Impact of Culinary Procedures on Nutritional and Technological Properties of Reduced-Fat Longanizas Formulated with Chia (Salvia hispanica L.) or Oat (Avena sativa L.) Emulsion Gel

Abstract

:1. Introduction

2. Materials and Methods

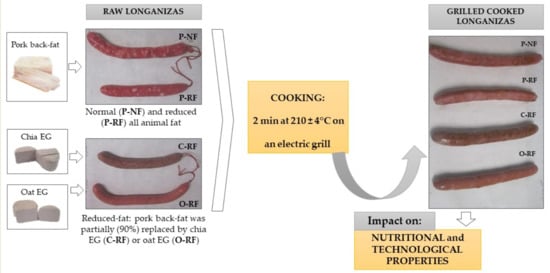

2.1. Oil-in-Water Emulsion Gels and Longanizas Preparation

2.2. Cooking Method for the Longanizas and Weight Loss

2.3. Composition and Energy Content of Longanizas

2.3.1. Proximate Composition

2.3.2. Fatty Acid Profile

2.3.3. Energy Content

2.4. Technological Properties

2.4.1. Color and pH Determination

2.4.2. Texture Analysis

2.4.3. Lipid Oxidation Stability

2.5. Statistical Analysis

3. Results and Discussion

3.1. Cooking Method for the Longanizas and Weight Loss

3.2. Composition and Energy Content of Longanizas

3.2.1. Proximate Composition

3.2.2. Fatty Acid Profile

3.2.3. Energy Value

3.2.4. Overall Nutritional Value: Nutrition and Health Claims

3.3. Technological Properties

3.3.1. pH

3.3.2. Color

3.3.3. Texture Analysis

3.3.4. Lipid Oxidation Stability

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, W.; Xiao, S.; Samaraweera, H.; Lee, E.J.; Ahn, D.U. Improving functional value of meat products. Meat Sci. 2010, 86, 15–31. [Google Scholar] [CrossRef] [PubMed]

- Hygreeva, D.; Pandey, M.C.; Radhakrishna, K. Potential applications of plant based derivatives as fat replacers, antioxidants and antimicrobials in fresh and processed meat products. Meat Sci. 2014, 98, 47–57. [Google Scholar] [CrossRef] [PubMed]

- Yilmaz, I.; Daglioglu, O. The effect of replacing fat with oat bran on fatty acid composition and physicochemical properties of meatballs. Meat Sci. 2003, 65, 819–823. [Google Scholar] [CrossRef]

- Santhi, D.; Kalaikannan, A. The effect of the addition of oat flour in low-fat chicken nuggets. J. Nutr. Food Sci. 2014, 4, 260. [Google Scholar]

- Szpicer, A.; Onopiuk, A.; Poltorak, A.; Wierzbicka, A. The influence of oat beta-glucan content on the physicochemical and sensory properties of low-fat beef burgers. CYTA J. Food 2020, 18, 315–327. [Google Scholar] [CrossRef]

- Munoz, L.A.; Cobos, A.; Diaz, O.; Aguilera, J.M. Chia seed (Salvia hispanica): An ancient grain and a new functional food. Food Rev. Int. 2013, 29, 394–408. [Google Scholar] [CrossRef]

- Souza, A.H.P.; Gohara, A.K.; Rotta, E.M.; Chaves, M.A.; Silva, C.M.; Dias, L.F.; Matsushita, M. Effect of the addition of chia’s by-product on the composition of fatty acids in hamburgers through chemometric methods. J. Sci. Food Agric. 2015, 95, 928–935. [Google Scholar] [CrossRef]

- Pintado, T.; Herrero, A.M.; Jiménez-Colmenero, F.; Ruiz-Capillas, C. Strategies for incorporation of chia (Salvia hispanica L.) in frankfurters as a health-promoting ingredient. Meat Sci. 2016, 114, 75–84. [Google Scholar] [CrossRef]

