Three-Dimensional Carbon Nanostructures for Advanced Lithium-Ion Batteries

Abstract

:1. Introduction

2. Literature Survey

3. 3D Carbon-Nanostructured Electrodes: Published Results

3.1. Fabrication of 3D CNTs

3.2. 3D CNT Growth

3.3. 3D Multi-Layered CNTs

3.4. 3D CNT-Based Flexible LIB

3.5. 3D Carbon Nanotube–Graphene Seamless Structure

3.6. 3D Carbon Nanotube–Graphene for Flexible LIB

3.7. 3D Carbon Nanotube–Amorphous Silicon

3.8. 3D Multi-Layered Structure of Graphene–Silicon Quantum Dots

4. Conclusions and Perspectives

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Yang, Z.G.; Zhang, J.L.; Kintner-Meyer, M.C.W.; Lu, X.C.; Choi, D.W.; Lemmon, J.P.; Liu, J. Electrochemical energy storage for green grid. Chem. Rev. 2011, 111, 3577–3613. [Google Scholar] [CrossRef] [PubMed]

- Jeong, G.; Kim, Y.U.; Kim, H.; Kim, Y.J.; Sohn, H.J. Prospective materials and applications for Li secondary batteries. Energy Environ. Sci. 2011, 4, 1986–2002. [Google Scholar] [CrossRef]

- Winter, M.; Moeller, K.-C.; Besenhard, J.O. Carbonaceous and Graphitic Anodes. In Lithium Batteries: Science and Technology; Nazri, G.-A., Pistoia, G., Eds.; Springer: New York, NY, USA, 2004; pp. 144–194. [Google Scholar]

- Ji, L.; Lin, Z.; Alcoutlabi, M.; Zhang, X. Recent developments in nanostructured anode materials for rechargeable lithium-ion batteries. Energy Environ. Sci. 2011, 4, 2682–2699. [Google Scholar] [CrossRef]

- Landi, B.J.; Ganter, M.J.; Cress, C.D.; DiLeo, R.A.; Raffaelle, R.P. Carbon nanotubes for lithium ion batteries. Energy Environ. Sci. 2009, 2, 638–654. [Google Scholar] [CrossRef]

- Yoo, E.; Kim, J.; Hosono, E.; Zhou, H.; Kudo, T.; Honma, I. Large Reversible Li Storage of Graphene Nanosheet Families for Use in Rechargeable Lithium Ion Batteries. Nano Lett. 2008, 8, 2277–2282. [Google Scholar] [CrossRef] [PubMed]

- Ajayan, P.M.; Zhou, O.Z. Applications of Carbon Nanotubes. In Carbon Nanotubes Synthesis, Structure, Properties, and Application; Dresselhaus, M.S., Dresselhaus, G., Avouris, P., Eds.; Springer: New York, NY, USA, 2001; pp. 401–404. [Google Scholar]

- Aricò, A.S.; Bruce, P.; Scrosati, B.; Tarascon, J.M.; Schalkwijk, W.V. Nanostructured materials for advanced energy conversion and storage devices. Nat. Mater. 2005, 4, 366–377. [Google Scholar] [CrossRef] [PubMed]

- Che, G.; Lakshmi, B.B.; Fisher, E.R.; Martin, C.R. Carbon nanotubule membranes for electrochemical energy storage and production. Nature 1998, 393, 346–349. [Google Scholar] [CrossRef]

- Frackowiak, E.; Gautier, S.; Gaucher, H.; Bonnamy, S.; Beguin, F. Electrochemical storage of lithium in multiwalled carbon nanotubes. Carbon 1999, 37, 61–69. [Google Scholar] [CrossRef]

- Gao, B.; Bower, C.; Lorentzen, J.D.; Fleming, L.; Kleinhammes, A.; Tang, X.P.; McNeil, L.E.; Wu, Y.; Zhou, O. Enhanced saturation lithium composition in ball-milled single-walled carbon nanotubes. Chem. Phys. Lett. 2000, 327, 69–75. [Google Scholar] [CrossRef]

- Shin, H.C.; Liu, M.; Sadanadan, B.; Rao, A.M. Lithium insertion into chemically etched multi-walled carbon nanotubes. J. Solid State Electrochem. 2004, 8, 908–913. [Google Scholar] [CrossRef]

- Chen, J.; Minett, A.I.; Liu, Y.; Lynam, C.; Sherrell, P.; Wang, C.; Wallace, G.G. Direct Growth of Flexible Carbon Nanotube Electrodes. Adv. Mater. 2008, 20, 566–570. [Google Scholar] [CrossRef]

- Wang, X.X.; Wang, J.N.; Chang, H.; Zhang, Y.F. Preparation of Short Carbon Nanotubes and Application as an Electrode Material in Li-Ion Batteries. Adv. Funct. Mater. 2007, 17, 3613–3618. [Google Scholar] [CrossRef]

- Ng, S.H.; Wang, J.; Guo, Z.P.; Chen, J.; Wang, G.X.; Liu, H.K. Single wall carbon nanotube paper as anode for lithium-ion battery. Electrochim. Acta 2005, 51, 23–28. [Google Scholar] [CrossRef]

- Shah, A.; Ates, M.N.; Kotz, S.; Seo, J.; Abraham, M.; Somu, S.; Busnaina, A. A Layered Carbon Nanotube Architecture for High Power Lithium Ion Batteries. J. Electrochem. Soc. 2014, 161, A989–A995. [Google Scholar] [CrossRef]

- Yang, S.; Huo, J.; Song, H.; Chen, X. A comparative study of electrochemical properties of two kinds of carbon nanotubes as anode materials for lithium ion batteries. Electrochim. Acta 2008, 53, 2238–2244. [Google Scholar] [CrossRef]

