Nanostructured Bioaerogels as a Potential Solution for Particulate Matter Pollution

Abstract

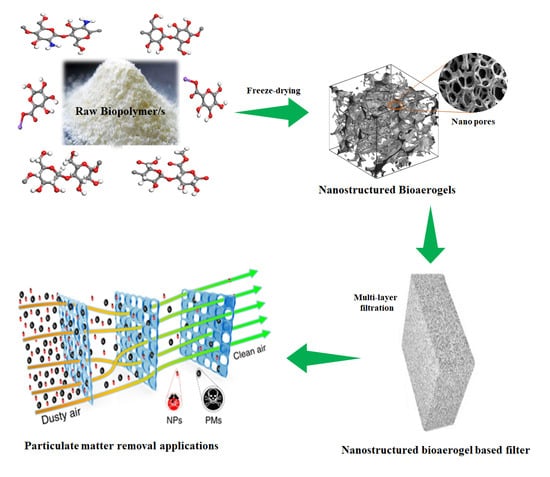

:1. Introduction

2. Nanostructured Bioaerogels

2.1. Preparation of Nanostructured Bioaerogels

2.2. Properties of Nanostructured Bioaerogels

2.3. Applications of Nanostructured Bioaerogel

3. Particulate Matter Pollution

3.1. Types and Sources of Particulate Matter

3.2. Health Effects of Particulate Matter

4. Applications of Nanostructured Bioaerogel in Particulate Matter Removal

4.1. Biomass-Based Nanostructured Aerogel

4.2. Cellulose-Based Nanostructured Aerogel

4.3. Chitosan-Based Nanostructured Aerogel

4.4. Alginate-Based Nanostructured Aerogel

5. Challenges of Nanostructured Bioaerogels in Particulate Matter Removal

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lu, T.; Cui, J.; Qu, Q.; Wang, Y.; Zhang, J.; Xiong, R.; Ma, W.; Huang, C. Multistructured electrospun nanofibers for air filtration: A review. ACS Appl. Mater. Interfaces 2021, 13, 23293–23313. [Google Scholar] [CrossRef] [PubMed]

- Mack, S.M.; Madl, A.K.; Pinkerton, K.E. Respiratory health effects of exposure to ambient particulate matter and bioaerosols. Compr. Physiol. 2019, 10, 1. [Google Scholar]

- Almetwally, A.A.; Bin-Jumah, M.; Allam, A.A. Ambient air pollution and its influence on human health and welfare: An overview. Environ. Sci. Pollut. Res. 2020, 27, 24815–24830. [Google Scholar] [CrossRef]

- Alfano, B.; Barretta, L.; Del Giudice, A.; De Vito, S.; Di Francia, G.; Esposito, E.; Formisano, F.; Massera, E.; Miglietta, M.L.; Polichetti, T. A review of low-cost particulate matter sensors from the developers’ perspectives. Sensors 2020, 20, 6819. [Google Scholar] [CrossRef] [PubMed]

- Thangavel, P.; Park, D.; Lee, Y.-C. Recent insights into particulate matter (PM2.5)-mediated toxicity in humans: An overview. Int. J. Environ. Res. Public Health 2022, 19, 7511. [Google Scholar] [CrossRef]

- Ćurić, M.; Zafirovski, O.; Spiridonov, V.; Zafirovski, O.; Spiridonov, V. Air quality and health. Essent. Med. Meteorol. 2022, 16, 143–182. [Google Scholar]

- Hachem, M.; Loizeau, M.; Saleh, N.; Momas, I.; Bensefa-Colas, L. Short-term association of in-vehicle ultrafine particles and black carbon concentrations with respiratory health in Parisian taxi drivers. Environ. Int. 2021, 147, 106346. [Google Scholar] [CrossRef]

- Liang, W.; Xu, Y.; Li, X.; Wang, X.-X.; Zhang, H.-D.; Yu, M.; Ramakrishna, S.; Long, Y.-Z. Transparent polyurethane nanofiber air filter for high-efficiency PM2.5 capture. Nanoscale Res. Lett. 2019, 14, 361. [Google Scholar] [CrossRef] [Green Version]

- Han, K.S.; Lee, S.; Kim, M.; Park, P.; Lee, M.H.; Nah, J. Electrically activated ultrathin PVDF-TrFE air filter for high-efficiency PM1. 0 filtration. Adv. Funct. Mater. 2019, 29, 1903633. [Google Scholar] [CrossRef]

- Cui, J.; Wang, Y.; Lu, T.; Liu, K.; Huang, C. High performance, environmentally friendly and sustainable nanofiber membrane filter for removal of particulate matter 1.0. J. Colloid Interface Sci. 2021, 597, 48–55. [Google Scholar] [CrossRef]

- Lalagiri, M.; Bhat, G.; Singh, V.; Parameswaran, S.; Kendall, R.J.; Ramkumar, S. Filtration efficiency of submicrometer filters. Ind. Eng. Chem. Res. 2013, 52, 16513–16518. [Google Scholar] [CrossRef]

- Liu, C.; Hsu, P.-C.; Lee, H.-W.; Ye, M.; Zheng, G.; Liu, N.; Li, W.; Cui, Y. Transparent air filter for high-efficiency PM2.5 capture. Nat. Commun. 2015, 6, 6205. [Google Scholar] [CrossRef] [Green Version]

- Lv, L.; Zhang, T.; Xiang, Y.; Chai, W.; Liu, W. Distribution and transport characteristics of fine particulate matter in Beijing with mobile lidar measurements from 2015 to 2018. J. Environ. Sci. 2022, 115, 65–75. [Google Scholar] [CrossRef]

- Liu, H.; Huang, J.; Mao, J.; Chen, Z.; Chen, G.; Lai, Y. Transparent antibacterial nanofiber air filters with highly efficient moisture resistance for sustainable particulate matter capture. Iscience 2019, 19, 214–223. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xie, X.; Zheng, Z.; Wang, X.; Lee Kaplan, D. Low-density silk nanofibrous aerogels: Fabrication and applications in air filtration and oil/water purification. ACS Nano 2021, 15, 1048–1058. [Google Scholar] [CrossRef]

