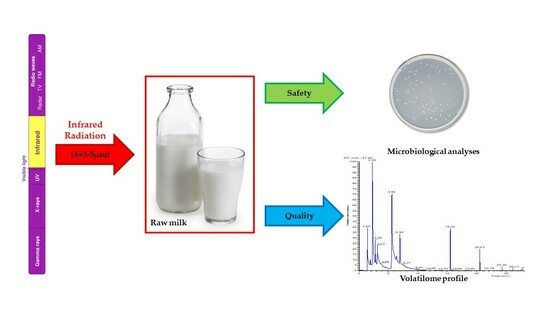

Preliminary Investigation towards the Use of Infrared Technology for Raw Milk Treatment

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Collection

2.2. Milk Homogenisation

2.3. IR Treatment

2.4. Microbiological Analyses

2.5. Volatilome Profiling of Milk

2.5.1. Extraction of Volatile Compounds (VOCs)

2.5.2. Gas Chromatography–Mass Spectrometry

2.6. Statistical Analysis

3. Results and Discussion

3.1. Microbiological Analyses

3.2. Volatilome Profiling of Milk

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- UN. Global Sustainable Development Report 2019: The Future is Now—Science for Achieving Sustainable Development; United Nations: New York, NY, USA, 2019. [Google Scholar]

- FAO; IFAD; UNICEF; WFP; WHO. The State of Food Security and Nutrition in the World 2019—Safeguarding against Economic Slowdowns and Downturns; FAO: Rome, Italy, 2019. [Google Scholar]

- Vasilaki, V.; Katsou, E.; Ponsá, S.; Colón, J. Water and carbon footprint of selected dairy products: A case study in Catalonia. J. Clean. Prod. 2016, 139, 504–516. [Google Scholar] [CrossRef]

- Clal.it. Available online: https://www.clal.it/ (accessed on 15 March 2024).

- OECD/FAO. OECD-FAO Agricultural Outlook; OECD Agriculture Statistics (Database): Paris, France, 2020. [Google Scholar] [CrossRef]

- Swaisgood, H.E. Characteristics of milk. In Fennema’s Food Chemistry, 3rd ed.; Fennema, O.R., Ed.; CRC Press: Ney York, NY, USA, 1996; pp. 897–934. [Google Scholar]

- Johler, S.; Weder, D.; Bridy, C.; Huguenin, M.C.; Robert, L.; Hummerjohann, J.; Stephan, R. Outbreak of staphylococcal food poisoning among children and staff at a Swiss boarding school due to soft cheese made from raw milk. J. Dairy Sci. 2015, 98, 2944–2948. [Google Scholar] [CrossRef]

- Jørgensen, H.J.; Mørk, T.; Rørvik, L.M. The occurrence of Staphylococcus aureus on a farm with small-scale production of raw milk cheese. J. Dairy Sci. 2005, 88, 3810–3817. [Google Scholar] [CrossRef] [PubMed]

- Sakudo, A. Recent advances in gas plasma technology for decontamination of food surfaces. Food Preserv. 2017, 2017, 197–228. [Google Scholar] [CrossRef]

- Commission Regulation (EC) N. 2074/2005 of 5 December 2005 Laying Down Implementing Measures for Certain Products Under Regulation (EC) No 853/2004 of the European Parliament and of the Council and for the Organisation of Official Controls Under Regulation (EC) No 854/2004 of the European Parliament and of the Council and Regulation (EC) No 882/2004 of the European Parliament and of the Council, Derogating from Regulation (EC) No 852/2004 of the European Parliament and of the Council and Amending Regulations (EC) No 853/2004 and (EC) No 854/2004. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX%3A32005R2074 (accessed on 15 March 2024).

