Flexible Strain-Sensitive Silicone-CNT Sensor for Human Motion Detection

Abstract

:1. Introduction

2. Materials and Methods

2.1. Components

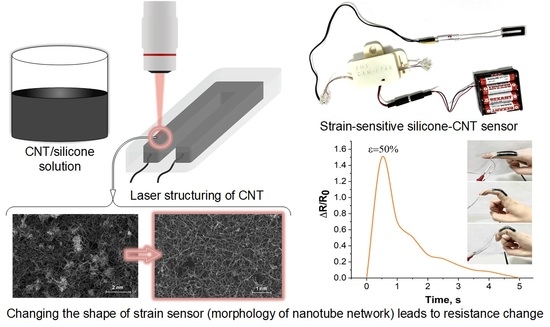

2.2. Manufacturing of the Strain-Sensitive Material

2.3. Manufacturing of Electronic Circuit

2.4. Determination of Strain Sensor Sensitivity

2.5. Measurement of Strain Sensor Mechanical Characteristics

2.6. Investigation of Temperature Influence on Strain Sensor

2.7. Investigation of Strain Sensor Working Capacity

3. Results and Discussion

3.1. Structure

3.2. Electrical Characteristics and Sensitivity

3.3. Mechanical Characteristics

3.4. Resistance Dependence of Temperature

3.5. Working Capacity

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chong, H.; Lou, J.; Bogie, K.M.; Zorman, C.A.; Majerus, S.J.A. Vascular Pressure–Flow Measurement Using CB-PDMS Flexible Strain Sensor. IEEE Trans. Biomed. Circuits Syst. 2019, 13, 1451–1461. [Google Scholar] [CrossRef]

- Slobodian, P.; Danova, R.; Olejnik, R.; Matyas, J.; Münster, L. Multifunctional flexible and stretchable polyurethane/carbon nanotube strain sensor for human breath monitoring. Polym. Adv. Technol. 2019, 30, 1891–1898. [Google Scholar] [CrossRef]

- Zhang, P.; Chen, Y.; Li, Y.; Zhang, Y.; Zhang, J.; Huang, L. A Flexible Strain Sensor Based on the Porous Structure of a Carbon Black/Carbon Nanotube Conducting Network for Human Motion Detection. Sensors 2020, 20, 1154. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Toledo-Pérez, D.C.; Martínez-Prado, M.A.; Gómez-Loenzo, R.A.; Paredes-García, W.J.; Rodríguez-Reséndiz, J. A Study of Movement Classification of the Lower Limb Based on up to 4-EMG Channels. Electronics 2019, 8, 259. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Y.; Huang, Y.; Hu, W.; Guo, X.; Wang, Y.; Liu, P.; Liu, C.; Zhang, Y. Highly sensitive flexible strain sensor based on threadlike spandex substrate coating with conductive nanocomposites for wearable electronic skin. Smart Mater. Struct. 2018, 28, 035004. [Google Scholar] [CrossRef]

- Dong, W.; Yang, L.; Fortino, G. Stretchable Human Machine Interface Based on Smart Glove Embedded with PDMS-CB Strain Sensors. IEEE Sens. J. 2020, 20, 8073–8081. [Google Scholar] [CrossRef]

- Yeo, J.C.; Yap, H.K.; Xi, W.; Wang, Z.; Yeow, C.-H.; Lim, C.T. Flexible and Stretchable Strain Sensing Actuator for Wearable Soft Robotic Applications. Adv. Mater. Technol. 2016, 1, 1600018. [Google Scholar] [CrossRef]

- Ghate, S.; Yu, L.; Du, K.; Lim, C.T.; Yeo, J.C. Sensorized fabric glove as game controller for rehabilitation. In Proceedings of the 2020 IEEE Sensors, Rotterdam, The Netherlands, 25–28 October 2020; pp. 1–4. [Google Scholar]