- Chen, Y.; Zhou, L.; Chen, L.; Duan, G.; Mei, C.; Huang, C.; Han, J.; Jiang, S. Anisotropic nanocellulose aerogels with ordered structures fabricated by directional freeze-drying for fast liquid transport. Cellulose 2019, 26, 6653–6667. [Google Scholar] [CrossRef]

- Ji, F.; Sun, Z.; Hang, T.; Zheng, J.; Li, X.; Duan, G.; Zhang, C.; Chen, Y. Flexible piezoresistive pressure sensors based on nanocellulose aerogels for human motion monitoring: A review. Compos. Commun. 2022, 35, 101351. [Google Scholar] [CrossRef]

- Chen, Y.; Li, S.; Li, X.; Mei, C.; Zheng, J.; E, S.; Duan, G.; Liu, K.; Jiang, S. Liquid transport and real-time dye purification via lotus petiole-inspired long-range-ordered anisotropic cellulose nanofibril aerogels. ACS Nano 2021, 15, 20666–20677. [Google Scholar] [CrossRef] [PubMed]

- Zou, Y.; Zhao, J.; Zhu, J.; Guo, X.; Chen, P.; Duan, G.; Liu, X.; Li, Y. A mussel-inspired polydopamine-filled cellulose aerogel for solar-enabled water remediation. ACS Appl. Mater. Interfaces 2021, 13, 7617–7624. [Google Scholar] [CrossRef] [PubMed]

- Tian, E.; Gao, Y.; Mo, J. Electrostatically assisted air coarse filtration for energy efficient ambient particles removal: Long-term performance in real environment and influencing factors. Build. Environ. 2019, 164, 106348. [Google Scholar] [CrossRef]

- Xiong, Z.; Li, X.; Wang, J.; Lin, J. Nanocellulose implantation enriched the pore structure of aerogel for effective particulate matter removal. Int. J. Biol. Macromol. 2022, 219, 1237–1243. [Google Scholar] [CrossRef]

- Sun, B.; Zhao, J.; Wang, T.; Li, Y.; Yang, X.; Tan, F.; Li, Y.; Chen, C.; Sun, D. Highly efficient construction of sustainable bacterial cellulose aerogels with boosting PM filter efficiency by tuning functional group. Carbohydr. Polym. 2023, 309, 120664. [Google Scholar] [CrossRef]

- Wang, H.-L.; Hsu, C.-Y.; Wu, K.C.; Lin, Y.-F.; Tsai, D.-H. Functional nanostructured materials: Aerosol, aerogel, and de novo synthesis to emerging energy and environmental applications. Adv. Powder Technol. 2020, 31, 104–120. [Google Scholar] [CrossRef]

- Yahya, E.B.; Jummaat, F.; Amirul, A.; Adnan, A.; Olaiya, N.; Abdullah, C.; Rizal, S.; Mohamad Haafiz, M.; Khalil, H.A. A review on revolutionary natural biopolymer-based aerogels for antibacterial delivery. Antibiotics 2020, 9, 648. [Google Scholar] [CrossRef]

- Mariana, M.; Abdul Khalil, H.P.S.; Yahya, E.B.; Olaiya, N.; Alfatah, T.; Suriani, A.; Mohamed, A. Recent trends and future prospects of nanostructured aerogels in water treatment applications. J. Water Process Eng. 2022, 45, 102481. [Google Scholar] [CrossRef]

- Yahya, E.B.; Alzalouk, M.M.; Alfallous, K.A.; Abogmaza, A.F. Antibacterial cellulose-based aerogels for wound healing application: A review. Biomed. Res. Ther. 2020, 7, 4032–4040. [Google Scholar] [CrossRef]

- Guastaferro, M.; Reverchon, E.; Baldino, L. Agarose, alginate and chitosan nanostructured aerogels for pharmaceutical applications: A short review. Front. Bioeng. Biotechnol. 2021, 9, 688477. [Google Scholar] [CrossRef] [PubMed]

- Khalil, H.A.; Yahya, E.B.; Jummaat, F.; Adnan, A.; Olaiya, N.; Rizal, S.; Abdullah, C.; Pasquini, D.; Thomas, S. Biopolymers based aerogels: A review on revolutionary solutions for smart therapeutics delivery. Prog. Mater. Sci. 2023, 131, 101014. [Google Scholar] [CrossRef]

- Abdul Khalil, H.; Adnan, A.; Yahya, E.B.; Olaiya, N.; Safrida, S.; Hossain, M.S.; Balakrishnan, V.; Gopakumar, D.A.; Abdullah, C.; Oyekanmi, A.; et al. A review on plant cellulose nanofibre-based aerogels for biomedical applications. Polymers 2020, 12, 1759. [Google Scholar] [CrossRef]

- Barrios, E.; Fox, D.; Li Sip, Y.Y.; Catarata, R.; Calderon, J.E.; Azim, N.; Afrin, S.; Zhang, Z.; Zhai, L. Nanomaterials in advanced, high-performance aerogel composites: A review. Polymers 2019, 11, 726. [Google Scholar] [CrossRef] [Green Version]

- Darpentigny, C.; Nonglaton, G.; Bras, J.; Jean, B. Highly absorbent cellulose nanofibrils aerogels prepared by supercritical drying. Carbohydr. Polym. 2020, 229, 115560. [Google Scholar] [CrossRef] [PubMed]

- Rizal, S.; Yahya, E.B.; Abdul Khalil, H.; Abdullah, C.; Marwan, M.; Ikramullah, I.; Muksin, U. Preparation and characterization of nanocellulose/chitosan aerogel scaffolds using chemical-free approach. Gels 2021, 7, 246. [Google Scholar] [CrossRef] [PubMed]

