Preparation and Evaluation of Virgin Olive Oil Oleogels Including Thyme and Cumin Spices with Sunflower Wax

Abstract

:1. Introduction

2. Results and Discussion

2.1. Physico-Chemical Properties

2.2. Structural Properties

2.3. Thermal Properties

2.4. Rheological Properties

2.5. Volatile Aromatics Composition of the Oleogels

2.6. Descriptive Sensory Analysis

2.7. Consumer Test

3. Conclusions

4. Materials and Methods

4.1. Materials

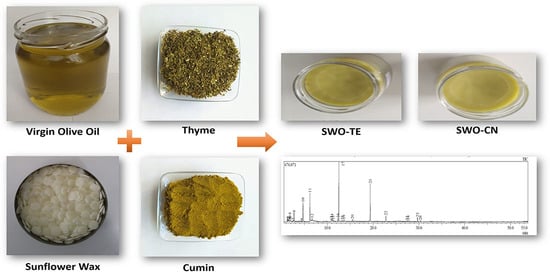

4.2. Preparation of the Oleogels

4.3. Physico-Chemical Analyses of the Oleogels

4.4. X-ray Diffraction Patterns of the Oleogels

4.5. Thermal Analyses of the Oleogels

4.6. Rheological Analyses of the Oleogels

4.7. Volatile Compound Analysis of the Oleogels

4.8. Descriptive Sensory Analysis of the Oleogels

4.9. Consumer Tests of the Oleogels

4.10. Statistical Analysis

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Boskou, D. Olive Oil: Chemistry and Technology; AOCS Press: Champaign, IL, USA, 1996; pp. 1–161. [Google Scholar]

- Jimenez-Lopez, C.; Carpena, M.; Lourenço-Lopes, C.; Gallardo-Gomez, M.; Lorenzo, J.M.; Barba, F.J.; Prieto, M.A.; Simal-Gandara, J. Bioactive compounds and quality of extra virgin olive oil. Foods 2020, 9, 1014–1045. [Google Scholar] [CrossRef]

- Al-Asmari, K.M.; Al-Attar, A.M.; Abu Zeid, I.M. Potential health benefits and components of olive oil: An overview. Biosci. Res. 2020, 17, 2673–2687. [Google Scholar]

- Ozturk, M.; Altay, V.; Gönenç, T.M.; Unal, B.T.; Efe, R.; Akçiçek, E.; Bukhari, A. An overview of olive cultivation in turkey: Botanical features, eco-physiology and phytochemical aspects. Agronomy 2021, 11, 295–321. [Google Scholar] [CrossRef]

- Öğütcü, M.; Yılmaz, E. Oleogels of virgin olive oil with carnauba wax and monoglyceride as spreadable products. Grasas y Aceites 2014, 65, e040. [Google Scholar] [CrossRef] [Green Version]

- Yılmaz, E.; Öğütcü, M. Comparative analysis of olive oil organogels containing beeswax and sunflower wax with breakfast margarine. J. Food Sci. 2014, 79, E1732–E1738. [Google Scholar] [CrossRef]

- Yılmaz, E.; Öğütcü, M. Oleogels as spreadable fat and butter alternatives: Sensory description and consumer perception. RSC Adv. 2015, 5, 50259–50267. [Google Scholar] [CrossRef]

- Sharifi, M.; Goli, S.A.H.; Fayaz, G. Exploitation of high-intensity ultrasound to modify the structure of olive oil organogel containing propolis wax. Int. J. Food Sci. Technol. 2019, 54, 509–515. [Google Scholar] [CrossRef]

- Papadaki, A.; Kopsahelis, N.; Freire, D.M.G.; Mandala, I.; Koutinas, A.A. Olive oil oleogel formulation using wax esters derived from soybean fatty acid distillate. Biomolecules 2020, 10, 106–115. [Google Scholar] [CrossRef] [Green Version]

- Mattice, K.D.; Marangoni, A.G. New insights into wax crystal networks in oleogels. In Edible Oil Structuring: Concept, Methods and Applications, 1st ed.; Patel, A.R., Ed.; Royal Soc, Chem: Chambridge, UK, 2018; pp. 71–94. [Google Scholar]

