Enhanced Breaking of Lignin and Mesopore Formation in Zinc Chloride Assisted Hydrothermal Carbonization of Waste Biomasses

Abstract

:1. Introduction

2. Experimental

2.1. Materials

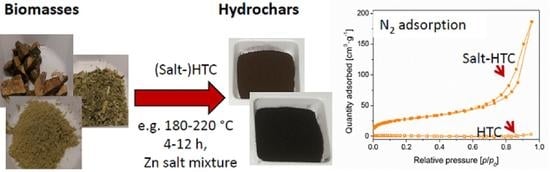

2.2. Hydrothermal Carbonization

2.3. Steam Activation

2.4. Characterization Techniques

2.5. Dye Adsorption Studies

3. Results and Discussion

3.1. Elemental Composition of the Hydrochars

3.2. Surface Composition of the Compounds

3.3. Morphology of the Hydrochars

3.4. Mechanistics

3.5. Surface Area and Adsorption Studies

3.6. Adsorption Studies with the Dyes Methylene Blue and Methyl Orange

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sharma, H.B.; Sarmah, A.K.; Dubey, B. Hydrothermal carbonization of renewable waste biomass for solid biofuel production: A discussion on process mechanism, the influence of process parameters, environmental performance and fuel properties of hydrochar. Renew. Sustain. Energy Rev. 2020, 123, 109761. [Google Scholar] [CrossRef]

- Funke, A.; Reebs, F.; Kruse, A. Experimental comparison of hydrothermal and vapothermal carbonization. Fuel Process. Technol. 2013, 115, 261–269. [Google Scholar] [CrossRef]

- Kambo, H.S.; Dutta, A. Comparative evaluation of torrefaction and hydrothermal carbonization of lignocellulosic biomass for the production of solid biofuel. Energy Convers. Manag. 2015, 105, 746–755. [Google Scholar] [CrossRef]

- Yeoh, K.H.; Shafie, S.A.; Al-Attab, K.A.; Zainal, Z.A. Upgrading agricultural wastes using three different carbonization methods: Thermal, hydrothermal and vapothermal. Bioresour. Technol. 2018, 265, 365–371. [Google Scholar] [CrossRef]

- Dai, L.; Wang, Y.; Liu, Y.; Ruan, R.; He, C.; Yu, Z.; Jiang, L.; Zeng, Z.; Tian, X. Integrated process of lignocellulosic biomass torrefaction and pyrolysis for upgrading bio-oil production: A state-of-the-art review. Renew. Sustain. Energy Rev. 2019, 107, 20–36. [Google Scholar] [CrossRef]

- Sudarsanam, P.; Zhong, R.; Van den Bosch, S.; Coman, S.M.; Parvulescu, V.I.; Sels, B.F. Functionalised heterogeneous catalysts for sustainable biomass valorization. Chem. Soc. Rev. 2018, 47, 8349–8402. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Titirici, M.M.; Antonietti, M. Chemistry and materials options of sustainable carbon materials made by hydrothermal carbonization. Chem. Soc. Rev. 2010, 39, 103–116. [Google Scholar] [CrossRef]

- Schonvogel, D.; Nowotny, M.; Woriescheck, T.; Multhaupt, H.; Wagner, P.; Dyck, A.; Agert, C.; Wark, M. Hydrothermal Carbonization-Derived Carbon from Waste Biomass as Renewable Pt Support for Fuel Cell Applications: Role of Carbon Activation. Energy Technol. 2019, 7, 1900344. [Google Scholar] [CrossRef] [Green Version]

- Magdziarz, A.; Mlonka-Medrala, A.; Sieradzka, M.; Aragon-Briceno, C.; Pozarlik, A.; Bramer, E.A.; Brem, G.; Niedzwiecki, L.; Pawlak-Kruczek, H. Multiphase analysis of hydrochars obtained by anaerobic digestion of municipal solid waste organic fraction. Renew. Energy 2021, 175, 108–118. [Google Scholar] [CrossRef]

- Budai, A.; Wang, L.; Gronli, M.; Strand, L.T.; Antal, M.J., Jr.; Abiven, S.; Dieguez-Alonso, A.; Anca-Couce, A.; Rasse, D.P. Surface Properties and Chemical Composition of Corncob and Miscanthus Biochars: Effects of Production Temperature and Method. J. Agric. Food Chem. 2014, 62, 3791–3799. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, F.S.; Wu, J. Characterization and application of chars produced from pinewood pyrolysis and hydrothermal treatment. Fuel 2010, 89, 510–514. [Google Scholar] [CrossRef]

