Physico-Chemical, Textural and Sensory Evaluation of Emulsion Gel Formulated with By-Products from the Vegetable Oil Industry

Abstract

:1. Introduction

2. Results and Discussion

2.1. Emulsion Gels Physicochemical Analysis

2.2. Low-Fat Mayonnaise-like Emulsion GelsTexture Profile Analysis

2.3. Sensory Quality Attributes of Low-Fat Mayonnaise-like Emulsion Gel Samples

2.4. Principal Component Analysis

3. Conclusions

4. Materials and Methods

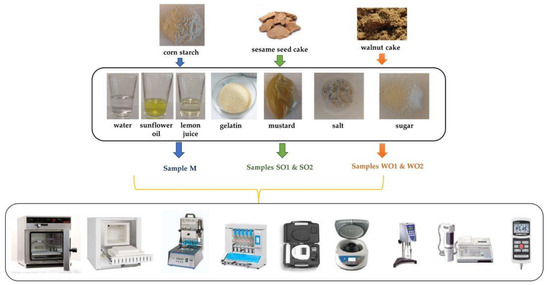

4.1. Materials

4.2. Preparation of Mayonnaise-like Emulsion Gels

4.3. Physicochemical Analysis

4.4. Textural Analysis

4.5. Sensory Evaluation

4.6. Statistical Analysis

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mirzanajafi-Zanjani, M.; Yousefi, M.; Ehsani, A. Challenges and approaches for production of a healthy and functional mayonnaise sauce. Food Sci. Nutr. 2019, 7, 2471–2484. [Google Scholar] [CrossRef]

- Di Mattia, C.; Balestra, F.; Sacchetti, G.; Neri, L.; Mastrocola, D.; Pittia, P. Physical and structural properties of extra-virgin olive oil based mayonnaise. LWT-Food Sci. Technol. 2015, 62, 764–770. [Google Scholar] [CrossRef]

- Senila, L.; Neag, E.; Cadar, O.; Kovacs, M.H.; Becze, A.; Senila, M. Chemical, nutritional and antioxidant characteristics of different food seeds. Appl. Sci. 2020, 10, 1589. [Google Scholar] [CrossRef]

- Mititelu, M.; Oancea, C.-N.; Neacșu, S.M.; Musuc, A.M.; Gheonea, T.C.; Stanciu, T.I.; Rogoveanu, I.; Hashemi, F.; Stanciu, G.; Ioniță-Mîndrican, C.-B.; et al. Evaluation of Junk Food Consumption and the Risk Related to Consumer Health among the Romanian Population. Nutrients 2023, 15, 3591. [Google Scholar] [CrossRef] [PubMed]

- Lin, D.; Kelly, A.L.; Miao, S. Preparation, structure-property relationships and applications of different emulsion gels: Bulk emulsion gels, emulsion gel particles, and fluid emulsion gels. Trends Food Sci. Technol. 2020, 102, 123–137. [Google Scholar] [CrossRef]

- Nour, V. Effect of sea buckthorn juice addition on the oxidative stability, physicochemical and sensory properties of soy milk mayonnaise during refrigerated storage. Ukr. J. Food Sci. 2021, 9, 5–17. [Google Scholar] [CrossRef]

- Yang, X.; Li, A.; Yu, W.; Li, X.; Sun, L.; Xue, J.; Guo, Y. Structuring oil-in-water emulsion by forming egg yolk/alginate complexes: Their potential application in fabricating low-fat mayonnaise-like emulsion gels and redispersible solid emulsions. Int. J. Biol. Macromol. 2020, 147, 595–606. [Google Scholar] [CrossRef]

- Song, L.; Zhang, S.; Liu, B. The fabrication and characterization of Pickering emulsion gels stabilized by sorghum flour. Foods 2022, 11, 2056. [Google Scholar] [CrossRef]

- Elleuch, M.; Besbes, S.; Roiseux, O.; Blecker, C.; Attia, H. Quality characteristics of sesame seeds and by-products. Food Chem. 2007, 103, 641–650. [Google Scholar] [CrossRef]

