Porous Carbon Monoliths Made from Cellulose and Starch

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Characterization Methods

3. Results and Discussion

3.1. Macroscopic Features and Morphology of Carbon Monoliths

3.2. Porosity

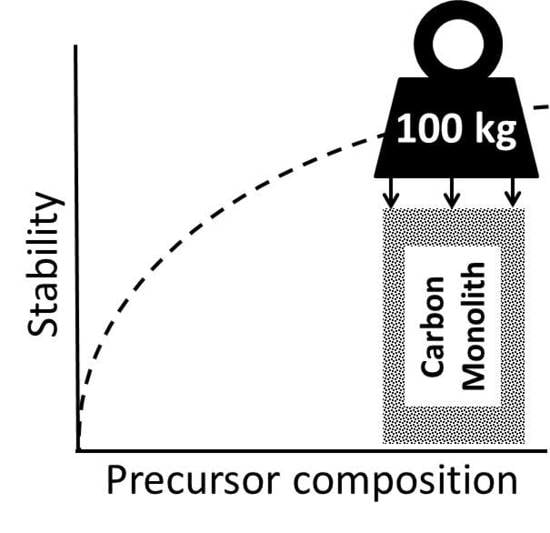

3.3. Fracture Strength

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kamm, B.; Gruber, P.; Kamm, M. Biorefineries—Industrial Processes and Products, 1st ed.; Wiley-VCH: Weinheim, Germany, 2006. [Google Scholar]

- Böhler, S.; Bartel, M.; Bohn, A.; Jacob, R.; Ganster, J.; Büsse, T.; Balko, J. Highly dense cellulose acetate specimens with superior mechanical properties produced by fused filament fabrication. Polymer 2020, 194, 122388. [Google Scholar] [CrossRef]

- Auer, E.; Freund, A.; Pietsch, J.; Tacke, T. Carbons as supports for industrial precious metal catalysts. Appl. Catal. A 1998, 173, 259–271. [Google Scholar] [CrossRef]

- Marsh, H.; Rodriguez-Reynoso, F. Activated Carbon, 1st ed.; Elsevier: Oxford, UK, 2006. [Google Scholar]

- Serp, P.; Figueiredo, J.L. Carbon Materials for Catalysis, 1st ed.; Wiley&Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Nishihara, H.; Kyotani, T. Templated nanocarbons for energy storage. Adv. Mater. 2012, 24, 4473–4498. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Kaskel, S. KOH activation of carbon-based materials for energy storage. J. Mater. Chem. 2012, 22, 23710–23725. [Google Scholar] [CrossRef]

- Kyotani, T.; Ma, Z.; Tomita, A. Template synthesis of novel porous carbons using various types of zeolites. Carbon 2003, 41, 1451–1459. [Google Scholar] [CrossRef]

- Ryoo, R.; Joo, S.H.; Jun, S. Synthesis of highly ordered carbon molecular sieves via template-mediated structural transformation. J. Phys. Chem. B 1999, 103, 7743–7746. [Google Scholar] [CrossRef]

- Juhl, A.C.; Elverfeldt, C.-P.; Hoffmann, F.; Fröba, M. Porous carbon monoliths with pore sizes adjustable between 10 nm and 2mm prepared by phase separation—New insights in the relation between synthesis composition and resulting structure. Microporous Mesoporous Mater. 2018, 255, 271–280. [Google Scholar] [CrossRef]

- Adelhelm, P.; Hu, Y.-S.; Chuenchom, L.; Antonietti, M.; Smarsly, B.M.; Maier, J. Generation of Hierarchical Meso- and Macroporous Carbon from Mesophase Pitch by Spinodal Decomposition using Polymer Templates. Adv. Mater. 2007, 19, 14012–14017. [Google Scholar] [CrossRef]

- Gutiérrez-Pardo, A.; Ramirez-Rico, J.; de Arellano-López, A.R.; Martinez-Fernández, J. Characterization of porous graphitic monoliths from pyrolyzed wood. J. Mater. Sci. 2014, 49, 7688–7696. [Google Scholar] [CrossRef]

- Budarin, V.; Clark, J.H.; Hardy, J.J.E.; Luque, R.; Milkowski, K.; Tavener, S.J.; Wilson, A.J. Starbons: New Starch-Derived Mesoporous Carbonaceous Materials with Tunable Properties. Angew. Chem. Int. Ed. 2006, 45, 3782–3786. [Google Scholar] [CrossRef]

- Shuo, Z.; Cheng-yang, W.; Ming-ming, C.; Zhi-qiang, S.; Na, L. Preparation of carbon spheres from potato starch and its stabilization mechanism. New Carbon Mater. 2010, 25, 438–443. [Google Scholar] [CrossRef]

- Xue, Z.; Chen, P.; Yang, Q.; Lifang, H.; Mu, S.; Cheng, B. Effects of low-temperature carbonization temperature and time on morphology of carbon particles from maize starch. J. Mater. Sci. 2014, 49, 2180–2186. [Google Scholar] [CrossRef]

