEALTHGRAIN diversity screen. J. Agric. Food Chem. 2008, 56, 9726–9732. [Google Scholar] [CrossRef]

- Kariluoto, S.; Edelmann, M.; Piironen, V. Effects of environment and genotype on folate contents in wheat in the HEALTHGRAIN diversity screen. J. Agric. Food Chem. 2010, 58, 9324–9331. [Google Scholar] [CrossRef]

- Boz, H. Effect of processing on cereal folates. J. Cereal Sci. 2021, 99, 103202. [Google Scholar] [CrossRef]

- De Arcangelis, E.; Trivisonno, M.C.; Angelicola, M.; Quiquero, M.; Di Nardo, V.; Falasca, L.; Sestili, F.; Messia, M.C.; Marconi, E. Milling and rheological properties of high amylose wheat. J. Cereal Sci. 2021, 102, 103335. [Google Scholar] [CrossRef]

- Messia, M.C.; De Arcangelis, E.; Candigliota, T.; Trivisonno, M.C.; Marconi, E. Production of β-glucan enriched flour from waxy barley. J. Cereal Sci. 2020, 93, 102989. [Google Scholar] [CrossRef]

- Ruggeri, S.; De Arcangelis, E.; Aguzzi, A.; Messia, M.C.; Marconi, E. Design of cereal products naturally enriched in folate from barley pearling by-products. Nutrients 2022, 14, 3729. [Google Scholar] [CrossRef]

- Dexter, J.E.; Wood, P.J. Recent applications of debranning of wheat before milling. Trends Food Sci. Technol. 1996, 7, 35–41. [Google Scholar] [CrossRef]

- Cubadda, R.E.; Marconi, E. Effects of debranning on milling yield and quality features of durum wheat semolina. Tec. Molit. 2007, 58, 369–383. [Google Scholar]

- Pasqualone, A.; Laddomada, B.; Centomani, I.; Paradiso, V.M.; Minervini, D.; Caponio, F.; Summo, C. Bread making aptitude of mixtures of re-milled semolina and selected durum wheat milling by-products. LWT-Food Sci. Technol. 2017, 78, 151–159. [Google Scholar] [CrossRef]

- Giordano, D.; Reyneri, A.; Blandino, M. Folate distribution in barley (Hordeum vulgare L.), common wheat (Triticum aestivum L.) and durum wheat (Triticum turgidum durum Desf.) pearled fractions. J. Sci. Food Agric. 2015, 96, 1709–1715. [Google Scholar] [CrossRef]

- UNI 10873:2000; Durum Wheat Semola and Semolina—Determination of the Granulometry. Ente Italiano di Normazione: Milano, Italy, 2000.

- Regulation (EC) No 1924/2006 of the European Parliament and of the Council of 20 December 2006 on nutrition and health claims made on food. Off. J. Eur. Union 2006, L404, 9–25.

- Commission Regulation (EU) No 432/2012 of 16 May 2012 establishing a list of permitted health claims made on foods, other than those referring to the reduction of disease risk and to children’s development and health. Off. J. Eur. Union 2012, L136, 1–40.

- Italian Presidential Decree No 187/2001. Regulation for the revision of laws concerning the production and sale of milling products and pasta, pursuant to Article 50 of Law N° 146, dated 22 February 1994. Off. Gaz. Ital. Repub. 2001, n.117, 1–16.

- ISO 7304-1:2016; Durum Wheat Semolina and Alimentary Pasta—Estimation of Cooking Quality of Alimentary Pasta by Sensory Analysis—Part 1: Reference Method. International Organization for Standardization: Geneva, Switzerland, 2016.

- ICC Standards: Standard Methods of the International Association for Cereal Science and Technology (ICC); ICC: Vienna, Austria, 1955.

- ISO 2171:2007; Cereals, Pulses and by-Products—Determination of Ash Yield by Incineration. International Organization for Standardization: Geneva, Switzerland, 2007.

- AOAC International. Methods No. 922.06, 985.29. In Official Methods of Analysis of AOAC, 17th ed.; Association of Analytical Communities: Gaithersburg, MD, USA, 2002. [Google Scholar]

- Murphy, E.W.; Criner, P.E.; Gray, B.C. Comparisons of methods for calculating retentions of nutrients in cooked foods. J. Agric. Food Chem. 1975, 23, 1153–1157. [Google Scholar] [CrossRef] [PubMed]

- Resmini, P.; Pellegrino, L.; Battelli, G. Accurate quantification of furosine in milk and dairy products by a direct HPLC method. Italian J. Food Sci. 1990, 2, 173–183. [Google Scholar]

- ISO 7304-2:2008; Alimentary Pasta Produced from Durum Wheat Semolina—Estimation of Cooking Quality by Sensory Analysis—Part 2: Routine Method. ISO: Geneva, Switzerland, 2008.

