Mechanical and Electrical Characterization of Carbon Fiber/Bucky Paper/Zinc Oxide Hybrid Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Synthesis

2.1.1. Seeding of ZnO Catalyst

2.1.2. Growth of ZnO Nanorods

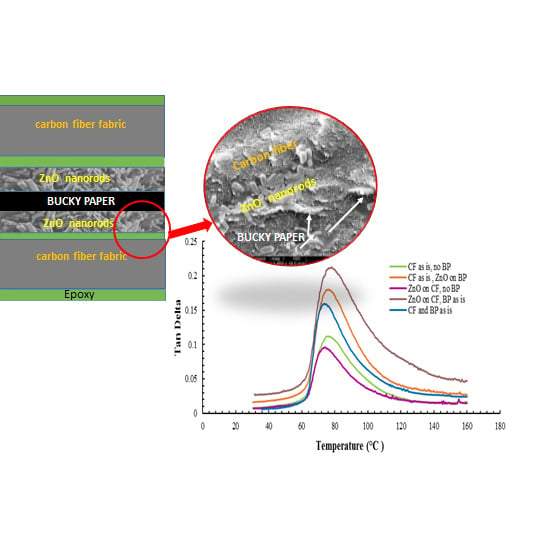

2.2. Composite Preparation

2.3. Analysis

2.3.1. Tensile Testing

2.3.2. Fracture Analysis

2.3.3. Dynamic Mechanical Analysis (DMA)

2.3.4. Electrical Resistivity Test

3. Results and Discussion

3.1. Tensile Testing Results

3.2. Fracture Analysis

3.3. DMA Results

3.3.1. Temperature Scan

3.3.2. Frequency Scan Results

3.4. Surface Resistivity Results

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Trabelsi, W.; Michel, L.; Othomene, R. Effects of stitching on delamination of satin weave carbon-epoxy laminates under mode I, mode II and mixed-mode I/II loadings. Appl. Compos. Mater. 2010, 17, 575–595. [Google Scholar] [CrossRef] [Green Version]

- Khan, S.U.; Kim, J.-K. Impact and Delamination Failure of Multiscale Carbon Nanotube-Fiber Reinforced Polymer Composites: A Review. Int. J. Aeronaut. Space Sci. 2011, 12, 115–133. [Google Scholar] [CrossRef]

- Gu, B.H.; Li, Y.L. Ballistic perforation of conically cylindrical steel projectile into three-dimensional braided composites. Aiaa J. 2005, 43, 426–434. [Google Scholar] [CrossRef]

- Chung, D.D.L. Structural composite materials tailored for damping. J. Alloys Compd. 2003, 355, 216–223. [Google Scholar] [CrossRef]

- Aksoy, A.; Carlsson, L. Interlaminar shear fracture of interleaved graphite/epoxy composites. Compos. Sci. Technol. 1992, 43, 55–69. [Google Scholar] [CrossRef]

- Vlasveld, D.P.N.; Bersee, H.E.N.; Picken, S.J. Nanocomposite matrix for increased fibre composite strength. Polymer 2005, 46, 10269–10278. [Google Scholar] [CrossRef]

- Hudnut, S.W.; Chung, D.D.L. Use of submicron diameter carbon filaments for reinforcement between continuous carbon-fiber layers in a polymer-matrix composite. Carbon 1995, 33, 1627–1631. [Google Scholar] [CrossRef]

- Thostenson, E.T.; Chou, T.-W. Aligned multi-walled carbon nanotube-reinforced composites: Processing and mechanical characterization. J. Phys. D 2002, 35, L77. [Google Scholar] [CrossRef]

- Alipour Skandani, A.; Masghouni, N.; Case, S.W.; Leo, D.J.; Al-Haik, M. Enhanced vibration damping of carbon fibers-ZnO nanorods hybrid composites. Appl. Phys. Lett. 2012, 101, 073111. [Google Scholar] [CrossRef]