- Chew, S.Y.; Ng, S.H.; Wang, J.; Novák, P.; Krumeich, F.; Chou, S.L.; Chen, J.; Liu, H.K. Flexible free-standing carbon nanotube films for model lithium-ion batteries. Carbon 2009, 47, 2976–2983. [Google Scholar] [CrossRef]

- Yoon, S.; Lee, S.; Kim, S.; Park, K.W.; Cho, D.; Jeong, Y. Carbon nanotube film anodes for flexible lithium ion batteries. J. Power Sources 2015, 279, 495–501. [Google Scholar] [CrossRef]

- Qie, L.; Chen, W.M.; Wang, Z.H.; Shao, Q.G.; Li, X.; Yuan, L.X.; Hu, X.L.; Zhang, W.X.; Huang, Y.H. Nitrogen-Doped Porous Carbon Nanofiber Webs as Anodes for Lithium Ion Batteries with a Superhigh Capacity and Rate Capability. Adv. Mater. 2012, 24, 2047–2050. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Yang, J.; Hu, Y.; Wang, J.; Li, Y.; Cai, M.; Li, R.; Sun, X. Novel approach toward a binder-free and current collector-free anode configuration: Highly flexible nanoporous carbon nanotube electrodes with strong mechanical strength harvesting improved lithium storage. J. Mater. Chem. 2012, 22, 18847–18853. [Google Scholar] [CrossRef]

- Lahiri, I.; Oh, S.W.; Hwang, J.Y.; Cho, S.; Sun, Y.K.; Banerjee, R.; Choi, W. High Capacity and Excellent Stability of Lithium Ion Battery Anode Using Interface-Controlled Binder-Free Multiwall Carbon Nanotubes Grown on Copper. ACS Nano 2010, 4, 3440–3446. [Google Scholar] [CrossRef] [PubMed]

- Lahiri, I.; Oh, S.M.; Hwang, J.Y.; Kang, C.W.; Choi, M.S.; Jeon, H.T.; Banerjee, R.; Sun, Y.K.; Choi, W.B. Ultrathin alumina-coated carbon nanotubes as an anode for high capacity Li-ion batteries. J. Mater. Chem. 2011, 21, 13621–13626. [Google Scholar] [CrossRef]

- Luo, B.; Zhi, L. Design and construction of three dimensional graphene-based composites for lithium ion battery applications. Energy Environ. Sci. 2015, 8, 456–477. [Google Scholar] [CrossRef]

- Raccichini, R.; Varzi, A.; Passerini, S.; Scrosati, B. The role of graphene for electrochemical energy storage. Nat. Mater. 2015, 14, 271–279. [Google Scholar] [CrossRef] [PubMed]

- Zhou, G.; Wang, D.W.; Yin, L.C.; Li, N.; Li, F.; Cheng, H.M. Oxygen Bridges between NiO Nanosheets and Graphene for Improvement of Lithium Storage. ACS Nano 2012, 6, 3214–3223. [Google Scholar] [CrossRef] [PubMed]

- Hou, J.; Cao, C.; Idrees, F.; Ma, X. Hierarchical Porous Nitrogen-Doped Carbon Nanosheets Derived from Silk for Ultrahigh-Capacity Battery Anodes and Supercapacitors. ACS Nano 2015, 9, 2556–2564. [Google Scholar] [CrossRef] [PubMed]

- Roberts, A.D.; Li, X.; Zhang, H. Porous carbon spheres and monoliths: Morphology control, pore size tuning and their applications as Li-ion battery anode materials. Chem. Soc. Rev. 2014, 43, 4341–4356. [Google Scholar] [CrossRef] [PubMed]

- Gogotsi, Y.; Simon, P. True Performance Metrics in Electrochemical Energy Storage. Science 2011, 334, 917–918. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, C.; Lv, W.; Tao, Y.; Yang, Q.H. Towards superior volumetric performance: Design and preparation of novel carbon materials for energy storage. Energy Environ. Sci. 2015, 8, 1390–1403. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, D.; Wang, X.; Jia, X.; Wei, F.; Li, H.; Lu, Y. High-Performance Energy-Storage Architectures from Carbon Nanotubes and Nanocrystal Building Blocks. Adv. Mater. 2012, 24, 2030–2036. [Google Scholar] [CrossRef] [PubMed]

- Novák, P.; Goers, D.; Spahr, M.E. Carbon Materials in Lithium-Ion Batteries. In Carbons for Electrochemical Energy Storage and Conversion Systems; Béguin, F., Frąckowiak, E., Eds.; CRC Press: Boca Raton, FL, USA, 2010; p. 300. [Google Scholar]

- Kang, C.W.; Lahiri, I.; Baskaran, R.; Kim, W.G.; Sun, Y.K.; Choi, W.B. 3-dimensional carbon nanotube for Li-ion battery anode. J. Power Sources 2012, 219, 364–370. [Google Scholar] [CrossRef]

- Dillon, S.J.; Sun, K. Microstructural design considerations for Li-ion battery systems. Curr. Opin. Solid State Mater. Sci. 2012, 16, 153–162. [Google Scholar] [CrossRef]

- Zhang, H.; Yu, X.; Braun, P.V. Three-dimensional bicontinuous ultrafast-charge and -discharge bulk battery electrodes. Nat. Nanotechnol. 2011, 6, 277–281. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.G.; Braun, P.V. Three-dimensional metal scaffold supported bicontinuous silicon battery anodes. Nano Lett. 2012, 12, 2778–2783. [Google Scholar] [CrossRef] [PubMed]

- Arbizzani, C.; Beninati, S.; Lazzari, M.; Mastragostino, M. Carbon paper as three-dimensional conducting substrate for tin anodes in lithium-ion batteries. J. Power Sources 2005, 141, 149–155. [Google Scholar] [CrossRef]