- Niamsuwan, S.; Kittisupakorn, P.; Mujtaba, I.M. Optimization approach to minimize energy consumption in pasteurized milk process. In International Proceedings of Chemical, Biological & Environmental Engineering, Bangkok, Thailand; IACSIT Press: Singapore, 2011; pp. 35–39. [Google Scholar]

- Petruzzi, L.; Campaniello, D.; Speranza, B.; Corbo, M.R.; Sinigaglia, M.; Bevilacqua, A. Thermal treatments for fruit and vegetable juices and beverages: A literature overview. CRFSFS 2017, 16, 668–691. [Google Scholar] [CrossRef] [PubMed]

- Yu, T.; Zhang, X.; Feng, R.; Wang, C.; Wang, X.; Wang, Y. Comparison of the effects of high hydrostatic pressure and pasteurization on quality of milk during storage. Foods 2022, 11, 2837. [Google Scholar] [CrossRef] [PubMed]

- Lugonja, N.; Marinković, V.; Miličić, B.; Avdalović, J.; Vrvić, M.; Spasić, S. Effect of storage process on nutritive properties of preterm human milk. Chem. Ind. Chem. Eng. Q. 2023, 29, 141–148. [Google Scholar] [CrossRef]

- Neoκleous, I.; Tarapata, J.; Papademas, P. Non-thermal processing technologies for dairy products: Their effect on safety and quality characteristics. Front. Sustain. Food Syst. 2022, 6, 856199. [Google Scholar] [CrossRef]

- Rodríguez-Alonso, P.; Centeno, J.A.; Garabal, J.I. Comparison of the volatile profiles of Arzúa-Ulloa and Tetilla cheeses manufactured from raw and pasteurized milk. LWT 2009, 42, 1722–1728. [Google Scholar] [CrossRef]

- Rashtchi, P.; Bazmi, A.; Noshirvani, N.; Moosavy, M.H. Comparison of the microbial, physicochemical, and sensorial properties of raw and pasteurized Lighvan cheeses during ripening time. Food Sci. Nutr. 2021, 9, 5527–5535. [Google Scholar] [CrossRef]

- Priyadarshini, A.; Rajauria, G.; O’Donnell, C.P.; Tiwari, B.K. Emerging food processing technologies and factors impacting their industrial adoption. Crit. Rev. Food Sci. Nutr. 2019, 59, 3082–3101. [Google Scholar] [CrossRef]

- Allai, F.M.; Azad, Z.A.A.; Mir, N.A.; Gul, K. Recent advances in non-thermal processing technologies for enhancing shelf life and improving food safety. Appl. Food Res. 2022, 3, 100258. [Google Scholar] [CrossRef]

- Aboud, S.A.; Altemimi, A.B.; R. S. Al-HiIphy, A.; Yi-Chen, L.; Cacciola, F. A Comprehensive Review on Infrared Heating Applications in Food Processing. Molecules 2019, 24, 4125. [Google Scholar] [CrossRef] [PubMed]

- Confagricoltura Lombardia. Available online: https://lombardia.confagricoltura.it/news/home/100885/la-zootecnia-da-latte-di-montagna-sempre-piu-in-difficolta.html (accessed on 15 March 2024).

- Bentivoglio, D.; Bucci, G.; Staffolani, G. Valorizzazione del latte «Prodotto di montagna»: Un’analisi esplorativa sulle scelte di acquisto dei consumatori. REA 2020, 75, 77–88. [Google Scholar] [CrossRef]

- Ziuzina, D.; Los, A.; Bourke, P. Inactivation of Staphylococcus aureus in foods by thermal and nonthermal control strategies. In Staphylococcus aureus; Fetsch, A., Ed.; Academic Press: Cambridge, MA, USA, 2018; pp. 235–255. [Google Scholar] [CrossRef]

- Coskun, E.; Ozturk, S.; Akpinar, M.; Halkman, A.K.; Erdogdu, F. Effect of far infrared heating process on surface decontamination and quality attributes of whole yellow and white onions. Food Control 2021, 130, 108376. [Google Scholar] [CrossRef]

