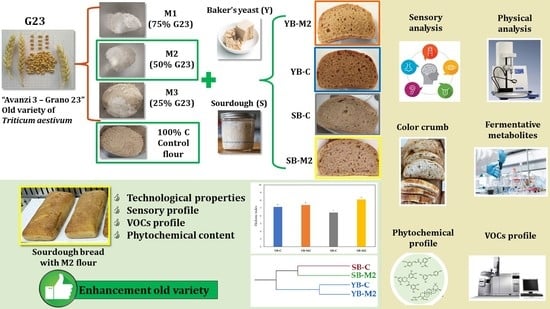

Valorization of an Old Variety of Triticum aestivum: A Study of Its Suitability for Breadmaking Focusing on Sensory and Nutritional Quality

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Chemical and Technological Parameters of Flours

2.3. Biga Preparation

2.4. Preliminary Leavening Tests

2.5. Bread Preparation

2.6. Physico-Chemical Characterization of Dough, Biga and Bread Samples

2.7. Volatile Organic Compounds (VOCs) of Bread

2.8. Sensory Profile of Bread

2.9. Statistical Analysis

3. Results and Discussion

3.1. Preliminary Leavening Test

3.2. Physico-Chemical Characterization of Bread

3.3. Color Characterization of Bread

3.4. Volatile Organic Profile of Bread Samples

3.5. Sensory Evaluation of Bread

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dapčević-Hadnađev, T.; Stupar, A.; Stevanović, D.; Škrobot, D.; Maravić, N.; Tomić, J.; Hadnađev, M. Ancient Wheat Varieties and Sourdough Fermentation as a Tool to Increase Bioaccessibility of Phenolics and Antioxidant Capacity of Bread. Foods 2022, 11, 3985. [Google Scholar] [CrossRef]

- Taglieri, I.; Macaluso, M.; Bianchi, A.; Sanmartin, C.; Quartacci, M.F.; Zinnai, A.; Venturi, F. Overcoming bread quality decay concerns: Main issues for bread shelf life as a function of biological leavening agents and different extra ingredients used in formulation A review. J. Sci. Food Agric. 2021, 101, 1732–1743. [Google Scholar] [CrossRef] [PubMed]

- Shewry, P.R.; Hey, S. Do “ancient” wheat species differ from modern bread wheat in their contents of bioactive components? J. Cereal Sci. 2015, 65, 236–243. [Google Scholar] [CrossRef] [Green Version]

- Geisslitz, S.; Longin, C.F.H.; Scherf, K.A.; Koehler, P. Comparative Study on Gluten Protein Composition of Ancient (Einkorn, Emmer and Spelt) and Modern Wheat Species (Durum and Common Wheat). Foods 2019, 8, 409. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dinelli, G.; Segura-Carretero, A.; Di Silvestro, R.; Marotti, I.; Arráez-Román, D.; Benedettelli, S.; Ghiselli, L.; Fernadez-Gutierrez, A. Profiles of phenolic compounds in modern and old common wheat varieties determined by liquid chromatography coupled with time-of-flight mass spectrometry. J. Chromatogr. A 2011, 1218, 7670–7681. [Google Scholar] [CrossRef]

- Bianchi, A.; Taglieri, I.; Zinnai, A.; Macaluso, M.; Sanmartin, C.; Venturi, F. Effect of Argon as Filling Gas of the Storage Atmosphere on the Shelf-Life of Sourdough Bread—Case Study on PDO Tuscan Bread. Foods 2022, 11, 3470. [Google Scholar] [CrossRef]

- Venturi, F.; Sanmartin, C.; Taglieri, I.; Nari, A.; Andrich, G. Effect of the baking process on artisanal sourdough bread-making: A technological and sensory evaluation. Agrochimica 2016, 60, 186–198. [Google Scholar] [CrossRef]

- Zinnai, A.; Venturi, F.; Sanmartin, C.; Andrich, G. Changes in physicochemical and sensory characteristics of fresh bread rolls maintained in different storage conditions. Agrochimica 2012, 56, 140–155. [Google Scholar]

- Sacchi, G.; Belletti, G.; Biancalani, M.; Lombardi, G.V.; Stefani, G. The valorisation of wheat production through locally-based bread chains: Experiences from Tuscany. J. Rural Stud. 2019, 71, 23–35. [Google Scholar] [CrossRef]