- Cheah, S.K.; Perre, E.; Rooth, M.; Fondell, M.; Hårsta, A.; Nyholm, L.; Boman, M.; Gustafsson, T.; Lu, J.; Simon, P.; et al. Self-Supported Three-Dimensional Nanoelectrodes for Microbattery Applications. Nano Lett. 2009, 9, 3230–3233. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.Q.; Xia, X.H.; Wang, X.L.; Mai, Y.J.; Shi, S.J.; Tang, Y.Y.; Gu, C.G.; Tu, J.P. Three-dimensional porous nano-Ni supported silicon composite film for high-performance lithium-ion batteries. J. Power Sources 2012, 213, 106–111. [Google Scholar] [CrossRef]

- Taberna, L.; Mitra, S.; Poizot, P.; Simon, P.; Tarascon, J.M. High rate capabilities Fe3O4-based Cu nano-architectured electrodes for lithium-ion battery applications. Nat. Mater. 2006, 5, 567–573. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.H.; Myung, S.T.; Sun, Y.K. Molten salt synthesis of LiNi0.5Mn1.5O4 spinel for 5 V class cathode material of Li-ion secondary battery. Electrochim. Acta 2004, 49, 219–227. [Google Scholar] [CrossRef]

- Guo, J.C.; Wang, C.S. A polymer scaffold binder structure for high capacity silicon anode of lithium-ion battery. Chem. Commun. 2010, 46, 1428–1430. [Google Scholar] [CrossRef] [PubMed]

- Gregorczyk, K.E.; Kozen, A.C.; Chen, X.; Schroeder, M.A.; Cao, M.N.A.; Hu, L.; Rubloff, G.W. Fabrication of 3D Core–Shell Multiwalled Carbon Nanotube@RuO2 Lithium-Ion Battery Electrodes through a RuO2 Atomic Layer Deposition Process. ACS Nano 2015, 9, 464–473. [Google Scholar] [CrossRef] [PubMed]

- Lahiri, I.; Choi, W. Carbon Nanostructures in Lithium Ion Batteries: Past, Present, and Future. Crit. Rev. Solid State Mater. Sci. 2013, 38, 128–166. [Google Scholar] [CrossRef]

- De Las Casas, C.; Li, W. A review of application of carbon nanotubes for lithium ion battery anode material. J. Power Sources 2012, 208, 74–85. [Google Scholar] [CrossRef]

- Kaskhedikar, N.A.; Maier, J. Lithium Storage in Carbon Nanostructures. Adv. Mater. 2009, 21, 2664–2680. [Google Scholar] [CrossRef]

- Yang, Z.; Ren, J.; Zhang, Z.; Chen, X.; Guan, G.; Qiu, L.; Zhang, Y.; Peng, H. Recent Advancement of Nanostructured Carbon for Energy. Chem. Rev. 2015, 115, 5159–5223. [Google Scholar] [CrossRef] [PubMed]

- Lee, T.I.; Jegal, J.P.; Park, J.H.; Choi, W.H.; Lee, J.O.; Kim, K.B.; Myoung, J.M. Three-Dimensional Layer-by-Layer Anode Structure Based on Co3O4 Nanoplates Strongly Tied by Capillary-like Multiwall Carbon Nanotubes for Use in High-Performance Lithium-Ion Batteries. ACS Appl. Mater. Interfaces 2015, 7, 3861–3865. [Google Scholar] [CrossRef] [PubMed]

- Kang, C.W.; Cha, E.; Baskaran, R.; Choi, W.B. Three-dimensional free-standing carbon nanotubes (CNTs) for flexible lithium-ion battery anode. Nanotechnology 2016, 27, 105402. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Zhu, H.; Chen, Y.C.; Shang, Y.; Cao, A.; Hu, L.; Rubloff, G.W. MWCNT/V2O5 Core/Shell Sponge for High Areal Capacity and Power Density Li-Ion Cathodes. ACS Nano 2012, 6, 7948–7955. [Google Scholar] [CrossRef] [PubMed]

- Hu, L.; Wu, H.; Gao, Y.; Cao, A.; Li, H.; McDough, J.; Xie, X.; Zhou, M.; Cui, Y. Silicon–Carbon Nanotube Coaxial Sponge as Li-Ion Anodes with High Areal Capacity. Adv. Energy Mater. 2011, 1, 523–527. [Google Scholar] [CrossRef]

- Hu, L.; Mantia, F.L.; Wu, H.; Xie, X.; McDonough, J.; Pasta, M.; Cui, Y. Lithium-Ion Textile Batteries with Large Areal Mass Loading. Adv. Energy Mater. 2011, 1, 1012–1017. [Google Scholar] [CrossRef]

- Xiao, Q.; Fan, Y.; Wang, X.; Susantyoko, R.A.; Zhang, Q. A multilayer Si/CNT coaxial nanofiber LIB anode with a high areal capacity. Energy Environ. Sci. 2014, 7, 655–661. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, H.; Shen, P.K. Ultrasmall metal oxide nanoparticles anchored on three-dimensional hierarchical porous gaphene-like networks as anode for high-performance lithium ion batteries. Nano Energy 2015, 13, 563–572. [Google Scholar] [CrossRef]

- Yang, Y.; Fan, X.; Casillas, G.; Peng, Z.; Ruan, G.; Wang, G.; Yacaman, M.J.; Tour, J.M. Three-Dimensional Nanoporous Fe2O3/Fe3C-Graphene Heterogeneous Thin Films for Lithium-Ion Batteries. ACS Nano 2014, 8, 3939–3946. [Google Scholar] [CrossRef] [PubMed]

- Xin, X.; Zhou, X.; Wang, F.; Yao, X.; Xu, X.; Zhu, Y.; Liu, Z. A 3D porous architecture of Si/graphene nanocomposite as high-performance anode materials for Li-ion batteries. J. Mater. Chem. 2012, 22, 7724–7730. [Google Scholar] [CrossRef]