- Niu, Z.; He, X.; Huang, T.; Tang, B.; Cheng, X.; Zhang, Y.; Shao, Z. A facile preparation of transparent methyltriethoxysilane based silica xerogel monoliths at ambient pressure drying. Microporous Mesoporous Mater. 2019, 286, 98–104. [Google Scholar] [CrossRef]

- Owens, G.J.; Singh, R.K.; Foroutan, F.; Alqaysi, M.; Han, C.-M.; Mahapatra, C.; Kim, H.-W.; Knowles, J.C. Sol–gel based materials for biomedical applications. Prog. Mater. Sci. 2016, 77, 1–79. [Google Scholar] [CrossRef] [Green Version]

- Onwukamike, K.N.; Lapuyade, L.; Maillé, L.; Grelier, S.; Grau, E.; Cramail, H.; Meier, M.A. Sustainable approach for cellulose aerogel preparation from the DBU–CO2 switchable solvent. ACS Sustain. Chem. Eng. 2019, 7, 3329–3338. [Google Scholar] [CrossRef] [Green Version]

- López-Iglesias, C.; Barros, J.; Ardao, I.; Gurikov, P.; Monteiro, F.J.; Smirnova, I.; Alvarez-Lorenzo, C.; García-González, C.A. Jet cutting technique for the production of chitosan aerogel microparticles loaded with vancomycin. Polymers 2020, 12, 273. [Google Scholar] [CrossRef] [Green Version]

- Iswar, S.; Malfait, W.J.; Balog, S.; Winnefeld, F.; Lattuada, M.; Koebel, M.M. Effect of aging on silica aerogel properties. Microporous Mesoporous Mater. 2017, 241, 293–302. [Google Scholar] [CrossRef] [Green Version]

- Mi, H.-Y.; Jing, X.; Liu, Y.; Li, L.; Li, H.; Peng, X.-F.; Zhou, H. Highly durable superhydrophobic polymer foams fabricated by extrusion and supercritical CO2 foaming for selective oil absorption. ACS Appl. Mater. Interfaces 2019, 11, 7479–7487. [Google Scholar] [CrossRef]

- Liu, R.; Wang, J.; Du, Y.; Liao, J.; Zhang, X. Phase-separation induced synthesis of superhydrophobic silica aerogel powders and granules. J. Solid State Chem. 2019, 279, 120971. [Google Scholar] [CrossRef]

- Pirzada, T.; Ashrafi, Z.; Xie, W.; Khan, S.A. Cellulose silica hybrid nanofiber aerogels: From sol–gel electrospun nanofibers to multifunctional aerogels. Adv. Funct. Mater. 2020, 30, 1907359. [Google Scholar] [CrossRef]

- Khalil, H.A.; Jummaat, F.; Yahya, E.B.; Olaiya, N.; Adnan, A.; Abdat, M.; NAM, N.; Halim, A.S.; Kumar, U.S.U.; Bairwan, R.; et al. A review on micro-to nanocellulose biopolymer scaffold forming for tissue engineering applications. Polymers 2020, 12, 2043. [Google Scholar] [CrossRef]

- Kam, D.; Chasnitsky, M.; Nowogrodski, C.; Braslavsky, I.; Abitbol, T.; Magdassi, S.; Shoseyov, O. Direct CRYO writing of aerogels via 3D Printing of aligned cellulose nanocrystals inspired by the plant cell wall. Colloids Interfaces 2019, 3, 46. [Google Scholar] [CrossRef] [Green Version]

- Saoud, K.M.; Saeed, S.; Bertino, M.F.; White, L.S. Fabrication of strong and ultra-lightweight silica-based aerogel materials with tailored properties. J. Porous Mater. 2018, 25, 511–520. [Google Scholar] [CrossRef]

- Zhang, D.; Liu, X.; Qiu, J. 3D printing of glass by additive manufacturing techniques: A review. Front. Optoelectron. 2021, 14, 263–277. [Google Scholar] [CrossRef] [PubMed]

- Tang, A.; Li, J.; Li, J.; Zhao, S.; Liu, W.; Liu, T.; Wang, J.; Liu, Y. Nanocellulose/PEGDA aerogel scaffolds with tunable modulus prepared by stereolithography for three-dimensional cell culture. J. Biomater. Sci. Polym. Ed. 2019, 30, 797–814. [Google Scholar] [CrossRef]

- Muhammad, S.; Yahya, E.B.; Abdul Khalil, H.; Marwan, M.; Albadn, Y.M. Recent Advances in Carbon and Activated Carbon Nanostructured Aerogels Prepared from Agricultural Wastes for Wastewater Treatment Applications. Agriculture 2023, 13, 208. [Google Scholar] [CrossRef]

- Bernardes, B.G.; Del Gaudio, P.; Alves, P.; Costa, R.; García-Gonzaléz, C.A.; Oliveira, A.L. Bioaerogels: Promising nanostructured materials in fluid management, healing and regeneration of wounds. Molecules 2021, 26, 3834. [Google Scholar] [CrossRef] [PubMed]

- Idumah, C.I. Novel trends in polymer aerogel nanocomposites. Polym.-Plast. Technol. Mater. 2021, 60, 1519–1531. [Google Scholar] [CrossRef]

- Abdullah; Zou, Y.; Farooq, S.; Walayat, N.; Zhang, H.; Faieta, M.; Pittia, P.; Huang, Q. Bio-aerogels: Fabrication, properties and food applications. Crit. Rev. Food Sci. Nutr. 2022, 224, 1–23. [Google Scholar] [CrossRef]

- Maleki, H.; Huesing, N. Silica-silk fibroin hybrid (bio) aerogels: Two-step versus one-step hybridization. J. Sol-Gel Sci. Technol. 2021, 98, 430–438. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhong, K.; Liu, W.; Cui, S.; Zhong, Y.; Jiang, S. Preparation and oil adsorption properties of hydrophobic microcrystalline cellulose aerogel. Cellulose 2020, 27, 7663–7675. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, L.; Yang, Y.; Pang, B.; Xu, W.; Duan, G.; Jiang, S.; Zhang, K. Recent progress on nanocellulose aerogels: Preparation, modification, composite fabrication, applications. Adv. Mater. 2021, 33, 2005569. [Google Scholar] [CrossRef]