- Yin, J.; Hinchet, R.; Shea, H.; Majidi, C. Wearable Soft Technologies for Haptic Sensing and Feedback. Adv. Funct. Mater. 2021, 31, 2007428. [Google Scholar] [CrossRef]

- Kanazawa, S.; Ushijima, H. Development of a Strain Sensor Matrix on Mobilized Flexible Substrate for the Imaging of Wind Pressure Distribution. Micromachines 2020, 11, 232. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhu, P.; Zhao, Z.; Nie, J.; Hu, G.; Li, L.; Zhang, Y. Ultra-high sensitivity strain sensor based on piezotronic bipolar transistor. Nano Energy 2018, 50, 744–749. [Google Scholar] [CrossRef] [Green Version]

- Amjadi, M.; Kyung, K.-U.; Park, I.; Sitti, M. Stretchable, Skin-Mountable, and Wearable Strain Sensors and Their Potential Applications: A Review. Adv. Funct. Mater. 2016, 26, 1678–1698. [Google Scholar] [CrossRef]

- Yu, J.; Xu, S.; Jiang, Y.; Chen, H.; Feng, W. Multi-parameter sensor based on the fiber Bragg grating combined with triangular-lattice four-core fiber. Optik 2020, 208, 164094. [Google Scholar] [CrossRef]

- He, T.; Shi, Q.; Wang, H.; Wen, F.; Chen, T.; Ouyang, J.; Lee, C. Beyond energy harvesting—Multi-functional triboelectric nanosensors on a textile. Nano Energy 2019, 57, 338–352. [Google Scholar] [CrossRef]

- Tian, Y.; He, P.; Yang, B.; Yi, Z.; Lu, L.; Liu, J. A Flexible Piezoelectric Strain Sensor Array With Laser-Patterned Serpentine Interconnects. IEEE Sens. J. 2020, 20, 8463–8468. [Google Scholar] [CrossRef]

- Panth, M.; Cook, B.; Zhang, Y.; Ewing, D.; Tramble, A.; Wilson, A.; Wu, J. High-Performance Strain Sensors Based on Vertically Aligned Piezoelectric Zinc Oxide Nanowire Array/Graphene Nanohybrids. ACS Appl. Nano Mater. 2020, 3, 6711–6718. [Google Scholar] [CrossRef]

- Aslanidis, E.; Skotadis, E.; Tsoukalas, D. Resistive crack-based nanoparticle strain sensors with extreme sensitivity and adjustable gauge factor, made on flexible substrates. Nanoscale 2021, 13, 3263–3274. [Google Scholar] [CrossRef]

- Cai, L.; Song, L.; Luan, P.; Zhang, Q.; Zhang, N.; Gao, Q.; Zhao, D.; Zhang, X.; Tu, M.; Yang, F.; et al. Super-stretchable, Transparent Carbon Nanotube-Based Capacitive Strain Sensors for Human Motion Detection. Sci. Rep. 2013, 3, 3048. [Google Scholar] [CrossRef] [Green Version]

- Dong, T.; Gu, Y.; Liu, T.; Pecht, M. Resistive and capacitive strain sensors based on customized compliant electrode: Comparison and their wearable applications. Sens. Actuators A Phys. 2021, 326, 112720. [Google Scholar] [CrossRef]

- Qaiser, N.; Al-Modaf, F.; Khan, S.M.; Shaikh, S.F.; El-Atab, N.; Hussain, M.M. A Robust Wearable Point-of-Care CNT-Based Strain Sensor for Wirelessly Monitoring Throat-Related Illnesses. Adv. Funct. Mater. 2021, 31, 2103375. [Google Scholar] [CrossRef]

- Song, X.; Liu, X.; Peng, Y.; Xu, Z.; Liu, W.; Pang, K.; Wang, J.; Zhong, L.; Yang, Q.; Meng, J. A graphene-coated silk-spandex fabric strain sensor for human movement monitoring and recognition. Nanotechnology 2021, 32, 215501. [Google Scholar] [CrossRef]