- Garcia, E.; Wardle, B.; deVilloria, R.; Guzman de Villoria, R.; Wicks, S.; Ishiguro, K.; Yamamoto, N.; Hart, A. Aligned Carbon Nanotube Reinforcement of Advanced Composite Ply Interfaces. In 49th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, 16th AIAA/ASME/AHS Adaptive Structures Conference,10th AIAA Non-Deterministic Approaches Conference, 9th AIAA Gossamer Spacecraft Forum, 4th AIAA Multidisciplinary Design Optimization Specialists Conference; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2008. [Google Scholar]

- Otsuka, K.; Abe, Y.; Kanai, N.; Kobayashi, Y.; Takenaka, S.; Tanabe, E. Synthesis of carbon nanotubes on Ni/carbon-fiber catalysts under mild conditions. Carbon 2004, 42, 727–736. [Google Scholar] [CrossRef]

- Zhu, S.; Su, C.-H.; Lehoczky, S.L.; Muntele, I.; Ila, D. Carbon nanotube growth on carbon fibers. Diam. Relat. Mater. 2003, 12, 1825–1828. [Google Scholar] [CrossRef]

- Sinnott, S.B.; Andrews, R. Carbon Nanotubes: Synthesis, Properties, and Applications. Crit. Rev. Solid State Mater. Sci. 2001, 26, 145–249. [Google Scholar] [CrossRef]

- Gibson, R.F. A review of recent research on mechanics of multifunctional composite materials and structures. Compos. Struct. 2010, 92, 2793–2810. [Google Scholar] [CrossRef]

- Luhrs, C.C.; Garcia, D.; Tehrani, M.; Al-Haik, M.; Taha, M.R.; Phillips, J. Generation of carbon nanofilaments on carbon fibers at 550 °C. Carbon 2009, 47, 3071–3078. [Google Scholar] [CrossRef]

- Al-Haik, M.; Luhrs, C.C.; Reda Taha, M.M.; Roy, A.K.; Dai, L.; Phillips, J.; Doorn, S. Hybrid Carbon Fibers/Carbon Nanotubes Structures for Next Generation Polymeric Composites. J. Nanotechnol. 2010, 2010, 860178. [Google Scholar] [CrossRef]

- Boskovic, B.O.; Golovko, V.B.; Cantoro, M.; Kleinsorge, B.; Chuang, A.T.H.; Ducati, C.; Hofmann, S.; Robertson, J.; Johnson, B.F.G. Low temperature synthesis of carbon nanofibres on carbon fibre matrices. Carbon 2005, 43, 2643–2648. [Google Scholar] [CrossRef]

- Phillips, J.; Leseman, Z.C.; Cordaro, J.; Luhrs, C.; Al-Haik, M. Novel Graphitic Structures by Design. In Proceedings of the ASME 2007 International Mechanical Engineering Congress and Exposition, Volume 13: Processing and Engineering Applications of Novel Materials, Seattle, WA, USA, 11–15 November 2007; pp. 177–179. [Google Scholar]

- Chen, X.; Saito, T.; Kusunoki, M.; Motojima, S. Three-dimensional vapor growth mechanism of carbon microcoils. J. Mater. Res. 2011, 14, 4329–4336. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, J.; Sager, R.; Dai, L.; Baur, J. Hierarchical composites of carbon nanotubes on carbon fiber: Influence of growth condition on fiber tensile properties. Compos. Sci. Technol. 2009, 69, 594–601. [Google Scholar] [CrossRef]

- Westwood, M.E.; Webster, J.D.; Day, R.J.; Hayes, F.H.; Taylor, R. Oxidation protection for carbon fibre composites. J. Mater. Sci. 1996, 31, 1389–1397. [Google Scholar] [CrossRef]

- Askari, D.; Ghasemi-Nejhad, M.N. Inter-Laminar Mechanical Properties Improvements in Carbon Nanotubes Reinforced Laminated Nanocomposites. In Proceedings of the ASME 2011 International Mechanical Engineering Congress and Exposition, Volume 8: Mechanics of Solids, Structures and Fluids; Vibration, Acoustics and Wave Propagation, Denver, CO, USA, 11–17 November 2011; pp. 533–538. [Google Scholar]