- Sevilla, M.; Fuertes, A.B. Chemical and structural properties of carbonaceous products obtained by hydrothermal carbonization of saccharides. Chem. Eur. J. 2009, 15, 4195–4203. [Google Scholar] [CrossRef] [PubMed]

- Titirici, M.M.; Thomas, A.; Yu, S.H.; Mueller, J.O.; Antonietti, M. A direct synthesis of mesoporous carbons with bicontinuous pore morphology from crude plant material by hydrothermal carbonization. Chem. Mater. 2007, 19, 4205–4212. [Google Scholar] [CrossRef]

- Jain, A.; Balasubramanian, R.; Srinivasan, M.P. Hydrothermal conversion of biomass waste to activated carbon with high porosity: A review. Chem. Eng. J. 2016, 283, 789–805. [Google Scholar] [CrossRef]

- Fechler, N.; Wohlgemuth, S.; Phillip, J.; Antonietti, M. Salt and sugar: Direct synthesis of high surface area carbon materials at low temperatures via hydrothermal carbonization of glucose under hypersaline conditions. J. Mater. Chem. A 2013, 1, 9418–9421. [Google Scholar] [CrossRef] [Green Version]

- Ma, Z.; Zhang, H.; Yang, Z.; Zhang, Y.; Yu, B.; Liu, Z. Highly mesoporous carbons derived from biomass feedstocks templated with eutectic salt ZnCl2/KCl. J. Mater. Chem. A 2014, 2, 19324–19329. [Google Scholar] [CrossRef]

- Liu, T.; Liu, Z.; Zheng, Q.; Lang, Q.; Xia, Y.; Peng, N.; Gai, C. Effect of hydrothermal carbonization on migration and environmental risk of heavy metals in sewage sludge during pyrolysis. Bioresour. Technol. 2018, 247, 282–290. [Google Scholar] [CrossRef]

- Tekin, K.; Karagöz, S.; Bektaş, S. A review of hydrothermal biomass processing. Renew. Sustain. Energy Rev. 2014, 40, 673–687. [Google Scholar] [CrossRef]

- Han, M.; Jiang, K.; Jiao, P.; Ji, Y.; Zhou, J.; Zhuang, W.; Chen, Y.; Liu, D.; Zhu, C.; Chen, X.; et al. Bio-butanol sorption performance on novel porous-carbon adsorbents from corncob prepared via hydrothermal carbonization and post-pyrolysis method. Sci. Rep. 2017, 7, 11753. [Google Scholar] [CrossRef] [Green Version]

- Lua, A.C.; Guo, J. Activated carbon prepared from oil palm stone by one-step CO2 activation for gaseous pollutant removal. Carbon 2000, 38, 1089–1097. [Google Scholar] [CrossRef]

- Papurello, D.; Santarelli, M.; Fiorilli, S. Physical Activation of Waste-Derived Materials for Biogas Cleaning. Energies 2018, 11, 2338. [Google Scholar] [CrossRef] [Green Version]

- Lee, Y.-W.; Kim, H.-J.; Park, J.-W.; Choi, B.-U.; Choi, D.-K.; Park, J.-W. Adsorption and reaction behavior for the simultaneous adsorption of NO-NO2 and SO2 on activated carbon impregnated with KOH. Carbon 2003, 41, 1881–1888. [Google Scholar] [CrossRef]

- Li, G.; Gao, X.; Wang, K.; Cheng, Z. Porous carbon nanospheres with high EDLC capacitance. Diam. Relat. Mater. 2018, 88, 12–17. [Google Scholar] [CrossRef]

- Lillo-Ródenas, M.A.; Juan-Juan, J.; Cazorla-Amorós, D.; Linares-Solano, A. About reactions occurring during chemical activation with hydroxides. Carbon 2004, 42, 1371–1375. [Google Scholar] [CrossRef]

- Alatalo, S.M.; Makila, E.; Repo, E.; Heinonen, M.; Salonen, J.; Kukk, E.; Sillanpaa, M.; Titirici, M.M. Meso-and microporous soft templated hydrothermal carbons for dye removal from water. Green Chem. 2016, 18, 1137–1146. [Google Scholar] [CrossRef] [Green Version]

- Rouquerol, F.; Rouquerol, J.; Sing, K.S.W.; Llewellyn, P.; Maurin, G. Adsorption by Powders and Porous Solids, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Falco, C.; Baccile, N.; Titirici, M.M. Morphological and structural differences between glucose, cellulose and lignocellulosic biomass derived hydrothermal carbons. Green Chem. 2011, 13, 3273–3281. [Google Scholar] [CrossRef] [Green Version]