- Pan, J.; Tang, L.; Dong, Q.; Li, Y.; Zhang, H. Effect of oleogelation on physical properties and oxidative stability of camellia oil-based oleogels and oleogel emulsions. Food Res. Int. 2021, 140, 110057. [Google Scholar] [CrossRef]

- Sharfe, M.; Flöter, E. Oleogelation: From scientific feasibility to applicability in food products. Eur. J. Lipid Sci. Technol. 2020, 122, 2000213. [Google Scholar] [CrossRef]

- Yılmaz, E.; Keskin Uslu, E.; Öz, C. Oleogels of some plant waxes: Characterization and comparison with sunflower wax oleogel. J. Amer. Oil Chem. Soc. 2021, 98, 643–655. [Google Scholar] [CrossRef]

- ISO. Animal and Vegetable Fats and Oils—Determination of Solid Fat Content by Pulsed NMR; ISO: Geneva, Switzerland, 2012. [Google Scholar]

- Öğütcü, M.; Yılmaz, E.; Güneser, O. Influence of storage on physicochemical and volatile features of enriched and aromatized wax organogels. J. Am. Oil Chem. Soc. 2015, 92, 1429–1443. [Google Scholar] [CrossRef]

- Chrysam, M.M. Margarines and spreads. In Bailey’s Industrial Oil Fat Products; Hui, Y.H., Ed.; Wiley-Intersience Pub.: New York, NY, USA, 1996. [Google Scholar]

- Codex. Turkish Food Codex for Olive Oil and Olive Pomace Oil (Codex No: 2017/26); Ministry of Agriculture: Ankara, Turkey, 2017.

- EC. Council of the European Union. Council Regulation (EC) No 1234/2007 of 22 October 2007 establishing a common organisation of agricultural markets and on specific provisions for certain agricultural products (Single CMO Regulation). Off. J. Eur. Union 2007, 299, 1–149. [Google Scholar]

- AOCS Official Method Cj 2-95. X-Ray Diffraction Analysis of Fats. Official Methods and Recommended Practices of the AOCS, 6th ed.; 2011–2012 Methods and Additions and Revisions; AOCS Press: Champaign, IL, USA, 2009. [Google Scholar]

- Yılmaz, E.; Keskin Uslu, E.; Toksöz, B. Structure, rheological and sensory properties of some animal wax based oleogels. J. Oleo Sci. 2020, 69, 1317–1329. [Google Scholar] [CrossRef] [PubMed]

- Mezger, T.G. Applied Rheology, 1st ed.; Anton Paar GmbH: Graz, Austria, 2014; pp. 1–192. [Google Scholar]

- Cecchi, L.; Migliorini, M.; Mulinacci, N. Virgin olive oil volatile compounds: Composition, sensory characteristics, analytical approaches, quality control, and authentication. J. Agric. Food Chem. 2021, 69, 2013–2040. [Google Scholar] [CrossRef]

- Venskutonis, P.R. Effect of drying on the volatile constituents of thyme (Thymus vulgaris L.) and sage (Salvia oficinalis L.). Food Chem. 1997, 59, 219–227. [Google Scholar] [CrossRef]

- Asadollahi-Baboli, M.; Aghakhani, A.; Bikdeloo, V. Application of polyamide nanofibers, SPME/GC-MS, and chemometrics for comprehensive analysis of volatiles in Thymus vulgaris L. and Thymus serpyllum L. Food Anal. Methods 2016, 9, 528–536. [Google Scholar] [CrossRef]

- Sowbhagya, H.B.; Srinivas, P.; Purnima, K.T.; Krishnamurty, N. Enzyme-assisted extraction of volatiles from cumin (Cuminum cyminum L.) seeds. Food Chem. 2011, 127, 1856–1861. [Google Scholar] [CrossRef]