- Dinu, M.; Whittaker, A.; Pagliai, G.; Benedettelli, S.; Sofi, F. Ancient wheat species and human health: Biochemical and clinical implications. J. Nutr. Biochem. 2018, 52, 1–9. [Google Scholar] [CrossRef]

- Angioloni, A.; Collar, C. Nutritional and functional added value of oat, Kamut ®, spelt, rye and buckwheat versus common wheat in breadmaking. J. Sci. Food Agric. 2011, 91, 1283–1292. [Google Scholar] [CrossRef]

- Suchowilska, E.; Wiwart, M.; Kandler, W.; Krska, R. A comparison of macro- and microelement concentrations in the whole grain of four Triticum species. Plant Soil Environ. 2012, 58, 141–147. [Google Scholar] [CrossRef] [Green Version]

- Mefleh, M.; Boukid, F.; Fadda, C. Suitability of Improved and Ancient Italian Wheat for Bread-Making: A Holistic Approach. Life 2022, 12, 1613. [Google Scholar] [CrossRef] [PubMed]

- Mefleh, M.; Conte, P.; Fadda, C.; Giunta, F.; Piga, A.; Hassoun, G.; Motzo, R. From ancient to old and modern durum wheat varieties: Interaction among cultivar traits, management, and technological quality. J. Sci. Food Agric. 2019, 99, 2059–2067. [Google Scholar] [CrossRef] [PubMed]

- Il Germoplasma della Toscana: Scheda Frumento Avanzi 3 -Grano 23. Available online: http://germoplasma.regione.toscana.it/MESI_Menu/Elemento.php?ID=1151 (accessed on 4 February 2023).

- Masaf. D.M. n. 39407 del 9 Dicembre 2019—Anagrafe Nazionale Della Biodiversità di Interesse Agricolo e Alimentare. Available online: https://www.politicheagricole.it/flex/cm/pages/ServeBLOB.php/L/IT/IDPagina/14785 (accessed on 4 February 2023).

- Il “grano 23” Iscritto nel Repertorio Regionale e all’Anagrafe Nazionale Dell’agrobiodiversità—Blog Agricoltura—Regione Toscana. Available online: https://blog-agricoltura.regione.toscana.it/web/blog-agricoltura/-/il-grano-23-iscritto-nel-repertorio-regionale-e-all-anagrafe-nazionale-dell-agrobiodiversità (accessed on 7 March 2023).

- Mancini, M. Grano 23, la Rinascita Della Lunigiana tra Testaroli e Panigacci—Intoscana. Available online: https://www.intoscana.it/it/articolo/grano-23-la-rinascita-della-lunigiana/ (accessed on 7 March 2023).

- Negri, V. Agro-Biodiversity Conservation in Europe: Ethical Issues. J. Agric. Environ. Ethics 2005, 18, 3–25. [Google Scholar] [CrossRef]

- Banu, I.; Vasilean, I.; Aprodu, I. Effect of lactic fermentation on antioxidant capacity of rye sourdough and bread. Food Sci. Technol. Res. 2010, 16, 571–576. [Google Scholar] [CrossRef] [Green Version]

- Pejcz, E.; Lachowicz-Wiśniewska, S.; Nowicka, P.; Wojciechowicz-Budzisz, A.; Spychaj, R.; Gil, Z. Effect of Inoculated Lactic Acid Fermentation on the Fermentable Saccharides and Polyols, Polyphenols and Antioxidant Activity Changes in Wheat Sourdough. Molecules 2021, 26, 4193. [Google Scholar] [CrossRef]

- Colosimo, R.; Gabriele, M.; Cifelli, M.; Longo, V.; Domenici, V.; Pucci, L. The effect of sourdough fermentation on Triticum dicoccum from Garfagnana: 1H NMR characterization and analysis of the antioxidant activity. Food Chem. 2020, 305, 125510. [Google Scholar] [CrossRef]

- Sanmartin, C.; Taglieri, I.; Venturi, F.; Macaluso, M.; Zinnai, A.; Tavarini, S.; Botto, A.; Serra, A.; Conte, G.; Flamini, G.; et al. Flaxseed cake as a tool for the improvement of nutraceutical and sensorial features of sourdough bread. Foods 2020, 9, 204. [Google Scholar] [CrossRef] [Green Version]

- Struyf, N.; Van der Maelen, E.; Hemdane, S.; Verspreet, J.; Verstrepen, K.J.; Courtin, C.M. Bread Dough and Baker’s Yeast: An Uplifting Synergy. Compr. Rev. Food Sci. Food Saf. 2017, 16, 850–867. [Google Scholar] [CrossRef] [Green Version]