- Wang, X.; Liu, X.; Schubert, D.W. Highly Sensitive Ultrathin Flexible Thermoplastic Polyurethane/Carbon Black Fibrous Film Strain Sensor with Adjustable Scaffold Networks. Nano-Micro Lett. 2021, 13, 1–19. [Google Scholar] [CrossRef]

- Lee, J.; Kim, S.; Lee, J.; Yang, D.; Park, B.C.; Ryu, S.; Park, I. A stretchable strain sensor based on a metal nanoparticle thin film for human motion detection. Nanoscale 2014, 6, 11932–11939. [Google Scholar] [CrossRef] [PubMed]

- Ha, S.-H.; Kim, J.-M. Highly sensitive and stretchable strain sensor based on self-aligned and periodic cracking of wavy metal nanowire/elastomer composite film. Smart Mater. Struct. 2021, 30, 065022. [Google Scholar] [CrossRef]

- Zhu, M.; Sakamoto, K.; Li, J.; Inomata, N.; Toda, M.; Ono, T. Piezoresistive strain sensor based on monolayer molybdenum disulfide continuous film deposited by chemical vapor deposition. J. Micromech. Microeng. 2019, 29, 055002. [Google Scholar] [CrossRef]

- Selvan, N.T.; Eshwaran, S.B.; Das, A.; Stöckelhuber, K.W.; Wießner, S.; Pötschke, P.; Nando, G.B.; Chervanyov, A.I.; Heinrich, G. Piezoresistive natural rubber-multiwall carbon nanotube nanocomposite for sensor applications. Sens. Actuators A Phys. 2016, 239, 102–113. [Google Scholar] [CrossRef]

- Lin, L.; Choi, Y.; Chen, T.; Kim, H.; Lee, K.S.; Kang, J.; Lyu, L.; Gao, J.; Piao, Y. Superhydrophobic and wearable TPU based nanofiber strain sensor with outstanding sensitivity for high-quality body motion monitoring. Chem. Eng. J. 2021, 419, 129513. [Google Scholar] [CrossRef]

- Park, J.W.; Kim, T.; Kim, D.; Hong, Y.; Gong, H.S. Measurement of finger joint angle using stretchable carbon nanotube strain sensor. PLoS ONE 2019, 14, e0225164. [Google Scholar] [CrossRef] [PubMed]

- Ryu, S.; Lee, P.; Chou, J.B.; Xu, R.; Zhao, R.; Hart, A.J.; Kim, S.-G. Extremely Elastic Wearable Carbon Nanotube Fiber Strain Sensor for Monitoring of Human Motion. ACS Nano 2015, 9, 5929–5936. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, G.; Ren, X. Graphene assisted ion-conductive hydrogel with super sensitivity for strain sensor. Polym. J. 2021, 215, 123340. [Google Scholar] [CrossRef]

- Ibrahim, K.S. Carbon nanotubes-properties and applications: A review. Carbon Lett. 2013, 14, 131–144. [Google Scholar] [CrossRef] [Green Version]

- Jung, S.; Choi, H.W.; Mocanu, F.C.; Shin, D.-W.; Chowdhury, M.F.; Han, S.D.; Suh, Y.-H.; Cho, Y.; Lee, H.; Fan, X.; et al. Modeling Electrical Percolation to optimize the Electromechanical Properties of CNT/Polymer Composites in Highly Stretchable Fiber Strain Sensors. Sci. Rep. 2019, 9, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Vaicekauskaite, J.; Mazurek, P.; Vudayagiri, S.; Skov, A.L. Mapping the mechanical and electrical properties of commercial silicone elastomer formulations for stretchable transducers. J. Mater. Chem. C 2020, 8, 1273–1279. [Google Scholar] [CrossRef]

