Applications of Life Cycle Assessment in the Chocolate Industry: A State-of-the-Art Analysis Based on Systematic Review

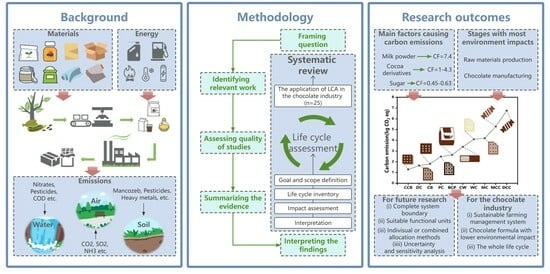

Abstract

:1. Introduction

2. Material and Methods

2.1. Description of Systematic Review

2.2. Framing Questions

2.3. Locating the Studies

2.4. Selection and Evaluation

3. Results

3.1. Publication Trend

3.2. Goal and Scope Definition

3.2.1. Study Aim

3.2.2. Functional Unit

3.2.3. System Boundary

3.2.4. Allocation

3.3. Life Cycle Inventory

3.3.1. Data Collection

3.3.2. Inputs in LCI

3.3.3. Outputs in LCI

3.3.4. LCIA Methods

3.3.5. Impact Categories

3.3.6. LCIA Results

Impacts of Life Cycle Stages

Impacts of Raw Material Production and Manufacturing

Comparison of Different Types of Chocolate Product

Reduction in GHG Emissions of the Chocolate Industry

3.4. Interpretation

3.4.1. Sensitivity Analysis

3.4.2. Uncertainty Analysis

3.4.3. Research Findings of Literature

3.4.4. Integration with Other Techniques

4. Discussion

4.1. Opportunities of LCA in the Chocolate Industry

4.2. Limitations of This Study

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Author (Year) | Object | Functional Unit | Life Cycle Stages |

|---|---|---|---|

| Ntiamoah and Afrane (2008) [61] | Cocoa | 1 kg of cocoa beans processed | Cradle to grave |

| Büsser and Jungbluth (2009) [49] | Dark, milk and white chocolate and chocolate with sultanas | 1 kg of chocolate | Cradle to retailer |

| Ortiz-R et al. (2014) [27] | Cocoa | 1 ha of land planted with cocoa (25 year life span) | Cradle to grave |

| Jeswani et al. (2015) [43] | Breakfast cereals and snacks | 1 kg of breakfast cereal products | Cradle to grave |

| Ortiz-Rodríguez et al. (2016) [33] | Cocoa | 1 kg of cocoa beans | Cradle to farm gate |

| Pérez Neira (2016) [55] | Chocolate | 1 kg of pure chocolate | Cradle to retailer |

| Utomo et al. (2016) [34] | Cocoa pod | 1 t of cocoa pod | Cradle to on-farm gate |

| James et al. (2017) [30] | Cocoa | 1 ton of dried cocoa beans | Gate to gate |

| Miah et al. (2018) [36] | Sugar, milk chocolate, dark chocolate, chocolate biscuit and milk | 1 kg of packaged confectionery product | Cradle to grave |

| Konstantas et al. (2018) [54] | Chocolate coated wafers (chocolate countlines), milk chocolate (molded chocolate) and malty chocolates (chocolates in bag) | 1 kg of packaged chocolate consumed at home | Cradle to grave |

| Recanati et al. (2018) [19] | Italian dark chocolate | 1 kg of dark chocolate and packaging | Cradle to grave |

| Jeswani et al. (2018) [47] | Breakfast cereals and snacks | The annual production of ready-to-eat breakfast cereal products | Cradle to grave |

| Raschio et al. (2018) [56] | Cocoa | 1 hectare per year of land to produce cocoa; 1 t of raw cocoa | Farming stage |

| Konstantas et al. (2019) [44] | Biscuits, cakes, chocolates and ice creams | 1 kg of product consumed at home; The annual consumption of each product in the UK | Cradle to grave |

| Konstantas et al. (2019) [42] | Ice cream with differing compositions and flavors (vanilla regular; vanilla premium; chocolate regular; and chocolate premium) | 1 kg of ice cream consumed at home | Cradle to grave |

| Konstantas et al. (2019) [35] | Six types of biscuit: crackers, low fat/sugar, semi-sweet, chocolate-coated, chocolate cream sandwich and vanilla cream sandwich | 1 kg of biscuits consumed at home | Cradle to grave |

