A Simple Two-Step Process for Producing Strong and Aligned Carbon Nanotube-Polymer Composites

Abstract

:1. Introduction

2. Experimental Methods and Techniques

2.1. CNT Sheet Assembly

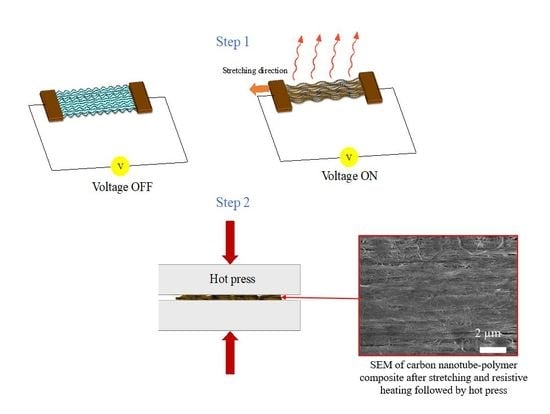

2.2. Polymer-CNT Composite Fabrication

2.3. Characterization

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Balandin, A.A. Thermal properties of graphene and nanostructured carbon materials. Nat. Mater. 2011, 10, 569–581. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, Q.; Li, Y.; Zhang, X.; Chikkannanavar, S.B.; Zhao, Y.; Dangelewicz, A.M.; Zheng, L.; Doorn, S.; Jia, Q.; Peterson, D.; et al. Structure-dependent electrical properties of carbon nanotube fibers. Adv. Mater. 2007, 19, 3358–3363. [Google Scholar] [CrossRef]

- Zhang, R.; Wen, Q.; Qian, W.; Su, D.S.; Zhang, Q.; Wei, F. Superstrong ultralong carbon nanotubes for mechanical energy storage. Adv. Mater. 2011, 23, 3387–3391. [Google Scholar] [CrossRef] [PubMed]

- Laurent, C.; Flahaut, E.; Peigney, A. The weight and density of carbon nanotubes versus the number of walls and diameter. Carbon 2010, 48, 2994–2996. [Google Scholar] [CrossRef] [Green Version]

- Kim, S.H.; Mulholland, G.W.; Zachariah, M.R. Density measurement of size selected multiwalled carbon nanotubes by mobility-mass characterization. Carbon 2009, 47, 1297–1302. [Google Scholar] [CrossRef]

- Dervishi, E.; Li, Z.; Watanabe, F.; Saini, V.; Biris, A.R.; Xu, Y.; Biris, A.S. High-aspect ratio and horizontally oriented carbon nanotubes synthesized by RF-cCVD. Diam. Relat. Mater. 2010, 19, 67–72. [Google Scholar] [CrossRef]

- Zhu, L.; Xu, J.; Xiu, Y.; Sun, Y.; Hess, D.W.; Wong, C.P. Growth and electrical characterization of high-aspect-ratio carbon nanotube arrays. Carbon 2006, 44, 253–258. [Google Scholar] [CrossRef]

- Wang, W.; Ciselli, P.; Kuznetsov, E.; Peijs, T.; Barber, A.H. Effective reinforcement in carbon nanotube-polymer composites. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2008, 366, 1613–1626. [Google Scholar] [CrossRef] [PubMed]

- Konnola, R.; Nair, C.P.R.; Joseph, K. High strength toughened epoxy nanocomposite based on poly(ether sulfone)-grafted multi-walled carbon nanotube. Polym. Adv. Technol. 2016, 27, 82–89. [Google Scholar] [CrossRef]

- Yang, K.; Gu, M.; Guo, Y.; Pan, X.; Mu, G. Effects of carbon nanotube functionalization on the mechanical and thermal properties of epoxy composites. Carbon 2009, 47, 1723–1737. [Google Scholar] [CrossRef]

- Zhou, L.; Gao, C.; Xu, W. Efficient grafting of hyperbranched polyglycerol from hydroxyl-functionalized multiwalled carbon nanotubes by surface-initiated anionic ring-opening polymerization. Macromol. Chem. Phys. 2009, 210, 1011–1018. [Google Scholar] [CrossRef]

- Malik, R.; Mcconnell, C.; Alvarez, N.T.; Haase, M.; Gbordzoe, S.; Shanov, V. Rapid, In Situ Plasma Functionalization of Carbon Nanotubes For Improved CNT/Epoxy Composites. RSC Adv. 2016, 6, 108840–108850. [Google Scholar] [CrossRef]