- Fidelis, M.; de Moura, C.; Kabbas Junior, T.; Pap, N.; Mattila, P.; Mäkinen, S.; Putnik, P.; Bursać Kovačević, D.; Tian, Y.; Yang, B.; et al. Fruit Seeds as Sources of Bioactive Compounds: Sustainable Production of High Value-Added Ingredients from By-Products within Circular Economy. Molecules 2019, 24, 3854. [Google Scholar] [CrossRef] [PubMed]

- Cozma, P.; Smaranda, C.; Comăniță, E.D.; Roşca, M.; Ghinea, C.; Campean, T.; Gavrilescu, M. Knowledge transfer in university-industry research collaboration for extending life cycle of materials in the context of circular economy. Environ. Eng. Manag. J. 2020, 19, 2097–2112. [Google Scholar]

- Teo, S.H.; Ching, Y.C.; Fahmi, M.Z.; Lee, H.V. Surface Functionalization of Sugarcane-Bagasse-Derived Cellulose Nanocrystal for Pickering Emulsion Gel: Microstructural Properties and Stability Efficiency. Gels 2023, 9, 734. [Google Scholar] [CrossRef] [PubMed]

- Petraru, A.; Ursachi, F.; Amariei, S. Nutritional characteristics assessment of sunflower seeds, oil and cake. Perspective of using sunflower oilcakes as a functional ingredient. Plants 2021, 10, 2487. [Google Scholar] [CrossRef] [PubMed]

- Wei, P.; Zhao, F.; Wang, Z.; Wang, Q.; Chai, X.; Hou, G.; Meng, Q. Sesame (Sesamum Indicum L.): A comprehensive review of nutritional value, phytochemical composition, health benefits, development of food, and industrial applications. Nutrients 2022, 14, 4079. [Google Scholar] [CrossRef]

- Leahu, A.; Oroian, M.; Ropciuc, S. The quality and stability of walnut oil under the influence of storage conditions. Sci. Pap. Ser. Anim. Sci. 2016, 65, 230–236. [Google Scholar]

- Petrović-Oggiano, G.; Debeljak-Martačić, J.; Ranković, S.; Pokimica, B.; Mirić, A.; Glibetić, M.; Popović, T. The Effect of Walnut Consumption on n-3 Fatty Acid Profile of Healthy People Living in a Non-Mediterranean West Balkan Country, a Small Scale Randomized Study. Nutrients 2020, 12, 192. [Google Scholar] [CrossRef]

- Ojeda-Amador, R.M.; Salvador, M.D.; Gómez-Alonso, S.; Fregapane, G. Characterization of virgin walnut oils and their residual cakes produced from different varieties. Food Res. Int. 2018, 108, 396–404. [Google Scholar] [CrossRef] [PubMed]

- Smeu, I.; Dobre, A.A.; Cucu, E.M.; Mustățea, G.; Belc, N.; Ungureanu, E.L. Byproducts from the vegetable oil industry: The challenges of safety and sustainability. Sustainability 2022, 14, 2039. [Google Scholar] [CrossRef]

- Pop, A.; Păucean, A.; Socaci, S.A.; Alexa, E.; Man, S.M.; Mureșan, V.; Chiş, M.S.; Salanță, L.; Popescu, I.; Berbecea, A.; et al. Quality characteristics and volatile profile of macarons modified with walnut oilcake by-product. Molecules 2020, 25, 2214. [Google Scholar] [CrossRef]

- Pycia, K.; Kapusta, I.; Jaworska, G. Walnut oil and oilcake affect selected the physicochemical and antioxidant properties of wheat bread enriched with them. J. Food Process. Preserv. 2020, 44, e14573. [Google Scholar] [CrossRef]

- Prakash, K.; Naik, S.N.; Vadivel, D.; Hariprasad, P.; Gandhi, D.; Saravanadevi, S. Utilization of defatted sesame cake in enhancing the nutritional and functional characteristics of biscuits. J. Food Process. Preserv. 2018, 42, e13751. [Google Scholar] [CrossRef]

