Effect of Buckwheat Groats Processing on the Content and Bioaccessibility of Selected Minerals

Abstract

:1. Introduction

2. Materials and Methods

2.1. Food Samples

2.2. Determination of Minerals

2.3. Enzymatic Digestion

2.4. Statistical Analysis

3. Results and Discussion

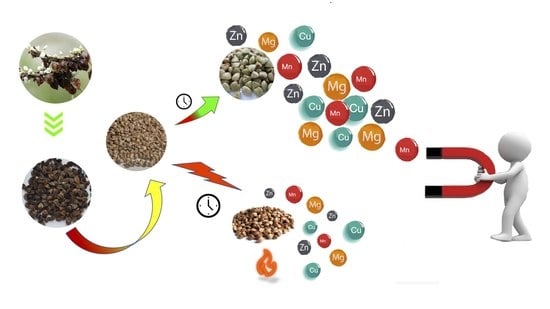

3.1. The Total Content of Minerals in Buckwheat Grains and Groats

3.2. The Content of Minerals Released by Enzymatic Digestion and Their Bioaccessibility from Buckwheat Grains and Groats

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Badimon, L.; Chagas, P.; Chiva-Blanch, G. Diet and Cardiovascular Disease: Effects of Foods and Nutrients in Classical and Emerging Cardiovascular Risk Factors. Curr. Med. Chem. 2019, 26, 3639–3651. [Google Scholar] [CrossRef]

- Scherz, H.; Kirchhoff, E. Trace elements in foods: Zinc contents of raw foods—A comparison of data originating from different geographical regions of the world. J. Food Compos. Anal. 2006, 19, 420–433. [Google Scholar] [CrossRef]

- Almohanna, H.M.; Ahmed, A.A.; Tsatalis, J.P.; Tosti, A. The Role of Vitamins and Minerals in Hair Loss: A Review. Dermatol. Ther. 2018, 9, 51–70. [Google Scholar] [CrossRef] [Green Version]

- Yu, Q.; Sun, X.; Zhao, J.; Zhao, L.; Chen, Y.; Fan, L.; Li, Z.; Sun, Y.; Wang, M.; Wang, F. The effects of zinc deficiency on homeostasis of twelve minerals and trace elements in the serum, feces, urine and liver of rats. Nutr. Metab. 2019, 16, 73–78. [Google Scholar] [CrossRef]

- Lazo, A.; Lazo, P.; Urtubia, A.; Lobos, M.G.; Gutiérrez, C.; Hansen, H.K. Copper Analysis by Two Different Procedures of Sequential Extraction after Electrodialytic Remediation of Mine Tailings. Int. J. Environ. Res. Public Health 2019, 16, 3957. [Google Scholar] [CrossRef] [Green Version]

- Joung, H.; Nam, G.; Yoon, S.; Lee, J.; Shim, J.E.; Paik, H.-Y. Bioavailable zinc intake of Korean adults in relation to the phytate content of Korean foods. J. Food Compos. Anal. 2004, 17, 713–724. [Google Scholar] [CrossRef]

- Krishnan, R.; Meera, M.S. Pearl millet minerals: Effect of processing on bioaccessibility. J. Food Sci. Technol. 2018, 55, 3362–3372. [Google Scholar] [CrossRef]

- Suliburska, J.; Krejpcio, Z. Evaluation of the content and bioaccessibility of iron, zinc, calcium and magnesium from groats, rice, leguminous grains and nuts. J. Food Sci. Technol. 2011, 51, 589–594. [Google Scholar] [CrossRef] [Green Version]

- Alsharairi, N.A. Diet and Food Allergy as Risk Factors for Asthma in the Arabian Gulf Region: Current Evidence and Future Research Needs. Int. J. Environ. Res. Public Health 2019, 16, 3852. [Google Scholar] [CrossRef] [Green Version]

- Rybicka, I.; Gliszczyńska-Świgło, A. Minerals in grain gluten-free products. The content of calcium, potassium, magnesium, sodium, copper, iron, manganese, and zinc. J. Food Compos. Anal. 2017, 59, 61–67. [Google Scholar] [CrossRef]

- Pandey, S.; Senthil, A.; Fatema, K. Effect of Hydrothermal Treatment on the Nutritional and Functional Properties of Husked and Dehusked Buckwheat. J. Food Process. Technol. 2015, 6, 6–7. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, A.; Khalid, N.; Ahmad, A.; Abbasi, N.A.; Latif, M.S.Z.; Randhawa, M.A. Phytochemicals and biofunctional properties of buckwheat: A review. J. Agric. Sci. 2013, 152, 349–369. [Google Scholar] [CrossRef]

- Bonafaccia, G.; Gambelli, L.; Fabjan, N.; Kreft, I. Trace elements in flour and bran from common and tartary buckwheat. Food Chem. 2003, 83, 1–5. [Google Scholar] [CrossRef]