- Brouns, F.; Hemery, Y.; Price, R.; Anson, N.M. Wheat aleurone: Separation, composition, health aspects, and potential food use. Crit. Rev. Food Sci. Nutr. 2012, 52, 553–568. [Google Scholar] [CrossRef]

- Edelmann, M.; Kariluoto, S.; Nyström, L.; Piironen, V. Folate in oats and its milling fractions. Food Chem. 2012, 135, 1938–1947. [Google Scholar] [CrossRef]

- Fang, F.; Junejo, S.A.; Wang, K.; Yang, X.; Yuan, Y.; Zha, B. Fibre matrices for enhanced gut health: A mini review. Int. J. Food Sci. Techn. 2022. early view. [Google Scholar] [CrossRef]

- Yao, W.; Gong, Y.; Li, L.; Hu, X.; You, L. The effects of dietary fibers from rice bran and wheat bran on gut microbiota: An overview. Food Chem. X 2022, 13, 100252. [Google Scholar] [CrossRef]

- Jefferson, A.; Adolphus, K. The effects of intact cereal grain fibers, including wheat bran on the gut microbiota composition of healthy studies: A sistematic review. Front. Nut 2019, 6, 33. [Google Scholar] [CrossRef]

- Molzer, C.; Wilson, H.M.; Kuffova, L.; Forrester, J.V. A role for folate in microbiome-linked control of autoimmunity. J. Immunol. Res. 2021, 2021, 9998200. [Google Scholar] [CrossRef]

- Marti, A.; Cattaneo, S.; Benedetti, S.; Buratti, S.; Abbasi Parizad, P.; Masotti, F.; Iametti, S.; Pagani, M.A. Characterization of whole grain pasta: Integrating physical, chemical, molecular, and instrumental sensory approaches. J. Food Sci. 2017, 82, 2583–2590. [Google Scholar] [CrossRef] [PubMed]

- De Noni, I.; Pagani, M.A. Cooking properties and heat damage of dried pasta as influenced by raw material characteristics and processing conditions. Crit. Rev. Food Sci. Nutr. 2010, 50, 465–472. [Google Scholar] [CrossRef]

- Messia, M.C.; Cuomo, F.; Verardo, V.; Quiquero, M.; Marconi, E. Assessment of Nutritional Value and Maillard Reaction in Different Gluten-Free Pasta. Foods 2023, 12, 1221. [Google Scholar] [CrossRef] [PubMed]

- Cubadda, R.E.; Carcea, M.; Marconi, E.; Trivisonno, M.C. Influence of Gluten Proteins and Drying Temperature on the Cooking Quality of Durum Wheat Pasta. Cereal Chem. 2007, 84, 48–55. [Google Scholar] [CrossRef]

- Bresciani, A.; Pagani, M.A.; Marti, A. Pasta-Making Process: A Narrative Review on the Relation between Process Variables and Pasta Quality. Foods 2022, 11, 256. [Google Scholar] [CrossRef]

- Jones, J.M.; Adams, J.; Harriman, C.; Miller, C.; Van der Kamp, J.W. Nutritional impacts of different whole grain milling techniques: A review of milling practices and existing data. Cereal Foods World 2015, 60, 130–139. [Google Scholar] [CrossRef]

- Hirawan, R.; Beta, T. Whole wheat pasta and health. In Wheat and Rice in Disease Prevention and Health; Elsevier: Amsterdam, The Netherlands, 2014; pp. 5–16. [Google Scholar]

- Regulation (EU) No 1169/2011 of the European Parliament and of the Council of 25 October 2011 on the provision of food information to consumers, amending Regulations (EC) No 1924/2006 and (EC) No 1925/2006 of the European Parliament and of the Council, and repealing Commission Directive 87/250/EEC, Council Directive 90/496/EEC, Commission Directive 1999/10/EC, Directive 2000/13/EC of the European Parliament and of the Council, Commission Directives 2002/67/EC and 2008/5/EC and Commission Regulation (EC) No 608/2004. Off. J. Eur. Union 2011, L304, 18–63.