- Rangasamy, B.; Hwang, J.Y.; Choi, W.B. Multi layered Si–CuO quantum dots wrapped by graphene for high-performance anode material in lithium-ion battery. Carbon 2014, 77, 1065–1072. [Google Scholar] [CrossRef]

- Shen, L.; Zhang, X.; Li, H.; Yuan, C.; Cao, G. Design and Tailoring of a Three-Dimensional TiO2-Graphene-Carbon Nanotube Nanocomposite for Fast Lithium Storage. J. Phys. Chem. Lett. 2011, 2, 3096–3101. [Google Scholar] [CrossRef]

- Li, N.; Chen, Z.; Ren, W.; Li, F.; Cheng, H.M. Flexible graphene-based lithium ion batteries with ultrafast charge and discharge rates. Proc. Natl. Acad. Sci. USA 2012, 109, 17360–17365. [Google Scholar] [CrossRef] [PubMed]

- Tao, L.; Zai, J.; Wang, K.; Wan, Y.; Zhang, H.; Yu, C.; Xiao, Y.; Qian, X. 3D-hierarchical NiO–graphene nanosheet composites as anodes for lithium ion batteries with improved reversible capacity and cycle stability. RSC Adv. 2012, 2, 3410–3415. [Google Scholar] [CrossRef]

- Wang, B.; Li, X.; Qiu, T.; Luo, B.; Ning, J.; Li, J.; Zhang, X.; Liang, M.; Zhi, L. High Volumetric Capacity Silicon-Based Lithium Battery Anodes by Nanoscale System Engineering. Nano Lett. 2013, 13, 5578–5584. [Google Scholar] [CrossRef] [PubMed]

- Qin, J.; He, C.; Zhao, N.; Wang, Z.; Shi, C.; Liu, E.N.; Li, J. Graphene Networks Anchored with Sn@Graphene as Lithium Ion Battery Anode. ACS Nano 2014, 8, 1728–1738. [Google Scholar] [CrossRef] [PubMed]

- Kang, C.W.; Baskaran, R.; Hwang, J.Y.; Ku, B.C.; Choi, W.B. Large Scale Patternable 3-Dimensional Carbon Nanotubes-Graphene Structure for Flexible Li-ion Battery. Carbon 2014, 68, 493–500. [Google Scholar] [CrossRef]

- Li, L.; Zhou, G.; Weng, Z.; Shan, X.Y.; Li, F.; Cheng, H.M. Monolithic Fe2O3/graphene hybrid for highly efficient lithium storage and arsenic removal. Carbon 2014, 67, 500–507. [Google Scholar] [CrossRef]

- Wang, R.; Xu, C.; Sun, J.; Gao, L.; Lin, C. Flexible free-standing hollow Fe3O4/graphene hybrid films for lithium-ion batteries. J. Mater. Chem. A 2013, 1, 1794–1800. [Google Scholar] [CrossRef]

- Yu, A.; Park, H.W.; Davies, A.; Higgins, D.C.; Chen, Z.; Xiao, X. Free-Standing Layer-By-Layer Hybrid Thin Film of Graphene-MnO2 Nanotube as Anode for Lithium Ion Batteries. J. Phys. Chem. Lett. 2011, 2, 1855–1860. [Google Scholar] [CrossRef]

- Wang, G.; Wang, B.; Wang, X.; Park, J.; Dou, S.; Ahn, H.; Kim, K. Sn/graphene nanocomposite with 3D architecture for enhanced reversible lithium storage in lithium ion batteries. J. Mater. Chem. 2009, 19, 8378–8384. [Google Scholar] [CrossRef]

- Zhou, H.; Zhu, S.; Hibino, M.; Honma, I.; Ichihara, M. Lithium Storage in Ordered Mesoporous Carbon (CMK-3) with High Reversible Specific Energy Capacity and Good Cycling Performance. Adv. Mater. 2003, 15, 2107–2111. [Google Scholar] [CrossRef]

- Hu, Y.S.; Adelhelm, P.; Smarsly, B.M.; Hore, S.; Antonietti, M.; Maier, J. Synthesis of Hierarchically Porous Carbon Monoliths with Highly Ordered Microstructure and Their Application in Rechargeable Lithium Batteries with High-Rate Capability. Adv. Funct. Mater. 2007, 17, 1873–1878. [Google Scholar] [CrossRef]

- Fang, B.; Kim, M.S.; Kim, J.H.; Lim, S.; Yu, J.S. Ordered multimodal porous carbon with hierarchical nanostructure for high Li storage capacity and good cycling performance. J. Mater. Chem. 2010, 20, 10253–10259. [Google Scholar] [CrossRef]

- Xu, Y.; Guo, J.; Wang, C. Sponge-like porous carbon/tin composite anode materials for lithium ion batteries. J. Mater. Chem. 2012, 22, 9562–9567. [Google Scholar] [CrossRef]

- Bresser, D.; Paillard, E.; Passerini, S. Lithium-ion batteries (LIBs) for medium- and large-scale energy storage. In Advances in Batteries for Medium and Large-Scale Energy Storage; Menictas, C., Skyllas-Kazacos, M., Mariana, L.T., Eds.; Elsevier: Waltham, MA, USA, 2015; pp. 125–211. [Google Scholar]

- Peled, E.; Menachem, C.; Bar-Tow, D.; Melman, A. Improved Graphite Anode for Lithium-Ion Batteries Chemically Bonded Solid Electrolyte Interface and Nanochannel Formation. J. Electrochem. Soc. 1996, 143, L4–L7. [Google Scholar] [CrossRef]

- Placke, T.; Siozios, V.; Schmitz, R.; Lux, S.F.; Bieker, P.; Colle, C.; Meyer, H.; Passerini, S.; Winter, M. Influence of graphite surface modifications on the ratio of basal plane to “non-basal plane” surface area and on the anode performance in lithium ion batteries. J. Power Sources 2012, 200, 83–91. [Google Scholar] [CrossRef]