- Melo, D.; Álvarez-Ortí, M.; Nunes, M.A.; Costa, A.S.; Machado, S.; Alves, R.C.; Pardo, J.E.; Oliveira, M.B.P. Whole or defatted sesame seeds (Sesamum indicum L.)? The effect of cold pressing on oil and cake quality. Foods 2021, 10, 2108. [Google Scholar] [CrossRef] [PubMed]

- Jeong, H.; Huh, C.K.; Ha, H.K.; Kim, J.; Oh, I. Development of an Emulsion Gel Containing Peanut Sprout Oil as a Fat Replacer in Muffins: Physicochemical, Tomographic, and Texture Properties. Gels 2023, 9, 783. [Google Scholar] [CrossRef] [PubMed]

- Amin, M.H.H.; Elbeltagy, A.E.; Mustafa, M.; Khalil, A.H. Development of low-fat mayonnaise containing different types and levels of hydrocolloid gum. J. Agroaliment. Process. Technol. 2014, 20, 54–63. [Google Scholar]

- Rani, R.; Badwaik, L.S. Functional properties of oilseed cakes and defatted meals of mustard, soybean and flaxseed. Waste Biomass Valorization 2021, 12, 5639–5647. [Google Scholar] [CrossRef]

- Kotecka-Majchrzak, K.; Sumara, A.; Fornal, E.; Montowska, M. Oilseed proteins–Properties and application as a food ingredient. Trends Food Sci. Technol. 2020, 106, 160–170. [Google Scholar] [CrossRef]

- Pintado, T.; Herrero, A.M.; Jiménez-Colmenero, F.; Ruiz-Capillas, C. Emulsion gels as potential fat replacers delivering β-glucan and healthy lipid content for food applications. J. Food Sci. Technol. 2016, 53, 4336–4347. [Google Scholar] [CrossRef] [PubMed]

- Pintado, T.; Cofrades, S. Quality characteristics of healthy dry fermented sausages formulated with a mixture of olive and chia oil structured in oleogel or emulsion gel as animal fat replacer. Foods 2020, 9, 830. [Google Scholar] [CrossRef]

- Ma, Z.; Boye, J.I. Advances in the Design and Production of Reduced-Fat and Reduced-Cholesterol Salad Dressing and Mayonnaise: A Review. Food Bioprocess Technol. 2013, 6, 648–670. [Google Scholar] [CrossRef]

- Carcelli, A.; Crisafulli, G.; Carini, E.; Vittadini, E. Can a physically modified corn flour be used as fat replacer in a mayonnaise? Eur. Food Res. Technol. 2020, 246, 2493–2503. [Google Scholar] [CrossRef]

- Worrasinchai, S.; Suphantharika, M.; Pinjai, S.; Jamnong, P. β-Glucan prepared from spent brewer’s yeast as a fat replacer in mayonnaise. Food Hydrocoll. 2006, 20, 68–78. [Google Scholar] [CrossRef]

- Khushbu, S.; Sunil, C.K. Comparative study on effect of shallot flour as a thickener, with commercially available thickeners on properties of low fat mayonnaise. Trends Biosci. 2018, 11, 4401–4407. [Google Scholar]

- Park, J.J.; Olawuyi, I.F.; Lee, W.Y. Characteristics of low-fat mayonnaise using different modified arrowroot starches as fat replacer. Int. J. Biol. Macromol. 2020, 153, 215–223. [Google Scholar] [CrossRef] [PubMed]

- Kumar, Y.; Roy, S.; Devra, A.; Dhiman, A.; Prabhakar, P.K. Ultrasonication of mayonnaise formulated with xanthan and guar gums: Rheological modeling, effects on optical properties and emulsion stability. LWT 2021, 149, 111632. [Google Scholar] [CrossRef]

- Herald, T.J.; Abugoush, M.; Aramouni, F. Physical and sensory properties of egg yolk and egg yolk substitutes in a model mayonnaise system. J. Texture Stud. 2009, 40, 692–709. [Google Scholar] [CrossRef]