- Zhu, L.; Zong, L.; Wu, X.; Li, M.; Wang, H.; You, J.; Li, C. Shapeable fibrous aerogels of metal–organic-frameworks templated with nanocellulose for rapid and large-capacity adsorption. ACS Nano 2018, 12, 4462–4468. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, V.T.; Ha, L.Q.; Nguyen, T.D.; Ly, P.H.; Nguyen, D.M.; Hoang, D. Nanocellulose and graphene oxide aerogels for adsorption and removal methylene blue from an aqueous environment. ACS Omega 2021, 7, 1003–1013. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Xu, T.; Cai, C.; Liu, K.; Liu, W.; Zhang, M.; Du, H.; Si, C.; Zhang, K. Multifunctional superelastic, superhydrophilic, and ultralight nanocellulose-based composite carbon aerogels for compressive supercapacitor and strain sensor. Adv. Funct. Mater. 2022, 32, 2113082. [Google Scholar] [CrossRef]

- Takeshita, S.; Zhao, S.; Malfait, W.J.; Koebel, M.M. Chemistry of chitosan aerogels: Three-dimensional pore control for tailored applications. Angew. Chem. Int. Ed. 2021, 60, 9828–9851. [Google Scholar] [CrossRef]

- de Luna, M.S.; Ascione, C.; Santillo, C.; Verdolotti, L.; Lavorgna, M.; Buonocore, G.; Castaldo, R.; Filippone, G.; Xia, H.; Ambrosio, L. Optimization of dye adsorption capacity and mechanical strength of chitosan aerogels through crosslinking strategy and graphene oxide addition. Carbohydr. Polym. 2019, 211, 195–203. [Google Scholar] [CrossRef]

- Takeshita, S.; Akasaka, S.; Yoda, S. Structural and acoustic properties of transparent chitosan aerogel. Mater. Lett. 2019, 254, 258–261. [Google Scholar] [CrossRef]

- Stoica, R.; Pop, S.; Ion, R. Evaluation of natural polyphenols entrapped in calcium alginate beads prepared by the ionotropic gelation method. J. Optoel. Adv. Mater. 2013, 15, 893–898. [Google Scholar]

- Baldino, L.; Concilio, S.; Della Porta, G.; Tabernero, A. Challenges and Solutions in the Production of Advanced Nanostructured Biomaterials for Medical Applications. Front. Mater. 2021, 8, 794192. [Google Scholar] [CrossRef]

- Zhang, A.; Zou, Y.; Xi, Y.; Wang, P.; Zhang, Y.; Wu, L.; Zhang, H. Fabrication and characterization of bamboo shoot cellulose/sodium alginate composite aerogels for sustained release of curcumin. Int. J. Biol. Macromol. 2021, 192, 904–912. [Google Scholar] [CrossRef] [PubMed]

- Yahya, E.B.; Khalil, H.A.; Ahmad, M.I.; Rizal, S.; Muhammad, S. Cleaner approach of preparing antibacterial bioaerogel scaffolds using oil palm waste nanocellulose. Ind. Crops Prod. 2023, 191, 115897. [Google Scholar] [CrossRef]

- Athamneh, T.; Hajnal, A.; Al-Najjar, M.A.; Alshweiat, A.; Obeidat, R.; Awad, A.A.; Al-Alwany, R.; Keitel, J.; Wu, D.; Kieserling, H.; et al. In vivo tests of a novel wound dressing based on agar aerogel. Int. J. Biol. Macromol. 2023, 239, 124238. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, M.; Chen, J.; Fan, S.; Liang, J.; Ding, L.; Chen, S. Flexible chitosan/carbon nanotubes aerogel, a robust matrix for in-situ growth and non-enzymatic biosensing applications. Sens. Actuators B Chem. 2016, 232, 750–757. [Google Scholar] [CrossRef]

- Xie, Y.; Guo, F.; Mao, J.; Huang, J.; Chen, Z.; Jiang, Y.; Lai, Y. Freestanding MoS2@ carbonized cellulose aerogel derived from waste cotton for sustainable and highly efficient particulate matter capturing. Sep. Purif. Technol. 2021, 254, 117571. [Google Scholar] [CrossRef]

- Wu, C.; Dan, Y.; Tian, D.; Zheng, Y.; Wei, S.; Xiang, D. Facile fabrication of MOF (Fe)@ alginate aerogel and its application for a high-performance slow-release N-fertilizer. Int. J. Biol. Macromol. 2020, 145, 1073–1079. [Google Scholar] [CrossRef] [PubMed]

- Fan, S.; Chen, J.; Fan, C.; Chen, G.; Liu, S.; Zhou, H.; Liu, R.; Zhang, Y.; Hu, H.; Huang, Z.; et al. Fabrication of a CO2-responsive chitosan aerogel as an effective adsorbent for the adsorption and desorption of heavy metal ions. J. Hazard. Mater. 2021, 416, 126225. [Google Scholar] [CrossRef]

- Liu, Y.; Tang, P.; Zhu, Y.; Xie, W.; Yang, P.; Zhang, Z.; Liu, B. Green aerogel adsorbent for removal of organic compounds in shale gas wastewater: High-performance tuning and adsorption mechanism. Chem. Eng. J. 2021, 416, 129100. [Google Scholar] [CrossRef]

- Yue, Y.; Wang, Y.; Li, J.; Cheng, W.; Han, G.; Lu, T.; Huang, C.; Wu, Q.; Jiang, J. High strength and ultralight lignin-mediated fire-resistant aerogel for repeated oil/water separation. Carbon 2022, 193, 285–297. [Google Scholar] [CrossRef]