- Wang, X.; Yong, Z.Z.; Li, Q.W.; Bradford, P.D.; Liu, W.; Tucker, D.S.; Cai, W.; Wang, H.; Yuan, F.G.; Zhu, Y.T. Ultrastrong, Stiff and Multifunctional Carbon Nanotube Composites. Mater. Res. Lett. 2013, 1, 19–25. [Google Scholar] [CrossRef]

- Andrews, R.; Weisenberger, M.C. Carbon nanotube polymer composites. Curr. Opin. Solid State Mater. Sci. 2004, 8, 31–37. [Google Scholar] [CrossRef]

- Safadi, B.; Andrews, R.; Grulke, E.A. Multiwalled carbon nanotube polymer composites: Synthesis and characterization of thin films. J. Appl. Polym. Sci. 2002, 84, 2660–2669. [Google Scholar] [CrossRef]

- Claes, M.; Bonduel, D.; Pegel, S.; Alexandre, M.; Poetschke, P.; Dubois, P.; Luizi, F. New route to manufacture high performance carbon nanotubes nanocomposites based on pre-dispersed concentrates generated by in-situ polymerisation. In Technical Proceedings of the 2006 NSTI Nanotechnology Conference and Trade Show; ICCN: Lope Haydenville, MA, USA, 2006; pp. 218–221. [Google Scholar]

- Spitalsky, Z.; Tasis, D.; Papagelis, K.; Galiotis, C. Carbon nanotube-polymer composites: Chemistry, processing, mechanical and electrical properties. Prog. Polym. Sci. 2010, 35, 357–401. [Google Scholar] [CrossRef]

- Chien, A.T.; Cho, S.; Joshi, Y.; Kumar, S. Electrical conductivity and Joule heating of polyacrylonitrile/carbon nanotube composite fibers. Polym 2014, 55, 6896–6905. [Google Scholar] [CrossRef]

- Kim, J.W.; Sauti, G.; Siochi, E.J.; Smith, J.G.; Wincheski, R.A.; Cano, R.J.; Connell, W.J.; Wise, K.E. Toward high performance thermoset/carbon nanotube sheet nanocomposites via resistive heating assisted infiltration and cure. ACS Appl. Mater. Interfaces 2014, 6, 18832–18843. [Google Scholar] [CrossRef]

- Nam, T.H.; Goto, K.; Yamaguchi, Y.; Premalal, E.V.A.; Shimamura, Y.; Inoue, Y.; Naito, K.; Ogihara, S. Effects of CNT diameter on mechanical properties of aligned CNT sheets and composites. Compos. Part A Appl. Sci. Manuf. 2015, 76, 289–298. [Google Scholar] [CrossRef] [Green Version]

- Nam, T.H.; Goto, K.; Yamaguchi, Y.; Premalal, E.V.A.; Shimamura, Y.; Inoue, Y.; Naito, K.; Ogihara, S. Improving mechanical properties of high volume fraction aligned multi-walled carbon nanotube/epoxy composites by stretching and pressing. Compos. Part B Eng. 2016, 85, 15–23. [Google Scholar] [CrossRef] [Green Version]

- Nam, T.H.; Goto, K.; Yamaguchi, Y.; Premalal, E.V.A.; Shimamura, Y.; Inoue, Y.; Naito, K.; Ogihara, S. Mechanical property enhancement of aligned multi-walled carbon nanotube sheets and composites through press-drawing process. Adv. Compos. Mater. 2016, 25, 73–86. [Google Scholar] [CrossRef]

- Huu, T.; Goto, K.; Nakayama, H.; Oshima, K.; Premalal, V.; Shimamura, Y.; Inoue, Y.; Naito, K.; Kobayashi, S. Composites: Part A Effects of stretching on mechanical properties of aligned multi-walled carbon nanotube/epoxy composites. Compos. Part A 2014, 64, 194–202. [Google Scholar] [CrossRef]