- Gélinas, P. Fermentation Control in Baker’s Yeast Production: Mapping Patents. Compr. Rev. Food Sci. Food Saf. 2014, 13, 1141–1164. [Google Scholar] [CrossRef]

- Taglieri, I.; Sanmartin, C.; Venturi, F.; Macaluso, M.; Zinnai, A.; Tavarini, S.; Serra, A.; Conte, G.; Flamini, G.; Angelini, L.G. Effect of the leavening agent on the compositional and sensorial characteristics of bread fortified with flaxseed cake. Appl. Sci. 2020, 10, 5235. [Google Scholar] [CrossRef]

- ISO 712; 2009 Cereals and Cereal Products—Determination of Moisture Content. International Organization for Standardization: Geneva, Switzerland, 2009.

- ISO 2171; 2007 Cereals, Pulses and By-Products-Determination of Ash Yield by Incineration. International Organization for Standardization: Geneva, Switzerland, 2007.

- ISO 20483; 2013 Cereals and Pulses—Determination of the Nitrogen Content and Calculation of the Crude Protein Content—Kjeldahl Method. International Organization for Standardization: Geneva, Switzerland, 2013.

- ISO 11085; 2015 Cereals, Cereals-Based Products and Animal Feeding Stuffs—Determination of Crude Fat and Total Fat Content by the Randall Extraction Method. International Organization for Standardization: Geneva, Switzerland, 2015.

- ISO 3093; 2009 Wheat, Rye and Their Flours, Durum Wheat and Durum Wheat Semolina—Determination of the Falling Number according to Hagberg-Perten. International Organization for Standardization: Geneva, Switzerland, 2009.

- ISO 21415-2; 2015 Wheat and Wheat Flour—Gluten Content—Part 2: Determination of Wet Gluten and Gluten Index by Mechanical Means. International Organization for Standardization: Geneva, Switzerland, 2015.

- ISO 21415-3; 2006 Wheat and Wheat Flour—Gluten Content—Part 3: Determination of Dry Gluten from Wet Gluten by an oven Drying Method. International Organization for Standardization: Geneva, Switzerland, 2006.

- McCleary, B.V.; Sloane, N.; Draga, A.; Lazewska, I. Measurement of total dietary fiber using AOAC method 2009.01 (AACC International Approved Method 32-45.01): Evaluation and updates. Cereal Chem. 2013, 90, 396–414. [Google Scholar] [CrossRef]

- Hu, X.; Fang, C.; Lu, L.; Hu, Z.; Shao, Y.; Zhu, Z. Determination of soluble sugar profile in rice. J. Chromatogr. B Anal. Technol. Biomed. Life Sci. 2017, 1058, 19–23. [Google Scholar] [CrossRef] [PubMed]

- McCleary, B.V.; Solah, V.; Gibson, T.S. Quantitative measurement of total starch in cereal flours and products. J. Cereal Sci. 1994, 20, 51–58. [Google Scholar] [CrossRef]

- ISO 27971; 2015 Common Wheat (Triticum aestivum L.)—Determination of Alveograph Properties of Dough at Constant Hydration from Commercial or Test Flours and Test Milling Methodology. International Organization for Standardization: Geneva, Switzerland, 2015.

- Taglieri, I.; Sanmartin, C.; Venturi, F.; Macaluso, M.; Bianchi, A.; Sgherri, C.; Quartacci, M.F.; De Leo, M.; Pistelli, L.; Palla, F.; et al. Bread fortified with cooked purple potato flour and citrus albedo: An evaluation of its compositional and sensorial properties. Foods 2021, 10, 942. [Google Scholar] [CrossRef]

- Balestra, F.; Pinnavaia, G.G.; Romani, S. Evaluation of the Effects of Different Fermentation Methods on Dough Characteristics. J. Texture Stud. 2015, 46, 262–271. [Google Scholar] [CrossRef]

- Macaluso, M.; Bianchi, A.; Sanmartin, C.; Taglieri, I.; Venturi, F.; Testai, L.; Flori, L.; Calderone, V.; De Leo, M.; Braca, A.; et al. By-Products from Winemaking and Olive Mill Value Chains for the Enrichment of Refined Olive Oil: Technological Challenges and Nutraceutical Features. Foods 2020, 9, 1390. [Google Scholar] [CrossRef]

