Development of CNT-Based Nanocomposites with Ohmic Heating Capability towards Self-Healing Applications in Extrusion-Based 3D Printing Technologies

Abstract

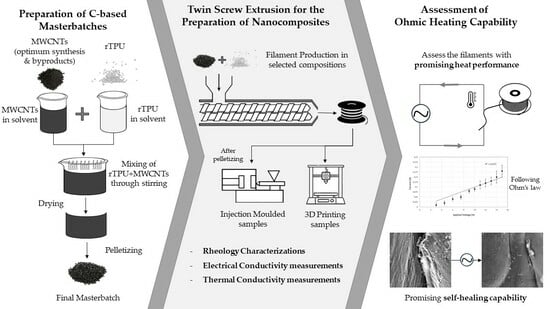

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of Nanomaterials

2.2.1. Synthesis of MWCNTs

2.2.2. Synthesis of CVD Byproduct

2.3. Preparation of Nanocomposites

2.3.1. Masterbatch Preparation

2.3.2. Twin-Screw Extrusion

2.4. Preparation of Samples for Characterization

2.5. Characterization Methods

2.5.1. Characterization of Nanomaterials

2.5.2. Rheology Tests

2.5.3. Thermal Conductivity

2.5.4. Broadband Dielectric Spectroscopy

2.5.5. Ohmic Heating Capability

3. Results

3.1. Characterization of Nanomaterials

3.1.1. SEM

3.1.2. XRD

3.1.3. Raman Spectroscopy

3.2. Rheology Analysis

3.3. Thermal Conductivity Measurements

3.4. Broadband Dielectric Spectroscopy Results

3.5. Ohmic Heating Capability Assessment

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wu, D.Y.; Meure, S.; Solomon, D. Self-healing polymeric materials: A review of recent developments. Prog. Polym. Sci. 2008, 33, 479–522. [Google Scholar] [CrossRef]

- Yongxu, D.; Li, D.; Liu, L.; Gai, G. Recent Achievements of Self-Healing Graphene/Polymer Composites. Polymers 2018, 10, 114. [Google Scholar]

- Huynh, T.P.; Sonar, P.; Haick, H. Advanced Materials for Use in Soft Self-Healing Devices. Adv. Mater. 2017, 29, 1604973. [Google Scholar] [CrossRef]

- Amaël, C.; Callum, B.; Steven, R.; Ian, B.; Véronique, M. Progress in Self-Healing Fiber-Reinforced Polymer Composites. Adv. Mater. Interfaces 2018, 5, 1800177. [Google Scholar]

- Orellana, J.; Moreno-Villoslada, I.; Ranjita; Bose, K.; Picchioni, F.; Flores, M.E.; Araya-Hermosilla, R. Self-Healing Polymer Nanocomposite Materials by Joule Effect. Polymers 2021, 13, 649. [Google Scholar] [CrossRef]

- Kim, J.W.; Sauti, G.; Siochi, E.J.; Smith, J.G.; Wincheski, R.A.; Cano, R.J.; Connell, J.W.; Wise, K.E. Toward high performance thermoset/carbon nanotube sheet nanocomposites via resistive heating assisted infiltration and cure. ACS Appl. Mater. Interfaces 2014, 6, 18832–18843. [Google Scholar] [CrossRef]

- Konstantopoulos, G.; Maroulas, P.; Dragatogiannis, D.A.; Koutsoumpis, S.; Kyritsis, A.; Charitidis, C.A. The effect of interfacial resistance and crystallinity on heat transfer mechanism in carbon nanotube reinforced polyethylene. Mater. Des. 2021, 199, 109420. [Google Scholar] [CrossRef]

- Thakur, V.K.; Kessler, M.R. Self-healing polymer nanocomposite materials: A review. Polymer 2015, 69, 369–383. [Google Scholar] [CrossRef]

- Thangavel, G.; Tan, M.W.M.; Lee, P.S. Advances in self-healing supramolecular soft materials and nanocomposites. Nano Converg. 2019, 6, 29. [Google Scholar] [CrossRef] [PubMed]

- Idumah, C.I. Recent advancements in self-healing polymers, polymer blends, and nanocomposites. Polym. Polym. Compos. 2020, 29, 246–258. [Google Scholar] [CrossRef]

- Konstantopoulos, G.; Fotou, E.; Ntziouni, A.; Kordatos, K.; Charitidis, C.A. A systematic study of electrolyte effect on exfoliation efficiency and green synthesis of graphene oxide. Ceram. Int. 2021, 47, 2276–32289. [Google Scholar] [CrossRef]

- Stanciu, N.-V.; Stan, F.; Sandu, I.-L.; Fetecau, C.; Turcanu, A.-M. Thermal, Rheological, Mechanical, and Electrical Properties of Polypropylene/Multi-Walled Carbon Nanotube Nanocomposites. Polymers 2021, 13, 187. [Google Scholar] [CrossRef]

