Graphene Nanocomposites in Space Sector—Fundamentals and Advancements

Abstract

:1. Introduction

2. Graphene

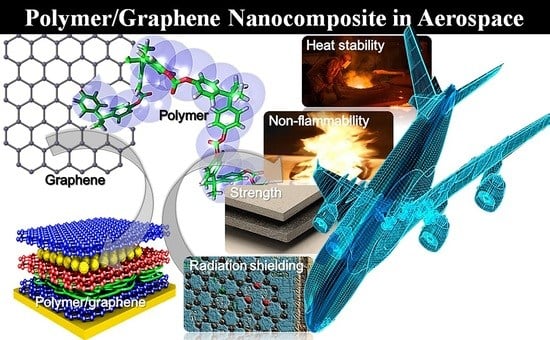

3. Composite/Nanocomposite Materials Regarding Aerospace

4. Graphene in Polymeric Nanocomposites for Space Relevance

5. Epoxy/Graphene Nanocomposites for Aerospace Applications

6. Polymers with Graphene-Modified Carbon Fiber for Aerospace

7. Graphene Nanomaterials and Present Aerospace Industry

8. Forthcoming and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lebedev, O.V.; Kurkin, T.S.; Golubev, E.K.; Vasiliev, A.L.; Gatin, A.K.; Goncharuk, G.P.; Ozerin, A.N. Detonation Synthesis Nanodiamond Soot as a Promising Filler for Polymer Composites. C 2022, 8, 69. [Google Scholar] [CrossRef]

- Padmanaban, D.B.; Mohan, L.; Giri, P.; Bera, P.; Anandan, C.; Barshilia, H.C. Effect of Molybdenum Content on Mechanical and Tribological Properties of Diamond-Like Carbon Coatings over Titanium β-21S Alloy. C 2020, 7, 1. [Google Scholar] [CrossRef]

- Gbordzoe, S.; Adusei, P.K.; Chauhan, D.; Alvarez, N.T.; Haase, M.R.; Mansari, K.; Kanakaraj, S.N.; Hsieh, Y.-Y.; Shanov, V. A Simple Two-Step Process for Producing Strong and Aligned Carbon Nanotube-Polymer Composites. C 2019, 5, 35. [Google Scholar] [CrossRef] [Green Version]

- Susi, B.T.; Tu, J.F. Digital Synthesis of Realistically Clustered Carbon Nanotubes. C 2022, 8, 34. [Google Scholar] [CrossRef]

- Driscoll, A.J.; Johnson, P.A. Numerical modeling of analyte diffusion and adsorption behavior in microparticle and nanoparticle based biosensors. Chem. Eng. Sci. 2018, 184, 141–148. [Google Scholar] [CrossRef]

- Rambabu, P.; Prasad, N.E.; Kutumbarao, V.; Wanhill, R. Aluminium alloys for aerospace applications. In Aerospace Materials and material Technologies; Springer: Singapore, 2017; pp. 29–52. [Google Scholar]

- Gorbatikh, L.; Wardle, B.L.; Lomov, S.V. Hierarchical lightweight composite materials for structural applications. Mrs Bull. 2016, 41, 678–682. [Google Scholar] [CrossRef] [Green Version]

- Bilisik, K.; Akter, M. Graphene nanocomposites: A review on processes, properties, and applications. J. Ind. Text. 2022, 51, 3718S–3766S. [Google Scholar] [CrossRef]

- Razaq, A.; Bibi, F.; Zheng, X.; Papadakis, R.; Jafri, S.H.M.; Li, H. Review on graphene-, graphene oxide-, reduced graphene oxide-based flexible composites: From fabrication to applications. Materials 2022, 15, 1012. [Google Scholar] [CrossRef]

- Al Faruque, M.A.; Syduzzaman, M.; Sarkar, J.; Bilisik, K.; Naebe, M. A review on the production methods and applications of graphene-based materials. Nanomaterials 2021, 11, 2414. [Google Scholar] [CrossRef]

- Kausar, A. Aerospace applications of polymer/carbonaceous nanofiller nanocomposites: Mechanical, thermal, nonflammability, and physical aspects. In Polymeric Nanocomposites with Carbonaceous Nanofillers for Aerospace Applications; Elsevier: Amsterdam, The Netherlands, 2022; p. 85. [Google Scholar]

- Liu, Y.; Du, H.; Liu, L.; Leng, J. Shape memory polymers and their composites in aerospace applications: A review. Smart Mater. Struct. 2014, 23, 023001. [Google Scholar] [CrossRef]

- Kausar, A. Aeronautical composites and materials. In Polymeric Nanocomposites with Carbonaceous Nanofillers for Aerospace Applications; Elsevier: Amsterdam, The Netherlands, 2022; p. 1. [Google Scholar]

- Gao, Y.; Zhang, Y.; Chen, P.; Li, Y.; Liu, M.; Gao, T.; Ma, D.; Chen, Y.; Cheng, Z.; Qiu, X. Toward single-layer uniform hexagonal boron nitride–graphene patchworks with zigzag linking edges. Nano Lett. 2013, 13, 3439–3443. [Google Scholar] [CrossRef] [PubMed]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.-e.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wei, C.; Negishi, R.; Ogawa, Y.; Akabori, M.; Taniyasu, Y.; Kobayashi, Y. Turbostratic multilayer graphene synthesis on CVD graphene template toward improving electrical performance. Jpn. J. Appl. Phys. 2019, 58, SIIB04. [Google Scholar] [CrossRef]

- Narayanam, P.K.; Botcha, V.D.; Ghosh, M.; Major, S.S. Growth and Photocatalytic Behaviour of Transparent Reduced GO-ZnO Nanocomposite Sheets. Nanotechnology 2019, 30, 485601. [Google Scholar] [CrossRef]

- Shen, X.J.; Zeng, X.L.; Dang, C.Y. Graphene Composites. Handb. Graphene 2019, 1, 1–25. [Google Scholar]

- Zandiatashbar, A.; Lee, G.-H.; An, S.J.; Lee, S.; Mathew, N.; Terrones, M.; Hayashi, T.; Picu, C.R.; Hone, J.; Koratkar, N. Effect of defects on the intrinsic strength and stiffness of graphene. Nat. Commun. 2014, 5, 3186. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Q.; Xia, G.; Du, M.; Lu, Y.; Xu, H. Scotch-tape-like exfoliation effect of graphene quantum dots for efficient preparation of graphene nanosheets in water. Appl. Surf. Sci. 2019, 483, 52–59. [Google Scholar] [CrossRef]

- Pei, S.; Cheng, H.-M. The reduction of graphene oxide. Carbon 2012, 50, 3210–3228. [Google Scholar] [CrossRef]

- Lee, H.; Lee, K.S. Interlayer Distance Controlled Graphene, Supercapacitor and Method of Producing the Same. U.S. Patent 10,214,422, 26 February 2019. [Google Scholar]