- Barros, J.C.; Munekata, P.E.S.; Pires, M.A.; Rodrigues, I.; Andaloussi, O.S.; Rodrigues, C.E.D.; Trindade, M.A. Omega-3-and fibre-enriched chicken nuggets by replacement of chicken skin with chia (Salvia hispanica L.) flour. LWT 2018, 90, 283–289. [Google Scholar] [CrossRef]

- Ding, Y.; Lin, H.W.; Lin, Y.L.; Yang, D.J.; Yu, Y.S.; Chen, J.W.; Wang, S.Y.; Chen, Y.C. Nutritional composition in the chia seed and its processing properties on restructured ham-like products. J. Food Drug Anal. 2018, 26, 124–134. [Google Scholar] [CrossRef]

- Antonini, E.; Torri, L.; Piochi, M.; Cabrino, G.; Meli, M.A.; De Bellis, R. Nutritional, antioxidant and sensory properties of functional beef burgers formulated with chia seeds and goji puree, before and after in vitro digestion. Meat Sci. 2020, 161, 108021. [Google Scholar] [CrossRef] [PubMed]

- Camara, A.K.F.I.; Okuro, P.K.; da Cunha, R.L.; Herrero, A.M.; Ruiz-Capillas, C.; Pollonio, M.A.R. Chia (Salvia hispanica L.) mucilage as a new fat substitute in emulsified meat products: Technological, physicochemical, and rheological characterization. LWT 2020, 125, 109193. [Google Scholar] [CrossRef]

- Pires, M.A.; Barros, J.C.; Rodrigues, I.; Munekata, P.E.S.; Trindade, M.A. Improving the lipid profile of bologna type sausages with Echium (Echium plantagineum L.) oil and chia (Salvia hispanica L) flour. LWT 2020, 19, 108907. [Google Scholar] [CrossRef]

- Arendt, E.K.; Zannini, E. Oats. In Cereal Grains for the Food and Beverages Industries; Arendt, E.K., Zannini, E., Eds.; Woodhead Publishing: Philadelphia, PA, USA, 2013; pp. 243–282. [Google Scholar]

- Valdivia-López, M.Á.; Tecante, A. Chia (Salvia hispanica): A review of native Mexican seed and its nutritional and functional properties. In Advances in Food and Nutrition Research; Jeyakumar, H., Ed.; Academic Press: Cambridge, MA, USA, 2015; Volume 75, pp. 53–75. [Google Scholar]

- Pintado, T.; Ruiz-Capillas, C.; Jiménez-Colmenero, F.; Carmona, P.; Herrero, A.M. Oil-in-water emulsion gels stabilized with chia (Salvia hispanica L.) and cold gelling agents: Technological and infrared spectroscopic characterization. Food Chem. 2015, 185, 470–478. [Google Scholar] [CrossRef] [PubMed]

- Pintado, T.; Herrero, A.M.; Jiménez-Colmenero, F.; Ruiz-Capillas, C. Emulsion gels as potential fat replacers delivering β-glucan and healthy lipid content for food applications. J. Food Sci. Technol. 2016, 53, 4336–4347. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- European Commission. Regulation (EC) No 1924/2006 of the European Parliament and of the Council of 20 December 2006 on nutrition and health claims made on foods. Eur. Comm. Off. J. Eur. Union 2006, 404, 3–18. [Google Scholar]

- European Commission. Regulation (EU) No 432/2012 of the European Parliament and of the Council of 16 may 2012 establishing a list of permitted health claims made on foods other than those referring to the reduction of disease risk and to children’s development and health. Eur. Comm. Off. J. Eur. Union 2012, 136, 1–40. [Google Scholar]

- Pintado, T.; Herrero, A.M.; Jiménez-Colmenero, F.; Pasqualin Cavalheiro, C.; Ruiz-Capillas, C. Chia and oat emulsion gels as new animal fat replacers and healthy bioactive sources in fresh sausage formulation. Meat Sci. 2018, 135, 6–13. [Google Scholar] [CrossRef]