- Huang, L.; Sites, J. Elimination of Listeria monocytogenes on hotdogs by infrared surface treatment. J. Food Sci. 2008, 73, M27–M31. [Google Scholar] [CrossRef] [PubMed]

- Alkaya, G.B.; Erdogdu, F.; Halkman, A.K.; Ekiz, H.I. Surface decontamination of whole-shell eggs using far-infrared radiation. FBP 2016, 98, 275–282. [Google Scholar] [CrossRef]

- Alkaya, G.B.; Erdogdu, F.; Ekiz, H.I. Comparison of conventional far-infrared (IR) heating to continuous IR heating–cooling for surface pasteurization of shell eggs contaminated by Salmonella enterica serotype Enteritidis. J. Food Process Preserv. 2022, 46, e16168. [Google Scholar] [CrossRef]

- Krishnamurthy, K.; Jun, S.; Irudayaraj, J.; Demirci, A.L.I. Efficacy of infrared heat treatment for inactivation of staphylococcus aureus in milk. J. Food Process Eng. 2008, 31, 798–816. [Google Scholar] [CrossRef]

- Dhankhar, P. Homogenization fundamentals. IOSR J. Comput. Eng. 2014, 4, 8. [Google Scholar] [CrossRef]

- Panseri, S.; Soncin, S.; Chiesa, L.M.; Biondi, P.A. A headspace solid-phase microextraction gas-chromatographic mass-spectrometric method (HS-SPME–GC/MS) to quantify hexanal in butter during storage as marker of lipid oxidation. Food Chem. 2011, 127, 886–889. [Google Scholar] [CrossRef] [PubMed]

- European Commission. Commission Regulation (EC) No. 2073/2005 of 15 November 2005 on microbiological criteria for foodstuffs. Off. J. Eur. Union 2005, 50, 1–26. [Google Scholar]

- Böhnlein, C.; Fiedler, G.; Loop, J.; Franz, C.M.; Kabisch, J. Microbiological quality and safety of raw milk from direct sale in northern Germany. Int. Dairy J. 2021, 114, 104944. [Google Scholar] [CrossRef]

- Thomas, E.L. Trends in milk flavors. JDS 1981, 64, 1023–1027. [Google Scholar] [CrossRef]

- Calvo, M.M.; de la Hoz, L. Flavour of heated milks. A review. Int. Dairy J. 1992, 2, 69–81. [Google Scholar] [CrossRef]

- Urbach, G. Effect of feed on flavor in dairy foods. JDS 1990, 73, 3639–3650. [Google Scholar] [CrossRef]

- Moio, L.; Dekimpe, J.; Etievant, P.; Addeo, F. Neutral volatile compounds in the raw milks from different species. J. Dairy Res. 1993, 60, 199–213. [Google Scholar] [CrossRef]

- Cadwallader, K.R.; Singh, T.K. Flavours and off-flavours in milk and dairy products. In Advanced Dairy Chemistry: Volume 3: Lactose, Water, Salts and Minor Constituents; Springer: New York, NY, USA, 2009; pp. 631–690. [Google Scholar]

- Shipe, W.F. Analysis and control of milk flavor. In The Analysis and Control of Less Desirable Flavors in Foods and Beverages; Academic Press: New York, NY, USA, 1980; pp. 201–239. [Google Scholar]

- Vazquez-Landaverde, P.A.; Velazquez, G.; Torres, J.A.; Qian, M.C. Quantitative determination of thermally derived off-flavor compounds in milk using solid-phase microextraction and gas chromatography. JDS 2005, 88, 3764–3772. [Google Scholar] [CrossRef]

- Havemose, M.S.; Weisbjerg, M.R.; Bredie, W.L.P.; Poulsen, H.D.; Nielsen, J.H. Oxidative stability of milk influenced by fatty acids, antioxidants, and copper derived from feed. JDS 2006, 89, 1970–1980. [Google Scholar] [CrossRef]