- Yu, P.; Ritter, J.; White, R.; Popov, B. Ni-composite microencapsulated graphite as the negative electrode in lithium-ion batteries - I. Initial irreversible capacity study. J. Electrochem. Soc. 2000, 147, 1280–1285. [Google Scholar] [CrossRef]

- Yu, P.; Ritter, J.; White, R.; Popov, B. Ni-composite microencapsulated graphite as the negative electrode in lithium-ion batteries II. Electrochemical impedance and self-discharge studies. J. Electrochem. Soc. 2000, 147, 2081–2085. [Google Scholar] [CrossRef]

- Doi, T.; Fukutsuka, T.; Takeda, K.; Abe, T.; Miyazaki, K.; Ogumi, Z. Surface Modification of Graphitized Carbonaceous Thin-Film Electrodes with Silver for Enhancement of Interfacial Lithium-Ion Transfer. J. Phys. Chem. C 2012, 116, 12422–12425. [Google Scholar] [CrossRef]

- Doi, T.; Takeda, K.; Fukutsuka, T.; Iriyama, Y.; Abe, T.; Ogumi, Z. Surface modification of graphitized carbonaceous materials by electropolymerization of thiophene and their effects on electrochemical properties. Carbon 2005, 43, 2352–2357. [Google Scholar] [CrossRef]

- Gaberscek, M.; Bele, M.; Drofenik, J.; Dominko, R.; Pejovnik, S. Improved carbon anode properties: Pretreatment of particles in polyelectrolyte solution. J. Power Sources 2001, 97–98, 67–69. [Google Scholar] [CrossRef]

- Gaberscek, M.; Bele, M.; Drofenik, J.; Dominko, R.; Pejovnik, S. Improved carbon anode for lithium batteries - Pretreatment of carbon particles in a polyelectrolyte solution. Electrochem. Solid State Lett. 2000, 3, 171–173. [Google Scholar] [CrossRef]

- Pan, Q.; Wang, H.; Jiang, Y. Natural graphite modified with nitrophenyl multilayers as anode materials for lithium ion batteries. J. Mater. Chem. 2007, 17, 329–334. [Google Scholar] [CrossRef]

- Yoshio, M.; Wang, H.; Fukuda, K.; Umeno, T.; Abe, T.; Ogumi, Z. Improvement of natural graphite as a lithium-ion battery anode material, from raw flake to carbon-coated sphere. J. Mater. Chem. 2004, 14, 1754–1758. [Google Scholar] [CrossRef]

- Yoon, S.; Kim, H.; Oh, S.M. Surface modification of graphite by coke coating for reduction of initial irreversible capacity in lithium secondary batteries. J. Power Sources 2001, 94, 68–73. [Google Scholar] [CrossRef]

- Kim, J.-S.; Yoon, W.-Y.; Yoo, K.S.; Park, G.-S.; Lee, C.W.; Murakami, Y.; Shindo, D. Charge–discharge properties of surface-modified carbon by resin coating in Li-ion battery. J. Power Sources 2002, 104, 175–180. [Google Scholar] [CrossRef]

- Ren, Y.; Wang, J.; Huang, X.; Ding, J. The synthesis of polypyrrole@Mn3O4/reduced graphene oxide anode with improved coulombic efficiency. Electrochim. Acta 2015, 186, 345–352. [Google Scholar] [CrossRef]

- Fu, K.; Xue, L.; Yildiz, O.; Li, S.; Lee, H.; Li, Y.; Xu, G.; Zhou, L.; Bradford, P.D.; Zhang, X. Effect of CVD carbon coatings on Si@CNF composite as anode for lithium-ion batteries. Nano Energy 2013, 2, 976–986. [Google Scholar] [CrossRef]

- Wang, Q.; Li, H.; Chen, L.; Huang, X. Novel spherical microporous carbon as anode material for Li-ion batteries. Solid State Ion. 2002, 152, 43–50. [Google Scholar] [CrossRef]

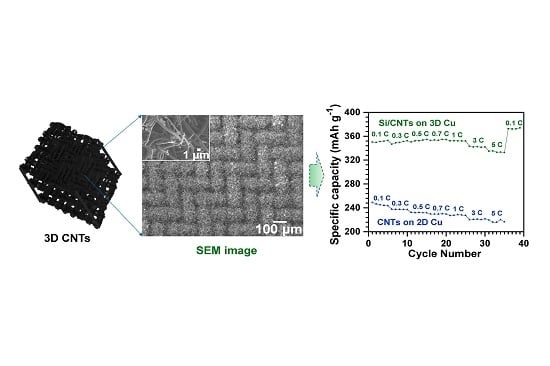

- Kang, C.W.; Patel, M.; Baskaran, R.; Jung, K.N.; Xia, C.; Shi, S.; Choi, W.B. Three-dimensional carbon nanotubes for high capacity lithium-ion batteries. J. Power Sources 2015, 299, 465–471. [Google Scholar] [CrossRef]

- Ducati, C.; Alexandrou, I.; Chhowalla, M.; Amaratunga, G.A.J.; Robertson, J. Temperature selective growth of carbon nanotubes by chemical vapor deposition. J. Appl. Phys. 2002, 92, 3299–3303. [Google Scholar] [CrossRef]

- Dai, H. Nanotube Growth and Characterization. In Carbon Nanotubes Synthesis, Structure, Properties, and Application; Dresselhaus, M.S., Dresselhaus, G., Avouris, P., Eds.; Springer: New York, NY, USA, 2001; pp. 30–34. [Google Scholar]

- Baker, R.T.K.; Barber, M.A.; Harris, P.S.; Feates, F.S.; Waite, R.J. Nucleation and growth of carbon deposits from the nickel catalyzed decomposition of acetylene. J. Catal. 1972, 26, 51–62. [Google Scholar] [CrossRef]