- Jiménez-Colmenero, F.; Cofrades, S.; Herrero, A.M.; Ruiz-Capillas, C. Implications of domestic food practices for the presence of bioactive components in meats with special reference to meat-based functional foods. Crit. Rev. Food Sci. 2018, 14, 2334–2345. [Google Scholar] [CrossRef]

- Sobral, M.M.C.; Cunha, S.C.; Faria, M.A.; Ferreira, I. Domestic cooking of muscle foods: Impact on composition of nutrients and contaminants. Compr. Rev. Food Sci. Food Saf. 2018, 17, 309–333. [Google Scholar] [CrossRef] [Green Version]

- AOAC. Official Methods of Analysis, 18th ed.; Association of Official Analytical Chemists: Washington, DC, USA, 2005. [Google Scholar]

- Bligh, E.G.; Dyer, W.J. A rapid method of total lipid extraction and purification. Can. J. Biochem. Physiol. 1959, 37, 911–917. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- EU Regulation. No 1169/2011 of the European Parliament and of the Council of 25 October 2011 on the provision of food information to consumers. Eur. Comm. Off. J. Eur. Union 2011, 20, 168–213. [Google Scholar]

- López-López, I.; Cofrades, S.; Caneque, V.; Diaz, M.T.; López, O.; Jiménez-Colmenero, F. Effect of cooking on the chemical composition of low-salt, low-fat Wakame/olive oil added beef patties with special reference to fatty acid content. Meat Sci. 2011, 89, 27–34. [Google Scholar] [CrossRef] [PubMed]

- Salcedo-Sandoval, L.; Cofrades, S.; Ruiz-Capillas, C.; Jiménez-Colmenero, F. Effect of cooking method on the fatty acid content of reduced-fat and PUFA-enriched pork patties formulated with a konjac-based oil bulking system. Meat Sci. 2014, 4, 795–803. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Berry, B.W. Cooked color in high pH beef patties as related to fat content and cooking from the frozen or thawed state. J. Food Sci. 1998, 63, 797–800. [Google Scholar] [CrossRef]

- Aaslyng, M.D.; Bejerholm, C.; Ertbjerg, P.; Bertram, H.C.; Andersen, H.J. Cooking loss and juiciness of pork in relation to raw meat quality and cooking procedure. Food Qual. Prefer. 2003, 14, 277–288. [Google Scholar] [CrossRef]

- Alejandre, M.; Passarini, D.; Astiasaran, I.; Ansorena, D. The effect of low-fat beef patties formulated with a low-energy fat analogue enriched in long-chain polyunsaturated fatty acids on lipid oxidation and sensory attributes. Meat Sci. 2017, 134, 7–13. [Google Scholar] [CrossRef]

- Maranesi, M.; Bochicchio, D.; Montellato, L.; Zaghini, A.; Pagliuca, G.; Badiani, A. Effect of microwave cooking or broiling on selected nutrient contents, fatty acid patterns and true retention values in separable lean from lamb rib-loins, with emphasis on conjugated linoleic acid. Food Chem. 2005, 90, 207–218. [Google Scholar] [CrossRef]

- EFSA. Scientific opinion on dietary reference values for fats, including saturated fatty acids, polyunsaturated fatty acids, monounsaturated fatty acids, trans fatty acids, and cholesterol. Eur. Food Saf. Agency J. 2010, 8, 1461–1568. [Google Scholar]

- WHO. Diet, Nutrition and the Prevention of Chronic Diseases; World Health Organization Technical Report Series; WHO: Geneve, Switzerland, 2003. [Google Scholar]

- Serrano, A.; Librelotto, J.; Cofrades, S.; Sánchez-Muniz, F.J.; Jiménez-Colmenero, F. Composition and physicochemical beef steaks containing walnuts as characteristics of restructured affected by cooking method. Meat Sci. 2007, 77, 304–313. [Google Scholar] [CrossRef]