- Han, J.T.; Jang, J.I.; Cho, J.Y.; Hwang, J.Y.; Woo, J.S.; Jeong, H.J.; Jeong, S.Y.; Seo, S.H.; Lee, G.-W. Synthesis of nanobelt-like 1-dimensional silver/nanocarbon hybrid materials for flexible and wearable electronics. Sci. Rep. 2017, 7, 4931. [Google Scholar] [CrossRef] [Green Version]

- Schwierz, F. Graphene transistors: Status, prospects, and problems. Proc. IEEE 2013, 101, 1567–1584. [Google Scholar] [CrossRef]

- Marconcini, P.; Macucci, M. Transport Simulation of Graphene Devices with a Generic Potential in the Presence of an Orthogonal Magnetic Field. Nanomaterials 2022, 12, 1087. [Google Scholar] [CrossRef] [PubMed]

- Panwar, N.; Soehartono, A.M.; Chan, K.K.; Zeng, S.; Xu, G.; Qu, J.; Coquet, P.; Yong, K.-T.; Chen, X. Nanocarbons for biology and medicine: Sensing, imaging, and drug delivery. Chem. Rev. 2019, 119, 9559–9656. [Google Scholar] [CrossRef] [PubMed]

- Tang, C.; Titirici, M.-M.; Zhang, Q. A review of nanocarbons in energy electrocatalysis: Multifunctional substrates and highly active sites. J. Energy Chem. 2017, 26, 1077–1093. [Google Scholar] [CrossRef] [Green Version]

- Bao, Q.; Zhang, H.; Yang, J.x.; Wang, S.; Tang, D.Y.; Jose, R.; Ramakrishna, S.; Lim, C.T.; Loh, K.P. Graphene–polymer nanofiber membrane for ultrafast photonics. Adv. Funct. Mater. 2010, 20, 782–791. [Google Scholar] [CrossRef]

- Wazalwar, R.; Sahu, M. Novel applications of graphene in the aerospace industry. In Novel Applications of Carbon Based Nano-Materials; CRC Press: Boca Raton, FL, USA, 2022; pp. 180–198. [Google Scholar]

- Gao, W.; Alemany, L.B.; Ci, L.; Ajayan, P.M. New insights into the structure and reduction of graphite oxide. Nat. Chem. 2009, 1, 403–408. [Google Scholar] [CrossRef] [PubMed]

- Eigler, S.; Dotzer, C.; Hof, F.; Bauer, W.; Hirsch, A. Sulfur species in graphene oxide. Chem. Eur. J. 2013, 19, 9490–9496. [Google Scholar] [CrossRef] [PubMed]

- Bailey, E.J.; Winey, K.I. Dynamics of polymer segments, polymer chains, and nanoparticles in polymer nanocomposite melts: A review. Prog. Polym. Sci. 2020, 105, 101242. [Google Scholar] [CrossRef]

- Zhao, Q.; Qi, H.J.; Xie, T. Recent progress in shape memory polymer: New behavior, enabling materials, and mechanistic understanding. Prog. Polym. Sci. 2015, 49, 79–120. [Google Scholar] [CrossRef] [Green Version]

- Pilate, F.; Toncheva, A.; Dubois, P.; Raquez, J.-M. Shape-memory polymers for multiple applications in the materials world. Eur. Polym. J. 2016, 80, 268–294. [Google Scholar] [CrossRef]

- Ghori, S.W.; Siakeng, R.; Rasheed, M.; Saba, N.; Jawaid, M. The role of advanced polymer materials in aerospace. In Sustainable Composites for Aerospace Applications; Jawaid, M., Thariq, M., Eds.; Woodhead Publishing, Elsevier: Amsterdam, The Netherlands, 2018; pp. 19–34. [Google Scholar]

- Ramli, N.; Norkhairunnisa, M.; Ando, Y.; Abdan, K.; Leman, Z. Advanced Polymer Composite for Aerospace Engineering Applications. In Advanced Composites in Aerospace Engineering Applications; Springer: Berlin/Heidelberg, Germany, 2022; pp. 1–21. [Google Scholar]

- Zeyrek, B.; Aydogan, B.; Dilekcan, E. Review of Thermoplastic Composites in Aerospace Industry. Int. J. Eng. Tech. Inf. 2022, 3, 1–6. [Google Scholar]

- Norkhairunnisa, M.; Chai Hua, T.; Sapuan, S.; Ilyas, R. Evolution of Aerospace Composite Materials. In Advanced Composites in Aerospace Engineering Applications; Springer: Berlin/Heidelberg, Germany, 2022; pp. 367–385. [Google Scholar]

- Pervaiz, M.; Panthapulakkal, S.; Sain, M.; Tjong, J. Emerging trends in automotive lightweighting through novel composite materials. Mater. Sci. Appl. 2016, 7, 26. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Lin, G.; Vaidya, U.; Wang, H. Past, present and future prospective of global carbon fibre composite developments and applications. Compos. Part B Eng. 2022, 250, 110463. [Google Scholar] [CrossRef]

- McIlhagger, A.; Archer, E.; McIlhagger, R. Manufacturing processes for composite materials and components for aerospace applications. In Polymer Composites in the Aerospace Industry; Elsevier: Amsterdam, The Netherlands, 2020; pp. 59–81. [Google Scholar]

- Long, V.T.; Tung, H.V. Thermomechanical Nonlinear Buckling of Pressurized Shear Deformable FGM Cylindrical Shells Including Porosities and Elastically Restrained Edges. J. Aerosp. Eng. 2021, 34, 04021011. [Google Scholar] [CrossRef]

- Weber, T.A.; Ruff-Stahl, H.-J.K. Advances in composite manufacturing of helicopter parts. Int. J. Aviat. Aeronaut. Aerosp. 2017, 4, 5. [Google Scholar] [CrossRef] [Green Version]

- Tiwari, K.A.; Raisutis, R.; Samaitis, V. Hybrid signal processing technique to improve the defect estimation in ultrasonic non-destructive testing of composite structures. Sensors 2017, 17, 2858. [Google Scholar] [CrossRef] [Green Version]

- Duodu, E.; Gu, J.; Shang, Z.; Ding, W.; Tang, S. Damage induced by high-velocity impact on composite structures using finite element simulation. Iran. J. Sci. Technol. Trans. Mech. Eng. 2017, 41, 97–107. [Google Scholar] [CrossRef]

- Rana, S.; Fangueiro, R. Advanced Composite Materials for Aerospace Engineering: Processing, Properties and Applications; Woodhead Publishing: Sawston, UK, 2016. [Google Scholar]

- Wang, Z.; Zulifqar, A.; Hu, H. Auxetic composites in aerospace engineering. In Advanced Composite Materials for Aerospace Engineering; Elsevier: Amsterdam, The Netherlands, 2016; pp. 213–240. [Google Scholar]