- Li, Y.; Luo, S.; Yang, M.-C.; Liang, R.; Zeng, C. Poisson Ratio and Piezoresistive Sensing: A New Route to High-Performance 3D Flexible and Stretchable Sensors of Multimodal Sensing Capability. Adv. Funct. Mater. 2016, 26, 2900–2908. [Google Scholar] [CrossRef]

- Lee, J.; Pyo, S.; Kwon, D.-S.; Jo, E.; Kim, W.; Kim, J. Ultrasensitive Strain Sensor Based on Separation of Overlapped Carbon Nanotubes. Small 2019, 15, 1805120. [Google Scholar] [CrossRef]

- Mai, H.; Mutlu, R.; Tawk, C.; Alici, G.; Sencadas, V. Ultra-stretchable MWCNT–Ecoflex piezoresistive sensors for human motion detection applications. Compos. Sci. Technol. 2019, 173, 118–124. [Google Scholar] [CrossRef]

- Park, S.-J.; Kim, J.; Chu, M.; Khine, M. Highly Flexible Wrinkled Carbon Nanotube Thin Film Strain Sensor to Monitor Human Movement. Adv. Mater. Technol. 2016, 1, 1600053. [Google Scholar] [CrossRef] [Green Version]

- Kim, S.Y.; Park, S.; Park, H.W.; Park, D.H.; Jeong, Y.; Kim, D.H. Highly Sensitive and Multimodal All-Carbon Skin Sensors Capable of Simultaneously Detecting Tactile and Biological Stimuli. Adv. Mater. 2015, 27, 4178–4185. [Google Scholar] [CrossRef]

- Wang, H.; Zhao, Z.; Liu, P.; Guo, X. Laser-induced porous graphene on Polyimide/PDMS composites and its kirigami-inspired strain sensor. Theor. Appl. Mech. Lett. 2021, 11, 100240. [Google Scholar] [CrossRef]

- Kulyk, B.; Silva, B.F.R.; Carvalho, A.F.; Silvestre, S.; Fernandes, A.J.S.; Martins, R.; Fortunato, E.; Costa, F.M. Laser-Induced Graphene from Paper for Mechanical Sensing. ACS Appl. Mater. Interfaces 2021, 13, 10210–10221. [Google Scholar] [CrossRef]

- Chu, M.; E Naguib, H. Soft flexible conductive CNT nanocomposites for ECG monitoring. Smart Mater. Struct. 2021, 30, 065003. [Google Scholar] [CrossRef]

- Zhang, S.; Wen, L.; Wang, H.; Zhu, K.; Zhang, M. Vertical CNT–Ecoflex nanofins for highly linear broad-range-detection wearable strain sensors. J. Mater. Chem. C 2018, 6, 5132–5139. [Google Scholar] [CrossRef]

- Yan, B.; Ding, H.; Zhang, Y.; Lin, P.; Wu, D.; Shi, Z.; Chen, X.; Tian, Y.; Li, X. Skin-attachable and flexible MWCNT grid/Ecoflex strain sensors with fast equilibrium of response for detection of sound vibrations and human motions. J. Mater. Sci. Mater. Electron. 2021, 32, 26439–26448. [Google Scholar] [CrossRef]

- Suzuki, K.; Yataka, K.; Okumiya, Y.; Sakakibara, S.; Sako, K.; Mimura, H.; Inoue, Y. Rapid-Response, Widely Stretchable Sensor of Aligned MWCNT/Elastomer Composites for Human Motion Detection. ACS Sens. 2016, 1, 817–825. [Google Scholar] [CrossRef]

- Jeong, S.-Y.; Lee, J.-U.; Hong, S.-M.; Lee, C.-W.; Hwang, S.-H.; Cho, S.-C.; Shin, B.-S. Highly Skin-Conformal Laser-Induced Graphene-Based Human Motion Monitoring Sensor. Nanomaterials 2021, 11, 951. [Google Scholar] [CrossRef]