- Baccile, N.; Weber, J.; Falco, C.; Titirici, M.M. Sustainable Carbon Materials from Hydrothermal Processes; Titirici, M.M., Ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2013; Chapter 6; pp. 151–211. [Google Scholar]

- Baccile, N.; Laurent, G.; Babonneau, F.; Fayon, F.; Titirici, M.M.; Antonietti, M. Structural Characterization of Hydrothermal Carbon Spheres by Advanced Solid-State MAS C-13 NMR Investigations. J. Phys. Chem. C 2009, 113, 9644–9654. [Google Scholar] [CrossRef] [Green Version]

- Islam, M.A.; Benhouria, A.; Asif, M.; Hameed, B.H. Methylene blue adsorption on factory-rejected tea activated carbon prepared by conjunction of hydrothermal carbonization and sodium hydroxide activation processes. J. Taiwan Inst. Chem. Eng. 2015, 52, 57–64. [Google Scholar] [CrossRef]

- Fang, J.; Gao, B.; Chen, J.; Zimmerman, A.R. Hydrochars derived from plant biomass under various conditions: Characterization and potential applications and impacts. Chem. Eng. J. 2015, 267, 253–259. [Google Scholar] [CrossRef]

- Reza, M.T.; Wirth, B.; Luder, U.; Werner, M. Behavior of selected hydrolyzed and dehydrated products during hydrothermal carbonization of biomass. Bioresour. Technol. 2014, 169, 352–361. [Google Scholar] [CrossRef]

- Mumme, J.; Eckervogt, L.; Pielert, J.; Diakite, M.; Rupp, F.; Kern, J. Hydrothermal carbonization of anaerobically digested maize silage. Bioresour. Technol. 2011, 102, 9255–9260. [Google Scholar] [CrossRef]

- Licursi, D.; Antonetti, C.; Bernardini, J.; Cinelli, P.; Coltelli, M.B.; Lazzeri, A.; Martinelli, M.; Galletti, A.M.R. Characterization of the Arundo Donax L. solid residue from hydrothermal conversion: Comparison with technical lignins and application perspectives. Ind. Crops Prod. 2015, 76, 1008–1024. [Google Scholar] [CrossRef]

- Zeeh, B. Spektroskopische Methoden in der Organischen Chemie, 7th ed.; Hesse, M., Meier, H., Zeeh, B., Eds.; Georg Thieme Publisher: Stuttgart, Germany, 2005; Chapter 2; pp. 33–73. [Google Scholar]

- Ahmadpour, A.; Do, D.D. The preparation of activated carbon from macadamia nutshell by chemical activation. Carbon 1997, 35, 1723–1732. [Google Scholar] [CrossRef]

- Cesano, F.; Rahman, M.M.; Bertarione, S.; Vitillo, J.G.; Scarano, D.; Zecchina, A. Preparation and adsorption properties of activated porous carbons obtained using volatile zinc templating phases. Carbon 2012, 50, 2045–2060. [Google Scholar] [CrossRef]

- Fischer, S. Unconventional dissolution and derivatization of cellulose. Lenzing. Ber. 2004, 83, 71–78. [Google Scholar]

- Hu, Z.; Srinivasan, M.P.; Ni, Y. Novel activation process for preparing highly microporous and mesoporous activated carbons. Carbon 2001, 39, 877–886. [Google Scholar] [CrossRef]

- Dinjus, E.; Kruse, A.; Troger, N. Hydrothermal Carbonization-1. Influence of Lignin in Lignocelluloses. Chem. Eng. Technol. 2011, 34, 2037–2043. [Google Scholar] [CrossRef]

- Liu, Z.G.; Quek, A.; Hoekman, S.K.; Balasubramanian, R. Production of solid biochar fuel from waste biomass by hydrothermal carbonization. Fuel 2013, 103, 943–949. [Google Scholar] [CrossRef]

- Zhou, L.; Yang, X.; Xu, J.; Shi, M.; Wang, F.; Chen, C.; Xu, J. Depolymerization of cellulose to glucose by oxidation-hydrolysis. Green Chem. 2015, 17, 1519–1524. [Google Scholar] [CrossRef]

- Wysokowski, M.; Klapiszewski, L.; Moszyński, D.; Bartczak, P.; Szatkowski, T.; Majchrzak, I.; Siwińska-Stefańska, K.; Bazhenov, V.V.; Jesionowski, T. Modification of Chitin with Kraft Lignin and Development of New Biosorbents for Removal of Cadmium(II) and Nickel(II) Ions. Mar. Drugs 2014, 12, 2245–2268. [Google Scholar] [CrossRef] [Green Version]

