Pristine and Coated Carbon Nanotube Sheets—Characterization and Potential Applications

Abstract

:1. Background

Polysilazane Sealant Description

2. Experimentation

2.1. Sheet Thickness Measurement

2.2. Vertical Flame Test

2.2.1. General Procedure

2.2.2. Experimental Results

2.3. Average Resistivity of Thin CNT Sheets

2.3.1. General Procedure

2.3.2. Experimental Results

2.4. Tensile Strength

2.4.1. Procedure

2.4.2. Experimental Results

2.5. Raman Spectroscopy

2.5.1. Procedure

2.5.2. Experimental Results

2.6. Handleability (Ability to Be Manipulated, Folded, Pulled)

2.6.1. Procedure

2.6.2. Experimental Results

2.7. Density

2.7.1. Procedure

2.7.2. Experimental Results

2.8. Hydrophobicity Test

2.8.1. Procedure

2.8.2. Experimental Results

2.9. Other Properties

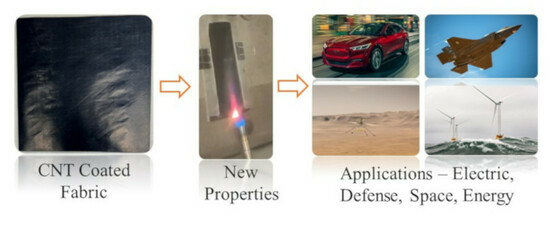

3. Applications

3.1. Battery Secondary Enclosure

3.2. Textile Conductor for Soft Actuators

3.3. CNT Composited Textiles as Shielding Materials

3.4. Automotive Smart Fabric Components

3.5. Aircraft High-Temperature Laminated Composites

4. Conclusions and Summary

- Vertical flame test: Both the polysilazane-coated CNT and the pristine CNT demonstrated notable flame resistance. The polysilazane-coated CNT had a shorter tear length and less burn damage after exposure to a flame in comparison to the uncoated pristine CNT;

- Average surface resistivity: Both the pristine and polysilazane-coated materials exhibited moderate electrical resistance, indicating their applicability for electrical applications such as electromagnetic shielding;

- Tensile strength: Polysilazane-coated CNT sheets on average were stronger than pristine CNT sheer and stronger in the winding direction versus the transverse in-plane direction. Polysilazane coating reduces the shedding of CNT particles from the sheet. The polysilazane-coated CNT sheet also seems to be a more compacted CNT fabric, thus increasing the strength. CNT sheets, being nonwoven, have low strength and very high strain to failure;

- Raman spectroscopy: The G/D ratio of the peaks for the pristine CNT sample is 7.5 and that for the polysilazane-coated CNT sheet is 4.5. The pristine sample’s higher G/D ratio indicates increased crystallinity and purity (which is related to quality) of the CNT sheets, as polysilazane-coated CNT sheets are composed of materials other than carbon;

- Handleability: The polysilazane-coated CNT sheet exhibited a comparatively higher rigidity when compared to the pristine CNT sheet and notably lacked the creases or wrinkles that were apparent in the pristine material. The polysilazane-coated CNT sheet emitted significantly less audible noise in comparison to the pristine CNT sheet when flexing the fabric. An important outcome of the study was that coated CNT almost eliminated shedding of CNT strands from the fabric;

- Density: The density for the pristine CNT was found to be 0.48 g/cc and that for the polysilazane-coated sheet was 0.65 g/cc. Thickness of the sheet was difficult to measure due to compressibility of the material, which causes error in the density calculation;

- Hydrophobicity: Both sheets are hydrophobic. The polysilazane-coated CNT fabric is more hydrophobic than the pristine CNT fabric. However, oil droplets slowly seeped through both sheets.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Giri, P.; Kondapalli, V.K.R.; Joseph, K.M.; Shanov, V.; Schulz, M. Manufacturing Scalable Carbon Nanotube–Silicone/Kevlar Fabrics. Nanomaterials 2023, 13, 2728. [Google Scholar] [CrossRef] [PubMed]

- Available online: https://www.huntsman.com/products/detail/344/miralon (accessed on 25 November 2023).

- Available online: https://ceas.uc.edu/research/centers-labs/nanoworld.html (accessed on 25 November 2023).

- Polysilazane Suppliers: Hathaway Advanced Materials and Durazane®|Merck KGaA, Darmstadt, Germany (emdgroup.com). Available online: https://www.hathawayresearch.com/ (accessed on 26 November 2023).

- Available online: https://docplayer.net/32233542-Tb1-kion-polysilazane-polyureasilazane-and-kion-polysilazane-polysilazane-20-heat-curable-resins-description-uses.html (accessed on 26 November 2023).

- D’Elia, R.; Dusserre, G.; Del-Confetto, S.; Eberling-Fux, N.; Descamps, C.; Cutard, T. Cure kinetics of a polysilazane system: Experimental characterization and numerical modelling. Eur. Polym. J. 2016, 76, 40–52. [Google Scholar] [CrossRef]

- Arevalo-Fester, J. Re: Are Carbon Nano Tubes Flammable? 2014. Available online: https://www.researchgate.net/post/Are_carbon_nano_tubes_flammable/532c4a41d11b8bfe148b460a/citation/download (accessed on 26 November 2023).