- Zabbia, A.; Buys, E.M.; De Kock, H.L. Undesirable sulphur and carbonyl flavor compounds in UHT milk: A review. Crit. Rev. Food Sci. Nutr. 2012, 52, 21–30. [Google Scholar] [CrossRef]

- Li, Y.H.; Wang, W.J.; Zhang, F.; Shao, Z.P.; Guo, L. Formation of the oxidized flavor compounds at different heat treatment and changes in the oxidation stability of milk. FSN 2019, 7, 238–246. [Google Scholar] [CrossRef] [PubMed]

- Contarini, G.; Povolo, M. Volatile fraction of milk: Comparison between purge and trap and solid phase microextraction techniques. J. Agric. Food Chem. 2002, 50, 7350–7355. [Google Scholar] [CrossRef] [PubMed]

- Natrella, G.; Gambacorta, G.; De Palo, P.; Maggiolino, A.; Faccia, M. Volatile organic compounds in milk and mozzarella: Comparison between two different farming systems. Int. J. Food Sci. Tech. 2020, 55, 3403–3411. [Google Scholar] [CrossRef]

- Jansson, T.; Clausen, M.R.; Sundekilde, U.K.; Eggers, N.; Nyegaard, S.; Larsen, L.B.; Ray, C.; Sundgren, A.; Andersen, H.J.; Bertram, H.C. Lactose-hydrolyzed milk is more prone to chemical changes during storage than conventional ultra-high-temperature (UHT) milk. J. Agric. Food Chem. 2014, 62, 7886–7896. [Google Scholar] [CrossRef] [PubMed]

- Badings, H.T.; Van der Pol, J.J.G.; Nester, R. Aroma compounds which contribute to the difference in flavour between pasteurized milk and UHT milk. In Flavour’81; Schreier, P., Ed.; Walter de Gruyter: Berlin, Germany, 1981; pp. 683–692. [Google Scholar]

- Vazquez-Landaverde, P.A.; Torres, J.A.; Qian, M.C. Quantification of trace volatile sulfur compounds in milk by solid-phase microextraction and gas chromatography–pulsed flame photometric detection. JDS 2006, 89, 2919–2927. [Google Scholar] [CrossRef] [PubMed]

- Contarini, G.; Povolo, M.; Leardi, R.; Toppino, P.M. Influence of heat treatment on the volatile compounds of milk. J. Agric. Food Chem. 1997, 45, 3171–3177. [Google Scholar] [CrossRef]

- Panseri, S.; Chiesa, L.M.; Biondi, P.A.; Cantoni, C. Head Space-Solid Phase Microextraction for characterization of volatile compounds and microbiological parameters in milk tainted with off-flavour. Milchwissenschaft 2009, 64, 372–375. [Google Scholar]

- Badings, H.T.; de Jong, C. Headspace analysis for the study of aroma compounds in milk and dairy products. In Analysis of Volatiles. Methods and Applications; Schreier, P., Ed.; Walter de Gruyter: Berlin, Germany, 1984; pp. 401–417. [Google Scholar]

- Al-Attabi, Z.H.; Ehsan, S.; Rahman, M.S. Quality Assessment of Milk by Sensory and Instrument Methods. In Techniques to Measure Food Safety and Quality; Khan, M.S., Shafiur Rahman, M., Eds.; Springer: Cham, Switzerland, 2021; pp. 383–425. [Google Scholar] [CrossRef]

- Shibamoto, T.; Mihara, S.; Nishimura, O.; Kamiya, Y.; Aitoku, A.; Hayashi, J. Chapter 12-Flavor volatiles formed by heated milk. In The Analysis and Control of Less-Desirable Flavors in Foods and Beverages; Charalambous, G., Ed.; Academic Press: Salt Lake City, UT, USA, 1980; pp. 241–265. [Google Scholar]

- Burbank, H.M.; Qian, M.C. Volatile sulfur compounds in Cheddar cheese determined by headspace solid-phase microextraction and gas chromatograph-pulsed flame photometric detection. J. Chromatogr. A 2005, 1066, 149–157. [Google Scholar] [CrossRef]