- Cheng, Q.; Bao, J.; Park, J.; Liang, Z.; Zhang, C.; Wang, B. High Mechanical Performance Composite Conductor: Multi-Walled Carbon Nanotube Sheet/Bismaleimide Nanocomposites. Adv. Funct. Mater. 2009, 19, 3219–3225. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, X.; Li, R.; Li, Q.; Bradford, P.D.; Zhu, Y. Microcombing enables high-performance carbon nanotube composites. Compos. Sci. Technol. 2016, 123, 92–98. [Google Scholar] [CrossRef]

- Martin, C.A.; Sandler, J.K.W.; Windle, A.H.; Schwarz, M.K.; Bauhofer, W.; Schulte, K.; Shaffer, M.S.P. Electric field-induced aligned multi-wall carbon nanotube networks in epoxy composites. Polymer 2005, 46, 877–886. [Google Scholar] [CrossRef]

- Moaseri, E.; Karimi, M.; Baniadam, M.; Maghrebi, M. Improvements in mechanical properties of multi-walled carbon nanotube-reinforced epoxy composites through novel magnetic-assisted method for alignment of carbon nanotubes. Compos. Part A Appl. Sci. Manuf. 2014, 64, 228–233. [Google Scholar] [CrossRef]

- Alvarez, N.T.; Miller, P.; Haase, M.; Kienzle, N.; Zhang, L.; Schulz, M.J.; Shanov, V. Carbon Nanotube Assembly at Near-industrial Natural-fiber Spinning Rates. Carbon 2015, 86, 350–357. [Google Scholar] [CrossRef]

- Gbordzoe, S.; Malik, R.; Alvarez, N.; Wolf, R.; Shanov, V. Flexible Low-Voltage Carbon Nanotube Heaters and their Applications. In Advances in Carbon Nanostructures; Intech: London, UK, 2016; pp. 123–136. [Google Scholar]

- Gbordzoe, S.; Yarmolenko, S.; Hsieh, Y.Y.; Adusei, P.K.; Alvarez, N.T.; Fialkova, S.; Shanov, V. Three-dimensional texture analysis of aligned carbon nanotube structures. Carbon 2017, 121, 591–601. [Google Scholar] [CrossRef]

- Berrueco, C.; Alvarez, P.; Venditti, S.; Morgan, T.J.; Herod, A.A.; Millan, M.; Kandiyoti, R. Sample contamination with NMP-oxidation products and byproduct-free NMP removal from sample solutions. Energy Fuels 2009, 23, 3008–3015. [Google Scholar] [CrossRef]

- Cai, M.F.; Smart, R.B. Quantitative Analysis of N-Methyl-2-pyrrolidinone in Coal Extracts by TGA-FTIR. Energy Fuels 1993, 7, 52–56. [Google Scholar] [CrossRef]

- Carey, B.J.; Daeneke, T.; Nguyen, E.P.; Wang, Y.; Ou, J.Z.; Zhuiykov, S.; Kalantar-Zadeh, K. Two solvent grinding sonication method for the synthesis of two-dimensional tungsten disulphide flakes. Chem. Commun. 2015, 51, 3770–3773. [Google Scholar] [CrossRef] [PubMed]

- Abbasi, H.; Antunes, M.; Velasco, J.I. Graphene nanoplatelets-reinforced polyetherimide foams prepared by water vapor-induced phase separation. Express Polym. Lett. 2015, 9, 412–423. [Google Scholar] [CrossRef]

- Zhu, H.; Jie, X.; Wang, L.; Kang, G.; Liu, D.; Cao, Y. Effect of MIL-53 on phase inversion and gas separation performance of mixed matrix hollow fiber membranes. RSC Adv. 2016, 6, 69124–69134. [Google Scholar] [CrossRef]

- Mao, H.; Zhang, S. Synthesis, characterization and gas transport properties of novel poly(amine-imide)s containing tetraphenylmethane pendant groups. J. Mater. Chem. A 2014, 2, 9835–9843. [Google Scholar] [CrossRef]

- Carroccio, S.; Puglisi, C.; Montaudo, G. Thermal degradation mechanisms of polyetherimide investigated by direct pyrolysis mass spectrometry. Macromol. Chem. Phys. 1999, 200, 2345–2355. [Google Scholar] [CrossRef]

- Liu, H.; Dong, M.; Huang, W.; Gao, J.; Dai, K.; Guo, J.; Zheng, G.; Liu, C.; Shena, C.; Guo, Z. Lightweight conductive graphene/thermoplastic polyurethane foams with ultrahigh compressibility for piezoresistive sensing. J. Mater. Chem. C 2017, 5, 73–83. [Google Scholar] [CrossRef]