- Available online: https://albarrie.com/products/nonwoven-meta-aramid-nomex-technical-fabric/#details (accessed on 26 November 2023).

- Wang, C.; Chen, F.; Kuan, S.; Chen, R.; Li, M.; Zhou, X.; Sun, Y.; Chen, D.; Wang, C. Contributed Review: Instruments for measuring Seebeck coefficient of thin film thermoelectric materials: A mini-review. Rev. Sci. Instrum. 2018, 89, 101501. [Google Scholar] [CrossRef] [PubMed]

- Nagaraj, N. A short account of thermoelectric film characterization techniques. Mater. Today Phys. 2023, 36, 101173. [Google Scholar] [CrossRef]

- Tang, X.; Tian, M.; Qu, L.; Zhu, S. Functionalization of cotton fabric with graphene oxide nanosheet and polyaniline for conductive and UV blocking properties. Synth. Met. 2015, 202, 82–88. [Google Scholar] [CrossRef]

- Characterizing Carbon Materials with Raman Spectroscopy. Available online: https://assets.thermofisher.com/TFS-Assets/CAD/Application-Notes/D19504.pdf (accessed on 26 November 2023).

- Sian, F.; Christopher, A.; Howard, R.; Heenan, K.; Neal, T.; Skipper, T.; Milo, S.; Shaffer, P. Scalable Method for the Reductive Dissolution, Purification, and Separation of Single-Walled Carbon Nanotubes. ACS Nano 2012, 6, 54–62. [Google Scholar]

- Lithium-Ion Battery Fires from Electric Cars, Bikes and Scooters Are on the Rise. Are Firefighters Ready?—CBS News. Available online: https://www.cbsnews.com/news/lithium-ion-battery-fires-electric-cars-bikes-scooters-firefighters/ (accessed on 26 November 2023).

- Available online: https://www.pcmag.com/news/profit-vs-the-planet-heres-why-us-automakers-are-all-in-on-electric-vehicles#:~:text=Under%20CEO%20Mary%20Barra’s%20%E2%80%9Czero,are%20first%20up%2C%20by%202030 (accessed on 26 November 2023).

- Available online: https://www.vox.com/the-highlight/2023/1/17/23470878/tesla-fires-evs-florida-hurricane-batteries-lithium-ion (accessed on 26 November 2023).

- Ng, V.; Hou, G.; Kim, J.; Beaucage, G.; Schulz, M.J. Carbon nanofabric: A multifunctional fire-resistant material. Carbon Trends 2022, 7, 100165. [Google Scholar] [CrossRef]

- Chambers, S. Everything You Need to Know About EMI Shielding. Strouse. 17 August 2023. Available online: https://www.strouse.com/blog/what-is-emi-shielding (accessed on 26 November 2023).

- Bonaldi, R.R.; Siores, E.; Shah, T. Characterization of electromagnetic shielding fabrics obtained from carbon nanotube composite coatings. Synth. Met. 2014, 187, 1–8. [Google Scholar] [CrossRef]

- Cirino, E.; Lamoreux, K. EMF Exposure. Healthline, Healthline Media. 8 May 2023. Available online: www.healthline.com/health/emf (accessed on 26 November 2023).

- The Modus Advanced Blog|EMI Shielding (3). Available online: https://www.modusadvanced.com/resources/blog/topic/emi-shielding (accessed on 26 November 2023).

- Blachowicz, T.; Wójcik, D.; Surma, M.; Magnuski, M.; Ehrmann, G.; Ehrmann, A. Textile Fabrics as Electromagnetic Shielding Materials—A Review of Preparation and Performance. Fibers 2023, 11, 29. [Google Scholar] [CrossRef]

- Available online: https://www.uc.edu/news/articles/2023/09/ohio-grant-gives-uc-researchers-over-25-million-in-total-to-research-firefighter-protective-gear.html (accessed on 26 November 2023).

- Available online: https://patents.google.com/patent/US9396829B2/en (accessed on 26 November 2023).

- Rawal, S.; Brantley, J.; Karabudak, N. Development of carbon nanotube-based composite for spacecraft components. In Proceedings of the RAST 2013 6th International Conference on Recent Advances in Space Technologies, Istanbul, Turkey, 12–14 June 2013; pp. 13–19. [Google Scholar] [CrossRef]

- Zhe, L.; Ayou, H.; Songlin, Z.; Yourri-Samuel, D.; Liang, R. Lightweight carbon nanotube surface thermal shielding for carbon fiber/bismaleimide composites. Carbon 2019, 153, 320–329. [Google Scholar]

- Chung, D.D.L. Materials for electromagnetic interference shielding. Mater. Chem. Phys. 2020, 255, 123587. [Google Scholar] [CrossRef]

- Subhash, B.; Kondawar, P.; Modak, R. Chapter 2—Theory of EMI Shielding; Kuruvilla, J., Runcy, W., Gejo, G., Eds.; Materials for Potential EMI Shielding Applications; Elsevier: Amsterdam, The Netherlands, 2020; pp. 9–25. ISBN 9780128175903. [Google Scholar] [CrossRef]

- Available online: https://www.iqsdirectory.com/articles/emi-shielding.html (accessed on 26 November 2023).