- Carey, J.; Melenka, G.; Hunt, A.; Cheung, B.; Ivey, M.; Ayranci, C. Braided composites in aerospace engineering. In Advanced Composite Materials for Aerospace Engineering; Elsevier: Amsterdam, The Netherlands, 2016; pp. 175–212. [Google Scholar]

- Kamiyama, S.; Hirano, Y.; Okada, T.; Ogasawara, T. Lightning strike damage behavior of carbon fiber reinforced epoxy, bismaleimide, and polyetheretherketone composites. Compos. Sci. Technol. 2018, 161, 107–114. [Google Scholar] [CrossRef]

- Adam, T.J.; Liao, G.; Petersen, J.; Geier, S.; Finke, B.; Wierach, P.; Kwade, A.; Wiedemann, M. Multifunctional composites for future energy storage in aerospace structures. Energies 2018, 11, 335. [Google Scholar] [CrossRef] [Green Version]

- Padture, N.P. Advanced structural ceramics in aerospace propulsion. Nat. Mater. 2016, 15, 804. [Google Scholar] [CrossRef]

- Ghoshal, S. Polymer/carbon nanotubes (CNT) nanocomposites processing using additive manufacturing (three-dimensional printing) technique: An overview. Fibers 2017, 5, 40. [Google Scholar] [CrossRef] [Green Version]

- Safaei, B.; Moradi-Dastjerdi, R.; Behdinan, K.; Chu, F. Critical buckling temperature and force in porous sandwich plates with CNT-reinforced nanocomposite layers. Aerosp. Sci. Technol. 2019, 91, 175–185. [Google Scholar] [CrossRef]

- Rafique, I.; Kausar, A.; Anwar, Z.; Muhammad, B. Exploration of epoxy resins, hardening systems, and epoxy/carbon nanotube composite designed for high performance materials: A review. Polym.-Plast. Technol. Eng. 2016, 55, 312–333. [Google Scholar] [CrossRef]

- Ji, C.; Yan, C.; Wang, Y.; Xiong, S.; Zhou, F.; Li, Y.; Sun, R.; Wong, C.-P. Thermal conductivity enhancement of CNT/MoS2/graphene− epoxy nanocomposites based on structural synergistic effects and interpenetrating network. Compos. Part B Eng. 2019, 163, 363–370. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, K.; Liang, W.; Wang, Z.; Tay, T.E.; Lu, S.; Yang, B. Epoxy/CNT@ X nanocomposite: Improved quasi-static, dynamic fracture toughness, and conductive functionalities by non-ionic surfactant treatment. Polym. Test. 2020, 81, 106256. [Google Scholar] [CrossRef]

- Leng, J.; Lau, A.K.-T. Multifunctional Polymer Nanocomposites; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Cao, M.; Xiong, D.B.; Yang, L.; Li, S.; Xie, Y.; Guo, Q.; Li, Z.; Adams, H.; Gu, J.; Fan, T. Ultrahigh electrical conductivity of graphene embedded in metals. Adv. Funct. Mater. 2019, 29, 1806792. [Google Scholar] [CrossRef]

- Kausar, A. Shape memory polymer/graphene nanocomposites: State-of-the-art. e-Polym. 2022, 22, 165–181. [Google Scholar] [CrossRef]

- Garg, K.K.; Pandey, S.; Kumar, A.; Rana, A.; Sahoo, N.G.; Singh, R.K. Graphene nanosheets derived from waste plastic for cost-effective thermoelectric applications. Results Mater. 2022, 13, 100260. [Google Scholar] [CrossRef]

- Evgin, T.; Turgut, A.; Hamaoui, G.; Spitalsky, Z.; Horny, N.; Micusik, M.; Chirtoc, M.; Sarikanat, M.; Omastova, M. Size effects of graphene nanoplatelets on the properties of high-density polyethylene nanocomposites: Morphological, thermal, electrical, and mechanical characterization. Beilstein J. Nanotechnol. 2020, 11, 167–179. [Google Scholar] [CrossRef]

- Sing, S.L.; Yeong, W.Y. Emerging Materials for Additive Manufacturing. Materials 2022, 16, 127. [Google Scholar] [CrossRef]

- Ahmadi, Z. Epoxy in nanotechnology: A short review. Prog. Org. Coat. 2019, 132, 445–448. [Google Scholar] [CrossRef]

- Ahmad, H.; Laini, V.V.; Qian, T.Z.; Jelani, R.M.; Rosli, F.A.; Kamaruzaman, S. Efficient removal of lead from aqueous using hybrid graphite nanoflakes/mesoporous silica nanoparticles, amine functionalized mesoporous silica and graphite nanoflakes as adsorbents. Malays. J. Anal. Sci. 2020, 24, 236–246. [Google Scholar]

- Nie, Q.; Wei, X.; Qin, X.; Huang, Y.; Chen, G.; Yang, L.; Wang, B.; Tang, W. Microstructure and properties of graphite nanoflakes/Cu matrix composites fabricated by pressureless sintering and subsequent thermo-mechanical treatment. Diam. Relat. Mater. 2020, 108, 107948. [Google Scholar] [CrossRef]

- Dimic-Misic, K.; Buffiere, J.; Imani, M.; Nieminen, K.; Sixta, H.; Gane, P. Improved stabilisation of graphite nanoflake dispersions using hydrothermally-produced nanocellulose. Colloids Surf. A Physicochem. Eng. Asp. 2021, 610, 125668. [Google Scholar] [CrossRef]

- Eayal Awwad, K.; Yousif, B.; Fallahnezhad, K.; Saleh, K.; Zeng, X. Influence of Graphene Nanoplatelets on Mechanical Properties and Adhesive Wear Performance of Epoxy-Based Composites. Friction 2020, 9, 856–875. [Google Scholar] [CrossRef]

- Vincent, V.A.; Kailasanathan, C.; Shanmuganathan, V.; Kumar, J.S.P.; Prakash, V.A. Strength characterization of caryota urens fibre and aluminium 2024-T3 foil multi-stacking sequenced SiC-toughened epoxy structural composite. Biomass Convers. Biorefin. 2020, 12, 4009–4019. [Google Scholar] [CrossRef]

- Jayabalakrishnan, D.; Saravanan, K.; Ravi, S.; Prabhu, P.; Maridurai, T.; Prakash, V.A. Fabrication and characterization of acrylonitrile butadiene rubber and stitched E-glass fibre tailored Nano-silica epoxy resin composite. Silicon 2020, 13, 2509–2517. [Google Scholar] [CrossRef]

- Qiu, J.; Wang, S. Enhancing polymer performance through graphene sheets. J. Appl. Polym. Sci. 2011, 119, 3670–3674. [Google Scholar] [CrossRef]