| Crenna et al. (2019) [68] | 32 representative food products of consumption in the European Union | The average food consumption in the European Union and per EU citizen in terms of selected food categories in 2015 | Cradle to grave |

| Pérez-Neira et al. (2020) [17] | Ecuadorian cacao/chocolate | 1 kg of dark chocolate | Cradle to retailer |

| Bianchi et al. (2021) [37] | Dark, milk and white chocolate | 1 kg of chocolate; 1 kcal | Cradle to grave |

| Konstantas et al. (2020) [79] | Biscuits, cakes, chocolates and ice creams | 1 kg of packaged product consumed at home; the annual consumption based on the sales of the products in the two sectors | Cradle to grave |

| Armengot et al. (2021) [29] | Cocoa | 1 kg of cacao; 1 kg of cocoa, banana and other crops | Cradle to farm gate |

| Boakye-Yiadom et al. (2021) [28] | Extra dark chocolate (EDC), dark chocolate (DC), milk chocolate (MC), and flavoured milk chocolate (FMC) | 1 kg packaged chocolate bar | Cradle to retailer |

| Hajiyeva and Shamilova-Jalilova (2022) [48] | Cocoa, chocolate and sugar confectioneries | 1 kg of the product | Gate to gate |

| Caicedo-Vargas et al. (2022) [38] | Cocoa | 1 kg of cocoa; 1 kg of output sold; 1 ha | Cradle to farm gate |

| Parra-Paitan and Verburg (2022) [31] | Cocoa | 1 kg of cocoa beans | Around the agricultural phase |

References

- Dillinger, T.L.; Barriga, P.; Escárcega, S.; Jimenez, M.; Lowe, D.S.; Grivetti, L.E. Food of the gods: Cure for humanity? A cultural history of the medicinal and ritual use of chocolate. J. Nutr. 2000, 130, 2057S–2072S. [Google Scholar] [CrossRef]

- Verna, R. The history and science of chocolate. Malays. J. Pathol. 2013, 35, 111. [Google Scholar]

- Comunicaffe. Lo Stampatore Della Classifica Euromonitor sul Consumo del Cioccolato Scorda l’Italia. Available online: https://www.comunicaffe.it/eurmonitor-cioccolato/ (accessed on 9 February 2023).

- TRIDGE. Overview of Global Chocolate Market. Available online: https://www.tridge.com/intelligences/chocolate (accessed on 20 August 2023).

- RationalStat. How Much Chocolate Is Consumed per Year? RationalStat LLC: Wilmington, DE, USA, 2022. [Google Scholar]

- GVR. Chocolate Confectionery Market Share Report. Available online: https://www.grandviewresearch.com/industry-analysis/chocolate-confectionery-market (accessed on 15 November 2023).

- Newton, P.; Agrawal, A.; Wollenberg, L. Enhancing the sustainability of commodity supply chains in tropical forest and agricultural landscapes. Glob. Environ. Chang. 2013, 23, 1761–1772. [Google Scholar] [CrossRef]

- Camargo, M.C.; Hogarth, N.J.; Pacheco, P.; Nhantumbo, I.; Kanninen, M. Greening the dark side of chocolate: A qualitative assessment to inform sustainable supply chains. Environ. Conserv. 2019, 46, 9–16. [Google Scholar] [CrossRef]

- Caligiani, A.; Palla, L.; Acquotti, D.; Marseglia, A.; Palla, G. Application of 1H NMR for the characterisation of cocoa beans of different geographical origins and fermentation levels. Food Chem. 2014, 157, 94–99. [Google Scholar] [CrossRef] [PubMed]

- TRIDGE. Production Trends Overview of Top 10 Countries. Available online: https://www.tridge.com/intelligences/cocoa-bean/production (accessed on 15 March 2023).