- Giménez-Bastida, J.A.; Zieliński, H. Buckwheat as a Functional Food and Its Effects on Health. J. Agric. Food Chem. 2015, 63, 7896–7913. [Google Scholar] [CrossRef]

- Christa, K.; Soral-Śmietana, M. Buckwheat grains and buckwheat products—Nutritional and prophylactic value of their components—A review. Czech J. Food Sci. 2008, 26, 153–162. [Google Scholar] [CrossRef] [Green Version]

- Roy, M.; Dutta, H.; Jaganmohan, R.; Choudhury, M.; Kumar, N.; Kumar, A. Effect of steam parboiling and hot soaking treatments on milling yield, physical, physicochemical, bioactive and digestibility properties of buckwheat (Fagopyrum esculentum L.). J. Food Sci. Technol. 2019, 56, 3524–3533. [Google Scholar] [CrossRef]

- Ikeda, S.; Yamashita, Y.; Kusumoto, K.; Kreft, I. Nutritional characteristics of minerals in various byckwheat groats. Fagopyrum 2005, 22, 71–75. [Google Scholar]

- Dziedzic, K.; Górecka, D.; Kucharska, M.; Przybylska, B. Influence of technological process during buckwheat groats production on dietary fibre content and sorption of bile acids. Food Res. Int. 2012, 47, 279–283. [Google Scholar] [CrossRef]

- Górecka, D.; Dziedzic, K.; Sell, S. The influence of the technological processes applied to production of buckwheat groats on the dietary fiber content. Sci. Nat. Technol. 2010, 4, 1–9. [Google Scholar]

- Pongrac, P.; Scheers, N.; Sandberg, A.-S.; Potisek, M.; Arčon, I.; Kreft, I.; Kump, P.; Vogel-Mikuš, K. The effects of hydrothermal processing and germination on Fe speciation and Fe bioaccessibility to human intestinal Caco-2 cells in Tartary buckwheat. Food Chem. 2016, 199, 782–790. [Google Scholar] [CrossRef]

- Whiteside, P.J. Atomic Absorption, Data Book, 3rd ed.; Pye Unicam Ltd.: Cambridge, UK, 1979. [Google Scholar]

- Ikeda, S. Dietary zinc and the zinc components in various foods subjected to in-vitro enzymic digestion. J. Sci. Food Agric. 1990, 53, 229–234. [Google Scholar] [CrossRef]

- Skibniewska, K.; Kozirok, W.; Fornal, L.; Markiewicz, K. In vitro availability of minerals from oat products. J. Sci. Food Agric. 2002, 82, 1676–1681. [Google Scholar] [CrossRef]

- Nalepa, B.; Siemianowska, E.; Skibniewska, K. Influence of Bifidobacterium bifidum on Release of Minerals from Bread with Differing Bran Content. J. Toxicol. Environ. Health Part A 2011, 75, 1–5. [Google Scholar] [CrossRef]

- Steadman, K.J.; Burgoon, M.S.; Lewis, B.A.; Edwardson, S.E.; Obendorf, R.L. Minerals, phytic acid, tannin and rutin in buckwheat seed milling fractions. J. Sci. Food Agric. 2001, 81, 1094–1100. [Google Scholar] [CrossRef]

- Ekholm, P.J.; Reinivuo, H.; Mattila, P.H.; Pakkala, H.; Koponen, J.; Happonen, A.; Hellström, J.; Ovaskainen, M.-L. Changes in the mineral and trace element contents of cereals, fruits and vegetables in Finland. J. Food Compos. Anal. 2007, 20, 487–495. [Google Scholar] [CrossRef]

- Peng, L.-X.; Huang, Y.-F.; Liu, Y.; Zhang, Z.-F.; Lu, L.-Y.; Zhao, G. Evaluation of Essential and Toxic Element Concentrations in Buckwheat by Experimental and Chemometric Approaches. J. Integr. Agric. 2014, 13, 1691–1698. [Google Scholar] [CrossRef] [Green Version]

- Lintschinger, J.; Fuchs, N.; Moser, H.; Jager, R.; Hlebeina, T.; Markolin, G.; Gossler, W. Uptake of various trace elements during germination of wheat, buckwheat and quinoa. Plant Foods Hum. Nutr. 1997, 50, 223–237. [Google Scholar] [CrossRef]

- Khan, F.; Arif, M.; Khan, T.U.; Khan, M.I.; Bangash, J.A. Nutritional evaluation of common buckwheat of four different villages of Gilgit-Baltistan. J. Agric. Biol. Sci. 2013, 8, 264–266. [Google Scholar]