- Sagis, L.M.; Yang, J. Protein-stabilized interfaces in multiphase food: Comparing structure-function relations of plant-based and animal-based proteins. Curr. Opin. Food Sci. 2022, 43, 53–60. [Google Scholar] [CrossRef]

- Drozłowska, E.; Bartkowiak, A.; Łopusiewicz, Ł. Characterization of flaxseed oil bimodal emulsions prepared with flaxseed oil cake extract applied as a natural emulsifying agent. Polymers 2020, 12, 2207. [Google Scholar] [CrossRef]

- Burgos-Díaz, C.; Mosi-Roa, Y.; Opazo-Navarrete, M.; Bustamante, M.; Garrido-Miranda, K. Comparative Study of Food-Grade Pickering Stabilizers Obtained from Agri-Food Byproducts: Chemical Characterization and Emulsifying Capacity. Foods 2022, 11, 2514. [Google Scholar] [CrossRef]

- Pourramezan, H.; Labbafi, M.; Khodaiyan, F.; Mousavi, M.; Gharaghani, M.; Saadatvand, M.; Mahmoudi, A. Preparation of octenyl succinylated kappa-carrageenan; reaction optimization, characterization, and application in low-fat vegan mayonnaise. Int. J. Biol. Macromol. 2022, 223, 882–898. [Google Scholar] [CrossRef]

- Hosseini, A.; Jafari, S.M.; Mirzaei, H.; Asghari, A.; Akhavan, S. Application of image processing to assess emulsion stability and emulsification properties of Arabic gum. Carbohydr. Polym. 2015, 126, 1–8. [Google Scholar] [CrossRef]

- Golchoobi, L.; Alimi, M.; Shokoohi, S.; Yousefi, H. Interaction between nanofibrillated cellulose with guar gum and carboxy methyl cellulose in low-fat mayonnaise. J. Texture Stud. 2016, 47, 403–412. [Google Scholar] [CrossRef]

- Lastra-Ripoll, S.E.; Quintana, S.E.; Garcia-Zapateiro, L.A. Chemical, technological, and rheological properties of hydrocolloids from sesame (Sesamum indicum) with potential food applications. Arab. J. Chem. 2022, 15, 104146. [Google Scholar] [CrossRef]

- Shi, L.S.; Yang, X.Y.; Gong, T.; Hu, C.Y.; Shen, Y.H.; Meng, Y.H. Ultrasonic treatment improves physical and oxidative stabilities of walnut protein isolate-based emulsion by changing protein structure. LWT 2023, 173, 114269. [Google Scholar] [CrossRef]

- Flamminii, F.; Di Mattia, C.D.; Sacchetti, G.; Neri, L.; Mastrocola, D.; Pittia, P. Physical and sensory properties of mayonnaise enriched with encapsulated olive leaf phenolic extracts. Foods 2020, 9, 997. [Google Scholar] [CrossRef] [PubMed]

- Malaviya, R.; Yadav, N. Exploring Nutritional and Functional Properties of Different Varieties of Sesame Seed Cakes: An Industrial By-Product. Plant Arch. 2022, 22, 09725210. [Google Scholar] [CrossRef]

- Iordănescu, O.A.; Radulov, I.; Buhan, I.P.; Cocan, I.; Berbecea, A.A.; Popescu, I.; Poșta, D.S.; Camen, D.; Lalescu, D. Physical, Nutritional and Functional Properties of Walnuts Genotypes (Juglans regia L.) from Romania. Agronomy 2021, 11, 1092. [Google Scholar] [CrossRef]

- Hadnađev, M.; Hadnađev, T.D.; Dokić, L.; Pajin, B.; Torbica, A.; Šarić, L.; Ikonić, P. Physical and sensory aspects of maltodextrin gel addition used as fat replacers in confectionery filling systems. LWT-Food Sci. Technol. 2014, 59, 495–503. [Google Scholar] [CrossRef]