- Wojdalski, J.; Grochowicz, J.; Dróżdż, B.; Bartoszewska, K.; Zdanowska, P.; Kupczyk, A.; Ekielski, A.; Florczak, I.; Hasny, A.; Wójcik, G. Energy efficiency of a confectionery plant–Case study. J. Food Eng. 2015, 146, 182–191. [Google Scholar] [CrossRef]

- Jolly, M.S.; Blackburn, S.; Beckett, S.T. Energy reduction during chocolate conching using a reciprocating multihole extruder. J. Food Eng. 2003, 59, 137–142. [Google Scholar] [CrossRef]

- Miah, J.H. From Factory to Supply Chain: Reducing Environmental Impacts of Confectionery Manufacturing Using Heat Integration and Life Cycle Assessment; University of Surrey: Guildford, UK, 2018. [Google Scholar]

- Hosseinzadeh-Bandbafha, H.; Kiehbadroudinezhad, M. Environmental impacts of chocolate production and consumption. In Trends in Sustainable Chocolate Production; Springer: Cham, Switzerland, 2022; pp. 229–258. [Google Scholar]

- SAIC. Scientific Applications International Corporation. 2006. Available online: http://people.cs.uchicago.edu/~ftchong/290N-W10/EPAonLCA2006.pdf (accessed on 30 March 2023).

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- Pérez-Neira, D.; Copena, D.; Armengot, L.; Simón, X. Transportation can cancel out the ecological advantages of producing organic cacao: The carbon footprint of the globalized agrifood system of Ecuadorian chocolate. J. Environ. Manag. 2020, 276, 111306. [Google Scholar] [CrossRef] [PubMed]

- Higgins, J.P.T.; Green, S. Cochrane Handbook for Systematic Reviews of Interventions. Available online: https://handbook-5-1.cochrane.org/ (accessed on 8 December 2022).

- Recanati, F.; Marveggio, D.; Dotelli, G. From beans to bar: A life cycle assessment towards sustainable chocolate supply chain. Sci. Total Environ. 2018, 613–614, 1013–1023. [Google Scholar] [CrossRef] [PubMed]

- McClelland, S.C.; Arndt, C.; Gordon, D.R.; Thoma, G. Type and number of environmental impact categories used in livestock life cycle assessment: A systematic review. Livest. Sci. 2018, 209, 39–45. [Google Scholar] [CrossRef]

- Clune, S.; Crossin, E.; Verghese, K. Systematic review of greenhouse gas emissions for different fresh food categories. J. Clean. Prod. 2017, 140, 766–783. [Google Scholar] [CrossRef]

- Khan, K.S.; Kunz, R.; Kleijnen, J.; Antes, G. Five steps to conducting a systematic review. J. Roy. Soc. Med. 2003, 96, 118–121. [Google Scholar] [CrossRef]

- Tawfik, G.M.; Dila, K.A.S.; Mohamed, M.Y.F.; Tam, D.N.H.; Kien, N.D.; Ahmed, A.M.; Huy, N.T. A step by step guide for conducting a systematic review and meta-analysis with simulation data. Trop. Med. Health. 2019, 47, 46. [Google Scholar] [CrossRef]

- Frandsen, T.F.; Bruun Nielsen, M.F.; Lindhardt, C.L.; Eriksen, M.B. Using the full PICO model as a search tool for systematic reviews resulted in lower recall for some PICO elements. J. Clin. Epidemiol. 2020, 127, 69–75. [Google Scholar] [CrossRef]

- Meline, T. Selecting studies for systemic review: Inclusion and exclusion criteria. CICSD 2006, 33, 21–27. [Google Scholar] [CrossRef]

- Johnson, C. Repetitive, duplicate, and redundant publications: A review for authors and readers. J. Manip. Physiol. Ther. 2006, 29, 505–509. [Google Scholar] [CrossRef] [PubMed]

- Ortiz-R, O.O.; Villamizar Gallardo, R.A.; Rangel, J.M. Applying life cycle management of Colombian cocoa production. Food Sci. Technol. 2014, 34, 62–68. [Google Scholar] [CrossRef]

- Boakye-Yiadom, K.A.; Duca, D.; Foppa Pedretti, E.; Ilari, A. Environmental performance of chocolate produced in Ghana using life cycle assessment. Sustainability 2021, 13, 6155. [Google Scholar] [CrossRef]

- Armengot, L.; Beltrán, M.J.; Schneider, M.; Simón, X.; Pérez-Neira, D. Food-energy-water nexus of different cacao production systems from a LCA approach. J. Clean. Prod. 2021, 304, 126941. [Google Scholar] [CrossRef]

- James, E.; Leyte, J.; Pacardo, E.; Rebancos, C.; Protacio, C.; Alcantara, A. Environmental performance of cacao (Theobroma cacao L.) production and primary processing. Philipp. J. Crop Sci. 2017, 42, 51–58. [Google Scholar]

- Parra-Paitan, C.; Verburg, P.H. Accounting for land use changes beyond the farm-level in sustainability assessments: The impact of cocoa production. Sci. Total Environ. 2022, 825, 154032. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006; Volume 157.