- Tavarini, S.; Clemente, C.; Bender, C.; Angelini, L.G. Health-Promoting Compounds in Stevia: The Effect of Mycorrhizal Symbiosis, Phosphorus Supply and Harvest Time. Molecules 2020, 25, 5399. [Google Scholar] [CrossRef]

- Shimamura, T.; Sumikura, Y.; Yamazaki, T.; Tada, A.; Kashiwagi, T.; Ishikawa, H.; Matsui, T.; Sugimoto, N.; Akiyama, H.; Ukeda, H. Applicability of the DPPH assay for evaluating the antioxidant capacity of food additives—Inter-laboratory evaluation study. Anal. Sci. 2014, 30, 717–721. [Google Scholar] [CrossRef] [Green Version]

- Macaluso, M.; Taglieri, I.; Venturi, F.; Sanmartin, C.; Bianchi, A.; De Leo, M.; Braca, A.; Quartacci, M.F.; Zinnai, A. Influence of the Atmosphere Composition during Malaxation and Storage on the Shelf Life of an Unfiltered Extra Virgin Olive Oil: Preliminary Results. Eur. J. Lipid Sci. Technol. 2021, 123, 2000122. [Google Scholar] [CrossRef]

- Clemente, C.; Angelini, L.G.; Ascrizzi, R.; Tavarini, S. Stevia rebaudiana (Bertoni) as a multifunctional and sustainable crop for the mediterranean climate. Agriculture 2021, 11, 123. [Google Scholar] [CrossRef]

- Modesti, M.; Shmuleviz, R.; Macaluso, M.; Bianchi, A.; Venturi, F.; Brizzolara, S.; Zinnai, A.; Tonutti, P. Pre-processing Cooling of Harvested Grapes Induces Changes in Berry Composition and Metabolism, and Affects Quality and Aroma Traits of the Resulting Wine. Front. Nutr. 2021, 8, 728510. [Google Scholar] [CrossRef]

- Alam, S.S.; Bharti, D.; Pradhan, B.K.; Sahu, D.; Dhal, S.; Kim, N.M.; Jarzębski, M.; Pal, K. Analysis of the Physical and Structure Characteristics of Reformulated Pizza Bread. Foods 2022, 11, 1979. [Google Scholar] [CrossRef]

- Sanmartin, C.; Venturi, F.; Macaluso, M.; Nari, A.; Quartacci, M.F.; Sgherri, C.; Flamini, G.; Taglieri, I.; Ascrizzi, R.; Andrich, G.; et al. Preliminary Results About the Use of Argon and Carbon Dioxide in the Extra Virgin Olive Oil (EVOO) Storage to Extend Oil Shelf Life: Chemical and Sensorial Point of View. Eur. J. Lipid Sci. Technol. 2018, 120, 1800156. [Google Scholar] [CrossRef]

- Hasted, A. Statistical Analysis of Descriptive Data. In Descriptive Analysis in Sensory Evaluation; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2018; pp. 165–210. ISBN 9781118991657. [Google Scholar]

- Siepmann, F.B.; Ripari, V.; Waszczynskyj, N.; Spier, M.R. Overview of Sourdough Technology: From Production to Marketing. Food Bioprocess Technol. 2018, 11, 242–270. [Google Scholar] [CrossRef]

- Acquistucci, R. Influence of Maillard Reaction on Protein Modification and Colour Development in Pasta. Comparison of Different Drying Conditions. LWT 2000, 33, 48–52. [Google Scholar] [CrossRef]

- Acquistucci, R.; Melini, V.; Tusa, S.; Mecozzi, M. Effect of different leavening agents on the nutritional characteristics of two durum wheat breads. Eur. Food Res. Technol. 2019, 245, 2173–2181. [Google Scholar] [CrossRef]

- Martínez, J.A.; Melgosa, M.; Pérez, M.M.; Hita, E.; Negueruela, A.I. Note. Visual and Instrumental Color Evaluation in Red Wines. Food Sci. Technol. Int. 2001, 7, 439–444. [Google Scholar] [CrossRef]

- Cho, I.H.; Peterson, D.G. Chemistry of bread aroma: A review. Food Sci. Biotechnol. 2010, 19, 575–582. [Google Scholar] [CrossRef]