- Roehrdanz, M.; Rebling, T.; Ohlert, J.; Jasper, J.; Greve, T.; Buchwald, R.; von Frieling, P.; Wark, M. Hydrothermal carbonization of biomass from landscape management—Influence of process parameters on soil properties of hydrochars. J. Environ. Managem. 2016, 173, 72–78. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.P.; Yan, R.; Chen, H.P.; Zheng, C.G.; Lee, D.H.; Liang, D.T. In-depth investigation of biomass pyrolysis based on three major components: Hemicellulose, cellulose and lignin. Energy Fuels 2006, 20, 388–393. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S.W. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.; Liu, X.; Li, W.; Huang, X.; Luan, S.; Huo, X.; Zhang, M.; Wang, Q. CO2 mediated fabrication of hierarchically porous metal-organic frameworks. Microporous Mesoporous Mater 2019, 277, 154–162. [Google Scholar] [CrossRef]

- Juarez-Galan, J.M.; Silvestre-Albero, A.; Silvestre-Albero, J.; Rodriguez-Reinoso, F. Synthesis of activated carbon with highly developed “mesoporosity”. Microporous Mesoporous Mater. 2009, 117, 519–521. [Google Scholar] [CrossRef]

- Guo, Y.P.; Yang, S.F.; Fu, W.Y.; Qi, J.R.; Li, R.Z.; Wang, Z.C.; Xu, H.D. Adsorption of malachite green on micro- and mesoporous rice husk-based active carbon. Dyes Pigment. 2003, 56, 219–229. [Google Scholar] [CrossRef]

- Danish, M.; Hashim, R.; Mohamad Ibrahim, M.N.; Sulaiman, O. Characterization of physically activated acacia mangium wood-based carbon for the removal of methyl orange dye. BioResources 2013, 8, 4323–4339. [Google Scholar] [CrossRef] [Green Version]

- Zhao, X.; Bu, X.; Wu, T.; Zheng, S.T.; Wang, L.; Feng, P. Selective anion exchange with nanogated isoreticular positive metal-organic frameworks. Nat. Commun. 2013, 4, 2344–2353. [Google Scholar] [CrossRef]

- Saetea, P.; Tippayawong, N. Characterization of Adsorbent from Hydrothermally Carbonized and Steam Activated Sewage Sludge. In Proceedings of the World Congress on Engineering, London, UK, 3–5 July 2013; Volume III. [Google Scholar]

- Mok, W.S.L.; Antal, M.J.; Szabo, P.; Varhegyi, G.; Zelei, B. Formation of charcoal from biomass in a sealed reactor. Ind. Eng. Chem. Res. 1992, 31, 1162–1166. [Google Scholar] [CrossRef]

- Martin-Jimeno, F.J.; Suarez-Garcia, F.; Paredes, J.I.; Martinez-Alonso, A.; Tascon, J.M.D. Activated carbon xerogels with a cellular morphology derived from hydrothermally carbonized glucose-graphene oxide hybrids and their performance towards CO2 and dye adsorption. Carbon 2015, 81, 137–147. [Google Scholar] [CrossRef]

- Vargas, A.M.M.; Cazetta, A.L.; Kunita, M.H.; Silva, T.L.; Almeida, V.C. Adsorption of methylene blue on activated carbon produced from flamboyant pods (Delonix regia): Study of adsorption isotherms and kinetic models. Chem. Eng. J. 2011, 168, 722–730. [Google Scholar] [CrossRef]

- Tran, H.N.; You, S.J.; Chao, H.P. Insight into adsorption mechanism of cationic dye onto agricultural residues-derived hydrochars: Negligible role of pi-pi interaction. Korean J. Chem. Eng. 2017, 34, 1708–1720. [Google Scholar] [CrossRef]

- Ma, Y.H.; Wang, Q.H.; Wang, X.N.; Sun, X.H.; Wang, X.Q. A comprehensive study on activated carbon prepared from spent shiitake substrate via pyrolysis with ZnCl2. J. Porous Mater. 2015, 22, 157–169. [Google Scholar] [CrossRef]