- Kausar, A. Nanodiamond Reinforced Polymer Nanocomposite: Prospective Corrosion Protection Materials. In Phenomena and Theories in Corrosion Science, Methods of Prevention; Andras, G., Ed.; NOVA Science Publishers Inc.: Hauppauge, NY, USA, 2019; p. 181. [Google Scholar]

- Xue, G.; Zhang, B.; Sun, M.; Zhang, X.; Li, J.; Wang, L.; Song, C. Morphology, thermal and mechanical properties of epoxy adhesives containing well-dispersed graphene oxide. Int. J. Adhes. Adhes. 2019, 88, 11–18. [Google Scholar] [CrossRef]

- Gopanna, A.; Rajan, K.P.; Thomas, S.P.; Chavali, M. Polyethylene and polypropylene matrix composites for biomedical applications. In Materials for Biomedical Engineering; Elsevier: Amsterdam, The Netherlands, 2019; pp. 175–216. [Google Scholar]

- Suner, S.; Joffe, R.; Tipper, J.; Emami, N. Ultra high molecular weight polyethylene/graphene oxide nanocomposites: Thermal, mechanical and wettability characterisation. Compos. Part B Eng. 2015, 78, 185–191. [Google Scholar] [CrossRef]

- Bhawal, P.; Ganguly, S.; Das, T.K.; Mondal, S.; Choudhury, S.; Das, N. Superior electromagnetic interference shielding effectiveness and electro-mechanical properties of EMA-IRGO nanocomposites through the in-situ reduction of GO from melt blended EMA-GO composites. Compos. Part B Eng. 2018, 134, 46–60. [Google Scholar] [CrossRef]

- Song, P.; Cao, Z.; Cai, Y.; Zhao, L.; Fang, Z.; Fu, S. Fabrication of exfoliated graphene-based polypropylene nanocomposites with enhanced mechanical and thermal properties. Polymer 2011, 52, 4001–4010. [Google Scholar] [CrossRef]

- Feicht, P.; Biskupek, J.; Gorelik, T.E.; Renner, J.; Halbig, C.E.; Maranska, M.; Puchtler, F.; Kaiser, U.; Eigler, S. Brodie’s or Hummers’ method: Oxidation conditions determine the structure of graphene oxide. Chem. Eur. J. 2019, 25, 8955–8959. [Google Scholar] [CrossRef] [PubMed]

- Saha, M.; Tambe, P.; Pal, S. Thermodynamic approach to enhance the dispersion of graphene in epoxy matrix and its effect on mechanical and thermal properties of epoxy nanocomposites. Compos. Interfaces 2016, 23, 255–272. [Google Scholar] [CrossRef]

- Yang, J.; Tang, L.-S.; Bao, R.-Y.; Bai, L.; Liu, Z.-Y.; Yang, W.; Xie, B.-H.; Yang, M.-B. Largely enhanced thermal conductivity of poly (ethylene glycol)/boron nitride composite phase change materials for solar-thermal-electric energy conversion and storage with very low content of graphene nanoplatelets. Chem. Eng. J. 2017, 315, 481–490. [Google Scholar] [CrossRef]

- Huang, G.; Chen, S.; Song, P.; Lu, P.; Wu, C.; Liang, H. Combination effects of graphene and layered double hydroxides on intumescent flame-retardant poly (methyl methacrylate) nanocomposites. Appl. Clay Sci. 2014, 88, 78–85. [Google Scholar] [CrossRef]

- Singho, N.D.; Lah, N.A.C.; Johan, M.R.; Ahmad, R. FTIR studies on silver-poly (methylmethacrylate) nanocomposites via in-situ polymerization technique. Int. J. Electrochem. Sci. 2012, 7, 5596–5603. [Google Scholar]

- Xu, Y.; Hong, W.; Bai, H.; Li, C.; Shi, G. Strong and ductile poly (vinyl alcohol)/graphene oxide composite films with a layered structure. Carbon 2009, 47, 3538–3543. [Google Scholar] [CrossRef]

- Chen, B.; Berretta, S.; Evans, K.; Smith, K.; Ghita, O. A primary study into graphene/polyether ether ketone (PEEK) nanocomposite for laser sintering. Appl. Surf. Sci. 2018, 428, 1018–1028. [Google Scholar] [CrossRef] [Green Version]

- Arif, M.; Alhashmi, H.; Varadarajan, K.; Koo, J.H.; Hart, A.; Kumar, S. Multifunctional performance of carbon nanotubes and graphene nanoplatelets reinforced PEEK composites enabled via FFF additive manufacturing. Compos. Part B Eng. 2020, 184, 107625. [Google Scholar] [CrossRef]

- Xu, F.; Wu, X.; Wang, H.; Liu, H.; Ye, Z. Experimental research on moulding of graphene/PEKK composite powder by spark plasma sintering technology. Appl. Phys. A 2022, 128, 122. [Google Scholar] [CrossRef]

- Cortes, L.Q.; Racagel, S.; Lonjon, A.; Dantras, E.; Lacabanne, C. Electrically conductive carbon fiber/PEKK/silver nanowires multifunctional composites. Compos. Sci. Technol. 2016, 137, 159–166. [Google Scholar] [CrossRef] [Green Version]

- Shan, C.; Wang, L.; Han, D.; Li, F.; Zhang, Q.; Zhang, X.; Niu, L. Polyethyleneimine-functionalized graphene and its layer-by-layer assembly with Prussian blue. Thin Solid Film. 2013, 534, 572–576. [Google Scholar] [CrossRef]

- Sali, S.; Mackey, H.R.; Abdala, A.A. Effect of graphene oxide synthesis method on properties and performance of polysulfone-graphene oxide mixed matrix membranes. Nanomaterials 2019, 9, 769. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Puértolas, J.; Castro, M.; Morris, J.; Ríos, R.; Ansón-Casaos, A. Tribological and mechanical properties of graphene nanoplatelet/PEEK composites. Carbon 2019, 141, 107–122. [Google Scholar] [CrossRef] [Green Version]

- Alvaredo, Á.; Martín, M.I.; Castell, P.; Guzmán de Villoria, R.; Fernández-Blázquez, J.P. Non-isothermal crystallization behavior of PEEK/graphene nanoplatelets composites from melt and glass states. Polymers 2019, 11, 124. [Google Scholar] [CrossRef] [Green Version]

- Wang, Q.; Jia, D.; Pei, X.; Wu, X.; Xu, F.; Wang, H.; Cao, M.; Chen, H. Investigation of electromagnetic pulse compaction on conducting graphene/PEKK composite powder. Materials 2021, 14, 636. [Google Scholar] [CrossRef]

- Sun, Z.; Li, Y.-Q.; Huang, P.; Cao, H.-J.; Zeng, W.; Li, J.; Li, F.; Sun, B.-G.; Shi, H.-Q.; Zhou, Z.-l. Temperature-dependent mechanical properties of polyetherimide composites reinforced by graphene oxide-coated short carbon fibers. Compos. Struct. 2021, 270, 114075. [Google Scholar] [CrossRef]