- Bosset, J.O.; Eberhard, P.; Gallmann, P.; Gauch, R.; Rattray, W.; Sieber, R. Occurrence and behaviour of volatile sulfur-containing compounds in milk by heat treatment. In Heat Treatments and Alternative Methods; International Dairy Federation: Brussels, Belgium, 1996; pp. 409–421. [Google Scholar]

- Parisi, S.; Luo, W. Maillard Reaction in Processed Foods—Reaction Mechanisms. In Chemistry of Maillard Reactions in Processed Foods; Springer: Cham, Switzerland, 2018; pp. 39–51. [Google Scholar] [CrossRef]

- Vranova, J.; Ciesarova, Z. Furan in food—A review. Czech. J. Food Sci. 2009, 27, 1–10. [Google Scholar] [CrossRef]

| Trial | Matrix | Energy Tested | Analysis |

|---|---|---|---|

| Trial 1 | Raw non-homogenised milk | 60, 70, 80, 85 | Microbiology and VOCs |

| Trial 2 | Raw non-homogenised milk | 60, 70, 80, 85 | Microbiology and VOCs |

| Trial 3 | Raw non-homogenised milk | 60, 70, 80, 85 | Microbiology and VOCs |

| Trial 4 | Raw homogenised milk | 80 | Microbiology and VOCs |

| Trial 5 | Raw homogenised milk | 80 | Microbiology and VOCs |

| Trial | Mean (Log CFU/mL) | TVC | COLIFORMS | ENTEROBAC- TERIACEA | LAB |

|---|---|---|---|---|---|

| 1 | Raw milk | 4.87 | 2.31 | 2.66 | 3.84 |

| IR 60 | 4.70 | 2.65 | 3.32 | 3.81 | |

| Δ | −0.17 | 0.34 | 0.66 | −0.03 | |

| IR 70 | 4.75 | 1.36 | 3.39 | 3.77 | |

| Δ | −0.12 | −0.95 | 0.73 | −0.07 | |

| IR 80 | 3.76 | 1.57 | 1.93 | 3.16 | |

| Δ | −1.11 | −0.74 | −0.73 | −0.68 | |

| IR 85 | 3.30 | 1.30 | 1.00 | 2.84 | |

| Δ | −1.57 | −1.01 | −1.66 | −1.00 | |

| 2 | Raw milk | 5.20 | 3.99 | 4.09 | 4.54 |

| IR 60 | 5.37 | 3.80 | 4.28 | 4.95 | |

| Δ | 0.17 | −0.19 | 0.19 | 0.41 | |

| IR 70 | 4.85 | 3.58 | 4.11 | 4.21 | |

| Δ | −0.35 | −0.41 | 0.02 | −0.33 | |

| IR 80 | 3.24 | 1.45 | 1.65 | 2.77 | |

| Δ | −1.96 | −2.54 | −2.44 | −1.77 | |

| IR 85 | 3.06 | <1.00 | 1.00 | 2.19 | |

| Δ | −2.14 | >−2.99 | −3.09 | −2.35 | |

| 3 | Raw milk | 4.98 | 3.45 | 3.95 | 4.30 |

| IR 60 | 4.58 | 3.38 | 3.58 | 4.23 | |

