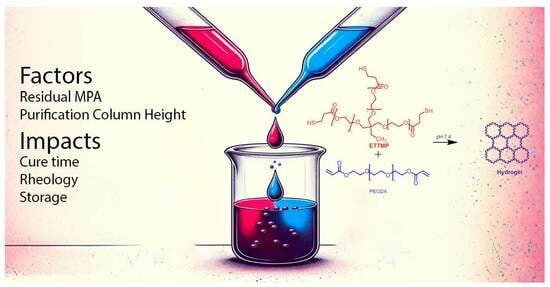

Factors That Influence Base-Catalyzed Thiol-Ene Hydrogel Synthesis

Abstract

:1. Introduction

1.1. Injectable Hydrogels for Drug Delivery

1.2. ETTMP-PEGDA Hydrogels

2. Results and Discussion

2.1. Premixing ETTMP-PEGDA Improves Aqueous Solubility and Enables Hydrogel Compositions over a Large Range

2.2. Sensitivity Analysis of the Experimental Conditions’ Effects on the Rheological Properties of Hydrogels

2.2.1. Purification Column Height Controls the Final Gelation Time

2.2.2. Buffer pH Is Another Parameter to Control Gelation Time

2.2.3. Vortex Mixing Results in Faster Gelation Times When Compared to Hand Mixing

2.3. ETTMP-PEGDA Can Be Stored Frozen for Longer Than Two Months without Changes to Gelation Time

3. Conclusions

4. Materials and Methods

4.1. Materials

4.2. Instrumentation

4.3. ETTMP and PEGDA Hydrogel Precursor Purification

4.4. Hydrogel Synthesis

4.5. Determining Mercaptopropionic Acid Concentration in ETTMP

4.6. Quantifying the Changes in Local pH Due to Mercaptopropionic Acid

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ahmed, E.M. Hydrogel: Preparation, characterization, and applications: A review. J. Adv. Res. 2015, 6, 105–121. [Google Scholar] [CrossRef] [PubMed]

- Correa, S.; Grosskopf, A.K.; Hernandez, H.L.; Chan, D.; Yu, A.C.; Stapleton, L.M.; Appel, E.A. Translational Applications of Hydrogels. Chem. Rev. 2021, 121, 11385–11457. [Google Scholar] [CrossRef] [PubMed]

- De Souza, R.; Zahedi, P.; Allen, C.J.; Piquette-Miller, M. Polymeric drug delivery systems for localized cancer chemotherapy. Drug Deliv. 2010, 17, 365–375. [Google Scholar] [CrossRef] [PubMed]

- Dai, S.; Ravi, P.; Tam, K.C. pH-Responsive polymers: Synthesis, properties and applications. Soft Matter 2008, 4, 435–449. [Google Scholar] [CrossRef]

- Liu, R.; Zuo, R.; Hudalla, G.A. Harnessing molecular recognition for localized drug delivery. Adv. Drug Deliv. Rev. 2021, 170, 238–260. [Google Scholar] [CrossRef]

- Giuri, D.; Barbalinardo, M.; Zanna, N.; Paci, P.; Montalti, M.; Cavallini, M.; Valle, F.; Calvaresi, M.; Tomasini, C. Tuning mechanical properties of pseudopeptide supramolecular hydrogels by graphene doping. Molecules 2019, 24, 4345. [Google Scholar] [CrossRef]

- Adorinni, S.; Rozhin, P.; Marchesan, S. Smart hydrogels meet carbon nanomaterials for new frontiers in medicine. Biomedicines 2021, 9, 570. [Google Scholar] [CrossRef]

- Khan, Z.M.; Munson, J.M.; Long, T.E.; Vlaisavljevich, E.; Verbridge, S.S. Development of a Synthetic, Injectable Hydrogel to Capture Residual Glioblastoma and Glioblastoma Stem-Like Cells with CXCL12-Mediated Chemotaxis. Adv. Healthc. Mater. 2023, 12, 2300671. [Google Scholar] [CrossRef]

- Patel, D.K.; Jung, E.; Priya, S.; Won, S.-Y.; Han, S.S. Recent advances in biopolymer-based hydrogels and their potential biomedical applications. Carbohydr. Polym. 2023, 323, 121408. [Google Scholar] [CrossRef]

- Khalili, M.H.; Williams, C.J.; Micallef, C.; Duarte-Martinez, F.; Afsar, A.; Zhang, R.; Wilson, S.; Dossi, E.; Impey, S.A.; Goel, S.; et al. Nanoindentation Response of 3D Printed PEGDA Hydrogels in a Hydrated Environment. ACS Appl. Polym. Mater. 2023, 5, 1180–1190. [Google Scholar] [CrossRef]