- Siegal, M.P.; Overmyer, D.L.; Provencio, P.P. Precise control of multiwall carbon nanotube diameters using thermal chemical vapor deposition. Appl. Phys. Lett. 2002, 80, 2171–2173. [Google Scholar] [CrossRef]

- Shimoda, H.; Gao, B.; Tang, X.P.; Kleinhammes, A.; Fleming, L.; Wu, Y.; Zhou, O. Lithium Intercalation into Opened Single-Wall Carbon Nanotubes: Storage Capacity and Electronic Properties. Phys. Rev. Lett. 2002, 88, 015502. [Google Scholar] [CrossRef] [PubMed]

- Eom, J.Y.; Kwon, H.S. Improved lithium insertion/extraction properties of single-walled carbon nanotubes by high-energy ball milling. J. Mater. Res. 2008, 23, 2458–2466. [Google Scholar] [CrossRef]

- Moshtev, R.; Johnson, B. State of the art of commercial Li ion batteries. J. Power Sources 2000, 91, 86–91. [Google Scholar] [CrossRef]

- Cui, L.F.; Hu, L.; Choi, J.W.; Cui, Y. Light-Weight Free-Standing Carbon Nanotube-Silicon Films for Anodes of Lithium Ion Batteries. ACS Nano 2010, 4, 3671–3678. [Google Scholar] [CrossRef] [PubMed]

- Fauvarque, J.F.; Simon, P. Principles of Electrochemistry and Electrochemical Methods. In Carbons for Electrochemical Energy Storage and Conversion Systems; Béguin, F., Frąckowiak, E., Eds.; CRC Press: Boca Raton, FL, USA, 2010; pp. 7–16. [Google Scholar]

- Sharifi, T.; Valvo, M.; Gracia-Espino, E.; Sandström, R.; Edström, K.; Wågberg, T. Hierarchical self-assembled structures based on nitrogen-doped carbon nanotubes as advanced negative electrodes for Li-ion batteries and 3D microbatteries. J. Power Sources 2015, 279, 581–592. [Google Scholar] [CrossRef]

- Welna, D.T.; Qu, L.; Taylor, B.E.; Dai, L.; Durstock, M.F. Vertically aligned carbon nanotube electrodes for lithium-ion batteries. J. Power Sources 2011, 196, 1455–1460. [Google Scholar] [CrossRef]

- Jeong, S.; Lee, J.P.; Ko, M.; Kim, G.; Park, S.; Cho, J. Etched Graphite with Internally Grown Si Nanowires from Pores as an Anode for High Density Li-Ion Batteries. Nano Lett. 2013, 13, 3403–3407. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.; Sun, X. Flexible rechargeable lithium ion batteries: Advances and challenges in materials and process technologies. J. Mater. Chem. A 2014, 2, 10712–10738. [Google Scholar] [CrossRef]

- Verma, V.P.; Das, S.; Lahiri, I.; Choi, W.B. Large-area graphene on polymer film for flexible and transparent anode in field emission device. Appl. Phys. Lett. 2010, 96, 203108. [Google Scholar] [CrossRef]

- Gwon, H.; Kim, H.S.; Lee, K.U.; Seo, D.H.; Park, Y.C.; Lee, Y.S.; Ahn, B.T.; Kang, K. Flexible energy storage devices based on graphene paper. Energy Environ. Sci. 2011, 4, 1277–1283. [Google Scholar] [CrossRef]

- Wei, D.; Haque, S.; Andrew, P.; Kivioja, J.; Ryhӓnen, T.; Pesquera, A.; Centeno, A.; Alonso, B.; Chuvilin, A.; Zurutuza, A. Ultrathin rechargeable all-solid-state batteries based on monolayer graphene. J. Mater. Chem. A 2013, 1, 3177–3181. [Google Scholar] [CrossRef]

- Yan, Z.; Ma, L.; Zhu, Y.; Lahiri, I.; Hahm, M.G.; Liu, Z.; Yang, S.; Xiang, C.; Lu, W.; Peng, Z.; et al. Three dimensional Metal-Graphene-Nanotube multifunctional hybrid materials. ACS Nano 2013, 7, 58–64. [Google Scholar] [CrossRef] [PubMed]

- Talapatra, S.; Kar, S.; Pal, S.K.; Vajtai, R.; Ci, L.; Victor, P.; Shaijumon, M.M.; Kaur, S.; Nalamasu, O.; Ajayan, P.M. Direct Growth of Aligned Carbon Nanotubes on Bulk Metals. Nat. Nanotechnol. 2006, 1, 112–116. [Google Scholar] [CrossRef] [PubMed]

- Kaempgen, M.; Chan, C.K.; Ma, J.; Cui, Y.; Gruner, G. Printable Thin Film Supercapacitors Using Single-Walled Carbon Nanotubes. Nano Lett. 2009, 9, 1872–1876. [Google Scholar] [CrossRef] [PubMed]

- Du, C.; Yeh, J.; Pan, N. High Power Density Supercapacitors Using Locally Aligned Carbon Nanotube Electrodes. Nanotechnology 2005, 16, 350–353. [Google Scholar] [CrossRef]

- Stoller, M.D.; Park, S.; Zhu, Y.; An, J.; Ruoff, R.S. Graphene-Based Ultracapacitors. Nano Lett. 2008, 8, 3498–3502. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Murali, S.; Stoller, M.D.; Ganesh, K.J.; Cai, W.; Ferreira, P.J.; Pirkle, A.; Wallace, R.M.; Cychosz, K.A.; Thommes, M.; et al. Carbon-Based Supercapacitors Produced by Activation of Graphene. Science 2011, 332, 1537–1541. [Google Scholar] [CrossRef] [PubMed]