| Δ | −0.30 | −0.07 | −0.37 | −0.07 | |

| IR 70 | 4.92 | 3.00 | 3.58 | 4.30 | |

| Δ | −0.06 | −0.45 | −0.37 | 0.00 | |

| IR 80 | 4.14 | 2.98 | 3.08 | 3.94 | |

| Δ | −0.84 | −0.47 | −0.87 | −0.36 | |

| IR 85 | 3.52 | <1.00 | 1.30 | 3.45 | |

| Δ | −1.46 | >−2.45 | −2.65 | −0.85 | |

| 4 | Raw milk | 5.00 | 4.54 | 3.40 | 4.57 |

| IR 80 | 4.30 | 1.48 | 1.50 | 4.21 | |

| Δ | −0.70 | −3.06 | −1.90 | −0.36 | |

| 5 | Raw milk | 5.42 | 3.39 | 3.45 | 5.27 |

| IR 80 | 4.37 | <1.00 | <1.00 | 3.05 | |

| Δ | −1.05 | >−2.39 | >−2.45 | −2.22 |

| Rt | Compound | Raw Milk (n = 3) | S.D. (±) | IR60 (n = 3) | S.D. (±) | IR70 (n = 3) | S.D. (±) | IR80 (n = 3) | S.D. (±) | IR85 (n = 3) | S.D. (±) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Aldehydes | |||||||||||

| 8.98 | Hexanal | 0.08 | 0.16 | n.d. | - | 0.32 | 0.63 | 2.90 | 1.39 | 4.21 * | 1.63 |

| Total | 0.08 | n.d. | 0.32 | 2.90 | 4.21 * | ||||||

| Ketones | |||||||||||

| 2.26 | 2-Propanone | 1212.95 | 268.77 | 1405.73 | 328.22 | 1369.23 * | 253.92 | 1553.42 * | 472.97 | 1613.35 * | 583.46 |

| 3.12 | 2-Butanone | 282.75 | 47.46 | 268.61 | 103.14 | 263.53 | 67.60 | 284.33 | 99.82 | 282.95 | 86.80 |

| 13.01 | 2-Heptanone, 6-methyl- | 0.26 | 0.29 | 0.55 | 0.29 | 0.89 | 0.27 | 2.93 * | 2.00 | 5.01 * | 3.61 |

| 13.83 | 2-Heptanone | 0.49 | 0.33 | 0.80 | 0.80 | 0.53 | 0.37 | 0.33 | 0.12 | 0.37 | 0.22 |

| 14.82 | Propanone, 1,1-dichloro- | 0.19 | 0.19 | 0.21 | 0.11 | 0.38 | 0.21 | 1.05 * | 0.80 | 1.77 * | 1.29 |

| 17.67 | 3-Hydroxy-2-butanone | 1.46 | 1.84 | 2.08 * | 2.81 | 2.02 * | 2.43 | 1.06 | 0.84 | 0.74 | 0.24 |

| Total | 1498.11 | 1677.98 * | 1636.58 * | 1843.13 * | 1904.19 * | ||||||

| Sulphur compounds | |||||||||||

| 1.90 | Dimethyl sulphide | 48.37 | 15.09 | 58.57 * | 25.59 | 57.37 * | 20.13 | 57.78 * | 19.86 | 58.76 * | 20.86 |

| 8.32 | Dimethyl disulphide | n.d. | - | 0.23 | 0.27 | 0.05 | 0.09 | 0.33 | 0.46 | 0.12 | 0.11 |

| 31.05 | Dimethyl sulphone | 10.76 | 6.48 | 10.08 | 5.06 | 14.79 | 2.94 | 13.00 | 4.15 | 26.40 * | 11.63 |