- Rosa, E.; Gallo, E.; Sibillano, T.; Giannini, C.; Rizzuti, S.; Gianolio, E.; Scognamiglio, P.L.; Morelli, G.; Accardo, A.; Diaferia, C. Incorporation of PEG Diacrylates (PEGDA) Generates Hybrid Fmoc-FF Hydrogel Matrices. Gels 2022, 8, 831. [Google Scholar] [CrossRef]

- Van Vlierberghe, S.; Dubruel, P.; Schacht, E. Biopolymer-based hydrogels as scaffolds for tissue engineering applications: A review. Biomacromolecules 2011, 12, 1387–1408. [Google Scholar] [CrossRef]

- Lee, K.Y.; Bouhadir, K.H.; Mooney, D.J. Controlled degradation of hydrogels using multi-functional cross-linking molecules. Biomaterials 2004, 25, 2461–2466. [Google Scholar] [CrossRef] [PubMed]

- Overstreet, D.J.; Dutta, D.; Stabenfeldt, S.E.; Vernon, B.L. Injectable hydrogels. J. Polym. Sci. Part B Polym. Phys. 2012, 50, 881–903. [Google Scholar] [CrossRef]

- Hoffman, A.S. Hydrogels for biomedical applications. Adv. Drug Deliv. Rev. 2002, 54, 3–12. [Google Scholar] [CrossRef] [PubMed]

- Peppas, N.A. Hydrogels and drug delivery. Curr. Opin. Colloid Interface Sci. 1997, 2, 531–537. [Google Scholar] [CrossRef]

- Lin, C.-C.; Metters, A.T. Hydrogels in controlled release formulations: Network design and mathematical modeling. Adv. Drug Deliv. Rev. 2006, 58, 1379–1408. [Google Scholar] [CrossRef]

- Metters, A.; Hubbell, J. Network formation and degradation behavior of hydrogels formed by michael-type addition reactions. Biomacromolecules 2004, 6, 290–301. [Google Scholar] [CrossRef]

- Hiemstra, C.; van der Aa, L.J.; Zhong, Z.; Dijkstra, P.J.; Feijen, J. Rapidly in situ-forming degradable hydrogels from dextran thiols through michael addition. Biomacromolecules 2007, 8, 1548–1556. [Google Scholar] [CrossRef]

- Norouzi, M.; Nazari, B.; Miller, D.W. Injectable hydrogel-based drug delivery systems for local cancer therapy. Drug Discov. Today 2016, 21, 1835–1849. [Google Scholar] [CrossRef]

- Kharkar, P.M.; Rehmann, M.S.; Skeens, K.M.; Maverakis, E.; Kloxin, A.M. Thiol–ene click hydrogels for therapeutic delivery. ACS Biomater. Sci. Eng. 2016, 2, 165–179. [Google Scholar] [CrossRef] [PubMed]

- Slotkin, J.R.; Ness, J.K.; Snyder, K.M.; Skiles, A.A.; Woodard, E.J.; O’Shea, T.; Layer, R.T.; Aimetti, A.A.; Toms, S.A.; Langer, R. Sustained local release of methylprednisolone from a thiol-acrylate poly (ethylene glycol) hydrogel for treating chronic compressive radicular pain. Spine 2016, 41, E441–E448. [Google Scholar] [CrossRef] [PubMed]

- Raman, T.; Kuehnert, M.; Daikos, O.; Scherzer, T.; Krömmelbein, C.; Mayr, S.G.; Abel, B.; Schulze, A. A study on the material properties of novel PEGDA/gelatin hybrid hydrogels polymerized by electron beam irradiation. Front. Chem. 2023, 10, 1094981. [Google Scholar] [CrossRef] [PubMed]

- Northrop, B.H.; Coffey, R.N. Thiol–ene click chemistry: Computational and kinetic analysis of the influence of alkene functionality. J. Am. Chem. Soc. 2012, 134, 13804–13817. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, K.T.; West, J.L. Photopolymerizable hydrogels for tissue engineering applications. Biomaterials 2002, 23, 4307–4314. [Google Scholar] [CrossRef] [PubMed]

- Lin-Gibson, S.; Bencherif, S.; Cooper, J.A.; Wetzel, S.J.; Antonucci, J.M.; Vogel, B.M.; Horkay, F.; Washburn, N.R. Synthesis and characterization of PEG dimethacrylates and their hydrogels. Biomacromolecules 2004, 5, 1280–1287. [Google Scholar] [CrossRef]