- Pétel, C.; Onno, B.; Prost, C. Sourdough volatile compounds and their contribution to bread: A review. Trends Food Sci. Technol. 2017, 59, 105–123. [Google Scholar] [CrossRef]

| Parameters | Units | C | G23 |

|---|---|---|---|

| Chemical | |||

| Humidity | % w/w | 10.93 ± 0.30 | 12.60 ± 0.20 |

| Ashes | % w/w | 1.35 ± 0.09 | 2.05 ± 0.18 |

| Proteins | % w/w | 12.42 ± 0.32 | 11.94 ± 0.82 |

| Total fats | % w/w | 2.53 ± 0.63 | 1.74 ± 0.52 |

| Total dietary fiber | % w/w | 5.72 ± 0.22 | 3.56 ± 0.32 |

| Maltose | % w/w | 6.28 ± 0.26 | 3.78 ± 0.36 |

| Glucose | % w/w | 0.43 ± 0.02 | 0.23 ± 0.05 |

| Fructose | % w/w | 0.14 ± 0.01 | 0.10 ± 0.03 |

| Sucrose | % w/w | 0.96 ± 0.05 | 0.46 ± 0.09 |

| Wet gluten | % w/w | 38.82 ± 2.02 | 29.02 ± 2.23 |

| Dry gluten | % w/w | 12.32 ± 1.62 | 9.82 ± 1.22 |

| Gluten index | % w/w | 72.22 ± 10.01 | 41.04 ± 15.12 |

| Total Starch | % w/w | 83.72 ± 0.52 | 72.54 ± 0.89 |

| Falling number | seconds | 333 ± 16 | 351 ± 18 |

| Total polyphenol | mg GAE/kg dm | 800 ± 17 | 415 ± 12 |

| Total flavonoids | mg CE/kg dm | 75.8 ± 0.9 | 47.4 ± 0.8 |

| ABTS | μmol TE/g dm | 1.17 ± 0.07 | 0.63 ± 0.02 |

| DPPH | μmol TE/g dm | 0.70 ± 0.05 | 0.45 ± 0.03 |

| FRAP | μmol TE/g dm | 1.57 ± 0.09 | 0.44 ± 0.02 |

| Technological | |||

| W | 10−4 joules | 263 ± 17 | 57 ± 14 |

| P | mm | 148 ± 14 | 27 ± 7 |

| L | mm | 50 ± 10 | 88 ± 28 |

| P/L | 2.96 ± 0.72 | 0.36 ± 0.12 | |

| G | 18.4 ± 1.6 | 20.8 ± 3.1 |

| Parameters | Units | S-Biga | Y-Biga |

|---|---|---|---|

| Dry matter | (% dm) | 55.20 ± 0.12 | 59.80 ± 0.16 |

| pH | 4.06 ± 0.02 | 5.43 ± 0.03 | |

| TTA | (meq lactic acid/kg dm) | 0.117 ± 0.002 | 0.038 ± 0.003 |

| Acetic acid | (mmol/kg dm) | 16.28 ± 0.26 | 2.56 ± 0.28 |

| Lactic acid | (mmol/kg dm) | 91.52 ± 0.62 | 4.22 ± 0.44 |

| Ethanol | (mmol/kg dm) | 56.24 ± 0.24 | 141.14 ± 0.34 |

| Parameters | Units | p-Value 1 | Y-M1 | Y-M2 | Y-M3 | S-M1 | S-M2 | S-M3 |

|---|---|---|---|---|---|---|---|---|

| Dry matter | (% dm) | * | 58.22 a | 57.23 b | 57.83 ab | 53.44 d | 54.12 c | 53.98 cd |

| pH | *** | 5.20 b | 5.16 b | 5.36 a | 3.90 e | 3.81 d | 4.25 c | |

| TTA | (meq lactic acid/kg dm) | *** | 0.040 d | 0.042 d | 0.035 e | 0.121 b | 0.129 a | 0.108 c |

| Acetic acid | (mmol/kg dm) | ** | 2.56 c | 2.62 c | 2.59 c | 19.83 a | 20.15 a | 12.24 b |

| Lactic acid | (mmol/kg dm) | *** | 4.71 d | 4.62 d | 4.42 d | 108.52 b | 117.54 a | 73.5 c |

| Ethanol | (mmol/kg dm) | ** | 189.62 a | 190.24 a | 152.18 b | 59.77 c | 60.26 c | 35.12 d |