- Ionita, M.; Pandele, A.M.; Crica, L.; Pilan, L. Improving the thermal and mechanical properties of polysulfone by incorporation of graphene oxide. Compos. Part B Eng. 2014, 59, 133–139. [Google Scholar] [CrossRef]

- Peña-Bahamonde, J.; San-Miguel, V.; Baselga, J.; Fernández-Blázquez, J.P.; Gedler, G.; Ozisik, R.; Cabanelas, J.C. Effect of polysulfone brush functionalization on thermo-mechanical properties of melt extruded graphene/polysulfone nanocomposites. Carbon 2019, 151, 84–93. [Google Scholar] [CrossRef]

- Gokulkumar, S.; Thyla, P.; Sathish, S.; Karthi, N.; Prabhu, L.; Vignesh, P.; Vishnu, R.; Srikanth, K.; Prasath, S.V. Acoustical and mechanical optimization of Camellia Sinensis/Ananas Comosus/GFRP/Epoxy composites by TOPSIS & Weighted Aggregates Sum Product Assessment method. Mater. Today Proc. 2021, 45, 7980–7985. [Google Scholar]

- Vinod, A.; Gowda, Y.; Vijay, R.; Gupta, M.K.; Jamil, M.; Kushvaha, V.; Siengchin, S. Novel Muntingia Calabura bark fiber reinforced green-epoxy composite: A sustainable and green material for cleaner production. J. Clean. Prod. 2021, 294, 126337. [Google Scholar] [CrossRef]

- Sadowski, Ł.; Hoła, J.; Czarnecki, L.; Mathia, T.G. New paradigm in the metrology of concrete surface morphology: Methods, parameters and applications. Measurement 2021, 169, 108497. [Google Scholar] [CrossRef]

- Alwash, D.; Kalfat, R.; Du, H.; Al-Mahaidi, R. Development of a new nano modified cement based adhesive for FRP strengthened RC members. Constr. Build. Mater. 2021, 277, 122318. [Google Scholar] [CrossRef]

- Kostagiannakopoulou, C.; Loutas, T.; Sotiriadis, G.; Kostopoulos, V. Effects of graphene geometrical characteristics to the interlaminar fracture toughness of CFRP laminates. Eng. Fract. Mech. 2021, 245, 107584. [Google Scholar] [CrossRef]

- Ghazanlou, S.I.; Eghbali, B.; Petrov, R. Microstructural Evolution and Strengthening Mechanisms in Al7075/Graphene Nano-plates/Carbon Nano-tubes Composite Processed through Accumulative Roll Bonding. Mater. Sci. Eng. A 2021, 807, 140877. [Google Scholar] [CrossRef]

- Shiu, S.-C.; Tsai, J.-L. Characterizing thermal and mechanical properties of graphene/epoxy nanocomposites. Compos. Part B Eng. 2014, 56, 691–697. [Google Scholar] [CrossRef]

- Kumar, A.; Sharma, K.; Dixit, A.R. A review of the mechanical and thermal properties of graphene and its hybrid polymer nanocomposites for structural applications. J. Mater. Sci. 2019, 54, 5992–6026. [Google Scholar] [CrossRef]

- Shadlou, S.; Ahmadi-Moghadam, B.; Taheri, F. The effect of strain-rate on the tensile and compressive behavior of graphene reinforced epoxy/nanocomposites. Mater. Des. 2014, 59, 439–447. [Google Scholar] [CrossRef]

- Bustero, I.; Gaztelumendi, I.; Obieta, I.; Mendizabal, M.A.; Zurutuza, A.; Ortega, A.; Alonso, B. Free-standing graphene films embedded in epoxy resin with enhanced thermal properties. Adv. Compos. Hybrid Mater. 2020, 3, 31–40. [Google Scholar] [CrossRef] [Green Version]

- Yogeshwaran, S.; Natrayan, L.; Rajaraman, S.; Parthasarathi, S.; Nestro, S. Experimental investigation on mechanical properties of epoxy/graphene/fish scale and fermented spinach hybrid bio composite by hand lay-up technique. Mater. Today Proc. 2021, 37, 1578–1583. [Google Scholar] [CrossRef]

- Jaafar, C.A.; Zainol, I.; Rizal, M.M.; Sultan, U. Preparation and characterisation of epoxy/silica/kenaf composite using hand lay-up method. In Proceedings of the 27th Scientific Conference of the Microscopy Society Malaysia (27th SCMSM 2018), Melaka, Malaysia, 3–4 December 2018; pp. 2–6. [Google Scholar]

- Peng, J.; Huang, C.; Cao, C.; Saiz, E.; Du, Y.; Dou, S.; Tomsia, A.P.; Wagner, H.D.; Jiang, L.; Cheng, Q. Inverse nacre-like epoxy-graphene layered nanocomposites with integration of high toughness and self-monitoring. Matter 2020, 2, 220–232. [Google Scholar] [CrossRef] [Green Version]

- García-Martínez, V.; Gude, M.R.; Calvo, S.; Ureña, A. Enhancing an Aerospace Grade Benzoxazine Resin by Means of Graphene Nanoplatelets Addition. Polymers 2021, 13, 2544. [Google Scholar] [CrossRef] [PubMed]

- He, X.; Feng, L.; Zhang, Z.; Hou, X.; Ye, X.; Song, Q.; Yang, Y.; Suo, G.; Zhang, L.; Fu, Q.-G. High-Performance Multifunctional Carbon–Silicon Carbide Composites with Strengthened Reduced Graphene Oxide. ACS Nano 2021, 15, 2880–2892. [Google Scholar] [CrossRef] [PubMed]

- Guan, F.; Ren, H.; Yu, L.; Cui, Q.; Zhao, W.; Liu, J. Nitrated Graphene Oxide Derived from Graphite Oxide: A Promising Energetic Two-Dimensional Material. Nanomaterials 2021, 11, 58. [Google Scholar] [CrossRef] [PubMed]

- Yuan, W.; Hu, Q.; Zhang, J.; Huang, F.; Liu, J. Hydrophobic Modification of Graphene Oxide and Its Effect on the Corrosion Resistance of Silicone-Modified Epoxy Resin. Metals 2021, 11, 89. [Google Scholar] [CrossRef]

- Yousefi, N.; Sun, X.; Lin, X.; Shen, X.; Jia, J.; Zhang, B.; Tang, B.; Chan, M.; Kim, J.K. Highly aligned graphene/polymer nanocomposites with excellent dielectric properties for high-performance electromagnetic interference shielding. Adv. Mater. 2014, 26, 5480–5487. [Google Scholar] [CrossRef]