- Gerasimenko, A.Y.; Kitsyuk, E.P.; Kuksin, A.V.; Ryazanov, R.M.; Savitskiy, A.I.; Savelyev, M.S.; Pavlov, A.A. Influence of laser structuring and barium nitrate treatment on morphology and electrophysical characteristics of vertically aligned carbon nanotube arrays. Diam. Relat. Mater. 2019, 96, 104–111. [Google Scholar] [CrossRef]

- Gerasimenko, A.; Kuksin, A.; Shaman, Y.; Kitsyuk, E.; Fedorova, Y.; Sysa, A.; Pavlov, A.; Glukhova, O. Electrically Conductive Networks from Hybrids of Carbon Nanotubes and Graphene Created by Laser Radiation. Nanomaterials 2021, 11, 1875. [Google Scholar] [CrossRef]

- Ichkitidze, L.P.; Gerasimenko, A.Y. Electrical Conductivity of the Nanocomposite Layers for Use in Biomedical Systems. Mater. Phys. Mech. 2018, 37, 140–145. [Google Scholar] [CrossRef]

- Gerasimenko, A.Y.; Kurilova, U.E.; Suetina, I.A.; Mezentseva, M.V.; Zubko, A.V.; Sekacheva, M.I.; Glukhova, O.E. Laser Technology for the Formation of Bioelectronic Nanocomposites Based on Single-Walled Carbon Nanotubes and Proteins with Different Structures, Electrical Conductivity and Biocompatibility. Appl. Sci. 2021, 11, 8036. [Google Scholar] [CrossRef]

- Gerasimenko, A.Y.; Kurilova, U.E.; Savelyev, M.S.; Murashko, D.T.; Glukhova, O.E. Laser fabrication of composite layers from biopolymers with branched 3D networks of single-walled carbon nanotubes for cardiovascular implants. Compos. Struct. 2021, 260, 113517. [Google Scholar] [CrossRef]

- Tereshchenko, S.A.; Lysenko, A.Y. Single-photon emission computed tomography in the scattering medium with the property of “scattering straight back”. J. Appl. Phys. 2021, 129, 035101. [Google Scholar] [CrossRef]

- Liu, Z.; Yuan, Y.; Shang, Y.; Han, W. Structural changes and electrical properties of nanowelded multiwalled carbon nanotube junctions. Appl. Opt. 2018, 57, 7435–7439. [Google Scholar] [CrossRef]

- Yao, Y.; Jiang, F.; Yang, C.; Fu, K.K.; Hayden, J.; Lin, C.-F.; Xie, H.; Jiao, M.; Yang, C.; Wang, Y.; et al. Epitaxial Welding of Carbon Nanotube Networks for Aqueous Battery Current Collectors. ACS Nano 2018, 12, 5266–5273. [Google Scholar] [CrossRef]

- Li, Z.; Sun, H.; Gao, C. Super structured Assembly of Nanocarbons: Fullerenes, Nanotubes, and Graphene. Chem. Rev. 2015, 115, 7046–7117. [Google Scholar] [CrossRef]

- Rao, R.; Pint, C.L.; Islam, A.E.; Weatherup, R.S.; Hofmann, S.; Meshot, E.R.; Wu, F.; Zhou, C.; Dee, N.; Amama, P.B.; et al. Carbon Nanotubes and Related Nanomaterials: Critical Advances and Challenges for Synthesis toward Mainstream Commercial Applications. ACS Nano 2018, 12, 11756–11784. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhangac, C.; Penga, Z.; Huanga, C.; Zhanga, B.; Xinga, C.; Chena, H.; Chengb, H.; Wanga, J.; Tangc, S. High-energy all-in-one stretchable micro-supercapacitor arrays based on 3D laser-induced graphene foams decorated with mesoporous ZnP nanosheets for self-powered stretchable systems. Nano Energy 2021, 81, 105609. [Google Scholar] [CrossRef]