- Wang, W.; Hu, C.; Sun, H.; Zhao, J.; Xu, C.; Ma, Y.; Ma, J.; Jiang, L.; Hou, J. Physicochemical Properties, Stability and Texture of Soybean-Oil-Body-Substituted Low-Fat Mayonnaise: Effects of Thickeners and Storage Temperatures. Foods 2022, 11, 2201. [Google Scholar] [CrossRef]

- Ding, M.; Zhang, T.; Zhang, H.; Tao, N.; Wang, X.; Zhong, J. Gelatin-stabilized traditional emulsions: Emulsion forms, droplets, and storage stability. Food Sci. Hum. Wellness 2020, 9, 320–327. [Google Scholar] [CrossRef]

- Yang, X.; Gong, T.; Li, D.; Li, A.; Sun, L.; Guo, Y. Preparation of high viscoelastic emulsion gels based on the synergistic gelation mechanism of xanthan and konjac glucomannan. Carbohydr. Polym. 2019, 226, 115278. [Google Scholar] [CrossRef]

- FAO. Chapter 4: Summary—Integration of Analytical Methods and Food Energy Conversion Factors. Available online: https://www.fao.org/3/y5022e/y5022e05.htm#bm5 (accessed on 23 March 2023).

- Leahu, A.; Ghinea, C.; Petraru, A.; Ropciuc, S. Defatted Sesame Seed Cake: Influence on the Physicochemical and Textural Characteristics of Mayonnaise. In Proceedings of the 2022 E-Health and Bioengineering Conference (EHB), Iasi, Romania, 17–18 November 2022; pp. 1–4. [Google Scholar]

- Ozcan, I.; Ozyigit, E.; Erkoc, S.; Tavman, S.; Kumcuoglu, S. Investigating the physical and quality characteristics and rheology of mayonnaise containing aquafaba as an egg substitute. J. Food Eng. 2023, 344, 111388. [Google Scholar] [CrossRef]

- Karas, R.; Skvarča, M.; Žlender, B. Sensory quality of standard and light mayonnaise during storage. Food Technol. Biotechnol. 2002, 40, 119–127. [Google Scholar]

| Samples | Fat (%) | Protein (%) | Ash (%) | Moisture (%) | Carbohydrate (%) | Caloric Value (Kcal/100 g) |

|---|---|---|---|---|---|---|

| M | 48.86 ± 0.06 c | 0.58 ± 0.15 e | 0.36 ± 0.02 e | 26.24 ± 0.09 de | 23.96 ± 0.12 a | 537.90 ± 0.53 b |

| SO1 | 49.79 ± 0.49 abc | 1.75 ± 0.04 c | 0.94 ± 0.02 c | 27.74 ± 0.02 b | 19.78 ± 0.49 b | 534.21 ± 2.60 b |

| SO2 | 50.71 ± 0.12 a | 2.86 ± 0.06 a | 2.06 ± 0.06 b | 26.86 ± 0.06 cd | 17.50 ± 0.15 c | 537.83 ± 0.93 b |

| WO1 | 49.64 ± 0.64 bc | 1.46 ± 0.06 d | 0.54 ± 0.03 d | 27.54 ± 0.03 bc | 20.82 ± 0.61 b | 535.86 ± 3.09 b |

| WO2 | 49.88 ± 0.14 ab | 2.44 ± 0.09 b | 2.91 ± 0.12 a | 28.58 ± 0.49 a | 16.19 ± 0.24 d | 523.47 ± 2.27 c |

| CM | 50.05 ± 0.23 ab | 0.32 ± 0.03 f | 0.24 ± 0.04 e | 25.58 ± 0.49 e | 23.81 ± 0.42 a | 546.97 ± 2.92 a |