- Multhaupt, H. Potential of Hydrochars Obtained by Hydrothermal Carbonization under Saline Conditions. Ph.D. Thesis, Carl von Ossietzky University of Oldenburg, Oldenburg, Germany, 2018. [Google Scholar]

| Substrate | Sample | C [wt.%] | N [wt.%] | O [wt.%] | H [wt.%] | Ash [wt.%] |

|---|---|---|---|---|---|---|

| Dandelion | Dd (raw material) | 37.5 | 2.16 | 44.3 | 5.5 | 10.76 |

| Dd-HTC | 49.7 | 2.3 | 32.7 | 6.0 | 9.3 | |

| Dd-HTC Zn | 52.0 | 1.4 | 29.1 | 4.1 | 13.6 | |

| Dd-Act500C | 49.8 | 1.9 | 19.8 | 0.5 | 28.0 | |

| Dd-Act500C Zn | 53.6 | 1.6 | 17.4 | 1.5 | 25.9 | |

| Sawdust | Sd (raw material) | 46.3 | 0.6 | 46.9 | 6.1 | 0.0 |

| Sd-HTC | 50.0 | 0.4 | 43.8 | 5.9 | 0.0 | |

| Sd-HTC Zn | 60.3 | 0.4 | 35.6 | 3.7 | 0.0 | |

| Sd-Act500C | 66.1 | 1.8 | 30.4 | 0.9 | 0.9 | |

| Sd-Act500C Zn | 73.0 | 0.6 | 22.0 | 1.7 | 2.8 | |

| Coconut | Cn (raw material) | 49.1 | 0.1 | 44.7 | 6.2 | 0.4 |

| Cn-HTC | 59.5 | 0.1 | 35.0 | 5.4 | 0.1 | |

| Cn-HTC Zn | 66.2 | 0.1 | 29.6 | 4.0 | 0.1 | |

| Cn-Act650C | 86.9 | 0.2 | 11.8 | 1.2 | 0.00 | |

| Cn-Act650C Zn | 82.9 | 0.1 | 12.8 | 1.1 | 3.1 | |

| Cn-Act500C | 77.2 | 0.2 | 20.9 | 1.7 | 0.0 | |

| Cn-Act500C Zn | 77.0 | 0.1 | 18.8 | 2.0 | 2.2 | |

| Cn-Act350C | 69.2 | 0.3 | 27.4 | 3.1 | 0.0 | |

| Cn-Act350C Zn | 69.2 | 0.1 | 26.1 | 3.0 | 1.7 | |

| Cn-Act200C | 59.3 | 0.2 | 35.3 | 5.2 | 0.0 | |

| Cn-Act200C Zn | 65.1 | 0.8 | 31.1 | 3.2 | 0.5 | |

| Cn-Act30min | 76.8 | 0.2 | 21.4 | 1.6 | 0.0 | |

| Cn-Act30min Zn | 75.3 | 0.0 | 20.8 | 1.9 | 1.9 | |

| Cn-Act10min | 74.4 | 0.3 | 23.1 | 2.3 | 0.0 | |

| Cn-Act10min Zn | 75.9 | 0.1 | 19.8 | 2.2 | 2.1 |

| Model | Parameter | Value |

|---|---|---|

| Langmuir | qm [mg∙g−1] | 277.01 |

| KL [L∙mg−1] | 2.6159 | |

| R2 | 0.9682 | |

| Freundlich | KF [(mg∙g−1) (L∙mg−1)1/n] | 199.29 |

| 1/n | 0.1140 | |

| R2 | 0.5436 | |

| Temkin | AT [L∙g−1] | 1455.59 |

| B | 90.5810 | |

| R2 | 0.5031 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Multhaupt, H.; Bottke, P.; Wark, M. Enhanced Breaking of Lignin and Mesopore Formation in Zinc Chloride Assisted Hydrothermal Carbonization of Waste Biomasses. C 2021, 7, 77. https://doi.org/10.3390/c7040077

Multhaupt H, Bottke P, Wark M. Enhanced Breaking of Lignin and Mesopore Formation in Zinc Chloride Assisted Hydrothermal Carbonization of Waste Biomasses. C. 2021; 7(4):77. https://doi.org/10.3390/c7040077

Chicago/Turabian StyleMulthaupt, Hendrik, Patrick Bottke, and Michael Wark. 2021. "Enhanced Breaking of Lignin and Mesopore Formation in Zinc Chloride Assisted Hydrothermal Carbonization of Waste Biomasses" C 7, no. 4: 77. https://doi.org/10.3390/c7040077

APA StyleMulthaupt, H., Bottke, P., & Wark, M. (2021). Enhanced Breaking of Lignin and Mesopore Formation in Zinc Chloride Assisted Hydrothermal Carbonization of Waste Biomasses. C, 7(4), 77. https://doi.org/10.3390/c7040077