- Sharma, L.K.; Agarwal, D.; Rathore, S.S.; Malhotra, S.K.; Saxena, S.N. Effect of cryogenic grinding on volatile and fatty oil constituents of cumin (Cuminum cyminum L.) genotypes. J. Food Sci. Technol. 2016, 53, 2827–2834. [Google Scholar] [CrossRef] [Green Version]

- Meilgaard, M.; Civille, G.V.; Carr, B.T. Sensory Evaluation Techniques, 2nd ed; CRC Press: Boca Raton, FL, USA, 1991; pp. 1–354. [Google Scholar]

- AOCS. Official Methods and Practices of the American Oil Chemists’ Society, 5th ed; AOCS Press: Champaign, IL, USA, 1998. [Google Scholar]

- Krist, S.; Stuebiger, G.; Bail, S.; Unterweger, H. Detection of adulteration of poppy seed oil with sunflower oil based on volatiles and triacylglycerol composition. J. Agric. Food Chem. 2006, 54, 6385–6389. [Google Scholar] [CrossRef]

- Yılmaz, E. Valorization of capia pepperseed flour in breakfast sauce production. Waste Biomass Valor. 2020, 11, 6803–6813. [Google Scholar] [CrossRef]

- Minitab. Minitab Statistical Software (Version 16.1); Minitab, Inc.: State College, PA, USA, 2010. [Google Scholar]

| SWO-TE | SWO-CN | |

|---|---|---|

| Gelation Time (min) | 0.75 ± 0.0 b,† | 1.00 ± 0.0 a |

| Oil Binding Capacity (%) | 99.99 ± 0.2 a | 99.99 ± 0.0 a |

| Centrifuge Stability | Stable | Stable |

| Solid Fat Index (20 °C, %) | 4.33 ± 0.5 a | 4.30 ± 0.2 a |

| Color L value | 50.88 ± 0.8 b | 66.35 ± 0.2 a |

| Color a* value | 5.38 ± 0.1 b | 7.03 ± 0.2 a |

| Color b* value | 22.82 ± 0.5 b | 31.27 ± 0.4 a |

| Peroxide Value (meq O2/kg) | 16.76 ± 1.5 a | 12.48 ± 0.7 b |

| Free Fatty Acidity (oleic %) | 2.14 ± 0.1 a | 1.95 ± 0.0 b |

| Crystallization | |||

|---|---|---|---|

| Onsetc (°C) | Peak (Tc, °C) | ΔHc (J/g) | |

| SWO-TE | 61.37 ± 0.26 a† | 59.54 ± 0.14 a | −11.44 ± 0.2 a |

| SWO-CN | 60.55 ± 0.04 b | 58.72 ± 0.10 b | −8.58 ± 0.4 b |

| Melting | |||

| Onsetm (°C) | Peak (Tc, °C) | ΔHc (J/g) | |

| SWO-TE | 48.41 ± 0.36 a | 62.53 ± 0.28 a | 13.64 ± 0.12 a |

| SWO-CN | 53.51 ± 0.53 b | 62.83 ± 0.39 a | 12.73 ± 0.11 a |

| SWO-TE | SWO-CN | |||||

|---|---|---|---|---|---|---|

| RT † (min) | Volatile Compound | Aroma Definition †† | Mean Peak Area | Peak Value (%) | Mean Peak Area | Peak Value (%) |

| 1.377 | Ethanol | Strong alcoholic, ethereal, medical | 54,150 ± 1200 | 0.95 | 86,014 ±1455 | 1.50 |

| 1.452 | 1-Propen-2-ol, acetate | Ethereal, acetic, fruity, sweet berry | 38,346 ± 975 | 0.67 | 49,176 ± 1005 | 0.85 |

| 1.537 | Acetol | Pungent, sweet caramellic, ethereal | 62,931 ± 1150 | 1.10 | Nd. | Nd. |

| 1.538 | Methyl acetate | Green, ethereal, fruity, fresh, rum and whiskey-like | Nd. | Nd. | 56,446 ± 3100 | 0.98 |

| 1.798 | Acetic acid | Sharp, pungent, sour vinegar | 178,460 ± 11,845 | 3.13 | 159,524 ± 8900 | 2.77 |