- Marini, J.; Pollet, E.; Averous, L.; Bretas, R.E.S. Elaboration and properties of novel biobased nanocomposites with halloysite nanotubes and thermoplastic polyurethane from dimerized fatty acids. Polym 2014, 55, 5226–5234. [Google Scholar] [CrossRef]

- Lekawa-Raus, A.; Patmore, J.; Kurzepa, L.; Bulmer, J.; Koziol, K. Electrical properties of carbon nanotube based fibers and their future use in electrical wiring. Adv. Funct. Mater. 2014, 24, 3661–3682. [Google Scholar] [CrossRef]

- Vigolo, B.; Vigolo, B.; Pe, A.; Coulon, C. Macroscopic Fibers and Ribbons of Oriented Carbon Nanotubes. Science 2000, 290, 1331–1334. [Google Scholar] [CrossRef]

| Sample | Thickness (µm) | Tensile Strength (MPa) | Load (N) | Modulus (GPa) | Conductivity (S/cm) | Weight Percent of CNT |

|---|---|---|---|---|---|---|

| Pristine | 4.89 | 461 ± 24 | 2.15 ± 0.20 | 38 ± 5 | 151 ± 9 | 100 |

| PMMA 0.5% | 4.82 | 545 ± 100 | 2.49 ± 0.46 | 58 ± 7 | 156 ± 23 | 62 |

| PMMA 1% | 5.16 | 652 ± 76 | 3.20 ± 0.37 | 59 ± 8 | 129 ± 3 | 55 |

| PMMA 2% | 6.1 | 534 ± 80 | 3.04 ± 0.46 | 53 ± 4 | 107 ± 3 | 52 |

| TPU 0.5% | 4.25 | 717 ± 87 | 2.90 ± 0.35 | 53 ± 6 | 180 ± 12 | 67 |

| TPU 1% | 4.40 | 858 ± 87 | 3.57 ± 0.36 | 48 ± 6 | 150 ± 5 | 57 |

| TPU 2% | 4.82 | 814 ± 129 | 3.71 ± 0.59 | 40 ± 6 | 137 ± 5 | 50 |

| UltemTM 0.5% | 4.18 | 671 ± 86 | 2.74 ± 0.49 | 59 ± 3 | 127 ± 3 | 64 |

| UltemTM 1% | 4.23 | 815 ± 124 | 3.28 ± 0.5 | 72 ± 6 | 139 ± 2 | 54 |

| UltemTM 2% | 5.19 | 631 ± 119 | 3.11 ± 0.59 | 68 ± 9 | 120 ± 15 | 50 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gbordzoe, S.; Adusei, P.K.; Chauhan, D.; Alvarez, N.T.; Haase, M.R.; Mansari, K.; Kanakaraj, S.N.; Hsieh, Y.-Y.; Shanov, V. A Simple Two-Step Process for Producing Strong and Aligned Carbon Nanotube-Polymer Composites. C 2019, 5, 35. https://doi.org/10.3390/c5030035

Gbordzoe S, Adusei PK, Chauhan D, Alvarez NT, Haase MR, Mansari K, Kanakaraj SN, Hsieh Y-Y, Shanov V. A Simple Two-Step Process for Producing Strong and Aligned Carbon Nanotube-Polymer Composites. C. 2019; 5(3):35. https://doi.org/10.3390/c5030035

Chicago/Turabian StyleGbordzoe, Seyram, Paa Kwasi Adusei, Devika Chauhan, Noe T. Alvarez, Mark R. Haase, Karim Mansari, Sathya N. Kanakaraj, Yu-Yun Hsieh, and Vesselin Shanov. 2019. "A Simple Two-Step Process for Producing Strong and Aligned Carbon Nanotube-Polymer Composites" C 5, no. 3: 35. https://doi.org/10.3390/c5030035

APA StyleGbordzoe, S., Adusei, P. K., Chauhan, D., Alvarez, N. T., Haase, M. R., Mansari, K., Kanakaraj, S. N., Hsieh, Y. -Y., & Shanov, V. (2019). A Simple Two-Step Process for Producing Strong and Aligned Carbon Nanotube-Polymer Composites. C, 5(3), 35. https://doi.org/10.3390/c5030035