- Shao, C.H.; Avens, J.S.; Schmidt, G.S.; Maga, J.A. Functional, sensory, and microbiological properties of restructured beef and emu steaks. J. Food Sci. 1999, 64, 1052–1054. [Google Scholar] [CrossRef]

- Salcedo-Sandoval, L.; Cofrades, S.; Ruiz-Capillas, C.; Carballo, J.; Jiménez-Colmenero, F. Konjac-based oil bulking system for development of improved-lipid pork patties: Technological, microbiological and sensory assessment. Meat Sci. 2015, 101, 95–102. [Google Scholar] [CrossRef] [PubMed]

- Freire, M.; Cofrades, S.; Serrano-Casas, V.; Pintado, T.; Jiménez, M.J.; Jiménez-Colmenero, F. Gelled double emulsions as delivery systems for hydroxytyrosol and n-3 fatty acids in healthy pork patties. J. Food Sci. Technol. 2017, 54, 3959–3968. [Google Scholar] [CrossRef] [PubMed]

- Bernardi, D.M.; Bertol, T.M.; Pflanzer, S.B.; Sgarbieri, V.C.; Pollonio, M.A.R. ω-3 in meat products: Benefits and effects on lipid oxidative stability. J. Sci. Food Agric. 2016, 96, 2620–2634. [Google Scholar] [CrossRef] [PubMed]

- Faure, A.M.; Nystroem, L. Metal binding capacity of oat beta-glucan affects its susceptibility to oxidation. Abstr. Pap. Am. Chem. Soc. 2014, 247, 31. [Google Scholar]

- Scapin, G.; Schimdt, M.M.; Prestes, R.C.; Ferreira, S.; Silva, A.F.C.; Rosa, C.S.D. Effect of extract of chia seed (Salvia hispanica) as an antioxidant in fresh pork sausage. Int. Food Res. J. 2015, 22, 1195–1202. [Google Scholar]

- Martínez, B.; Miranda, J.M.; Vázquez, B.I.; Fente, C.A.; Franco, C.M.; Rodríguez, J.L.; Cepeda, A. Development of a hamburger patty with healthier lipid formulation and study of its nutritional, sensory, and stability properties. Food Bioprocess Technol. 2012, 5, 200–208. [Google Scholar] [CrossRef]

- Poyato, C.; Astiasaran, I.; Barriuso, B.; Ansorena, D. A new polyunsaturated gelled emulsion as replacer of pork back-fat in burger patties: Effect on lipid composition, oxidative stability and sensory acceptability. LWT 2015, 62, 1069–1075. [Google Scholar] [CrossRef] [Green Version]

- Gómez-Estaca, J.; Pintado, T.; Jiménez-Colmenero, F.; Cofrades, S. The effect of household storage and cooking practices on quality attributes of pork burgers formulated with PUFA- and curcumin-loaded oleogels as healthy fat substitutes. LWT 2020, 119, 108909. [Google Scholar] [CrossRef]

| Parameters | Samples * | |||

|---|---|---|---|---|

| P-NF | P-RF | C-RF | O-RF | |

| Weight losses | 24.73 ± 0.17 c | 22.38 ± 0.27 b | 6.71 ± 0.72 a | 7.10 ± 1.13 a |