- Peppas, N.A.; Keys, K.B.; Torres-Lugo, M.; Lowman, A.M. Poly(ethylene glycol)-containing hydrogels in drug delivery. J. Control. Release 1999, 62, 81–87. [Google Scholar] [CrossRef]

- Maitra, J.; Shukla, V.K. Cross-linking in hydrogels-a review. Am. J. Polym. Sci. 2014, 4, 25–31. [Google Scholar]

- Mann, B.K.; Gobin, A.S.; Tsai, A.T.; Schmedlen, R.H.; West, J.L. Smooth muscle cell growth in photopolymerized hydrogels with cell adhesive and proteolytically degradable domains: Synthetic ECM analogs for tissue engineering. Biomaterials 2001, 22, 3045–3051. [Google Scholar] [CrossRef]

- Lu, S.; Ramirez, W.F.; Anseth, K.S. Photopolymerized, multilaminated matrix devices with optimized nonuniform initial concentration profiles to control drug release. J. Pharm. Sci. 2000, 89, 45–51. [Google Scholar] [CrossRef]

- Jiang, Y.; Chen, J.; Deng, C.; Suuronen, E.J.; Zhong, Z. Click hydrogels, microgels and nanogels: Emerging platforms for drug delivery and tissue engineering. Biomaterials 2014, 35, 4969–4985. [Google Scholar] [CrossRef] [PubMed]

- Rockwell, P.N.; Maneval, J.E.; Vogel, B.M.; Jablonski, E.L. Water Diffusion and Uptake in Injectable ETTMP/PEGDA Hydrogels. J. Phys. Chem. B 2023, 127, 5055–5061. [Google Scholar] [CrossRef] [PubMed]

- Shih, H.; Lin, C. Cross-linking and degradation of step-growth hydrogels formed by thiol–ene photoclick chemistry. Biomacromolecules 2012, 13, 2003–2012. [Google Scholar] [CrossRef] [PubMed]

- Lin, C.-C.; Raza, A.; Shih, H. PEG hydrogels formed by thiol-ene photo-click chemistry and their effect on the formation and recovery of insulin-secreting cell spheroids. Biomaterials 2011, 32, 9685–9695. [Google Scholar] [CrossRef]

- Nair, D.P.; Podgórski, M.; Chatani, S.; Gong, T.; Xi, W.; Fenoli, C.R.; Bowman, C.N. The Thiol-Michael Addition Click Reaction: A Powerful and Widely Used Tool in Materials Chemistry. Chem. Mater. 2014, 26, 724–744. [Google Scholar] [CrossRef]

- Pritchard, C.D.; O’shea, T.M.; Siegwart, D.J.; Calo, E.; Anderson, D.G.; Reynolds, F.M.; Thomas, J.A.; Slotkin, J.R.; Woodard, E.J.; Langer, R. An injectable thiol-acrylate poly(ethylene glycol) hydrogel for sustained release of methylprednisolone sodium succinate. Biomaterials 2011, 32, 587–597. [Google Scholar] [CrossRef]

- Browning, M.B.; Cereceres, S.N.; Luong, P.T.; Cosgriff-Hernandez, E.M. Determination of the in vivo degradation mechanism of PEGDA hydrogels. J. Biomed. Mater. Res. Part A 2014, 102, 4244–4251. [Google Scholar]

- O’Shea, T.M.; Aimetti, A.A.; Kim, E.; Yesilyurt, V.; Langer, R. Synthesis and characterization of a library of in-situ curing, nonswelling ethoxylated polyol thiol-ene hydrogels for tailorable macromolecule delivery. Adv. Mater. 2014, 27, 65–72. [Google Scholar] [CrossRef]

- Mather, B.D.; Viswanathan, K.; Miller, K.M.; Long, T.E. Michael addition reactions in macromolecular design for emerging technologies. Prog. Polym. Sci. 2006, 31, 487–531. [Google Scholar] [CrossRef]

- Khan, A.H.; Cook, J.K.; Wortmann, I.I.I.W.J.; Kersker, N.D.; Rao, A.; Pojman, J.A.; Melvin, A.T. Synthesis and characterization of thiol-acrylate hydrogels using a base-catalyzed Michael addition for 3D cell culture applications. J. Biomed. Mater. Res. Part B Appl. Biomater. 2020, 108, 2294–2307. [Google Scholar] [CrossRef]