- Fu, Q.; Si, Y.; Duan, C.; Yan, Z.; Liu, L.; Yu, J.; Ding, B. Highly carboxylated, cellular structured, and underwater superelastic nanofibrous aerogels for efficient protein separation. Adv. Funct. Mater. 2019, 29, 1808234. [Google Scholar] [CrossRef]

- Wu, W.; Wu, Y.; Lin, Y.; Shao, P. Facile fabrication of multifunctional citrus pectin aerogel fortified with cellulose nanofiber as controlled packaging of edible fungi. Food Chem. 2022, 374, 131763. [Google Scholar] [CrossRef] [PubMed]

- Song, M.; Jiang, J.; Qin, H.; Ren, X.; Jiang, F. Flexible and super thermal insulating cellulose nanofibril/emulsion composite aerogel with quasi-closed pores. ACS Appl. Mater. Interfaces 2020, 12, 45363–45372. [Google Scholar] [CrossRef] [PubMed]

- Cao, M.; Liu, B.-W.; Zhang, L.; Peng, Z.-C.; Zhang, Y.-Y.; Wang, H.; Zhao, H.-B.; Wang, Y.-Z. Fully biomass-based aerogels with ultrahigh mechanical modulus, enhanced flame retardancy, and great thermal insulation applications. Compos. Part B Eng. 2021, 225, 109309. [Google Scholar] [CrossRef]

- Zhuo, H.; Hu, Y.; Chen, Z.; Zhong, L. Cellulose carbon aerogel/PPy composites for high-performance supercapacitor. Carbohydr. Polym. 2019, 215, 322–329. [Google Scholar] [CrossRef]

- Wei, D.; Wu, C.; Jiang, G.; Sheng, X.; Xie, Y. Lignin-assisted construction of well-defined 3D graphene aerogel/PEG form-stable phase change composites towards efficient solar thermal energy storage. Sol. Energy Mater. Sol. Cells 2021, 224, 111013. [Google Scholar] [CrossRef]

- Aslam, A.; Ibrahim, M.; Mahmood, A.; Mubashir, M.; Sipra, H.F.K.; Shahid, I.; Ramzan, S.; Latif, M.T.; Tahir, M.Y.; Show, P.L. Mitigation of particulate matters and integrated approach for carbon monoxide remediation in an urban environment. J. Environ. Chem. Eng. 2021, 9, 105546. [Google Scholar] [CrossRef]

- Ji, X.; Huang, J.; Teng, L.; Li, S.; Li, X.; Cai, W.; Chen, Z.; Lai, Y. Advances in particulate matter filtration: Materials, performance, and application. Green Energy Environ. 2023, 8, 673–697. [Google Scholar] [CrossRef]

- Han, D.; Shen, H.; Duan, W.; Chen, L. A review on particulate matter removal capacity by urban forests at different scales. Urban For. Urban Green. 2020, 48, 126565. [Google Scholar] [CrossRef]

- Razzaq, A.; Cui, Y.; Irfan, M.; Maneengam, A.; Acevedo-Duque, Á. Asymmetric effects of fine particulate matter and stringency policy on COVID-19 intensity. Int. J. Environ. Health Res. 2022, 1–13. [Google Scholar] [CrossRef]

- Almeida, S.; Manousakas, M.; Diapouli, E.; Kertesz, Z.; Samek, L.; Hristova, E.; Šega, K.; Alvarez, R.P.; Belis, C.; Eleftheriadis, K. Ambient particulate matter source apportionment using receptor modelling in European and Central Asia urban areas. Environ. Pollut. 2020, 266, 115199. [Google Scholar] [CrossRef]

- Xu, W.; Wang, S.; Jiang, L.; Sun, X.; Wang, N.; Liu, X.; Yao, X.; Qiu, T.; Zhang, C.; Li, J.; et al. The influence of PM2.5 exposure on kidney diseases. Hum. Exp. Toxicol. 2022, 41, 09603271211069982. [Google Scholar] [CrossRef] [PubMed]

- Fischer, P.H.; Marra, M.; Ameling, C.B.; Velders, G.J.; Hoogerbrugge, R.; de Vries, W.; Wesseling, J.; Janssen, N.A.; Houthuijs, D. Particulate air pollution from different sources and mortality in 7.5 million adults—The Dutch Environmental Longitudinal Study (DUELS). Sci. Total Environ. 2020, 705, 135778. [Google Scholar] [CrossRef] [PubMed]

- Leachi, H.F.L.; Marziale, M.H.P.; Martins, J.T.; Aroni, P.; Galdino, M.J.Q.; Ribeiro, R.P. Polycyclic aromatic hydrocarbons and development of respiratory and cardiovascular diseases in workers. Rev. Bras. De Enferm. 2020, 73, e20180965. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bové, H.; Bongaerts, E.; Slenders, E.; Bijnens, E.M.; Saenen, N.D.; Gyselaers, W.; Van Eyken, P.; Plusquin, M.; Roeffaers, M.B.; Ameloot, M.; et al. Ambient black carbon particles reach the fetal side of human placenta. Nat. Commun. 2019, 10, 3866. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Puri, P.; Nandar, S.K.; Kathuria, S.; Ramesh, V. Effects of air pollution on the skin: A review. Indian J. Dermatol. Venereol. Leprol. 2017, 83, 415–423. [Google Scholar]

- Zhao, C.-N.; Xu, Z.; Wu, G.-C.; Mao, Y.-M.; Liu, L.-N.; Wu, Q.; Dan, Y.-L.; Tao, S.-S.; Zhang, Q.; Sam, N.B.; et al. Emerging role of air pollution in autoimmune diseases. Autoimmun. Rev. 2019, 18, 607–614. [Google Scholar] [CrossRef]

- Grzywa-Celińska, A.; Krusiński, A.; Milanowski, J. ‘Smoging kills’-effects of air pollution on human respiratory system. Ann. Agric. Environ. Med. 2020, 27, 1–5. [Google Scholar] [CrossRef]