- Ortiz-Rodríguez, O.O.; Villamizar-Gallardo, R.A.; Naranjo-Merino, C.A.; García-Caceres, R.G.; Castañeda-galvís, M.T. Carbon footprint of the Colombian cocoa production. Eng. Agricola. 2016, 36, 260–270. [Google Scholar] [CrossRef]

- Utomo, B.; Prawoto, A.A.; Bonnet, S.; Bangviwat, A.; Gheewala, S.H. Environmental performance of cocoa production from monoculture and agroforestry systems in Indonesia. J. Clean. Prod. 2016, 134, 583–591. [Google Scholar] [CrossRef]

- Konstantas, A.; Stamford, L.; Azapagic, A. Evaluation of environmental sustainability of biscuits at the product and sectoral levels. J. Clean. Prod. 2019, 230, 1217–1228. [Google Scholar] [CrossRef]

- Miah, J.H.; Griffiths, A.; McNeill, R.; Halvorson, S.; Schenker, U.; Espinoza-Orias, N.D.; Morse, S.; Yang, A.; Sadhukhan, J. Environmental management of confectionery products: Life cycle impacts and improvement strategies. J. Clean. Prod. 2018, 177, 732–751. [Google Scholar] [CrossRef]

- Bianchi, F.R.; Moreschi, L.; Gallo, M.; Vesce, E.; Del Borghi, A. Environmental analysis along the supply chain of dark, milk and white chocolate: A life cycle comparison. Int. J. Life Cycle Assess. 2021, 26, 807–821. [Google Scholar] [CrossRef]

- Caicedo-Vargas, C.; Pérez-Neira, D.; Abad-González, J.; Gallar, D. Assessment of the environmental impact and economic performance of cacao agroforestry systems in the Ecuadorian Amazon region: An LCA approach. Sci. Total Environ. 2022, 849, 157795. [Google Scholar] [CrossRef]

- Weidema, B.; Wenzel, H.; Petersen, C.; Hansen, K. The product, functional unit and reference flows in LCA. Environ. News 2004, 70, 1–46. [Google Scholar]

- Martínez-Blanco, J.; Antón, A.; Rieradevall, J.; Castellari, M.; Muñoz, P. Comparing nutritional value and yield as functional units in the environmental assessment of horticultural production with organic or mineral fertilization: The case of Mediterranean cauliflower production. Int. J. Life Cycle Assess. 2011, 16, 12–26. [Google Scholar] [CrossRef]

- Schau, E.M.; Fet, A.M. LCA studies of food products as background for environmental product declarations. Int. J. Life Cycle Assess. 2008, 13, 255–264. [Google Scholar] [CrossRef]

- Konstantas, A.; Stamford, L.; Azapagic, A. Environmental impacts of ice cream. J. Clean. Prod. 2019, 209, 259–272. [Google Scholar] [CrossRef]

- Jeswani, H.K.; Burkinshaw, R.; Azapagic, A. Environmental sustainability issues in the food–energy–water nexus: Breakfast cereals and snacks. Sustain. Prod. Consum. 2015, 2, 17–28. [Google Scholar] [CrossRef]

- Konstantas, A.; Stamford, L.; Azapagic, A. Economic sustainability of food supply chains: Life cycle costs and value added in the confectionary and frozen desserts sectors. Sci. Total Environ. 2019, 670, 902–914. [Google Scholar] [CrossRef] [PubMed]

- Perez, M.; Lopez-Yerena, A.; Vallverdú-Queralt, A. Traceability, authenticity and sustainability of cocoa and chocolate products: A challenge for the chocolate industry. Crit. Rev. Food Sci. 2022, 62, 475–489. [Google Scholar] [CrossRef] [PubMed]

- Montagna, M.T.; Diella, G.; Triggiano, F.; Caponio, G.R.; Giglio, O.D.; Caggiano, G.; Ciaula, A.D.; Portincasa, P. Chocolate,“food of the gods”: History, science, and human health. Int. J. Environ. Res. Public Health 2019, 16, 4960. [Google Scholar] [CrossRef] [PubMed]