- Gao, W.; Singh, N.; Song, L.; Liu, Z.; Reddy, A.L.M.; Ci, L.; Vajtai, R.; Zhang, Q.; Wei, B.; Ajayan, P.M. Direct Laser Writing of Micro-Supercapacitors on Hydrated Graphite Oxide Films. Nat. Nanotechnol. 2011, 6, 496–500. [Google Scholar] [CrossRef] [PubMed]

- Zhou, G.; Li, F.; Cheng, H.M. Progress in flexible lithium batteries and future prospects. Energy Environ. Sci. 2014, 7, 1307–1338. [Google Scholar] [CrossRef]

- Cole, M.; Hiralal, P.; Ying, K.; Li, C.; Zhang, Y.; Teo, K. Dry-Transfer of Aligned Multiwalled Carbon Nanotubes for Flexible Transparent Thin Films. J. Nanomater. 2012, 272960. [Google Scholar] [CrossRef]

- Fan, Z.J.; Yan, J.; Wei, T.; Ning, G.Q.; Zhi, L.J.; Liu, J.C. Nanographene-Constructed Carbon Nanofibers Grown on Graphene Sheets by Chemical Vapor Deposition: High-Performance Anode Materials for Lithium Ion Batteries. ACS Nano 2011, 5, 2787–2794. [Google Scholar] [CrossRef] [PubMed]

- Lahiri, I.; Seelaboyina, R.; Hwang, J.Y.; Banerjee, R.; Choi, W.B. Enhanced field emission from multi-walled carbon nanotubes grown on pure copper substrate. Carbon 2010, 48, 1531–1538. [Google Scholar] [CrossRef]

- Iqbal, Z.; Vepiek, S. Raman scattering from hydrogenated microcrystalline and amorphous silicon. J. Phys. C Solid State Phys. 1982, 15, 377–392. [Google Scholar] [CrossRef]

- Park, M.H.; Kim, M.G.; Joo, J.B.; Kim, K.T.; Kim, J.Y.; Ahn, S.H.; Cui, Y.; Cho, J.P. Silicon Nanotube Battery Anodes. Nano Lett. 2009, 9, 3844–3847. [Google Scholar] [CrossRef] [PubMed]

- Chan, C.K.; Peng, H.L.; Liu, G.; McIlwrath, K.; Zhang, X.F.; Huggins, R.A.; Cui, Y. High-performance lithium battery anodes using silicon nanowires. Nat. Nanotechnol. 2008, 3, 31–35. [Google Scholar] [CrossRef] [PubMed]

- Bae, J. Fabrication of carbon microcapsules containing silicon nanoparticles-carbon nanotubes nanocomposite by sol-gel method for anode in lithium ion battery. J. Solid State Chem. 2011, 184, 1749–1755. [Google Scholar] [CrossRef]

- Yang, X.; Wen, Z.; Xu, X.; Lin, B.; Huang, S. Nanosized silicon-based composite derived by in situ mechanochemical reduction for lithium ion batteries. J. Power Sources 2007, 164, 880–884. [Google Scholar] [CrossRef]

- Yoon, S.; Lee, S.I.; Kim, H.; Sohn, H.J. Enhancement of capacity of carbon-coated Si-Cu3Si composite anode using metal-organic compound for lithium-ion batteries. J. Power Sources 2006, 161, 1319–1323. [Google Scholar] [CrossRef]

- Johnson, D.C.; Mosby, J.M.; Riha, S.C.; Prieto, A.L. Synthesis of copper silicide nanocrystallites embedded in silicon nanowires for enhanced transport properties. J. Mater. Chem. 2010, 20, 1993–1998. [Google Scholar] [CrossRef]

- Kim, I.C.; Byun, D.; Lee, J.K. Electrochemical characteristics of silicon-metals coated graphites for anode materials of lithium secondary batteries. J. Electroceram. 2006, 17, 661–665. [Google Scholar] [CrossRef]

- Park, S.; An, J.; Piner, R.D.; Jung, I.; Yang, D.; Velamakanni, A.; Nguyen, S.T.; Ruoff, R.S. Aqueous suspension and characterization of chemically modified graphene sheets. Chem. Mater. 2008, 20, 6592–6594. [Google Scholar] [CrossRef]

- Boukamp, B.A.; Lesh, G.C.; Huggins, R.A. All-solid lithium electrodes with mixed-conductor matrix. J. Electrochem. Soc. 1981, 128, 725–729. [Google Scholar] [CrossRef]

- Jung, H.; Park, M.; Yoon, Y.G.; Kim, G.B.; Joo, S.K. Amorphous silicon anode for lithium-ion rechargeable batteries. J. Power Sources 2003, 115, 346–351. [Google Scholar] [CrossRef]

| 3D Carbon-Based Anode Nanostructure | Synthetic Method | Charge Capacity | C-Rate (C) or Current Density (mA·g−1) | Overall/1st Cycle Coulombic Efficiency (%) | Reference |

|---|---|---|---|---|---|

| Vertically aligned free-standing 3D CNTs | CVD | 490 mAh·g−1 | N/A | N/A | [9] |

| 3D amorphous Si-CNTs directly grown on Cu current collector | CVD and sputter deposition | 356 mAh·g−1 334 mAh·g−1 | 1C 5C | ~99%/~67% | [33] |

| 3D Core Shell Multiwalled Carbon Nanotube@RuO2 | ALD | ~600 μAh·cm−2 | N/A | ~88%/~91% | [43] |

| Multistacked layers of porous Co3O4 nanoplates wrapped by capillary-like CNT nets | Layer-by-layer (LBL) structure | >1000 mAh·g−1 ~710 mAh·g−1 | 5 A·g−1 50 A g−1 | 97%/~75% | [48] |

| 3D free-standing CNTs-graphene | CVD | 2 mAh·cm−2 (coin cell)/0.25 mAh·cm−2 and 300 mAh·cm−3 (flexible cell) | 0.1C | 99%/~44% | [49] |