- Huang, X.-Y.; Zeller, F.J.; Huang, K.-F.; Shi, T.-X.; Chen, Q.-F. Variation of major minerals and trace elements in seeds of tartary buckwheat (Fagopyrum tataricum Gaertn.). Genet. Resour. Crop. Evol. 2013, 61, 567–577. [Google Scholar] [CrossRef]

- Unal, H.; Izli, G.; Izli, N.; Asik, B.B. Comparison of some physical and chemical characteristics of buckwheat (Fagopyrum esculentumMoench) grains. CyTA J. Food 2016, 15, 257–265. [Google Scholar] [CrossRef] [Green Version]

- Pongrac, P.; Vogel-Mikuš, K.; Jeromel, L.; Vavpetič, P.; Pelicon, P.; Kaulich, B.; Gianoncelli, A.; Eichert, D.; Regvar, M.; Kreft, I. Spatially resolved distributions of the mineral elements in the grain of tartary buckwheat (Fagopyrum tataricum). Food Res. Int. 2013, 54, 125–131. [Google Scholar] [CrossRef]

- Steadman, K.J.; Burgoon, M.; Lewis, B.; Edwardson, S.; Obendorf, R. Buckwheat Seed Milling Fractions: Description, Macronutrient Composition and Dietary Fibre. J. Cereal Sci. 2001, 33, 271–278. [Google Scholar] [CrossRef]

- Stempińska, K.; Soral-Śmietana, M.; Zieliński, H.; Michalska, A. Effect of thermal treatment on chemical and antioxidant properties of buckwheat grains. Food Sci. Technol. Qual. 2007, 5, 66–76. [Google Scholar]

- Manthey, F.A.; Hall, C. Effect of processing and cooking on the content of minerals and protein in pasta containing buckwheat bran flour. J. Sci. Food Agric. 2007, 87, 2026–2033. [Google Scholar] [CrossRef]

- Janiszewska, A.S.; Stodolak, B.; Duliński, R.; Bączkowicz, M.; Mickowska, B.; Wikiera, A.; Byczyński, Ł. Effect of Solid-State Fermentation Tempe Type on Antioxidant and Nutritional Parameters of Buckwheat Groats as Compared with Hydrothermal Processing. J. Food Process. Preserv. 2015, 40, 298–305. [Google Scholar] [CrossRef]

- Florkiewicz, A.; Filipiak-Florkiewicz, A.; Topolska, K.; Cieślik, E.; Kapusta-Duch, J. The effect of hydrothermal processing on the content of selected minerals in different varietes of groats. J. Health Environ. Res. 2015, 2, 196–204. [Google Scholar]

- Mota, C.; Nascimento, A.C.; Santos, M.; Delgado, I.; Coelho, I.; Rego, A.; Matos, A.S.; Torres, D.P.; Castanheira, I.; Motta, C. The effect of cooking methods on the mineral content of quinoa (Chenopodium quinoa), amaranth (Amaranthus sp.) and buckwheat (Fagopyrum esculentum). J. Food Compos. Anal. 2016, 49, 57–64. [Google Scholar] [CrossRef]

- Worobiej, E.; Piecyk, M.; Perzyna, G.; Turos, J. Effect of processing and thermally treating buckwheat grains on nutrients. Food Sci. Technol. Qual. 2017, 24, 60–73. [Google Scholar] [CrossRef]

- Deng, Y.; Padilla-Zakour, O.; Zhao, Y.; Tao, S. Influences of high hydrostatic pressure, microwave heating, and boiling on chemical compositions, antinutritional factors, fatty acids, in vitro protein digestibility, and microstructure of buckwheat. Food Bioprocess Technol. 2015, 8, 2235–2245. [Google Scholar] [CrossRef]

- Dos Santos, A.M.P.; Lima, J.S.; Anunciação, D.S.; Souza, A.S.; Dos Santos, D.C.M.B.; Matos, G.D. Determination and Evaluation Employing Multivariate Analysis of the Mineral Composition of Broccoli (Brassica oleracea L. var. Italica). Food Anal. Methods 2012, 6, 745–752. [Google Scholar] [CrossRef]

- Irwing, P.; Hughes, D.J. Test Development. In The Wiley Handbook of Psychometric Testing: A Multidisciplinary Reference on Survey, Scale and Test Development; Irwing, P., Booth, T., Hughes, D.J., Eds.; Wiley: Hoboken, NJ, USA, 2018; Volume 6, pp. 4–47. [Google Scholar]

- Duliński, R.; Janiszewska, A.S.; Byczyński, Ł.; Błaszczyk, U. Myo-inositol phosphates profile of buckwheat and quinoa seeds: Effects of hydrothermal processing and solid-state fermentation withRhizopus oligosporus. Int. J. Food Prop. 2016, 20, 2088–2095. [Google Scholar] [CrossRef] [Green Version]

- Fairweather-Tait, S.J. The importance of trace element speciation in nutritional sciences. Anal. Bioanal. Chem. 1999, 363, 536–540. [Google Scholar] [CrossRef]