- Gao, L.; Zhou, X.; Ding, Y. Effective thermal and electrical conductivity of carbon nanotube composites. Chem. Phys. Lett. 2007, 434, 297–300. [Google Scholar] [CrossRef]

- Soni, S.K.; Thomas, B.; Kar, V.R. Comprehensive Review on CNTs and CNT-Reinforced Composites: Syntheses, Characteristics and Applications. Mater. Today Commun. 2020, 25, 101546. [Google Scholar] [CrossRef]

- Wang, X.-D.; Vinodgopal, K.; Dai, G.-P. Synthesis of Carbon Nanotubes by Catalytic Chemical Vapor Deposition; IntechOpen: London, UK, 2019. [Google Scholar]

- Kumar, M.; Ando, Y. Chemical vapor deposition of carbon nanotubes: A review on growth mechanism and mass production. J. Nanosci. Nanotechnol. 2010, 10, 3739–3758. [Google Scholar] [CrossRef]

- Chen, D.R.; Chitranshi, M.; Schulz, M.; Shanov, V. A Review of Three Major Factors Controlling Carbon Nanotubes Synthesis from the Floating Catalyst Chemical Vapor Deposition. Nano Life 2019, 9, 1930002. [Google Scholar] [CrossRef]

- Kinoshita, T.; Karita, M.; Nakano, T.; Inoue, Y. Two step floating catalyst chemical vapor deposition including in situ fabrication of catalyst nanoparticles and carbon nanotube forest growth with low impurity level. Carbon 2019, 144, 152–160. [Google Scholar] [CrossRef]

- Mohammadian, N.; Ghoreishi, S.M.; Hafeziyeh, S.; Saeidi, S.; Dionysiou, D.D. Optimization of Synthesis Conditions of Carbon Nanotubes via Ultrasonic-Assisted Floating Catalyst Deposition Using Response Surface Methodology. Nanomaterials 2018, 8, 316. [Google Scholar] [CrossRef]

- Magrez, A.; Seo, J.W.; Smajda, R.; Mionić, M.; Forró, L. Catalytic CVD Synthesis of Carbon Nanotubes: Towards High Yield and Low Temperature Growth. Materials 2010, 3, 4871–4891. [Google Scholar] [CrossRef]

- Aslam, Z.; Li, X.; Brydson, R.; Rand, B.; Falke, U.; Bleloch, A. Supported Catalytic Growth of SWCNTs using the CVD Method. J. Phys. Conf. Ser. 2006, 26, 139–142. [Google Scholar] [CrossRef]

- Yan, D.; Zhang, H.-B.; Jia, Y.; Hu, J.; Qi, X.-Y.; Zhang, Z.; Yu, Z.-Z. Improved electrical conductivity of polyamide 12/graphene nanocomposites with maleated polyethylene-octene rubber prepared by melt compounding. ACS Appl. Mater. Interfaces 2012, 4, 4740–4745. [Google Scholar] [CrossRef]

- Valino, A.D.; Dizon, J.R.C.; Espera, A.H.; Chen, Q.; Messman, J.; Advincula, R.C. Advances in 3D printing of thermoplastic polymer composites and nanocomposites. Prog. Polym. Sci. 2019, 98, 101162. [Google Scholar] [CrossRef]

- Tolinski, M. Processing Aids for Extrusion, in Additives for Polyolefins; William Andrew Publishing: Norwich, NY, USA, 2015; pp. 135–144. [Google Scholar]

- Zahid, M.; Nawab, Y.; Gulzar, N.; Rehan, Z.A.; Shakir, M.F.; Afzal, A.; Rashid, I.A.; Tariq, A. Fabrication of reduced graphene oxide (RGO) and nanocomposite with thermoplastic polyurethane (TPU) for EMI shielding application. J. Mater. Sci. Mater. Electron. 2019, 31, 967–974. [Google Scholar] [CrossRef]

- Badamshina, E.; Estrin, Y.; Gafurova, M. Nanocomposites based on polyurethanes and carbon nanoparticles: Preparation, properties and application. J. Mater. Chem. A 2013, 1, 6509. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, D. A Novel Self-Healing Polyurethane Based on Disulfide Bonds. Macromol. Chem. Phys. 2016, 217, 1191–1196. [Google Scholar] [CrossRef]

- Shen, P.; Jiang, Z.; Viktorova, J.; Pollard, B.; Kumar, A.; Stachurski, Z.; Connal, L.A. Conductive and Self-Healing Carbon Nanotube–Polymer Composites for Mechanically Strong Smart Materials. ACS Appl. Nano Mater. 2023, 6, 986–994. [Google Scholar] [CrossRef]