- Anderson, W.A.; Slaughter, D.; Laffey, C.; Lardner, C. Reduction of folic acid during baking and implications for mandatory fortification of bread. Int. J. Food Sci. Technol. 2010, 45, 1104–1110. [Google Scholar] [CrossRef]

- Lešková, E.; Kubíková, J.; Kováčiková, E.; Košická, M.; Porubská, J.; Holčíková, K. Vitamin losses: Retention during heat treatment and continual changes expressed by mathematical models. J. Food Comp. Anal. 2006, 19, 252–276. [Google Scholar] [CrossRef]

- Ranhotra, G.S.; Gelroth, J.A.; Novak, F.A.; Matthews, R.H. Retention of selected B vitamins in cooked pasta products. Cereal Chem. 1985, 62, 476–477. [Google Scholar]

- Liang, Q.; Wang, K.; Shariful, I.; Ye, X.; Zhang, C. Folate content and retention in wheat grains and wheat-based foods: Effects of storage, processing, and cooking methods. Food Chem. 2020, 333, 127459. [Google Scholar] [CrossRef] [PubMed]

- Bui, L.T.T.; Small, D.M. Folates in Asian noodles: II. A comparison of commercial samples and the impact of cooking. J. Food Sci. 2007, 72, C283–C287. [Google Scholar] [CrossRef] [PubMed]

- Steglich, T.; Bernin, D.; Moldin, A.; Topgaard, D.; Langton, M. Bran particle size influence on pasta microstructure, water distribution and sensory properties. Cereal Chem. 2015, 92, 617–623. [Google Scholar] [CrossRef]

| Sample | Whole Semolina (SEM) (%) | Fine Bran (FB) (%) | Coarse Bran (CB) (%) | Dough Moisture Content (%) | Hydration and Mixing Duration (Min) in Pre-Mixing Chamber |

|---|---|---|---|---|---|

| WP-FB | 94 | 6 | 0 | 30 | 20 |

| WP-CB | 90 | 0 | 10 | 30 | 20 |

| Sample | Moisture (% f.w.) | Ash (% d.m.) | Protein (% d.m.) | Total Folate (μg/100 g d.m.) |

|---|---|---|---|---|

| DWG | 8.3 ± 0.06 | 1.98 ± 0.021 c | 17.4 ± 0.28 b | 60.3 ± 1.5 c |

| SEM | 14.4 ± 0.03 | 1.32 ± 0.049 d | 16.7 ± 0.05 c | 30.2 ± 2.31 d |

| FB | 13.0 ± 0.07 | 8.30 ± 0.040 a | 22.3 ± 0.08 a | 218.9 ± 2.65 a |

| CB | 14.5 ± 0.11 | 5.43 ± 0.064 b | 21.8 ± 0.06 a | 204.9 ± 3.82 b |

| Pasta Sample | Moisture (g/100 g, f.w.) | Ash (g/100 g, f.w.) | Protein (g/100 g, f.w.) | Fat (g/100 g, f.w.) | Total Dietary Fibre (g/100 g, f.w.) | Carbohydrate * (g/100 g, f.w.) | Total Folate (µg/100 g f.w.) | L* | a* | b* | Furosine (mg/100 g Protein) | OCT (Min) | Total Score | Total Judgement |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| WP-FB | 10.3 ± 0.04 a | 1.52 ± 0.014 a | 15.0 ± 0.08 a | 2.2 ± 0.01 a | 6.5 ± 0.29 b | 64.4 ± 0.43 b | 37.8 ± 1.80 b | 52.8 ± 1.12 a | 5.2 ± 0.13 b | 21.5 ± 0.29 a | 224 ± 5 b | 15:00 | 87 | More than good |

| WP-CB | 10.0 ± 0.07 b | 1.53 ± 0.057 a | 15.2 ± 0.09 a | 2.4 ± 0.01 a | 8.3 ± 0.06 a | 62.5 ± 0.29 a | 43.1 ± 0.74 a | 51.6 ± 1.09 a | 6.0 ± 0.27 a | 20.7 ± 0.56 a | 245 ± 4 a | 14:09 | 82 | Good |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di Nardo, V.; De Arcangelis, E.; Messia, M.C.; Ruggeri, S.; Marconi, E. Folate Enrichment of Whole-Meal Spaghetti Using Durum Wheat Debranning Fractions. Foods 2023, 12, 2575. https://doi.org/10.3390/foods12132575

Di Nardo V, De Arcangelis E, Messia MC, Ruggeri S, Marconi E. Folate Enrichment of Whole-Meal Spaghetti Using Durum Wheat Debranning Fractions. Foods. 2023; 12(13):2575. https://doi.org/10.3390/foods12132575

Chicago/Turabian StyleDi Nardo, Valentina, Elisa De Arcangelis, Maria Cristina Messia, Stefania Ruggeri, and Emanuele Marconi. 2023. "Folate Enrichment of Whole-Meal Spaghetti Using Durum Wheat Debranning Fractions" Foods 12, no. 13: 2575. https://doi.org/10.3390/foods12132575

APA StyleDi Nardo, V., De Arcangelis, E., Messia, M. C., Ruggeri, S., & Marconi, E. (2023). Folate Enrichment of Whole-Meal Spaghetti Using Durum Wheat Debranning Fractions. Foods, 12(13), 2575. https://doi.org/10.3390/foods12132575