- Yousefi, N.; Lin, X.; Zheng, Q.; Shen, X.; Pothnis, J.R.; Jia, J.; Zussman, E.; Kim, J.-K. Simultaneous in situ reduction, self-alignment and covalent bonding in graphene oxide/epoxy composites. Carbon 2013, 59, 406–417. [Google Scholar] [CrossRef]

- Liu, W.; Wei, J.; Chen, Y.; Huo, P.; Wei, Y. Electrospinning of poly (L-lactide) nanofibers encapsulated with water-soluble fullerenes for bioimaging application. ACS Appl. Mater. Interfaces 2013, 5, 680–685. [Google Scholar] [CrossRef]

- Fioravante, A.; de Oliveira, P.C.; Siqueira, E.J.; Vitorino, L.S.; Brito, P.P.; Oréfice, R.L.; Isaac, A. From brittle-to-ductile fracture of polymer composites: The incorporation of energy dissipation mechanisms by carbon nanotubes-based multilayered interface. J. Appl. Polym. Sci. 2020, 137, 49348. [Google Scholar] [CrossRef] [Green Version]

- Sethy, D.; Makireddi, S.; Varghese, F.; Balasubramaniam, K. Piezoresistive behaviour of graphene nanoplatelet (GNP)/PMMA spray coated sensors on a polymer matrix composite beam. Express Polym. Lett. 2019, 13, 1018–1025. [Google Scholar] [CrossRef]

- Ahmadi, Z. Nanostructured epoxy adhesives: A review. Prog. Org. Coat. 2019, 135, 449–453. [Google Scholar] [CrossRef]

- Abdullah, S.I.; Ansari, M. Mechanical properties of graphene oxide (GO)/epoxy composites. Hbrc J. 2015, 11, 151–156. [Google Scholar] [CrossRef]

- Wu, H.; Cheng, L.; Liu, C.; Lan, X.; Zhao, H. Engineering the interface in graphene oxide/epoxy composites using bio-based epoxy-graphene oxide nanomaterial to achieve superior anticorrosion performance. J. Colloid Interface Sci. 2020, 587, 755–766. [Google Scholar] [CrossRef]

- Salom, C.; Prolongo, M.; Toribio, A.; Martínez-Martínez, A.; de Cárcer, I.A.; Prolongo, S. Mechanical properties and adhesive behavior of epoxy-graphene nanocomposites. Int. J. Adhes. Adhes. 2018, 84, 119–125. [Google Scholar] [CrossRef]

- Xiao, W.; Li, B.; Yan, J.; Wang, L.; Huang, X.; Gao, J. Three dimensional graphene composites: Preparation, morphology and their multi-functional applications. Compos. Part A Appl. Sci. Manuf. 2022, 165, 107335. [Google Scholar] [CrossRef]

- Theravalappil, R.; Rahaman, M. Patents on graphene-based polymer composites and their applications. In Polymer Nanocomposites Containing Graphene; Elsevier: Amsterdam, The Netherlands, 2022; pp. 615–638. [Google Scholar]

- Liu, J.; Hui, D.; Lau, D. Two-dimensional nanomaterial-based polymer composites: Fundamentals and applications. Nanotechnol. Rev. 2022, 11, 770–792. [Google Scholar] [CrossRef]

- Abreu, I.; Ferreira, D.P.; Fangueiro, R. Versatile graphene-based fibrous systems for military applications. NATO’s Sci. Technol. Organ. 2019, 1, 8–14. [Google Scholar]

- Hawal, T.T.; Patil, M.S.; Swamy, S.; Kulkarni, R.M. A Review on Synthesis, Functionalization, Processing and Applications of Graphene Based High Performance Polymer Nanocomposites. Curr. Nanosci. 2022, 18, 167–181. [Google Scholar] [CrossRef]

- Lynch, J. High Performance, Lightweight Graphene Enhanced Polymer Matrix Composites for Defense Applications. AVT 2020, 2, 18–28. [Google Scholar]

- Zhang, J.; Chevali, V.S.; Wang, H.; Wang, C.-H. Current status of carbon fibre and carbon fibre composites recycling. Compos. Part B Eng. 2020, 193, 108053. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-reinforced polymer composites: Manufacturing, properties, and applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef] [Green Version]

- Jayan, J.S.; Appukuttan, S.; Wilson, R.; Joseph, K.; George, G.; Oksman, K. An introduction to fiber reinforced composite materials. In Fiber Reinforced Composites; Elsevier: Amsterdam, The Netherlands, 2021; pp. 1–24. [Google Scholar]

- González, C.; LLorca, J. Mechanical behavior of unidirectional fiber-reinforced polymers under transverse compression: Microscopic mechanisms and modeling. Compos. Sci. Technol. 2007, 67, 2795–2806. [Google Scholar] [CrossRef]

- Sethi, S.; Ray, B.C. Environmental effects on fibre reinforced polymeric composites: Evolving reasons and remarks on interfacial strength and stability. Adv. Colloid Interface Sci. 2015, 217, 43–67. [Google Scholar] [CrossRef] [PubMed]

- ElKhoury, L.; Berg, J.C. The tailoring of interfacial adhesion and its effects on material properties for carbon-fiber reinforced polymeric composites. J. Adhes. Sci. Technol. 2023, 1–22. [Google Scholar] [CrossRef]

- Zhao, J.; Liebscher, M.; Schneider, K.; Junger, D.; Mechtcherine, V. Effect of surface profiling on the mechanical properties and bond behaviour of mineral-impregnated, carbon-fibre (MCF) reinforcement based on geopolymer. Constr. Build. Mater. 2023, 367, 130199. [Google Scholar] [CrossRef]

- Yuan, H.; Zhang, S.; Lu, C. Surface modification of carbon fibers by a polyether sulfone emulsion sizing for increased interfacial adhesion with polyether sulfone. Appl. Surf. Sci. 2014, 317, 737–744. [Google Scholar] [CrossRef]

- Sokolowski, K.; Pszczola, I.; Blazewicz, S.; Bernasik, A.; Kornaus, K.; Fraczek-Szczypta, A. Effect of Various Methods of Pre-Treatment of carbon Fibers on the mechanical Properties of PIP-Based ceramics/Carbon Composites. Res. Sq. 2023, 1, 1–31. [Google Scholar]

- Sharma, M.; Gao, S.; Mäder, E.; Sharma, H.; Wei, L.Y.; Bijwe, J. Carbon fiber surfaces and composite interphases. Compos. Sci. Technol. 2014, 102, 35–50. [Google Scholar] [CrossRef]

- Yang, L.; Chen, Y.; Xu, Z.; Xia, H.; Natuski, T.; Xi, Y.; Ni, Q. Effect of surface modification of carbon fiber based on magnetron sputtering technology on tensile properties. Carbon 2023, 204, 377–386. [Google Scholar] [CrossRef]