- Jeswani, H.K.; Hellweg, S.; Azapagic, A. Accounting for land use, biodiversity and ecosystem services in life cycle assessment: Impacts of breakfast cereals. Sci. Total Environ. 2018, 645, 51–59. [Google Scholar] [CrossRef] [PubMed]

- Hajiyeva, S.; Shamilova-Jalilova, M. The ecological profile of cocoa, chocolate, and sugar confectioneries in Azerbaijian. Adv. Biol. Earth Sci. 2022, 7, 29–39. [Google Scholar]

- Büsser, S.; Jungbluth, N. LCA of Chocolate Packed in Aluminium Foil Based Packaging; ESU-Services Ltd.: Uster, Switzerland, 2009. [Google Scholar]

- Schrijvers, D.L.; Loubet, P.; Sonnemann, G. Critical review of guidelines against a systematic framework with regard to consistency on allocation procedures for recycling in LCA. Int. J. Life Cycle Assess. 2016, 21, 994–1008. [Google Scholar] [CrossRef]

- Olofsson, J.; Börjesson, P. Residual biomass as resource–Life-Cycle environmental impact of wastes in circular resource systems. J. Clean. Prod. 2018, 196, 997–1006. [Google Scholar] [CrossRef]

- Schrijvers, D.L.; Loubet, P.; Sonnemann, G. Developing a systematic framework for consistent allocation in LCA. Int. J. Life Cycle Assess. 2016, 21, 976–993. [Google Scholar] [CrossRef]

- Moretti, C.; Corona, B.; Edwards, R.; Junginger, M.; Moro, A.; Rocco, M.; Shen, L. Reviewing ISO compliant multifunctionality practices in environmental life cycle modeling. Energies 2020, 13, 3579. [Google Scholar] [CrossRef]

- Konstantas, A.; Jeswani, H.K.; Stamford, L.; Azapagic, A. Environmental impacts of chocolate production and consumption in the UK. Food Res. Int. 2018, 106, 1012–1025. [Google Scholar] [CrossRef] [PubMed]

- Pérez Neira, D. Energy sustainability of Ecuadorian cacao export and its contribution to climate change. A case study through product life cycle assessment. J. Clean. Prod. 2016, 112, 2560–2568. [Google Scholar] [CrossRef]

- Raschio, G.; Smetana, S.; Contreras, C.; Heinz, V.; Mathys, A. Spatio-Temporal differentiation of Life Cycle Assessment Results for Average Perennial Crop Farm: A case study of Peruvian cocoa progression and deforestation issues. J. Ind. Ecol. 2018, 22, 1378–1388. [Google Scholar] [CrossRef]

- Ineichen, S.; Schenker, U.; Nemecek, T.; Reidy, B. Allocation of environmental burdens in dairy systems: Expanding a biophysical approach for application to larger meat-to-milk ratios. Livest. Sci. 2022, 261, 104955. [Google Scholar] [CrossRef]

- Saavedra-Rubio, K.; Thonemann, N.; Crenna, E.; Lemoine, B.; Caliandro, P.; Laurent, A. Stepwise guidance for data collection in the life cycle inventory (LCI) phase: Building technology-related LCI blocks. J. Clean. Prod. 2022, 366, 132903. [Google Scholar] [CrossRef]

- Tam, V.W.; Zhou, Y.; Illankoon, C.; Le, K.N. A critical review on BIM and LCA integration using the ISO 14040 framework. Build. Environ. 2022, 213, 108865. [Google Scholar] [CrossRef]

- Martínez-Rocamora, A.; Solís-Guzmán, J.; Marrero, M. LCA databases focused on construction materials: A review. Renew. Sust. Energ. Rev. 2016, 58, 565–573. [Google Scholar] [CrossRef]

- Ntiamoah, A.; Afrane, G. Environmental impacts of cocoa production and processing in Ghana: Life cycle assessment approach. J. Clean. Prod. 2008, 16, 1735–1740. [Google Scholar] [CrossRef]

- Takano, A.; Winter, S.; Hughes, M.; Linkosalmi, L. Comparison of life cycle assessment databases: A case study on building assessment. Build. Environ. 2014, 79, 20–30. [Google Scholar] [CrossRef]

- Bicalho, T.; Sauer, I.; Rambaud, A.; Altukhova, Y. LCA data quality: A management science perspective. J. Clean. Prod. 2017, 156, 888–898. [Google Scholar] [CrossRef]