- Zieliński, H.; Michalska-Ciechanowska, A.; Piskula, M.K.; Kozłowska, H. Antioxidants in thermally treated buckwheat groats. Mol. Nutr. Food Res. 2006, 50, 824–832. [Google Scholar] [CrossRef]

| Type of Process and Product | Type of Analysed Samples | Content of Mineral Elements [µg/g] | p-Value | |||

|---|---|---|---|---|---|---|

| Mg | Mn | Zn | Cu | |||

| The entire processing (raw material and the final product) | grains 1 | 1523.1 ± 28.22 bC | 20.28 ± 1.34 bB | 25.80 ± 0.70 aB | 6.00 ± 0.24 aA | <0.0001 |

| groats 2 | 1450.0 ± 31.47 aD | 12.56 ± 0.43 aB | 26.31 ± 1.66 aC | 5.34 ± 0.35 aA | <0.0001 | |

| p-value | <0.0001 | <0.0001 | <0.0100 | <0.0100 | ||

| Dehulling process | grains with hull | 1393.1 ± 27.6 aC | 26.38 ± 2.38 bB | 22.30 ± 1.02 aB | 6.22 ± 0.61 aA | <0.0001 |

| dehulled grains | 1653.1 ± 25.50 bD | 14.17 ± 0.77 aB | 29.30 ± 0.72 bC | 5.79 ± 0.37 aA | <0.0001 | |

| p-value | <0.0001 | 0.0002 | <0.0001 | 0.5533 | ||

| Comparison of different methods of hydrothermal treatment | unroasted groats | 1525.0 ± 22.2 bD | 12.60 ± 0.16 aB | 23.73 ± 0.46 aC | 4.75 ± 0.09 aA | <0.0001 |

| roasted groats | 1375.0 ± 41.27 aD | 12.52 ± 0.67 aB | 28.89 ± 2.43 bC | 5.92 ± 0.50 bA | <0.0001 | |

| p-value | <0.0001 | 0.6355 | 0.0492 | 0.0347 | ||

| Type of Process and Product | Type of Analysed Samples | Content of Mineral Elements Released by In Vitro Digestion [µg/g] | p-Value | |||

|---|---|---|---|---|---|---|

| Mg | Mn | Zn | Cu | |||

| The entire processing (raw material and the final product) | grains 1 | 857.6 ± 35.02 aC | 5.24 ± 0.88 aA | 27.34 ± 0.86 bB | 4.09 ± 0.11 aA | <0.0001 |

| groats 2 | 1034.9 ± 47.65 bC | 3.59 ± 0.41 aA | 19.39 ± 2.37 aB | 3.48 ± 0.14 aA | <0.0001 | |

| p-value | 0.0311 | 0.1331 | <0.0001 | 0.1500 | ||

| Dehulling process | grains with hull | 855.7 ± 100.13 aD | 7.88 ± 2.20 bB | 22.69 ± 0.61 aC | 3.59 ± 0.09 aA | <0.0001 |

| dehulled grains | 859.4 ± 19.97 aD | 2.61 ± 0.21 aA | 31.99 ± 0.72 bC | 4.59 ± 0.19 bB | <0.0001 | |

| p-value | 0.9714 | 0.0299 | <0.0001 | 0.0002 | ||

| Comparison of different methods of hydrothermal treatment | unroasted groats | 1233.8 ± 22.4 bD | 5.19 ± 0.31 bB | 28.81 ± 2.00 bC | 3.90 ± 0.46 bA | <0.0001 |

| roasted groats | 836.1 ± 24.3 aD | 1.99 ± 0.30 aA | 9.97 ± 1.60 aC | 3.06 ± 0.13 aB | <0.0001 | |

| p-value | 0.0169 | 0.0594 | 0.0129 | 0.0602 | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Klepacka, J.; Najda, A.; Klimek, K. Effect of Buckwheat Groats Processing on the Content and Bioaccessibility of Selected Minerals. Foods 2020, 9, 832. https://doi.org/10.3390/foods9060832

Klepacka J, Najda A, Klimek K. Effect of Buckwheat Groats Processing on the Content and Bioaccessibility of Selected Minerals. Foods. 2020; 9(6):832. https://doi.org/10.3390/foods9060832

Chicago/Turabian StyleKlepacka, Joanna, Agnieszka Najda, and Kamila Klimek. 2020. "Effect of Buckwheat Groats Processing on the Content and Bioaccessibility of Selected Minerals" Foods 9, no. 6: 832. https://doi.org/10.3390/foods9060832

APA StyleKlepacka, J., Najda, A., & Klimek, K. (2020). Effect of Buckwheat Groats Processing on the Content and Bioaccessibility of Selected Minerals. Foods, 9(6), 832. https://doi.org/10.3390/foods9060832