| Samples | L* | a* | b* |

|---|---|---|---|

| M | 65.81 ± 0.10 b | −6.75 ± 0.04 c | 15.89 ± 0.06 d |

| SO1 | 59.94 ± 0.24 c | −4.32 ± 0.04 b | 18.19 ± 0.03 b |

| SO2 | 56.60 ± 0.06 e | −4.30 ± 0.03 b | 19.83 ± 0.03 a |

| WO1 | 57.30 ± 0.13 d | −1.37 ± 0.02 a | 14.18 ± 0.15 e |

| WO2 | 52.31 ± 0.42 f | −1.30 ± 0.02 a | 13.18 ± 0.11 f |

| CM | 66.85 ± 0.16 a | −6.95 ± 0.04 d | 16.89 ± 0.06 c |

| Samples | Texture Attributes | |||||

|---|---|---|---|---|---|---|

| Hardness (N) | Adhesiveness (Joule) | Springiness (mm) | Cohesiveness | Gumminess (N) | Chewiness (N*mm) | |

| M | 4.8 ± 0.03 b | 16.11 ± 0.04 b | 0.67 ± 0.01 d | 0.6 ± 0.03 b | 3.00 ± 0.04 b | 2.00 ± 0.03 b |

| SO1 | 1.02 ± 0.04 e | 4.00 ± 0.03 d | 0.94 ± 0.02 bc | 0.74 ± 0.02 a | 0.76 ± 0.03 d | 0.71 ± 0.04 e |

| SO2 | 1.00 ± 0.03 e | 3.3 ± 0.04 f | 1.00 ± 0.01 b | 0.74 ± 0.02 a | 0.6 ± 0.02 e | 0.84 ± 0.03 d |

| WO1 | 2.6 ± 0.01 c | 10.88 ± 0.02 c | 0.74 ± 0.03 d | 0.65 ± 0.03 b | 1.69 ± 0.02 c | 1.25 ± 0.02 c |

| WO2 | 1.12 ± 0.03 d | 3.6 ± 0.03 e | 1.11 ± 0.03 a | 0.72 ± 0.01 a | 0.65 ± 0.01 e | 0.85 ± 0.02 d |

| CM | 6.12 ± 0.03 a | 20.6 ± 0.04 a | 0.91 ± 0.04 c | 0.72 ± 0.02 a | 3.65 ± 0.02 a | 2.85 ± 0.03 a |

| Ingredients | Samples | ||||

|---|---|---|---|---|---|

| M | SO1 | SO2 | WO1 | WO2 | |

| Corn starch | 4 | - | - | - | - |

| Sesame seeds cake (SSC) | - | 2 | 4 | - | - |

| Walnuts cake (WSC) | - | - | - | 2 | 4 |

| Lemon juice | 7 | 7 | 7 | 7 | 7 |

| Sunfloweroil | 37 | 39 | 37 | 39 | 37 |

| Mustard | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Sugar | 1 | 1 | 1 | 1 | 1 |

| Salt | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Gelatin | 2 | 2 | 2 | 2 | 2 |

| Water | 46 | 46 | 46 | 46 | 46 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leahu, A.; Ropciuc, S.; Ghinea, C.; Damian, C. Physico-Chemical, Textural and Sensory Evaluation of Emulsion Gel Formulated with By-Products from the Vegetable Oil Industry. Gels 2023, 9, 964. https://doi.org/10.3390/gels9120964

Leahu A, Ropciuc S, Ghinea C, Damian C. Physico-Chemical, Textural and Sensory Evaluation of Emulsion Gel Formulated with By-Products from the Vegetable Oil Industry. Gels. 2023; 9(12):964. https://doi.org/10.3390/gels9120964

Chicago/Turabian StyleLeahu, Ana, Sorina Ropciuc, Cristina Ghinea, and Cristina Damian. 2023. "Physico-Chemical, Textural and Sensory Evaluation of Emulsion Gel Formulated with By-Products from the Vegetable Oil Industry" Gels 9, no. 12: 964. https://doi.org/10.3390/gels9120964

APA StyleLeahu, A., Ropciuc, S., Ghinea, C., & Damian, C. (2023). Physico-Chemical, Textural and Sensory Evaluation of Emulsion Gel Formulated with By-Products from the Vegetable Oil Industry. Gels, 9(12), 964. https://doi.org/10.3390/gels9120964