- Pati, S.; Singh, B.P.; Dhakate, S.R. Self-Healing Polymer Composites Based on Graphene and Carbon Nanotubes. In Smart Polymer Nanocomposites; Springer: Cham, Switzerland, 2017; pp. 119–152. [Google Scholar]

- Gupta, S.; Ray, B.C. Self-Healing and Shape Memory Effects of Carbon Nanotube–Based Polymer Composites. In Handbook of Carbon Nanotubes; Abraham, J., Ed.; Springer: Cham, Switzerland, 2022; pp. 1113–1146. [Google Scholar]

- Wang, T.; Yu, W.-C.; Zhou, C.-G.; Sun, W.-J.; Zhang, Y.-P.; Jia, L.-C.; Gao, J.-F.; Dai, K.; Yan, D.-X.; Li, Z.-M. Self-healing and flexible carbon nanotube/polyurethane composite for efficient electromagnetic interference shielding. Compos. Part B Eng. 2020, 193, 108015. [Google Scholar] [CrossRef]

- Kausar, A. Self-healing polymer/carbon nanotube nanocomposite: A review. J. Plast. Film Sheeting 2020, 37, 160–181. [Google Scholar] [CrossRef]

- Gu, S.; Yan, B.; Liu, L.; Ren, J. Carbon nanotube–polyurethane shape memory nanocomposites with low trigger temperature. Eur. Polym. J. 2013, 49, 3867–3877. [Google Scholar] [CrossRef]

- Luan, Y.; Gao, F.; Li, Y.; Yang, J.; Hu, Y.; Guo, Z.; Wang, Z.; Zhou, A. Healing mechanisms induced by synergy of Graphene-CNTs and microwave focusing effect for the thermoplastic polyurethane composites. Compos. Part A Appl. Sci. Manuf. 2018, 106, 34–41. [Google Scholar] [CrossRef]

- Acquah, S.F.A.; Leonhardt, B.E.; Nowotarski, M.S.; Magi, J.M.; Chambliss, K.A.; Venzel, T.E.S.; Delekar, S.D.; Al-Hariri, L.A. Carbon Nanotubes and Graphene as Additives in 3D Printing. In Carbon Nanotubes—Current Progress of Their Polymer Composites; InTechOpen: London, UK, 2016. [Google Scholar]

- Hashemi Sanatgar, R.; Campagne, C.; Nierstrasz, V. Investigation of the adhesion properties of direct 3D printing of polymers and nanocomposites on textiles: Effect of FDM printing process parameters. Appl. Surf. Sci. 2017, 403, 551–563. [Google Scholar] [CrossRef]

- Das, A.; Gilmer, E.L.; Biria, S.; Bortner, M.J. Importance of Polymer Rheology on Material Extrusion Additive Manufacturing: Correlating Process Physics to Print Properties. ACS Appl. Polym. Mater. 2021, 3, 1218–1249. [Google Scholar] [CrossRef]

- Mackay, M.E. The importance of rheological behavior in the additive manufacturing technique material extrusion. J. Rheol. 2018, 62, 1549–1561. [Google Scholar] [CrossRef]

- Elbadawi, M. Polymeric Additive Manufacturing: The Necessity and Utility of Rheology. In Polymer Rheology; Jose Luis, R.-A., Beatriz Adriana, S.C., Eds.; InTechOpen: London, UK, 2018. [Google Scholar]

- Fico, D.; Rizzo, D.; Casciaro, R.; Corcione, C.E. A Review of Polymer-Based Materials for Fused Filament Fabrication (FFF): Focus on Sustainability and Recycled Materials. Polymers 2022, 14, 465. [Google Scholar] [CrossRef]

- Shinde, V.V.; Taylor, G.; Celestine, A.-D.N.; Beckingham, B.S. Fused Filament Fabrication 3D Printing of Self-Healing High-Impact Polystyrene Thermoplastic Polymer Composites Utilizing Eco-friendly Solvent-Filled Microcapsules. ACS Appl. Polym. Mater. 2022, 4, 3324–3332. [Google Scholar] [CrossRef]

- Kim, K.; Park, J.; Suh, J.-H.; Kim, M.; Jeong, Y.; Park, I. 3D printing of multiaxial force sensors using carbon nanotube (CNT)/thermoplastic polyurethane (TPU) filaments. Sens. Actuators A Phys. 2017, 263, 493–500. [Google Scholar] [CrossRef]

- Hohimer, C.J.; Petrossian, G.; Ameli, A.; Mo, C.; Pötschke, P. 3D printed conductive thermoplastic polyurethane/carbon nanotube composites for capacitive and piezoresistive sensing in soft pneumatic actuators. Addit. Manuf. 2020, 34, 101281. [Google Scholar] [CrossRef]