| 1.920 | Ethyl acetate | Ethereal, fruity, sweet, weedy green | 45,398 ± 2187 | 0.80 | 59,232 ± 1838 | 1.03 |

| 2.565 | 1-Penten-3-ol | Horseradish, tropical fruity | 46,779 ± 2400 | 0.82 | 44,253 ± 2450 | 0.77 |

| 2.716 | Diethyl ketone | Ethereal acetone | 237,320 ± 3612 | 4.16 | Nd. | Nd. |

| 4.679 | Hexanal | Fresh green, fatty, aldehydic, grass, leafy fruity, sweaty | 443,159 ± 1560 | 7.77 | 339,392 ± 1365 | 5.90 |

| 6.174 | (E)-2-Hexenal | Fresh green, leafy, fruity with rich vegetative nuances | 756,741 ± 1200 | 13.27 | 512,621 ± 6845 | 8.91 |

| 6.645 | 2-Hexen-1-ol, (Z)- | Fresh vegetative, slightly fatty with a green bean note | 91,771 ± 3150 | 1.61 | Nd. | Nd. |

| 10.339 | beta-Phellandrene | Mint terpentine | Nd. | Nd. | 36,041 ± 855 | 0.63 |

| 10.489 | beta- Pinene | Herbal, terpenic | Nd. | Nd. | 75,343 ± 505 | 1.31 |

| 10.865 | 6-Methyl-5-hepten-2-one | Citrus, green, musty, apple | 67,412 ± 2007 | 1.18 | Nd. | Nd. |

| 11.020 | Geranyl butyrate | Sweet fruity, rose, waxy, raspberry | 79,389 ± 3860 | 1.39 | Nd. | Nd. |

| 11.022 | beta-Myrcene | Spicy | Nd. | Nd. | 90,276 ± 1286 | 1.57 |

| 11.610 | l-Phellandrene | Minty | Nd. | Nd. | 45,754 ± 575 | 0.80 |

| 11.708 | delta-3-Carene | Citrus, terpenic, herbal, medicinal | Nd. | Nd. | 77,918 ± 860 | 1.35 |

| 12.318 | Cymol | Terpenic | 99,598 ± 555 | 1.75 | 449,216 ± 1258 | 7.81 |

| 12.505 | Limonene | Terpene, pine, herbal, peppery | 1,690,329 ± 18,525 | 29.65 | 1,319,846 ± 18,555 | 22.94 |

| 13.220 | beta-Ocimene | Citrus, tropical, green, terpene, woody | 37,854 ± 3150 | 0.66 | Nd. | Nd. |

| 13.645 | gamma-Terpinene | Terpy, citrus, lime-like, oily, green | 60,257 ± 1100 | 1.06 | 803,955 ± 7500 | 13.98 |

| 15.494 | Nonanal | Effervescent, aldehydic citrus, cucumber and melon rindy | 69,958 ± 3154 | 1.23 | 26,362 ± 745 | 0.46 |

| 20.662 | Propanal, 2-methyl-3-phenyl- | Aldehydic | Nd. | Nd. | 386,598 ± 1008 | 6.72 |

| 22.281 | 2-Caren-10-Al | Citrus | Nd. | Nd. | 112,619 | 1.96 |

| 22.785 | Carvacrol | Spicy, herbal, phenolic, medicinal and woody | 183,194 ± 2500 | 3.21 | Nd. | Nd. |

| 27.392 | Bergamotene <alpha-trans-> | Woody | 28,178 ± 269 | 0.49 | Nd. | Nd. |

| 27.629 | Cedrene <beta-> | Cedarwood woody | 45,190 ± 3180 | 0.79 | Nd. | Nd. |

| 29.701 | Farnesene | Woody | 137,168 ± 12,456 | 2.41 | 66,899 ± 3820 | 1.16 |

| 30.311 | Sesquiphellandrene <beta-> | Sweet, fruity, herbal | 51,413 ± 1873 | 0.99 | Nd. | Nd. |