- Švédová, B.; Raclavská, H.; Kucbel, M.; Růžičková, J.; Raclavský, K.; Koliba, M.; Juchelková, D. Concentration variability of water-soluble ions during the acceptable and exceeded pollution in an industrial region. Int. J. Environ. Res. Public Health 2020, 17, 3447. [Google Scholar] [CrossRef]

- Kitamura, H.; Dahlan, A.V.; Tian, Y.; Shimaoka, T.; Yamamoto, T.; Takahashi, F. Impact of secondary generated minerals on toxic element immobilization for air pollution control fly ash of a municipal solid waste incinerator. Environ. Sci. Pollut. Res. 2018, 25, 20700–20712. [Google Scholar] [CrossRef]

- Shahrbaf, M.A.; Akbarzadeh, M.A.; Tabary, M.; Khaheshi, I. Air pollution and cardiac arrhythmias: A comprehensive review. Curr. Probl. Cardiol. 2021, 46, 100649. [Google Scholar] [CrossRef]

- Dominici, F.; Wang, Y.; Correia, A.W.; Ezzati, M.; Pope III, C.A.; Dockery, D.W. Chemical composition of fine particulate matter and life expectancy: In 95 US counties between 2002 and 2007. Epidemiology 2015, 26, 556. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, H.-J.; Choi, W.S. 2D and 3D bulk materials for environmental remediation: Air filtration and oil/water separation. Materials 2020, 13, 5714. [Google Scholar] [CrossRef]

- Zeb, B.; Alam, K.; Sorooshian, A.; Blaschke, T.; Ahmad, I.; Shahid, I. On the morphology and composition of particulate matter in an urban environment. Aerosol Air Qual. Res. 2018, 18, 1431–1447. [Google Scholar]

- Gilham, R.J.; Spencer, S.J.; Butterfield, D.; Seah, M.P.; Quincey, P.G. On the applicability of XPS for quantitative total organic and elemental carbon analysis of airborne particulate matter. Atmos. Environ. 2008, 42, 3888–3891. [Google Scholar] [CrossRef]

- Xu, J.; Liu, C.; Hsu, P.-C.; Liu, K.; Zhang, R.; Liu, Y.; Cui, Y. Roll-to-roll transfer of electrospun nanofiber film for high-efficiency transparent air filter. Nano Lett. 2016, 16, 1270–1275. [Google Scholar] [CrossRef]

- Hopke, P.K.; Dai, Q.; Li, L.; Feng, Y. Global review of recent source apportionments for airborne particulate matter. Sci. Total Environ. 2020, 740, 140091. [Google Scholar] [CrossRef]

- Ramli, N.A.; Md Yusof, N.F.F.; Shith, S.; Suroto, A. Chemical and biological compositions associated with ambient respirable particulate matter: A review. Water Air Soil Pollut. 2020, 231, 120. [Google Scholar] [CrossRef]

- Lins, T.F.; O’Brien, A.M.; Kose, T.; Rochman, C.M.; Sinton, D. Toxicity of nanoplastics to zooplankton is influenced by temperature, salinity, and natural particulate matter. Environ. Sci. Nano 2022, 9, 2678–2690. [Google Scholar] [CrossRef]

- Han, B.; Xu, J.; Zhang, Y.; Li, P.; Li, K.; Zhang, N.; Han, J.; Gao, S.; Wang, X.; Geng, C.; et al. Associations of exposure to fine particulate matter mass and constituents with systemic inflammation: A cross-sectional study of urban older adults in China. Environ. Sci. Technol. 2022, 56, 7244–7255. [Google Scholar] [CrossRef] [PubMed]

- Lin, L.-Z.; Zhan, X.-L.; Jin, C.-Y.; Liang, J.-H.; Jing, J.; Dong, G.-H. The epidemiological evidence linking exposure to ambient particulate matter with neurodevelopmental disorders: A systematic review and meta-analysis. Environ. Res. 2022, 209, 112876. [Google Scholar] [CrossRef]

- Li, Z.; Tao, B.; Hu, Z.; Yi, Y.; Wang, J. Effects of short-term ambient particulate matter exposure on the risk of severe COVID-19. J. Infect. 2022, 84, 684–691. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.-H.; Zhu, Q.-H.; Zhang, L.; Yong, F.; Zhang, Z.; Wang, S.-L.; Wang, Y.; He, L.; Tao, G.-H. High-performance particulate matter including nanoscale particle removal by a self-powered air filter. Nat. Commun. 2020, 11, 1653. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Riediker, M.; Zink, D.; Kreyling, W.; Oberdörster, G.; Elder, A.; Graham, U.; Lynch, I.; Duschl, A.; Ichihara, G.; Ichihara, S. Particle toxicology and health-where are we? Part. Fibre Toxicol. 2019, 16, 19. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ali, M.U.; Liu, G.; Yousaf, B.; Ullah, H.; Abbas, Q.; Munir, M.A.M. A systematic review on global pollution status of particulate matter-associated potential toxic elements and health perspectives in urban environment. Environ. Geochem. Health 2019, 41, 1131–1162. [Google Scholar] [CrossRef]

- Darwish, Z.A.; Kazem, H.A.; Sopian, K.; Al-Goul, M.; Alawadhi, H. Effect of dust pollutant type on photovoltaic performance. Renew. Sustain. Energy Rev. 2015, 41, 735–744. [Google Scholar] [CrossRef]

- Arick, D.Q.; Choi, Y.H.; Kim, H.C.; Won, Y.-Y. Effects of nanoparticles on the mechanical functioning of the lung. Adv. Colloid Interface Sci. 2015, 225, 218–228. [Google Scholar] [CrossRef]

- Radiom, M.; Sarkis, M.; Brookes, O.; Oikonomou, E.K.; Baeza-Squiban, A.; Berret, J.-F. Pulmonary surfactant inhibition of nanoparticle uptake by alveolar epithelial cells. Sci. Rep. 2020, 10, 19436. [Google Scholar] [CrossRef]