- Unseld, S.; Baumer, A. Design and Analysis of a Hyperelastic Pneumatic Honeycomb Network Made of Ecoflex 00-35. In Proceedings of the COMSOL Conference 2020 Europe, Online, 14–15 October 2020. [Google Scholar]

- Huang, K.; Ning, H.; Hu, N.; Liu, F.; Wu, X.; Wang, S.; Liu, Y.; Zou, R.; Yuan, W.; Alamusi; et al. Ultrasensitive MWCNT/PDMS composite strain sensor fabricated by laser ablation process. Compos. Sci. Technol. 2020, 192, 108105. [Google Scholar] [CrossRef]

- De Vivo, B.; Lamberti, P.; Spinelli, G.; Tucci, V.; Vertuccio, L.; Vittoria, V. Simulation and experimental characterization of polymer/carbon nanotubes composites for strain sensor applications. J. Appl. Phys. 2014, 116, 54307. [Google Scholar] [CrossRef]

- Duan, L.; Fu, S.; Deng, H.; Zhang, Q.; Wang, K.; Chen, F.; Fu, Q. The resistivity–strain behavior of conductive polymer composites: Stability and sensitivity. J. Mater. Chem. A 2014, 2, 17085–17098. [Google Scholar] [CrossRef]

- Caradonna, A.; Badini, C.; Padovano, E.; Veca, A.; De Meo, E.; Pietroluongo, M. Laser Treatments for Improving Electrical Conductivity and Piezoresistive Behavior of Polymer–Carbon Nanofiller Composites. Micromachines 2019, 10, 63. [Google Scholar] [CrossRef] [Green Version]

- Amjadi, M.; Pichitpajongkit, A.; Lee, S.; Ryu, S.; Park, I. Highly Stretchable and Sensitive Strain Sensor Based on Silver Nanowire–Elastomer Nanocomposite. ACS Nano 2014, 8, 5154–5163. [Google Scholar] [CrossRef]

- Li, C.; Guan, G.; Reif, R.K.; Huang, Z.; Wang, R. Determining elastic properties of skin by measuring surface waves from an impulse mechanical stimulus using phase-sensitive optical coherence tomography. J. R. Soc. Interface 2012, 9, 831–841. [Google Scholar] [CrossRef] [PubMed]

- Karimov, K.S.; Khalid, F.A. Carbon nanotubes based flexible temperature sensors. Optoelectron. Adv. Mater. Rapid Commun. 2012, 6, 194–196. [Google Scholar]

- Gilshteyn, E.P.; Romanov, S.A.; Kopylova, D.S.; Savostyanov, G.V.; Anisimov, A.S.; Glukhova, O.E.; Nasibulin, A.G. Mechanically Tunable Single-Walled Carbon Nanotube Films as a Universal Material for Transparent and Stretchable Electronics. ACS Appl. Mater. Interfaces 2019, 11, 27327–27334. [Google Scholar] [CrossRef] [PubMed]

| Materials & Methods | ε, % | ΔR/R0 | GF | σ, MPa | E, kPa | Response Time, ms |

|---|---|---|---|---|---|---|

| CNT/Ecoflex, Transfer of an Array of Nanotubes [42] | 500 | <10 (Depending on the Height of the CNT Array) | 3–18 | Not Identified | Not Identified | Not Identified |

| MWCNT/Ecoflex, CNT Deposition [43] | 300 | 4 (ε = 80%); 0.45 θ = 90° | 2.1 | Not Identified | Not Identified | 274 |

| MWCNT/Ecoflex, CNT Deposition [37] | 750 | 0.5 (ε = 100%) | 0.65 (ε = 0–400%); 48 (ε = 400–700%) | Not Identified | Not Identified | Not Identified |