- Seyyed, A.H.; Ahmadreza, G.; Ehsan, H.; Sonia, B.; Parisa, N.; Navid, O.; Seyyed, M.M.; Majed, A.; Mehrorang, G.; Seeram, R.; et al. Recent progress on hybrid fibrous electromagnetic shields: Key protectors of living species against electromagnetic radiation. Matter 2022, 5, 3807–3868. [Google Scholar] [CrossRef]

- Elnashar, E. Functional Textiles for Airbags in Automotive Industrial. Academia.Edu. 19 March 2016. Available online: www.academia.edu/23437947/Functional_textiles_for_airbags_In_Automotive_Industrial?auto=download (accessed on 27 November 2023).

- Powell, N.B. Design of automotive interior textiles. In Textile Advances in the Automotive Industry; Elsevier Science: Amsterdam, The Netherlands, 2008; p. 113. [Google Scholar]

- Redaktion. Reutlingen University: User-Friendly Textile-Based Interactive Car Interior Using Bio-Based Materials. 12 May 2021. Available online: www.textiletechnology.net/technology/trendreports/reutlingen-university-user-friendly-textile-based-interactive-car-interior-using-bio-based-materials-30251 (accessed on 27 November 2023).

- Arora, S.; Rekha, M.Y.; Gupta, A.; Srivastava, C. High corrosion resistance offered by carbon nanotubes directly grown over mild steel substrate. Microsc. Microanal. 2019, 25, 750–751. [Google Scholar] [CrossRef]

- Electronic Sensors. Force Sensing Resistor (FSR). Available online: https://www.tekscan.com/blog/flexiforce/how-does-force-sensing-resistor-fsr-work (accessed on 26 November 2023).

- Available online: https://www.interlinkelectronics.com/force-sensing-resistor (accessed on 27 November 2023).

- Available online: https://news.mit.edu/2020/carbon-nanotubes-making-airplane-aerospace-parts-1013 (accessed on 25 November 2023).

- Available online: https://physicsworld.com/a/carbon-nanotubes-bring-aircraft-manufacturing-out-of-the-oven/ (accessed on 25 November 2023).

- Adhesive & Prepreg Supplier for the Aerospace Market|Renegade Materials. Available online: http://www.renegadematerials.com/ (accessed on 25 November 2023).

| Sample | After-Flame Time | Afterglow Time | Char Length | Tear Length |

|---|---|---|---|---|

| Pristine CNT | <1 s | <1 s | <30 mm | 20 mm |

| Polysilazane-coated CNT | <1 s | <1 s | <30 mm | 11 mm |

| S. No. | Sample Name | Average Sheet Resistance (Ω/sq) | Thickness (cm) | Thin-Film Resistivity (Ω·cm) |

|---|---|---|---|---|

| 1 | Pristine CNT | 0.649 | 0.00273 | 0.0018 |

| 2 | Polysilazane-Coated CNT | 0.482 | 0.00241 | 0.0012 |

| Type | Mass (g) | Length (cm) | Width (cm) | Thickness (cm) | Volume (cm^3) | Density (g/cc) |

|---|---|---|---|---|---|---|

| Pristine CNT | 0.1901 | 12 | 12 | 0.00273 | 0.3931 | 0.48 |

| Polysilazane-coated CNT | 0.2245 | 12 | 12 | 0.00241 | 0.3470 | 0.65 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Giri, P.; Gill, I.; Swensgard, M.; Kaiser, A.; Rust, A.; Stuparyk, B.; Fisher, A.; Williams, J.; Renoit, K.; Kreeb, E.; et al. Pristine and Coated Carbon Nanotube Sheets—Characterization and Potential Applications. C 2024, 10, 17. https://doi.org/10.3390/c10010017

Giri P, Gill I, Swensgard M, Kaiser A, Rust A, Stuparyk B, Fisher A, Williams J, Renoit K, Kreeb E, et al. Pristine and Coated Carbon Nanotube Sheets—Characterization and Potential Applications. C. 2024; 10(1):17. https://doi.org/10.3390/c10010017

Chicago/Turabian StyleGiri, Prakash, Irwin Gill, Morgan Swensgard, Alexandra Kaiser, Audrey Rust, Brian Stuparyk, Andrew Fisher, Justice Williams, Katie Renoit, Eleanor Kreeb, and et al. 2024. "Pristine and Coated Carbon Nanotube Sheets—Characterization and Potential Applications" C 10, no. 1: 17. https://doi.org/10.3390/c10010017

APA StyleGiri, P., Gill, I., Swensgard, M., Kaiser, A., Rust, A., Stuparyk, B., Fisher, A., Williams, J., Renoit, K., Kreeb, E., Lavenan, C., & Schulz, M. J. (2024). Pristine and Coated Carbon Nanotube Sheets—Characterization and Potential Applications. C, 10(1), 17. https://doi.org/10.3390/c10010017