- Keetels, C.J.A.M.; van Vliet, T.; Walstra, P. Gelation and retrogradation of concentrated starch systems: 1. Gelation. Food Hydrocoll. 1996, 10, 343–353. [Google Scholar] [CrossRef]

- Nishiyama, Y.; Langan, P.; Chanzy, H. Crystal Structure and Hydrogen-Bonding System in Cellulose Iβ from Synchrotron X-ray and Neutron Fiber Diffraction. J. Am. Chem. Soc. 2002, 124, 9074–9082. [Google Scholar] [CrossRef] [PubMed]

- Taguchi, A.; Smatt, J.H.; Linden, M. Carbon monoliths possessing a hierarchical, fully interconnected porosity. Adv. Mater. 2003, 15, 1209–1211. [Google Scholar] [CrossRef]

- Lu, A.H.; Smatt, J.H.; Backlund, S.; Linden, M. Easy and flexible preparation of nanocasted carbon monoliths exhibiting a multimodal hierarchical porosity. Microporous Mesoporous Mater. 2004, 72, 59–65. [Google Scholar] [CrossRef]

- Xia, Y.; Mokaya, R. Ordered mesoporous carbon monoliths: CVD nanocasting and hydrogen storage properties. J. Phys. Chem. C 2007, 111, 10035–10039. [Google Scholar] [CrossRef]

- Günther, D.; Beckmann, J.; Schöneich, M.; Schmidt, P.; Klepel, O. Porous concrete as a template for the synthesis of porous carbon materials. Carbon 2012, 50, 3096–3098. [Google Scholar] [CrossRef]

- Taubert, M.; Beckmann, J.; Lange, A.; Enke, D.; Klepel, O. Attempts to design porous carbon monoliths using porous concrete as a template. Microporous Mesoporous Mater. 2014, 197, 58–62. [Google Scholar] [CrossRef]

- Klepel, O.; Danneberg, N.; Dräger, M.; Erlitz, M.; Taubert, M. Synthesis of Porous Carbon Monoliths Using Hard Templates. Materials 2016, 9, 214. [Google Scholar] [CrossRef]

- Klepel, O.; Taubert, M. Attempts to design porous carbon monoliths using porous concrete as a template—Part II: Some aspects of the pore formation mechanism. Microporous Mesoporous Mater. 2019, 280, 243–247. [Google Scholar] [CrossRef]

- Sing, K.S.W.; Everett, D.H.; Haul, R.A.W.; Moscou, L.; Pierotti, R.A.; Rouquerol, J.; Siemieniewska, T. Reporting Physisorption Data for Gas/Solid Systems with Special Reference to the Determination of Surface Area and Porosity. Pure Appl. Chem. 1985, 157, 603–619. [Google Scholar] [CrossRef]

| Carbon Precursor 1 | Carbon Precursor 2 | Starch Content (wt.%) | Sample Denotation |

|---|---|---|---|

| cellulose fibers | wheat starch | 10…50 | FWx |

| cellulose fibers | potato starch | 10…50 | FPx |

| microcrystalline cellulose | wheat starch | 10…50 | MWx |

| microcrystalline cellulose | potato starch | 10…50 | MPx |

| Series | FWx; FPx (Low Starch Concentration) | MWx; MPx (Low Starch Concentration) | FWx; FPx (High Starch Concentration) | MWx; MPx (High Starch Concentration) |

|---|---|---|---|---|

| length (mm) | 14.5…17.0 | 12.5…15 | 14.5…17.0 | 17.5…20.0 |

| diameter (mm) | 17.0…18.5 | 12.5…13.5 | 17.0…18.5 | 17.5…20 |

| MW10 | MW10_3 | MW10_9 | MW30 | MW30_3 | MW30_9 | |

|---|---|---|---|---|---|---|

| Vsp (cm3g-1) | 0.20 | 0.28 | 0.42 | 0.19 | 0.18 | 0.53 |

| SBET (m2g-1) | 415 | 591 | 870 | 391 | 387 | 1122 |

| FW10_3 | FW10_9 | FW50_3 | FW50_9 | |

|---|---|---|---|---|

| Vsp (cm3g-1) | 0.44 | 1.16 | 0.36 | 1.08 |

| SBET (m2g-1) | 928 | 2468 | 770 | 2324 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Klepel, O.; Danneberg, N. Porous Carbon Monoliths Made from Cellulose and Starch. C 2020, 6, 32. https://doi.org/10.3390/c6020032

Klepel O, Danneberg N. Porous Carbon Monoliths Made from Cellulose and Starch. C. 2020; 6(2):32. https://doi.org/10.3390/c6020032

Chicago/Turabian StyleKlepel, Olaf, and Nina Danneberg. 2020. "Porous Carbon Monoliths Made from Cellulose and Starch" C 6, no. 2: 32. https://doi.org/10.3390/c6020032

APA StyleKlepel, O., & Danneberg, N. (2020). Porous Carbon Monoliths Made from Cellulose and Starch. C, 6(2), 32. https://doi.org/10.3390/c6020032