- Zhou, H.; Zhang, B.; Liu, W.; Xue, Y.; Zhao, C.; Zhang, X.; Cui, X.; Tang, Z. Grafting glycidyl methacrylate onto high-modulus carbon fiber by acid activation synergized with ionization radiation. Appl. Surf. Sci. 2023, 610, 155593. [Google Scholar] [CrossRef]

- Li, N.; Cheng, S.; Wang, B.; Zong, L.; Bao, Q.; Wu, G.; Hu, F.; Wang, J.; Liu, C.; Jian, X. Chemical grafting of graphene onto carbon fiber to produce composites with improved interfacial properties via sizing process: A step closer to industrial production. Compos. Sci. Technol. 2023, 231, 109822. [Google Scholar] [CrossRef]

- Dilsiz, N. Plasma surface modification of carbon fibers: A review. J. Adhes. Sci. Technol. 2000, 14, 975–987. [Google Scholar] [CrossRef]

- Qiao, Y.; Shin, Y.; Pallaka, M.R.; Nickerson, E.K.; Merkel, D.R.; Seffens, R.J.; Ortiz, A.; Ramos, J.L.; Simmons, K.L. Plasma surface modification coupled with thermal and step-over distance effects on significant fracture improvement of adhesively-bonded metal-CFRTP dissimilar materials. Compos. Sci. Technol. 2023, 232, 109833. [Google Scholar] [CrossRef]

- Xia, S.; Guo, Q.; Yu, Y.; Li, Y.; Wang, S.; Dong, D.; Liu, Z.; Zhou, H.; Zhou, X.; Liu, Z. Surface modification of carbon fiber cloth with graphene oxide through an electrophoresis method for lithium metal anode. Carbon 2023, 203, 743–752. [Google Scholar] [CrossRef]

- Huang, L.; Dong, Y.; Tian, Y.; Zhang, X. Electrophoretic deposition of Ti3C2Tx MXene nanosheets onto high modulus carbon fiber enhances their composites interfacial properties. Mater. Today Commun. 2023, 34, 105429. [Google Scholar] [CrossRef]

- Tkalya, E.E.; Ghislandi, M.; de With, G.; Koning, C.E. The use of surfactants for dispersing carbon nanotubes and graphene to make conductive nanocomposites. Curr. Opin. Colloid Interface Sci. 2012, 17, 225–232. [Google Scholar] [CrossRef]

- Qin, J.; Wang, C.; Lu, R.; Su, S.; Yao, Z.; Zheng, L.; Gao, Q.; Wang, Y.; Wang, Q.; Wei, H. Uniform growth of carbon nanotubes on carbon fiber cloth after surface oxidation treatment to enhance interfacial strength of composites. Compos. Sci. Technol. 2020, 195, 108198. [Google Scholar] [CrossRef]

- Steiner III, S.A.; Li, R.; Wardle, B.L. Circumventing the mechanochemical origins of strength loss in the synthesis of hierarchical carbon fibers. ACS Appl. Mater. Interfaces 2013, 5, 4892–4903. [Google Scholar] [CrossRef]

- Karakasidis, A. Hierarchical Carbon-Fibre Reinforced Polymer (CFRP) Composites Utilising Directly Grown Graphene Nanoflakes; Ulster University: Belfast, UK, 2022. [Google Scholar]

- Adstedt, K.; Buxton, M.L.; Henderson, L.C.; Hayne, D.J.; Nepal, D.; Gogotsi, Y.; Tsukruk, V.V. 2D graphene oxide and MXene nanosheets at carbon fiber surfaces. Carbon 2023, 203, 161–171. [Google Scholar] [CrossRef]

- Cui, S.; Cui, C.; Xie, J.; Liu, S.; Shi, J. Carbon fibers coated with graphene reinforced TiAl alloy composite with high strength and toughness. Sci. Rep. 2018, 8, 2364. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Fan, X.; Yan, C.; Li, H.; Zhu, Y.; Li, X.; Yu, L. Interfacial microstructure and properties of carbon fiber composites modified with graphene oxide. ACS Appl. Mater. Interfaces 2012, 4, 1543–1552. [Google Scholar] [CrossRef] [PubMed]

- Karakassides, A.; Ganguly, A.; Tsirka, K.; Paipetis, A.S.; Papakonstantinou, P. Radially grown graphene nanoflakes on carbon fibers as reinforcing interface for polymer composites. ACS Appl. Nano Mater. 2020, 3, 2402–2413. [Google Scholar] [CrossRef] [Green Version]

- Qiu, B.; Zhang, X.; Xia, S.; Sun, T.; Ling, Y.; Zhou, S.; Guang, H.; Chen, Y.; Xu, Z.; Liang, M. Magnetic graphene oxide/carbon fiber composites with improved interfacial properties and electromagnetic interference shielding performance. Compos. Part A Appl. Sci. Manuf. 2022, 155, 106811. [Google Scholar] [CrossRef]

- Maurya, A.; Sinha, S.; Kumar, P.; Singh, V. A review: Impact of surface treatment of nanofillers for improvement in thermo mechanical properties of the epoxy based nanocomposites. Mater. Today Proc. 2023, in press. [CrossRef]

- Raagulan, K.; Ghim, J.; Braveenth, R.; Chai, K.Y.; Kim, B.M. Improving the EMI shielding of graphene oxide (GNO)-coated glass-fiber–GNO–MA-grafted polypropylene (PP) composites and nylon 1D–2D nanocomposite foams. RSC Adv. 2022, 12, 15316–15328. [Google Scholar] [CrossRef] [PubMed]

- Ghaemi, F.; Yunus, R.; Salleh, M.; Rashid, S.; Ahmadian, A.; Lim, H. Effects of the surface modification of carbon fiber by growing different types of carbon nanomaterials on the mechanical and thermal properties of polypropylene. RSC Adv. 2015, 5, 28822–28831. [Google Scholar] [CrossRef]

- Lin, C.-L.; Li, J.-W.; Chen, Y.-F.; Chen, J.-X.; Cheng, C.-C.; Chiu, C.-W. Graphene Nanoplatelet/Multiwalled Carbon Nanotube/Polypyrrole Hybrid Fillers in Polyurethane Nanohybrids with 3D Conductive Networks for EMI Shielding. ACS Omega 2022, 7, 45697–45707. [Google Scholar] [CrossRef]

- Stefan, A.; Pelin, G.; Nae, C.C.; Pelin, C.E.; Cristea, G.C.; Botan, M.; Bocioaga, M. Suitability assessment of the component materials of advanced composite system for aircraft structural application. In Proceedings of the AIAA SCITECH 2023 Forum, National Harbor, MD, USA, 23–27 January 2023; p. 2122. [Google Scholar]

- Gaudenzi, R.; Stefani, D.; Cartamil-Bueno, S.J. Light-induced propulsion of graphene-on-grid sails in microgravity. Acta Astronaut. 2020, 174, 204–210. [Google Scholar] [CrossRef]