| DVI | % | *** | 360 a | 350 a | 180 d | 220 c | 250 b | 70 e |

| Parameters | Units | p-Value 1 | YB-M2 | YB-C | SB-M2 | SB-C |

|---|---|---|---|---|---|---|

| Dry matter | (% dm) | *** | 56.53 a | 55.42 b | 53.82 d | 54.54 c |

| Softness | mm | * | 2.05 ab | 1.81 b | 2.15 a | 1.73 b |

| aw | ns | 0.936 | 0.938 | 0.940 | 0.939 | |

| pH | ** | 5.99 a | 6.03 a | 4.28 d | 4.41 c | |

| TTA | (meq lactic acid/kg dm) | ** | 0.027 c | 0.026 c | 0.083 a | 0.072 b |

| Acetic acid | (mmol/kg dm) | ** | 1.75 c | 1.62 c | 21.28 a | 19.72 b |

| Lactic acid | (mmol/kg dm) | *** | 3.96 c | 4.27 c | 96.59 a | 87.4 b |

| Ethanol | (mmol/kg dm) | ** | 17.41 b | 18.31 a | 12.06 c | 11.94 c |

| Total polyphenol | mg GAE/kg dm | *** | 545 d | 618 c | 702 b | 1054 a |

| Total flavonoids | mg CE/kg dm | *** | 72.9 d | 84.5 c | 109.8 b | 113.8 a |

| ABTS | μmol TE/g dm | *** | 0.62 d | 0.73 c | 0.89 b | 1.15 a |

| DDPH | μmol TE/g dm | *** | 0.36 d | 0.42 c | 0.55 b | 0.72 a |

| FRAP | μmol TE/g dm | *** | 0.84 d | 0.98 c | 1.32 b | 1.72 a |

| Parameters | p-Value 1 | YB-M2 | YB-C | SB-M2 | SB-C |

|---|---|---|---|---|---|

| L* | *** | 53.69 c | 51.05 d | 57.32 a | 54.85 b |

| a* | ** | 3.56 b | 5.93 a | 3.25 b | 5.73 a |

| b* | *** | 19.28 b | 23.06 a | 17.36 c | 22.76 a |

| C* | *** | 19.60 b | 23.81 a | 17.66 c | 23.47 a |

| h* | ** | 79.53 a | 75.57 b | 79.39 a | 75.86 b |

| WI | *** | 50.09 b | 45.57 d | 53.81 a | 49.11 c |

| YI | *** | 51.30 c | 64.53 a | 43.27 d | 59.28 b |

| ΔE*ab | YB-C | YB-M2 | SB-C | SB-M2 |

|---|---|---|---|---|

| YB-C | 5.18 | 3.82 | 8.89 | |

| YB-M2 | 4.26 | 4.12 | ||

| SB-C | 6.44 | |||

| SB-M2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bianchi, A.; Venturi, F.; Zinnai, A.; Taglieri, I.; Najar, B.; Macaluso, M.; Merlani, G.; Angelini, L.G.; Tavarini, S.; Clemente, C.; et al. Valorization of an Old Variety of Triticum aestivum: A Study of Its Suitability for Breadmaking Focusing on Sensory and Nutritional Quality. Foods 2023, 12, 1351. https://doi.org/10.3390/foods12061351

Bianchi A, Venturi F, Zinnai A, Taglieri I, Najar B, Macaluso M, Merlani G, Angelini LG, Tavarini S, Clemente C, et al. Valorization of an Old Variety of Triticum aestivum: A Study of Its Suitability for Breadmaking Focusing on Sensory and Nutritional Quality. Foods. 2023; 12(6):1351. https://doi.org/10.3390/foods12061351

Chicago/Turabian StyleBianchi, Alessandro, Francesca Venturi, Angela Zinnai, Isabella Taglieri, Basma Najar, Monica Macaluso, Giorgio Merlani, Luciana Gabriella Angelini, Silvia Tavarini, Clarissa Clemente, and et al. 2023. "Valorization of an Old Variety of Triticum aestivum: A Study of Its Suitability for Breadmaking Focusing on Sensory and Nutritional Quality" Foods 12, no. 6: 1351. https://doi.org/10.3390/foods12061351

APA StyleBianchi, A., Venturi, F., Zinnai, A., Taglieri, I., Najar, B., Macaluso, M., Merlani, G., Angelini, L. G., Tavarini, S., Clemente, C., & Sanmartin, C. (2023). Valorization of an Old Variety of Triticum aestivum: A Study of Its Suitability for Breadmaking Focusing on Sensory and Nutritional Quality. Foods, 12(6), 1351. https://doi.org/10.3390/foods12061351