- Verones, F.; Bare, J.; Bulle, C.; Frischknecht, R.; Hauschild, M.; Hellweg, S.; Henderson, A.; Jolliet, O.; Laurent, A.; Liao, X.; et al. LCIA framework and cross-cutting issues guidance within the UNEP-SETAC Life Cycle Initiative. J. Clean. Prod. 2017, 161, 957–967. [Google Scholar] [CrossRef]

- Jolliet, O.; Müller-Wenk, R.; Bare, J.; Brent, A.; Goedkoop, M.; Heijungs, R.; Itsubo, N.; Peña, C.; Pennington, D.; Potting, J.; et al. The LCIA midpoint-damage framework of the UNEP/SETAC life cycle initiative. Int. J. Life Cycle Assess. 2004, 9, 394–404. [Google Scholar] [CrossRef]

- Lasvaux, S.; Achim, F.; Garat, P.; Peuportier, B.; Chevalier, J.; Habert, G. Correlations in Life Cycle Impact Assessment methods (LCIA) and indicators for construction materials: What matters? Ecol. Indic. 2016, 67, 174–182. [Google Scholar] [CrossRef]

- Chen, X.; Matthews, H.S.; Griffin, W.M. Uncertainty caused by life cycle impact assessment methods: Case studies in process-based LCI databases. Resour. Conserv. Recycl. 2021, 172, 105678. [Google Scholar] [CrossRef]

- Crenna, E.; Sinkko, T.; Sala, S. Biodiversity impacts due to food consumption in Europe. J. Clean. Prod. 2019, 227, 378–391. [Google Scholar] [CrossRef]

- García-Herrero, L.; Menna, F.D.; Vittuari, M. Sustainability concerns and practices in the chocolate life cycle: Integrating consumers’ perceptions and experts’ knowledge. Sustain. Prod. Consum. 2019, 20, 117–127. [Google Scholar] [CrossRef]

- Ashiagbor, G.; Asante, W.A.; Forkuo, E.K.; Acheampong, E.; Foli, E. Monitoring cocoa-driven deforestation: The contexts of encroachment and land use policy implications for deforestation free cocoa supply chains in Ghana. Appl. Geogr. 2022, 147, 102788. [Google Scholar] [CrossRef]

- Maney, C.; Sassen, M.; Hill, S.L.L. Modelling biodiversity responses to land use in areas of cocoa cultivation. Agric. Ecosyst. Environ. 2022, 324, 107712. [Google Scholar] [CrossRef]

- Sassen, M.; van Soesbergen, A.; Arnell, A.P.; Scott, E. Patterns of (future) environmental risks from cocoa expansion and intensification in West Africa call for context specific responses. Land Use Policy 2022, 119, 106142. [Google Scholar] [CrossRef]

- Escribano, M.; Elghannam, A.; Mesias, F.J. Dairy sheep farms in semi-arid rangelands: A carbon footprint dilemma between intensification and land-based grazing. Land Use Policy 2020, 95, 104600. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, J.; Tian, W.; Li, Y.; Song, Y.; Zhang, P. Multi-objective optimization of milk powder spray drying system considering environmental impact, economy and product quality. J. Clean. Prod. 2022, 369, 133353. [Google Scholar] [CrossRef]

- Xie, M.; Li, L.; Qiao, Q.; Sun, Q.; Sun, T. A comparative study on milk packaging using life cycle assessment: From PA-PE-Al laminate and polyethylene in China. J. Clean. Prod. 2011, 19, 2100–2106. [Google Scholar] [CrossRef]

- Barros, M.V.; Salvador, R.; Piekarski, C.M.; de Francisco, A.C. Mapping of main research lines concerning life cycle studies on packaging systems in Brazil and in the world. Int. J. Life Cycle Assess. 2019, 24, 1429–1443. [Google Scholar] [CrossRef]

- Neves, A.C.; Moyne, M.M.; Eyre, C.; Casey, B.P. Acceptability and societal impact of the introduction of bioplastics as novel environmentally friendly packaging materials in Ireland. Clean Technol. 2020, 2, 127–143. [Google Scholar] [CrossRef]