- Johnson, L.; Barnes, N.; Ceriotti, M.; Chen, T.Y.; Davoyan, A.; Friedman, L.; Garber, D.; Kezerashvili, R.; Kobayashi, K.; Matloff, G. Solar Sail Propulsion by 2050: An Enabling Capability for Heliophysics Missions. arXiv 2023, arXiv:2301.01297. [Google Scholar]

- Viale, A.; McInnes, C.R. Attitude control actuator scaling laws for orbiting solar reflectors. Adv. Space Res. 2023, 71, 604–623. [Google Scholar] [CrossRef]

- Ahmed, K.; Avi, S.D.; Tanvir, M.S.; Rahman, M.M.; Shufian, A.; Sagor, M.M.I.; Farrok, O. Transportation in Between the Earth and Space by Using Carbon Nanotubes as the Elevator Cable. In Proceedings of the 2019 5th International Conference on Advances in Electrical Engineering (ICAEE), Dhaka, Bangladesh, 26–28 September 2019; pp. 426–430. [Google Scholar]

- Scalia, T.; Bonventre, L.; Terranova, M.L. From Protosolar Space to Space Exploration: The Role of Graphene in Space Technology and Economy. Nanomaterials 2023, 13, 680. [Google Scholar] [CrossRef] [PubMed]

- Stutzmann, M.; Csoklich, C. The Physics of Renewable Energy; Springer Nature: Berlin/Heidelberg, Germany, 2023. [Google Scholar]

- Döscher, H.; Reiss, T. Graphene roadmap briefs (No. 1): Innovation interfaces of the Graphene Flagship. 2D Mater. 2021, 8, 022004. [Google Scholar] [CrossRef]

- Roche, S.; Åkerman, J.; Beschoten, B.; Charlier, J.-C.; Chshiev, M.; Dash, S.P.; Dlubak, B.; Fabian, J.; Fert, A.; Guimarães, M. Graphene spintronics: The European Flagship perspective. 2D Mater. 2015, 2, 030202. [Google Scholar] [CrossRef] [Green Version]

- Hong, H.; Part, F.; Nowack, B. Prospective Dynamic and Probabilistic Material Flow Analysis of Graphene-Based Materials in Europe from 2004 to 2030. Environ. Sci. Technol. 2022, 56, 13798–13809. [Google Scholar] [CrossRef]

- Alam, M.A.; Ya, H.; Sapuan, S.; Mamat, O.; Parveez, B.; Yusuf, M.; Masood, F.; Ilyas, R. Recent Advancements in Advanced Composites for Aerospace Applications: A Review. In Advanced Composites in Aerospace Engineering Applications; Springer: Cham, Switzerland, 2022; pp. 319–339. [Google Scholar]

- Wang, Z.; Shen, Y.; Tao, J.; Liu, S.; Jiang, J.; Xu, Y.; Liu, W.; Li, H. An integrated superhydrophobic anti/de-icing film heater with low energy consumption: Interpenetration behavior of components based on wet-film spraying method. Appl. Therm. Eng. 2023, 223, 120028. [Google Scholar] [CrossRef]

- Rout, D.; Nayak, R.K.; Praharaj, S. Aerospace and vehicle industry. In Handbook of Polymer Nanocomposites for Industrial Applications; Elsevier: Amsterdam, The Netherlands, 2021; pp. 399–417. [Google Scholar]

- Kurahatti, R.; Surendranathan, A.; Kori, S.; Singh, N.; Kumar, A.; Srivastava, S. Defence applications of polymer nanocomposites. Def. Sci. J. 2010, 60, 551–563. [Google Scholar] [CrossRef] [Green Version]

- Asyraf, M.; Ilyas, R.; Sapuan, S.; Harussani, M.; Hariz, H.; Aiman, J.; Baitaba, D.M.; Sanjay, M.; Ishak, M.; Norkhairunnisa, M. Advanced Composite in Aerospace Applications: Opportunities, Challenges, and Future Perspective. In Advanced Composites in Aerospace Engineering Applications; Springer: Cham, Switzerland, 2022; pp. 471–498. [Google Scholar]

- BUENDIA, L.; TORRES, I.; CASTELLANOS, A. Novel Testing Technique to Evaluate the Durability of Textile Composites at Extreme Environments. In Proceedings of the American Society for Composites—Thirty-Fifth Technical Conference, Tucson, AZ, USA, 19–21 September 2022. [Google Scholar]

- Kausar, A. Aeronautical Impact of Epoxy/Carbon Nanotube Nanocomposite. In Nanotechnology in Aerospace and Structural Mechanics; IGI Global: Hershey, PA, USA, 2019; pp. 80–102. [Google Scholar]

- Patel, V.; Mahajan, Y. Polymer nanocomposites: Emerging growth driver for the global automotive industry. In Handbook of Polymernanocomposites. Processing, Performance and Application; Springer: Berlin/Heidelberg, Germany, 2014; pp. 511–538. [Google Scholar]

- Farahani, R.D.; Dubé, M.; Therriault, D. Three-dimensional printing of multifunctional nanocomposites: Manufacturing techniques and applications. Adv. Mater. 2016, 28, 5794–5821. [Google Scholar] [CrossRef]

| Sample | YS (MPa) | TS (MPa) | YS (%) |

|---|---|---|---|

| Neat PP | 22 ± 0.8 | 24 ± 0.8 | - |

| PP + 0.1 wt.% nanofiller | 30 ± 1.1 | 33 ± 1.4 | 36 |

| PPG + 0.5 wt.% nanofiller | 36 ± 1.2 | 36 ± 1.5 | 50 |

| PP + 1.0 wt.% nanofiller | 38 ± 1.7 | 37 ± 1.6 | 75 |

| Sample | Contact Angle (Degree) |

|---|---|

| Unfilled epoxy resin | 60.4 ± 1 |

| Epoxy resin/graphene | 75.3 ± 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kausar, A.; Ahmad, I.; Eisa, M.H.; Maaza, M. Graphene Nanocomposites in Space Sector—Fundamentals and Advancements. C 2023, 9, 29. https://doi.org/10.3390/c9010029

Kausar A, Ahmad I, Eisa MH, Maaza M. Graphene Nanocomposites in Space Sector—Fundamentals and Advancements. C. 2023; 9(1):29. https://doi.org/10.3390/c9010029

Chicago/Turabian StyleKausar, Ayesha, Ishaq Ahmad, M. H. Eisa, and Malik Maaza. 2023. "Graphene Nanocomposites in Space Sector—Fundamentals and Advancements" C 9, no. 1: 29. https://doi.org/10.3390/c9010029

APA StyleKausar, A., Ahmad, I., Eisa, M. H., & Maaza, M. (2023). Graphene Nanocomposites in Space Sector—Fundamentals and Advancements. C, 9(1), 29. https://doi.org/10.3390/c9010029