| Total | 59.13 | 68.88 * | 72.21 * | 71.11 * | 85.28 * | ||||||

| Rt | Compound | Raw Milk (n = 2) | S.D. (±) | IR80 (n = 2) | S.D. (±) |

|---|---|---|---|---|---|

| Aldehydes | |||||

| 3.39 | 3-Methyl-butanal | 1.02 | 1.09 | 0.63 | 0.83 |

| 4.74 | Pentanal | 0.23 | 0.18 | 0.37 | 0.16 |

| 4.84 | Acetaldehyde | 0.08 | 0.10 | n.d. | - |

| 8.98 | Hexanal | 5.32 | 1.51 | 8.40 * | 2.81 |

| 14.01 | Heptanal | 0.36 | 0.35 | 0.66 * | 0.37 |

| 20.93 | Nonanal | 0.33 | 0.36 | 0.55 * | 0.30 |

| 22.57 | 2-Furancarboxaldehyde | 0.06 | 0.10 | 0.17 | 0.22 |

| 23.84 | Benzaldehyde | 0.18 | 0.19 | 0.48 * | 0.23 |

| Total | 7.59 | 11.26 * | |||

| Ketones | |||||

| 2.26 | 2-Propanone | 430.48 | 86.58 | 425.12 | 70.90 |

| 3.12 | 2-Butanone | 130.58 | 14.37 | 129.04 | 32.43 |

| 4.66 | 2-Pentanone | 0.42 | 0.21 | 1.53 * | 0.22 |

| 6.71 | 4,4-dimethoxy-2-butanone | 0.03 | 0.06 | n.d. | - |

| 13.83 | 2-Heptanone | 0.49 | 0.41 | 0.69 * | 0.37 |

| 14.98 | 4-Methyl-2-heptanone, | 0.03 | 0.05 | 0.97 * | 0.27 |

| 16.30 | 4,4-Dimethyl-1-penten-3-one | n.d. | - | 0.18 | 0.29 |

| 17.67 | 3-Hydroxy-2-butanone | 2.22 | 1.44 | 1.47 | 0.89 |

| 17.81 | 2-Dodecanone | 0.05 | 0.05 | 0.23 | 0.14 |

| 20.82 | 2-Nonanone | 0.17 | 0.18 | 0.18 | 0.12 |

| 28.19 | 4-Penten-2-one | 0.16 | 0.21 | 0.25 * | 0.20 |

| Total | 564.64 | 559.65 | |||

| Sulphur compounds | |||||

| 1.90 | Dimethyl sulphide | 21.09 | 6.49 | 11.02 * | 2.80 |

| 8.32 | Dimethyl disulphide | n.d. | - | 0.22 | 0.26 |

| 24.52 | Dimethyl sulphoxide | 2.57 | 1.81 | 2.71 | 0.94 |

| 31.05 | Dimethyl sulphone | 122.68 | 61.89 | 193.41 * | 47.08 |

| Total | 146.35 | 207.36 * | |||

| Furans | |||||

| 15.99 | 3-methyl-(3H)-isobenzofuran-1-one | 0.04 | 0.04 | 0.06 | 0.09 |

| 25.93 | dihydro-2(3H)-furanone | 0.27 | 0.19 | 0.30 | 0.35 |

| 29.09 | Tetrahydro-6-methyl-2H-pyran-2-one | 0.05 | 0.06 | 0.17 | 0.21 |

| Total | 0.36 | 0.53 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Danesi, L.; Nobile, M.; Fontana, M.; Tirloni, E.; Chiesa, L.M.; Savini, F.; Villa, R.E.; Panseri, S. Preliminary Investigation towards the Use of Infrared Technology for Raw Milk Treatment. Foods 2024, 13, 1117. https://doi.org/10.3390/foods13071117

Danesi L, Nobile M, Fontana M, Tirloni E, Chiesa LM, Savini F, Villa RE, Panseri S. Preliminary Investigation towards the Use of Infrared Technology for Raw Milk Treatment. Foods. 2024; 13(7):1117. https://doi.org/10.3390/foods13071117

Chicago/Turabian StyleDanesi, Luigi, Maria Nobile, Mauro Fontana, Erica Tirloni, Luca Maria Chiesa, Federica Savini, Roberto Edoardo Villa, and Sara Panseri. 2024. "Preliminary Investigation towards the Use of Infrared Technology for Raw Milk Treatment" Foods 13, no. 7: 1117. https://doi.org/10.3390/foods13071117

APA StyleDanesi, L., Nobile, M., Fontana, M., Tirloni, E., Chiesa, L. M., Savini, F., Villa, R. E., & Panseri, S. (2024). Preliminary Investigation towards the Use of Infrared Technology for Raw Milk Treatment. Foods, 13(7), 1117. https://doi.org/10.3390/foods13071117