- Wicks, S.S.; de Villoria, R.G.; Wardle, B.L. Interlaminar and intralaminar reinforcement of composite laminates with aligned carbon nanotubes. Compos. Sci. Technol. 2010, 70, 20–28. [Google Scholar] [CrossRef]

- Tehrani, M.; Safdari, M.; Boroujeni, A.Y.; Razavi, Z.; Case, S.W.; Dahmen, K.; Garmestani, H.; Al-Haik, M.S. Hybrid carbon fiber/carbon nanotube composites for structural damping applications. Nanotechnology 2013, 24, 155704. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Wang, Z.Z.; Liu, Q.L.; Wang, S.K.; Gu, Y.Z.; Li, Y.X.; Zhang, Z.G. Carbon Nanotube Film/Epoxy Composites With High Strength and Toughness. Polym. Compos. 2017, 38, 588–596. [Google Scholar] [CrossRef]

- Liu, W.; Wei, B.C.; Xu, F.J. Investigation on the mechanical and electrical properties of carbon nanotube/epoxy composites produced by resin transfer molding. J. Compos. Mater. 2017, 51, 2035–2043. [Google Scholar] [CrossRef]

- Shin, Y.C.; Novin, E.; Kim, H. Electrical and Thermal Conductivities of Carbon Fiber Composites with High Concentrations of Carbon Nanotubes. Int. J. Precis. Eng. Manuf. 2015, 16, 465–470. [Google Scholar] [CrossRef]

- Ashrafi, B.; Guan, J.; Mirjalili, V.; Hubert, P.; Simard, B.; Johnston, A. Correlation between Young’s Modulus and Impregnation Quality of Epoxy-Impregnated SWCNT Buckypaper. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1184–1191. [Google Scholar] [CrossRef]

- Jakubinek, M.B.; Ashrafi, B.; Guan, J.; Johnson, M.B.; White, M.A.; Simard, B. 3D chemically cross-linked single-walled carbon nanotube buckypapers. RSC Adv. 2014, 4, 57564–57573. [Google Scholar] [CrossRef]

- Lopes, P.E.; van Hattum, F.; Pereira, C.M.C.; Nóvoa, P.J.R.O.; Forero, S.; Hepp, F.; Pambaguian, L. High CNT content composites with CNT Buckypaper and epoxy resin matrix: Impregnation behaviour composite production and characterization. Compos. Struct. 2010, 92, 1291–1298. [Google Scholar] [CrossRef]

- Ribeiro, B.; Botelho, E.C.; Costa, M.L.; Bandeira, C.F. Carbon nanotube buckypaper reinforced polymer composites: A review. Polimeros 2017, 27, 247–255. [Google Scholar] [CrossRef]

- Pham, G.T.; Park, Y.B.; Wang, S.R.; Liang, Z.Y.; Wang, B.; Zhang, C.; Funchess, P.; Kramer, L. Mechanical and electrical properties of polycarbonate nanotube buckypaper composite sheets. Nanotechnology 2008, 19, 325705. [Google Scholar] [CrossRef] [PubMed]

- Han, J.H.; Zhang, H.; Chen, M.J.; Wang, G.R.; Zhang, Z. CNT buckypaper/thermoplastic polyurethane composites with enhanced stiffness, strength and toughness. Compos. Sci. Technol. 2014, 103, 63–71. [Google Scholar] [CrossRef]

- Yang, S.Y.; Ma, C.C.M.; Teng, C.C.; Huang, Y.W.; Liao, S.H.; Huang, Y.L.; Tien, H.W.; Lee, T.M.; Chiou, K.C. Effect of functionalized carbon nanotubes on the thermal conductivity of epoxy composites. Carbon 2010, 48, 592–603. [Google Scholar] [CrossRef]

- Ma, Q.; Wang, Y.; Kong, J.; Jia, H.; Wang, Z. Controllable synthesis of hierarchical flower-like ZnO nanostructures assembled by nanosheets and its optical properties. Superlattices Microstruct. 2015, 84, 1–12. [Google Scholar] [CrossRef]