| Proximate composition | ||||

| Ash | 3.89 ± 0.08 c | 3.27 ± 0.06 a | 3.49 ± 0.05 b | 3.51 ± 0.03 b |

| Moisture | 62.29 ± 1.04 a | 70.93 ± 0.02 c | 65.21 ± 0.56 b | 66.40 ± 0.20 b |

| Protein | 19.94 ± 0.33 c | 17.29 ± 0.34 b | 13.61 ± 1.27 a | 14.97 ± 0.61 a |

| Fat | 12.76 ± 0.53 c | 6.92 ± 0.30 a | 9.53 ± 0.75 b | 7.92 ± 0.55 a |

| Parameters | Samples ** | Raw | Grilled Cooked |

|---|---|---|---|

| pH | P-NF | 6.09 ± 0.06 b,1 | 6.30 ± 0.02 b,2 |

| P-RF | 6.01 ± 0.00 a,1 | 6.18 ± 0.01 a,2 | |

| C-RF | 6.39 ± 0.01 d,1 | 6.44 ± 0.02 d,1 | |

| O-RF | 6.22 ± 0.01 c,1 | 6.35 ± 0.02 c,2 | |

| Color parameters | |||

| L* | P-NF | 49.62 ± 4.82 ab,1 | 57.21 ± 1.21 b,2 |

| P-RF | 46.22 ± 2.90 a,1 | 59.21 ± 0.98 b,2 | |

| C-RF | 48.52 ± 2.15 ab,1 | 54.68 ± 0.85 a,2 | |

| O-RF | 50.56 ± 1.33 b,1 | 58.06 ± 1.15 b,2 | |

| a* | P-NF | 11.46 ± 1.03 b,2 | 9.47 ± 1.20 b,1 |

| P-RF | 11.32 ± 1.00 b,2 | 9.78 ± 0.87 b,1 | |

| C-RF | 7.11 ± 0.99 a,1 | 6.30 ± 0.73 a,1 | |

| O-RF | 11.40 ± 1.20 b,2 | 8.72 ± 1.00 b,1 | |

| b* | P-NF | 6.16 ± 0.80 a,2 | 4.49 ± 0.61 a,1 |

| P-RF | 5.92 ± 0.43 a,2 | 4.49 ± 0.38 a,1 | |

| C-RF | 8.11 ± 0.94 b,1 | 7.41 ± 0.39 b,1 | |

| O-RF | 8.19 ± 0.70 c,1 | 7.43 ± 0.97 b,1 | |

| TBA(mg MDA/kg sample) | P-NF | 0.602 ± 0.08 b,1 | 0.801 ± 0.151 b,1 |

| P-RF | 0.123 ± 0.04 a,1 | 0.367 ± 0.093 a,2 | |

| C-RF | 0.392 ± 0.03 a,1 | 0.663 ± 0.140 b,2 | |

| O-RF | 0.348 ± 0.08 a,1 | 2.006 ± 0.241 c,2 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pintado, T.; Ruiz-Capillas, C.; Jiménez-Colmenero, F.; Herrero, A.M. Impact of Culinary Procedures on Nutritional and Technological Properties of Reduced-Fat Longanizas Formulated with Chia (Salvia hispanica L.) or Oat (Avena sativa L.) Emulsion Gel. Foods 2020, 9, 1847. https://doi.org/10.3390/foods9121847

Pintado T, Ruiz-Capillas C, Jiménez-Colmenero F, Herrero AM. Impact of Culinary Procedures on Nutritional and Technological Properties of Reduced-Fat Longanizas Formulated with Chia (Salvia hispanica L.) or Oat (Avena sativa L.) Emulsion Gel. Foods. 2020; 9(12):1847. https://doi.org/10.3390/foods9121847

Chicago/Turabian StylePintado, Tatiana, Claudia Ruiz-Capillas, Francisco Jiménez-Colmenero, and Ana M. Herrero. 2020. "Impact of Culinary Procedures on Nutritional and Technological Properties of Reduced-Fat Longanizas Formulated with Chia (Salvia hispanica L.) or Oat (Avena sativa L.) Emulsion Gel" Foods 9, no. 12: 1847. https://doi.org/10.3390/foods9121847

APA StylePintado, T., Ruiz-Capillas, C., Jiménez-Colmenero, F., & Herrero, A. M. (2020). Impact of Culinary Procedures on Nutritional and Technological Properties of Reduced-Fat Longanizas Formulated with Chia (Salvia hispanica L.) or Oat (Avena sativa L.) Emulsion Gel. Foods, 9(12), 1847. https://doi.org/10.3390/foods9121847