- Gramlich, A.; Tandy, S.; Andres, C.; Chincheros Paniagua, J.; Armengot, L.; Schneider, M.; Schulin, R. Cadmium uptake by cocoa trees in agroforestry and monoculture systems under conventional and organic management. Sci. Total Environ. 2017, 580, 677–686. [Google Scholar] [CrossRef] [PubMed]

- Konstantas, A.; Stamford, L.; Azapagic, A. A framework for evaluating life cycle eco-efficiency and an application in the confectionary and frozen-desserts sectors. Sustain. Prod. Consum. 2020, 21, 192–203. [Google Scholar] [CrossRef]

- Flysjö, A.; Thrane, M.; Hermansen, J.E. Method to assess the carbon footprint at product level in the dairy industry. Int. Dairy J. 2014, 34, 86–92. [Google Scholar] [CrossRef]

- García, C.A.; García-Treviño, E.S.; Aguilar-Rivera, N.; Armendáriz, C. Carbon footprint of sugar production in Mexico. J. Clean. Prod. 2016, 112, 2632–2641. [Google Scholar] [CrossRef]

- Roibás, L.; Martínez, I.; Goris, A.; Barreiro, R.; Hospido, A. An analysis on how switching to a more balanced and naturally improved milk would affect consumer health and the environment. Sci. Total Environ. 2016, 566–567, 685–697. [Google Scholar] [CrossRef]

- de Figueiredo, E.B.; Panosso, A.R.; Romão, R.; La Scala, N., Jr. Greenhouse gas emission associated with sugar production in southern Brazil. Carbon Balance Manag. 2010, 5, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Yuttitham, M.; Gheewala, S.H.; Chidthaisong, A. Carbon footprint of sugar produced from sugarcane in eastern Thailand. J. Clean. Prod. 2011, 19, 2119–2127. [Google Scholar] [CrossRef]

- Palisade. Available online: https://palisade.lumivero.com/ (accessed on 3 March 2023).

- Muller, S.; Mutel, C.; Lesage, P.; Samson, R. Effects of distribution choice on the modeling of life cycle inventory uncertainty: An assessment on the ecoinvent v2. 2 database. J. Ind. Ecol. 2018, 22, 300–313. [Google Scholar] [CrossRef]

- Van Asselen, S.; Verburg, P.H. Land cover change or land-use intensification: Simulating land system change with a global-scale land change model. Glob. Chang. Biol. 2013, 19, 3648–3667. [Google Scholar] [CrossRef] [PubMed]

- Alkemade, R.; van Oorschot, M.; Miles, L.; Nellemann, C.; Bakkenes, M.; Ten Brink, B. GLOBIO3: A framework to investigate options for reducing global terrestrial biodiversity loss. Ecosystems 2009, 12, 374–390. [Google Scholar] [CrossRef]

- Ayres, R.U. Life cycle analysis: A critique. Resour. Conserv. Recycl. 1995, 14, 199–223. [Google Scholar] [CrossRef]

- Shabir, I.; Dash, K.K.; Dar, A.H.; Pandey, V.K.; Fayaz, U.; Srivastava, S.; Nisha, R. Carbon footprints evaluation for sustainable food processing system development: A comprehensive review. Fut. Food. 2023, 7, 100215. [Google Scholar] [CrossRef]

- Ncube, L.K.; Ude, A.U.; Ogunmuyiwa, E.N.; Zulkifli, R.; Beas, I.N. An overview of plastic waste generation and management in food packaging industries. Recycling 2021, 6, 12. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Dong, Y. Applications of Life Cycle Assessment in the Chocolate Industry: A State-of-the-Art Analysis Based on Systematic Review. Foods 2024, 13, 915. https://doi.org/10.3390/foods13060915

Wang S, Dong Y. Applications of Life Cycle Assessment in the Chocolate Industry: A State-of-the-Art Analysis Based on Systematic Review. Foods. 2024; 13(6):915. https://doi.org/10.3390/foods13060915

Chicago/Turabian StyleWang, Shuhan, and Yahong Dong. 2024. "Applications of Life Cycle Assessment in the Chocolate Industry: A State-of-the-Art Analysis Based on Systematic Review" Foods 13, no. 6: 915. https://doi.org/10.3390/foods13060915

APA StyleWang, S., & Dong, Y. (2024). Applications of Life Cycle Assessment in the Chocolate Industry: A State-of-the-Art Analysis Based on Systematic Review. Foods, 13(6), 915. https://doi.org/10.3390/foods13060915