- Byrne, D.; McGlynn, E.; Cullen, J.; Henry, M.O. A catalyst-free and facile route to periodically ordered and c-axis aligned ZnO nanorod arrays on diverse substrates. Nanoscale 2011, 3, 1675–1682. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hung, C.H.; Whang, W.T. A novel low-temperature growth and characterization of single crystal ZnO nanorods. Mater. Chem. Phys. 2003, 82, 705–710. [Google Scholar] [CrossRef]

- Liu, J.; Chang, M.-J.; Du, H.-L. Controllable growth of highly organized ZnO nanowires using templates of electrospun nanofibers. J. Mater. Sci. Mater. Electron. 2016, 27, 7124–7131. [Google Scholar] [CrossRef]

- Akgun, M.C.; Kalay, Y.E.; Unalan, H.E. Hydrothermal zinc oxide nanowire growth using zinc acetate dihydrate salt. J. Mater. Res. 2012, 27, 1445–1451. [Google Scholar] [CrossRef]

- Dong, J.J.; Zhen, C.Y.; Hao, H.Y.; Xing, J.; Zhang, Z.L.; Zheng, Z.Y.; Zhang, X.W. Controllable synthesis of ZnO nanostructures on the Si substrate by a hydrothermal route. Nanoscale Res. Lett. 2013, 8, 378. [Google Scholar] [CrossRef] [PubMed]

- Demes, T.; Ternon, C.; Riassetto, D.; Stambouli, V.; Langlet, M. Comprehensive study of hydrothermally grown ZnO nanowires. J. Mater. Sci. 2016, 51, 10652–10661. [Google Scholar] [CrossRef]

- Strano, V.; Urso, R.G.; Scuderi, M.; Iwu, K.O.; Simone, F.; Ciliberto, E.; Spinella, C.; Mirabella, S. Double Role of HMTA in ZnO Nanorods Grown by Chemical Bath Deposition. J. Phys. Chem. C 2014, 118, 28189–28195. [Google Scholar] [CrossRef]

- Allington, R.D.; Attwood, D.; Hamerton, I.; Hay, J.N.; Howlin, B.J. A model of the surface of oxidatively treated carbon fibre based on calculations of adsorption interactions with small molecules. Compos. Part A Appl. Sci. Manuf. 1998, 29, 1283–1290. [Google Scholar] [CrossRef]

- Ehlert, G.J.; Sodano, H.A. Zinc Oxide Nanowire Interphase for Enhanced Interfacial Strength in Lightweight Polymer Fiber Composites. ACS Appl. Mater. Interfaces 2009, 1, 1827–1833. [Google Scholar] [CrossRef] [PubMed]

- Al-Haik, M.S.; Garmestani, H.; Savran, A. Explicit and implicit viscoplastic models for polymeric composite. Int. J. Plast. 2004, 20, 1875–1907. [Google Scholar] [CrossRef]

- Al-Haik, M.S.; Hussaini, M.Y.; Garmestani, H. Prediction of nonlinear viscoelastic behavior of polymeric composites using an artificial neural network. Int. J. Plast. 2006, 22, 1367–1392. [Google Scholar] [CrossRef]

- Garmestani, H.; Al-Haik, M.S.; Dahmen, K.; Tannenbaum, R.; Li, D.; Sablin, S.S.; Hussaini, M.Y. Polymer-Mediated Alignment of Carbon Nanotubes under High Magnetic Fields. Adv. Mater. 2003, 15, 1918–1921. [Google Scholar] [CrossRef]

- Tehrani, M.; Safdari, M.; Al-Haik, M.S. Nanocharacterization of creep behavior of multiwall carbon nanotubes/epoxy nanocomposite. Int. J. Plast. 2011, 27, 887–901. [Google Scholar] [CrossRef]