- Kciuk, M.; Yahya, E.B.; Mohamed Ibrahim Mohamed, M.; Rashid, S.; Iqbal, M.O.; Kontek, R.; Abdulsamad, M.A.; Allaq, A.A. Recent Advances in Molecular Mechanisms of Cancer Immunotherapy. Cancers 2023, 15, 2721. [Google Scholar] [CrossRef]

- Zhao, K.; Huang, J.; Mao, J.; Bao, Z.; Chen, Z.; Lai, Y. Charged graphene aerogel filter enabled superior particulate matter removal efficiency in harsh environment. Chem. Eng. J. 2020, 395, 125086. [Google Scholar] [CrossRef]

- Zhu, C.; Yang, F.; Xue, T.; Wali, Q.; Fan, W.; Liu, T. Metal-organic framework decorated polyimide nanofiber aerogels for efficient high-temperature particulate matter removal. Sep. Purif. Technol. 2022, 300, 121881. [Google Scholar] [CrossRef]

- Kumar Sarangi, P.; Subudhi, S.; Bhatia, L.; Saha, K.; Mudgil, D.; Prasad Shadangi, K.; Srivastava, R.K.; Pattnaik, B.; Arya, R.K. Utilization of agricultural waste biomass and recycling toward circular bioeconomy. Environ. Sci. Pollut. Res. 2023, 30, 8526–8539. [Google Scholar] [CrossRef]

- Hu, B.C.; Zhang, H.R.; Li, S.C.; Chen, W.S.; Wu, Z.Y.; Liang, H.W.; Yu, H.P.; Yu, S.H. Robust Carbonaceous Nanofiber Aerogels from All Biomass Precursors. Adv. Funct. Mater. 2023, 33, 2207532. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, X.; Kuang, Y.; Xiao, M.; Su, Y.; Jiang, F. Microstructure and filtration performance of konjac glucomannan-based aerogels strengthened by wheat straw. Int. J. Low-Carbon Technol. 2019, 14, 335–343. [Google Scholar] [CrossRef] [Green Version]

- Wang, W.; Fang, Y.; Ni, X.; Wu, K.; Wang, Y.; Jiang, F.; Riffat, S.B. Fabrication and characterization of a novel konjac glucomannan-based air filtration aerogels strengthened by wheat straw and okara. Carbohydr. Polym. 2019, 224, 115129. [Google Scholar] [CrossRef]

- García-Mayagoitia, S.; Pérez-Hernández, H.; Medina-Pérez, G.; Campos-Montiel, R.G.; Fernández-Luqueño, F. Bio-nanomaterials in the air pollution treatment. In Nanomaterials for Air Remediation; Elsevier: Amsterdam, The Netherlands, 2020; pp. 227–248. [Google Scholar]

- Lin, S.; Fu, X.; Luo, M.; Zhong, W.-H. A Protein Aerogel with Distinctive Filtration Capabilities for Formaldehyde and Particulate Pollutants. Sep. Purif. Technol. 2023, 310, 123179. [Google Scholar] [CrossRef]

- Janmohammadi, M.; Nazemi, Z.; Salehi, A.O.M.; Seyfoori, A.; John, J.V.; Nourbakhsh, M.S.; Akbari, M. Cellulose-based composite scaffolds for bone tissue engineering and localized drug delivery. Bioact. Mater. 2023, 20, 137–163. [Google Scholar] [CrossRef]

- Liu, Y. Functional cellulose aerogel nanocomposites with enhanced adsorption capability and excellent photocatalytic performance. Int. J. Biol. Macromol. 2023, 231, 123393. [Google Scholar] [CrossRef] [PubMed]

- Lyu, P.; Xia, L.; Liu, X.; Hurren, C.; Xu, W.; Wang, X. Self-cleaning superhydrophobic aerogels from waste hemp noil for ultrafast oil absorption and highly efficient PM removal. Sep. Purif. Technol. 2023, 306, 122503. [Google Scholar] [CrossRef]

- Kou, S.G.; Peters, L.M.; Mucalo, M.R. Chitosan: A review of sources and preparation methods. Int. J. Biol. Macromol. 2021, 169, 85–94. [Google Scholar] [CrossRef] [PubMed]

- Yadav, M.; Goswami, P.; Paritosh, K.; Kumar, M.; Pareek, N.; Vivekanand, V. Seafood waste: A source for preparation of commercially employable chitin/chitosan materials. Bioresour. Bioprocess. 2019, 6, 8. [Google Scholar] [CrossRef]

- Chartier, C.; Buwalda, S.; Van Den Berghe, H.; Nottelet, B.; Budtova, T. Tuning the properties of porous chitosan: Aerogels and cryogels. Int. J. Biol. Macromol. 2022, 202, 215–223. [Google Scholar] [CrossRef] [PubMed]

- Desai, K.; Kit, K.; Li, J.; Davidson, P.M.; Zivanovic, S.; Meyer, H. Nanofibrous chitosan non-wovens for filtration applications. Polymer 2009, 50, 3661–3669. [Google Scholar] [CrossRef]

- Sun, Z.; Yue, Y.; He, W.; Jiang, F.; Lin, C.-H.; Pui, D.Y.; Liang, Y.; Wang, J. The antibacterial performance of positively charged and chitosan dipped air filter media. Build. Environ. 2020, 180, 107020. [Google Scholar] [CrossRef]

- Hao, D.; Fu, B.; Zhou, J.; Liu, J. Efficient particulate matter removal by metal-organic frameworks encapsulated in cellulose/chitosan foams. Sep. Purif. Technol. 2022, 294, 120927. [Google Scholar] [CrossRef]

- Venkatesan, J.; Lee, J.-Y.; Kang, D.S.; Anil, S.; Kim, S.-K.; Shim, M.S.; Kim, D.G. Antimicrobial and anticancer activities of porous chitosan-alginate biosynthesized silver nanoparticles. Int. J. Biol. Macromol. 2017, 98, 515–525. [Google Scholar] [CrossRef]