| 3D MWCNT/V2O5 Core/Shell Sponge | ALD | 816 μAh·cm−2 | 1C | ~99%/N/A | [50] |

| 3D Si-CNT sponges | Dichlorobenzene-based CVD for CNT growth and SiH4/Ar-based CVD for Si nanoparticles | ~1300 mAh·g−1 | 0.2C | ~97%/83% | [51] |

| Li4Ti5O12 (anode) imbedded in 3D CNT sponges | Dip coating of CNT ink into polyester fiber textile | 140–160 mAh·g−1 | 0.1C | >99.5%/95% | [52] |

| 3D multi-layered Si/CNT | Thermal and plasma-enhanced CVD | 2561.2 mAh·g−1, 1.25 mAh·cm−2 and 595.4 mAh·cm−3 | 1C | >99%/61% | [53] |

| 3D graphene/ultra-small SnO2 and Fe2O3 anodes | Annealing using ion-exchange resin and hydrothermal synthesis | 474 mAh·g−1 (SnO2) and 448 mAh·g−1 (Fe2O3) | 10 A·g−1 | >99.5%/58% | [54] |

| 3D nanoporous Fe2O3/Fe3C-Graphene heterogeneous thin films | Anodization/CVD | 1650 mAh·cm−3 and ~518 mAh·g−1 | ~6.6C | ~98%/~88% | [55] |

| 3D porous architecture of Si/graphene nanocomposite | Modified sol-gel method/in situ magnesiothermic reduction/spray-drying | ~900 mAh·g−1 | 100 mA·g−1 | ~93%/~49% | [56] |

| 3D multi-layered graphene/Si-CuO quantum dot | Electrophoresis deposition/annealing | 2869 mAh·g−1 | 0.5C | >99%/87% | [57] |

| 3D TiO2-Graphene-CNT | Solution-based method | 111.2 mAh·g−1 93.1 mAh·g−1 | 10C 30C | ~98%/N/A | [58] |

| 3D Li4Ti5O12/graphene foam | CVD and Hydrothermal Synthesis | 160 mAh·g−1 | 30C | >99%/98% | [59] |

| 3D hierarchical NiO-graphene | Hydrothermal/a modified Hummers method | 1065 mAh·g−1 | 200 mA·g−1 | 97%/~65% | [60] |

| 3D graphitic carbon layer conformally deposited on perforated silicon nanowire arrays | Metal-assisted chemical etching of silicon wafers/in situ decomposition of methane | 1500 mAh·cm−3 | 0.2C | ~99%/78% | [61] |

| 3D porous graphene networks anchored with Sn nanoparticles | Freeze-drying and CVD | 1089 mAh·g−1 | 0.2 A·g−1 | >99%/~69% | [62] |

| Large-area patterned 3D CNTs-graphene on flexible PET film | CVD and sputter deposition | 254 mAh·g−1 | 0.17C | >99%/N/A | [63] |

| 3D monolithic Fe2O3/graphene | Modified Hummers/Hydrothermal synthesis/freeze drying | 810 mAh·g−1 | 100 mA·g−1 | >97%/~65% | [64] |

| Flexible free-standing hollow Fe3O4/graphene | Vacuum filtration/thermal reduction | ~940 mAh·g−1 | 200 mA·g−1 | >99.5%/~56% | [65] |

| Free-standing layer-by-layer assembled hybrid graphene-MnO2 nanotube thin films | Modified Hummers/Hydrothermal reaction/ultrafiltration technique | 686 mAh·g−1 | 100 mA·g−1 | ~99%/~56% | [66] |

| 3D Sn/graphene nanocomposite | Modified Hummers/Chemical reduction | 508 mAh·g−1 | 55 mA·g−1 | 96.5%/~65% | [67] |

| 3D ordered mesoporous carbon (CMK-3) | Sacrificial silica template and thermal carbonization of sucrose | 850–1100 mAh·g−1 | 100 mA·g−1 | 90%–93%/~35% | [68] |

| Hierarchically Porous Carbon Monoliths with Highly Ordered Microstructure | Sacrificial meso-/macroporous silica/infiltration/carbonization | 260 mAh·g−1 | 10C | >98%/~57% | [69] |

| 3D Ordered multimodal porous carbon (OMPC) | Self-assembly/polymer infiltration/carbonization/silica etching | 758 mAh·g−1 904 mAh·g−1 | 100 mA·g−1 1000 mA·g−1 | >98%/57% | [70] |

| 3D porous carbon/Sn | Dispersing SnO2 nanoparticles into a sacrificial soft-template polymer matrix/carbonization | 950 mAh·g−1 | 200 mA·g−1 | >99.5%/75% | [71] |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, C.; Cha, E.; Patel, M.D.; Wu, H.F.; Choi, W. Three-Dimensional Carbon Nanostructures for Advanced Lithium-Ion Batteries. C 2016, 2, 23. https://doi.org/10.3390/c2040023

Kang C, Cha E, Patel MD, Wu HF, Choi W. Three-Dimensional Carbon Nanostructures for Advanced Lithium-Ion Batteries. C. 2016; 2(4):23. https://doi.org/10.3390/c2040023

Chicago/Turabian StyleKang, Chiwon, Eunho Cha, Mumukshu D. Patel, H. Felix Wu, and Wonbong Choi. 2016. "Three-Dimensional Carbon Nanostructures for Advanced Lithium-Ion Batteries" C 2, no. 4: 23. https://doi.org/10.3390/c2040023

APA StyleKang, C., Cha, E., Patel, M. D., Wu, H. F., & Choi, W. (2016). Three-Dimensional Carbon Nanostructures for Advanced Lithium-Ion Batteries. C, 2(4), 23. https://doi.org/10.3390/c2040023