- ASTM Committee D30 on Composite Materials. Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials; D3039/D3039M-17; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM Committee D30 on Composite Materials. Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials; D4056-12; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM Committee F-1 on Electronics. Standard Test Methods for Resistivity of Semiconductor Materials; F43-99; STM International: West Conshohocken, PA, USA, 1999. [Google Scholar]

- Goertzen, W.K.; Kessler, M.R. Dynamic mechanical analysis of carbon/epoxy composites for structural pipeline repair. Compos. Part B 2007, 38, 1–9. [Google Scholar] [CrossRef]

- Menard, K.P. Dynamic Mechanical Analysis: A Practical Introduction, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar]

- Li, G.; Lee-Sullivan, P.; Thring, R.W. Determination of Activation Energy for Glass Transition of an Epoxy Adhesive Using Dynamic Mechanical Analysis. J. Therm. Anal. Calorim. 2000, 60, 377–390. [Google Scholar] [CrossRef]

- Sumita, M.; Gohda, H.; Asai, S.; Miyasaka, K.; Furuta, A.; Suzuki, Y.; Uchino, K. New damping materials composed of piezoelectric and electro-conductive, particle-filled polymer composites: Effect of the electromechanical coupling factor. Makromol. Chem. Rapid Commun. 1991, 12, 657–661. [Google Scholar] [CrossRef]

| Configuration | % Change in Strength | % Change in Stiffness |

|---|---|---|

| CF as is, ZnO on BP | 23.26 | 1.98 |

| ZnO on CF, no BP | 20.14 | 2.61 |

| ZnO on CF, BP as is | 17.67 | 3.36 |

| CF and BP as is | −1.69 | −13.88 |

| Configuration | % Change in Tan (δ) | % Change in Storage Modulus |

|---|---|---|

| CF as is, ZnO on BP | 60.98 | 536.09 |

| ZnO on CF, no BP | −15.86 | 309.79 |

| ZnO on CF, BP as is | 86.6 | 411 |

| CF and BP as is | 41.6 | 441.284 |

| Configuration | % Change in Tan (δ) | % Change in Storage Modulus |

|---|---|---|

| CF as is, ZnO on BP | 86.20 | 202.86 |

| ZnO on CF, no BP | 0 | 122.86 |

| ZnO on CF, BP as is | 22.73 | 90.86 |

| CF and BP as is | 72.76 | 116 |

| Configuration | Length (mm) | Width (mm) | Resistance (Ω) | Volume Resistivity (Ωm) |

|---|---|---|---|---|

| CF as is, no BP | 56.21 | 5.71 | 19 | 0.00095 |

| CF as is, ZnO on BP | 56.46 | 6.51 | 3.93 | 0.00023 |

| ZnO on CF, no BP | 66.11 | 5.17 | 7.5 | 0.00028 |

| ZnO on CF, BP as is | 66.71 | 6.62 | 4.67 | 0.00026 |

| CF and BP as is | 66.78 | 5.6 | 4.12 | 0.00019 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ayyagari, S.; Al-Haik, M.; Rollin, V. Mechanical and Electrical Characterization of Carbon Fiber/Bucky Paper/Zinc Oxide Hybrid Composites. C 2018, 4, 6. https://doi.org/10.3390/c4010006

Ayyagari S, Al-Haik M, Rollin V. Mechanical and Electrical Characterization of Carbon Fiber/Bucky Paper/Zinc Oxide Hybrid Composites. C. 2018; 4(1):6. https://doi.org/10.3390/c4010006

Chicago/Turabian StyleAyyagari, Suma, Marwan Al-Haik, and Virginie Rollin. 2018. "Mechanical and Electrical Characterization of Carbon Fiber/Bucky Paper/Zinc Oxide Hybrid Composites" C 4, no. 1: 6. https://doi.org/10.3390/c4010006

APA StyleAyyagari, S., Al-Haik, M., & Rollin, V. (2018). Mechanical and Electrical Characterization of Carbon Fiber/Bucky Paper/Zinc Oxide Hybrid Composites. C, 4(1), 6. https://doi.org/10.3390/c4010006