- Sahoo, D.R.; Biswal, T. Alginate and its application to tissue engineering. SN Appl. Sci. 2021, 3, 30. [Google Scholar] [CrossRef]

- Lee, B.B.; Bhandari, B.R.; Howes, T. Air extrusion system for ionotropic alginate microgel particle formation: A review. Chem. Eng. Technol. 2016, 39, 2355–2369. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, C.; Ge, T.; Dai, Y.; Wang, R. Performance study of sodium alginate-nonwoven fabric composite membranes for dehumidification. Appl. Therm. Eng. 2018, 128, 214–224. [Google Scholar] [CrossRef]

- Deng, Y.; Lu, T.; Cui, J.; Ma, W.; Qu, Q.; Zhang, X.; Zhang, Y.; Zhu, M.; Xiong, R.; Huang, C. Morphology engineering processed nanofibrous membranes with secondary structure for high-performance air filtration. Sep. Purif. Technol. 2022, 294, 121093. [Google Scholar] [CrossRef]

- Wu, W.; Ma, L.; Chen, X.; Liu, L.; Dong, S.; Zou, H.; Hao, J. Polyelectrolyte aerogels with regeneration capacity for efficient removal of particulate matters. J. Colloid Interface Sci. 2022, 625, 446–456. [Google Scholar] [CrossRef]

- Alwin, S.; Sahaya Shajan, X. Aerogels: Promising nanostructured materials for energy conversion and storage applications. Mater. Renew. Sustain. Energy 2020, 9, 7. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.; He, J.; Xiong, S.; Xiao, Q.; Xiao, Y.; Ding, F.; Ji, H.; Yang, Z.; Li, Z. Construction and nanostructure of chitosan/nanocellulose hybrid aerogels. Biomacromolecules 2021, 22, 3216–3222. [Google Scholar] [CrossRef] [PubMed]

- Khalil, H.A.; Yahya, E.B.; Tajarudin, H.A.; Surya, I.; Muhammad, S.; Fazita, M.N. Enhancing the properties of industrial waste nanocellulose bioaerogels using turmeric nano particles. Ind. Crops Prod. 2023, 197, 116500. [Google Scholar] [CrossRef]

- Chandrasekaran, R.; Hillgärtner, M.; Ganesan, K.; Milow, B.; Itskov, M.; Rege, A. Computational design of biopolymer aerogels and predictive modelling of their nanostructure and mechanical behaviour. Sci. Rep. 2021, 11, 10198. [Google Scholar] [CrossRef] [PubMed]

- Zhao, S.; Malfait, W.J.; Guerrero-Alburquerque, N.; Koebel, M.M.; Nyström, G. Biopolymer aerogels and foams: Chemistry, properties, and applications. Angew. Chem. Int. Ed. 2018, 57, 7580–7608. [Google Scholar] [CrossRef]

| Field | Application | Type of Aerogel | Remark | Ref. |

| Medical | Drug delivery | Cellulose/sodium alginate aerogels | The aerogel showed sustained release of curcumin | [61] |

| Tissue scaffolding | Nanocellulose/chitosan aerogel | The aerogel exhibited enhanced biocompatibility to human cells | [62] | |

| Wound dressing | Agar-based aerogel | The aerogel significantly shortened in vivo wound healing time | [63] | |

| Biosensing | Chitosan/carbon nanotube aerogel | The aerogel had multifunctional biosensing applications | [64] | |

| Environmental | Air purification | Carbonized cellulose aerogel | The aerogel was able to remove all the PM2.5 and PM10 | [65] |

| Fertilizer delivery | Alginate-based aerogel | The aerogel exhibited sustained release of N-fertilizer | [66] | |

| Heavy metal removal | Chitosan-based aerogel | An effective adsorption and desorption of several heavy metals | [67] | |

| Water treatment | Green porous biochar aerogel | Complete removal of organic compounds was achieved from water | [68] | |

| Industrial | Oil/water separation | Lignin-mediated fire-resistant aerogel | The aerogel was ultralight and had a high strength oil absorption property | [69] |

| Protein separation | Nanofibrous aerogels | Super-elastic aerogel was prepared for efficient protein separation | [70] | |

| Food packaging | Nanocellulose/citrus pectin aerogel | The aerogels exhibited humidity control system for active packaging | [71] | |

| Thermal insulator | Cellulose nanofibril-based aerogel | The aerogel was highly flexible and had super thermal insulation properties | [72] | |

| Others | Flame retardancy | Fully biomass-based aerogels | High flame retardancy was achieved in addition to excellent thermal insulation | [73] |

| Supercapacitor | Cellulose carbon aerogel | High-performance supercapacitor was achieved | [74] | |

| Energy storage | Lignin/graphene/PEG aerogel | The aerogel showed efficient solar thermal energy storage | [75] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saleh, W.M.; Ahmad, M.I.; Yahya, E.B.; H.P.S., A.K. Nanostructured Bioaerogels as a Potential Solution for Particulate Matter Pollution. Gels 2023, 9, 575. https://doi.org/10.3390/gels9070575

Saleh WM, Ahmad MI, Yahya EB, H.P.S. AK. Nanostructured Bioaerogels as a Potential Solution for Particulate Matter Pollution. Gels. 2023; 9(7):575. https://doi.org/10.3390/gels9070575

Chicago/Turabian StyleSaleh, Wafa Mustafa, Mardiana Idayu Ahmad, Esam Bashir Yahya, and Abdul Khalil H.P.S. 2023. "Nanostructured Bioaerogels as a Potential Solution for Particulate Matter Pollution" Gels 9, no. 7: 575. https://doi.org/10.3390/gels9070575

APA StyleSaleh, W. M., Ahmad, M. I., Yahya, E. B., & H.P.S., A. K. (2023). Nanostructured Bioaerogels as a Potential Solution for Particulate Matter Pollution. Gels, 9(7), 575. https://doi.org/10.3390/gels9070575