| SWO-TE | SWO-CN | |

|---|---|---|

| Hardness | 8.15 ± 0.5 a,† | 8.25 ± 0.3 a |

| Spreadability | 10.00 ± 0.0 a | 10.00 ± 0.0 a |

| Liquefaction | 0.55 ± 0.0 a | 0.50 ± 0.0 a |

| Sandiness | 1.00 ± 0.0 a | 1.00 ± 0.0 a |

| Olive fruit | 4.20 ± 0.5 a | 4.00 ± 0.5 b |

| Grassy | 5.15 ± 0.2 b | 7.00 ± 0.2 a |

| Waxy | 0.50 ± 0.0 a | 0.50 ± 0.0 a |

| Rancid | 0.52 ± 0.3 a | 0.50 ± 0.3 a |

| Thyme | 5.23 ± 0.5 a | 0.00 ± 0.0 b |

| Cumin | 0.00 ± 0.0 b | 3.00 ± 0.0 a |

| Hay | 1.00 ± 0.0 a | 1.05 ± 0.0 a |

| Cooling | 2.05 ± 0.1 b | 2.55 ± 0.2 a |

| Mouth coating | 7.45 ± 0.4 a | 7.00 ± 0.4 a |

| SWO-TE | SWO-CN | |

|---|---|---|

| Appearance | 4.30 ± 0.7 a,† | 4.04 ± 0.8 a |

| Spreadability | 4.40 ± 0.7 a | 4.14 ± 0.8 a |

| Aroma | 4.18 ± 0.8 a | 4.18 ± 0.8 a |

| Flavor | 4.36 ± 0.8 a | 4.24 ± 0.8 a |

| Acceptability | 4.26 ± 0.7 a | 4.16 ± 0.7 a |

| Definition | References | |

|---|---|---|

| Hardness | Force required to push a knife into the sample | Min: Yoghurt, Max: Tallow |

| Spreadability | Easiness of deploying sample over a bread loaf | Min: Chewing gum, Max: Cream cheese |

| Liquefaction | Amount of fat melting after the sample was spread on bread surface | Min: Tallow, Max: Olive oil |

| Sandiness | The perceived gritty texture on tongue | Min: Absent, Max: Semolina |

| Olive fruit | The flavor and aroma of fresh green olives | Min: Absent, Max: Green olive |

| Grassy | The aroma of fresh cut grasses | Min: Absent, Max: Cut grass |

| Waxy | Aromas associated with waxes | Min: Absent, Max: Paraffin wax |

| Rancid | Aromas associated with oxidized oil | Min: Absent, Max: Used frying oil |

| Thyme | Aromas associated with thyme spice | Min: Absent, Max: Ground thyme |

| Cumin | Aromas associated with cumin spice | Min: Absent, Max: Ground cumin |

| Hay | The aromatics associated with sweet, dry grasses | Min: Absent, Max: Dry hay |

| Cooling | Cold feeling inside mouth | Min: Absent, Max: Menthol candy |

| Mouth coating | The perceived fatty coating inside mouth space | Min: liquid oil, Max: Butter |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yilmaz, E.; Demirci, Ş. Preparation and Evaluation of Virgin Olive Oil Oleogels Including Thyme and Cumin Spices with Sunflower Wax. Gels 2021, 7, 95. https://doi.org/10.3390/gels7030095

Yilmaz E, Demirci Ş. Preparation and Evaluation of Virgin Olive Oil Oleogels Including Thyme and Cumin Spices with Sunflower Wax. Gels. 2021; 7(3):95. https://doi.org/10.3390/gels7030095

Chicago/Turabian StyleYilmaz, Emin, and Şahin Demirci. 2021. "Preparation and Evaluation of Virgin Olive Oil Oleogels Including Thyme and Cumin Spices with Sunflower Wax" Gels 7, no. 3: 95. https://doi.org/10.3390/gels7030095

APA StyleYilmaz, E., & Demirci, Ş. (2021). Preparation and Evaluation of Virgin Olive Oil Oleogels Including Thyme and Cumin Spices with Sunflower Wax. Gels, 7(3), 95. https://doi.org/10.3390/gels7030095