| MWCNT/Ecoflex, Screen Printing [36] | 200 | <0.5 (ε = 100%) | <0.4 | 0.82 ± 0.12 | 200 | 1.16 |

| CNT/Rubber, Dry Spinning [44] | 500 | Not Identified | 10.5 | Not Identified | 2000–5000 | 15 |

| PSPI/PDMS, LIG [45] | 125 | Not Identified | 380 (ε = 115–120%) | Not Identified | Not Identified | 90 |

| MWCNT/Ecoflex, Laser Structuring (This Work) | 725 | 7 (ε = 100%) | 7 (ε = 100%) | 0.7 | 46 | 1 |

| Symbol | Meaning |

|---|---|

| GFl | Tensile Gauge Factor |

| ΔR | Absolute Change in Resistance |

| R0 | Initial Resistance Value |

| ΔR/R0 | Relative Change in Resistance |

| Ɛ | Relative Change in Length |

| dA/A0 | Relative Change in Cross-Sectional Area |

| υ | Poisson’s Ratio |

| Δp/p | Relative Change in Resistivity |

| GFlp | Stretching Gauge Factor |

| GFθ | Bending Gauge Factor |

| θ | Angle |

| h(%) | Hysteresis |

| Rt | Tensile Resistance |

| Rc | Compressive Resistance |

| Rmax | Maximum Resistance |

| E | Elastic Modulus |

| F | Applied Force |

| l0 | Initial Sample Length |

| S | Surface Area to Which Force Was Applied |

| ∆l | Elongation of Sample Due to Force Application |

| σ | Ultimate Strength |

| Fm | Maximum Load Applied to the Sample |

| A0 | Initial Cross-Sectional Area of Sample |

| λ | Temperature Coefficient |

| ΔT | Absolute Temperature Change |

| MWCNT Concentration, wt.% | Resistance, Ohm |

|---|---|

| 2% | 500 |

| 3% | 150 |

| 4% | 100 |

| 2% + L | 100 |

| 3% + L | 40 |

| 4% + L | 0.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Demidenko, N.A.; Kuksin, A.V.; Molodykh, V.V.; Pyankov, E.S.; Ichkitidze, L.P.; Zaborova, V.A.; Tsymbal, A.A.; Tkachenko, S.A.; Shafaei, H.; Diachkova, E.; et al. Flexible Strain-Sensitive Silicone-CNT Sensor for Human Motion Detection. Bioengineering 2022, 9, 36. https://doi.org/10.3390/bioengineering9010036

Demidenko NA, Kuksin AV, Molodykh VV, Pyankov ES, Ichkitidze LP, Zaborova VA, Tsymbal AA, Tkachenko SA, Shafaei H, Diachkova E, et al. Flexible Strain-Sensitive Silicone-CNT Sensor for Human Motion Detection. Bioengineering. 2022; 9(1):36. https://doi.org/10.3390/bioengineering9010036

Chicago/Turabian StyleDemidenko, Natalia A., Artem V. Kuksin, Victoria V. Molodykh, Evgeny S. Pyankov, Levan P. Ichkitidze, Victoria A. Zaborova, Alexandr A. Tsymbal, Svetlana A. Tkachenko, Hassan Shafaei, Ekaterina Diachkova, and et al. 2022. "Flexible Strain-Sensitive Silicone-CNT Sensor for Human Motion Detection" Bioengineering 9, no. 1: 36. https://doi.org/10.3390/bioengineering9010036

APA StyleDemidenko, N. A., Kuksin, A. V., Molodykh, V. V., Pyankov, E. S., Ichkitidze, L. P., Zaborova, V. A., Tsymbal, A. A., Tkachenko, S. A., Shafaei, H., Diachkova, E., & Gerasimenko, A. Y. (2022). Flexible Strain-Sensitive Silicone-CNT Sensor for Human Motion Detection. Bioengineering, 9(1), 36. https://doi.org/10.3390/bioengineering9010036

.jpg)