- Moon, N.G.; Pekkanen, A.M.; Long, T.E.; Showalter, T.N.; Libby, B. Thiol-Michael ‘click’hydrogels as an imageable packing material for cancer therapy. Polymer 2017, 125, 66–75. [Google Scholar] [CrossRef]

- Cheng, S.Z.D.; Wu, S.S.; Chen, J.; Zhuo, Q.; Quirk, R.P.; von Meerwall, E.D.; Hsiao, B.S.; Habenschuss, A.; Zschack, P.R. Isothermal thickening and thinning processes in low-molecular-weight poly(ethylene oxide) fractions crystallized from the melt. 4. End-group dependence. Macromolecules 1993, 26, 5105–5117. [Google Scholar] [CrossRef]

- Sirisinha, K.; Boonkongkaew, M.; Kositchaiyong, S. The effect of silane carriers on silane grafting of high-density polyethylene and properties of crosslinked products. Polym. Test. 2010, 29, 958–965. [Google Scholar] [CrossRef]

- Li, J.; Mooney, D.J. Designing hydrogels for controlled drug delivery. Nat. Rev. Mater. 2016, 1, 16071. [Google Scholar] [CrossRef] [PubMed]

| Polymer Concentration (wt%) | Gelation Time (min) | Crosslink Density (mol/m3) | Mesh Size (nm) | G′ (kPa) | G″ (kPa) | Tan δ |

|---|---|---|---|---|---|---|

| 15 | 4.76 ± 0.78 | 1.43 ± 1.16 | 14.40 ± 3.39 | 3.48 ± 2.85 | 0.019 ± 0.0034 | 0.0074 ± 0.0035 |

| 25 | 3.18 ± 0.08 | 6.94 ± 2.03 | 7.82 ± 0.78 | 16.91 ± 4.94 | 0.0525 ± 0.0024 | 0.0033 ± 0.0008 |

| 35 | 2.24 ± 0.06 | 20.35 ± 3.39 | 5.42 ± 0.31 | 49.57 ± 8.23 | 0.1248 ± 0.0066 | 0.0026± 0.0003 |

| 90 | 63.57 ± 16.75 | 77.22 ± 23.49 | 3.51 ± 0.32 | 188.80± 57.69 | 9.43 ± 1.11 | 0.0525 ± 0.0141 |

| Column Height (cm) | pH of ETTMP in PBS | pH of ETTMP in PBS + PEGDA |

|---|---|---|

| 0 | 4.06 | 4.25 |

| 0.635 | 5.43 | 5.64 |

| 1.27 | 6.84 | 7.00 |

| 1.905 | 6.87 | 7.02 |

| 2.54 | 7.02 | 7.22 |

| 3.81 | 7.08 | 7.40 |

| 5.08 | 7.07 | 7.41 |

| 6.35 | 7.09 | 7.43 |

| Mixing Time (s) | Mixing Type | 25 wt% Gelation Time (min) | 35 wt% Gelation Time (min) |

|---|---|---|---|

| 5 | Hand | 3.34 ± 0.03 | 2.47 ± 0.12 |

| 10 | Hand | 3.74 ± 0.04 | 2.50 ± 0.06 |

| 15 | Vortex | 3.18 ± 0.08 | 2.24 ± 0.06 |

| 25 | Vortex | 3.05 ± 0.33 | 1.98 ± 0.08 |

| Test Type | Frequency (s−1) | Strain (%) | Points Per Decade |

|---|---|---|---|

| Time Sweep | 10 | 5 | N/A |

| Frequency Sweep | 0.01 to 100 | 5 | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morrison, N.; Vogel, B.M. Factors That Influence Base-Catalyzed Thiol-Ene Hydrogel Synthesis. Gels 2023, 9, 917. https://doi.org/10.3390/gels9110917

Morrison N, Vogel BM. Factors That Influence Base-Catalyzed Thiol-Ene Hydrogel Synthesis. Gels. 2023; 9(11):917. https://doi.org/10.3390/gels9110917

Chicago/Turabian StyleMorrison, Nolan, and Brandon M. Vogel. 2023. "Factors That Influence Base-Catalyzed Thiol-Ene Hydrogel Synthesis" Gels 9, no. 11: 917. https://doi.org/10.3390/gels9110917

APA StyleMorrison, N., & Vogel, B. M. (2023). Factors That Influence Base-Catalyzed Thiol-Ene Hydrogel Synthesis. Gels, 9(11), 917. https://doi.org/10.3390/gels9110917