- Yang, L.; Liu, X.; Xiao, Y.; Zhang, Y.; Zhang, G.; Wang, Y. 3D Printing of Carbon Nanotube (CNT)/Thermoplastic Polyurethane (TPU) Functional Composites and Preparation of Highly Sensitive, Wide-range Detectable, and Flexible Capacitive Sensor Dielectric Layers via Fused Deposition Modeling (FDM). Adv. Mater. Technol. 2023, 8, 2201638. [Google Scholar] [CrossRef]

- Niu, J.-H.; Yang, T.-B.; Li, X.-Y.; Xu, L.; Lin, H.; Zhong, G.-J. 3D-Printed Co-continuous Segregated CNT/TPU Composites with Superb Electromagnetic Interference Shielding and Excellent Mechanical Properties. Ind. Eng. Chem. Res. 2023, 62, 10498–10506. [Google Scholar] [CrossRef]

- Wu, Q.; Zou, S.; Gosselin, F.P.; Therriault, D.; Heuzey, M.-C. 3D printing of a self-healing nanocomposite for stretchable sensors. J. Mater. Chem. C 2018, 6, 12180–12186. [Google Scholar] [CrossRef]

- Trompeta, A.-F.; Koklioti, M.A.; Perivoliotis, D.K.; Lynch, I.; Charitidis, C.A. Towards a holistic environmental impact assessment of carbon nanotube growth through chemical vapour deposition. J. Clean. Prod. 2016, 129, 384–394. [Google Scholar] [CrossRef]

- Trompeta, A.-F.A.; Preiss, I.; Ben-Ami, F.; Benayahu, Y.; Charitidis, C.A. Toxicity testing of MWCNTs to aquatic organisms. RSC Adv. 2019, 9, 36707–36716. [Google Scholar] [CrossRef]

- Lima, A.M.F.; de Castro, V.G.; Borges, R.S.; Silva, G.G. Electrical conductivity and thermal properties of functionalized carbon nanotubes/polyurethane composites. Polímeros 2012, 22, 117–124. [Google Scholar] [CrossRef]

- Sui, G.; Liu, D.; Liu, Y.; Ji, W.; Zhang, Q.; Fu, Q. The dispersion of CNT in TPU matrix with different preparation methods: Solution mixing vs melt mixing. Polymer 2019, 182, 121838. [Google Scholar] [CrossRef]

- Verma, M.; Chauhan, S.S.; Dhawan, S.K.; Choudhary, V. Graphene nanoplatelets/carbon nanotubes/polyurethane composites as efficient shield against electromagnetic polluting radiations. Compos. Part B Eng. 2017, 120, 118–127. [Google Scholar] [CrossRef]

- Soleimani, H.; Yahya, N.; Baig, M.; Khodapanah, L.; Sabet, M.; Burda, M.; Oechsner, A.; Awang, M. Synthesis of Carbon Nanotubes for Oil-water Interfacial Tension Reduction. Oil Gas Res. 2015, 1, 1000104. [Google Scholar]

- Dresselhaus, M.S.; Dresselhaus, G.; Saito, R.; Jorio, A. Raman spectroscopy of carbon nanotubes. Phys. Rep. 2005, 409, 47–99. [Google Scholar] [CrossRef]

- Bettinger, H.F. Carbon Nanotubes—Basic Concepts and Physical Properties. By S. Reich, C. Thomsen, J. Maultzsch. ChemPhysChem 2004, 5, 1914–1915. [Google Scholar] [CrossRef]

- Liu, H.; Huang, W.; Yang, X.; Dai, K.; Zheng, G.; Liu, C.; Shen, C.; Yan, X.; Guo, J.; Guo, Z. Organic vapor sensing behaviors of conductive thermoplastic polyurethane–graphene nanocomposites. J. Mater. Chem. C 2016, 4, 4459–4469. [Google Scholar] [CrossRef]

- Bertolino, M.; Battegazzore, D.; Arrigo, R.; Frache, A. Designing 3D printable polypropylene: Material and process optimisation through rheology. Addit. Manuf. 2021, 40, 101944. [Google Scholar] [CrossRef]

- Goh, G.D.; Yap, Y.L.; Tan, H.K.J.; Sing, S.L.; Goh, G.L. Process–Structure–Properties in Polymer Additive Manufacturing via Material Extrusion: A Review. Crit. Rev. Solid State Mater. Sci. 2019, 45, 113–133. [Google Scholar] [CrossRef]

- Dries, V.; Van Puyvelde, P. Semi-crystalline feedstock for filament-based 3D printing of polymers. Prog. Polym. Sci. 2021, 118, 101411. [Google Scholar]

- Arrigo, R.; Frache, A. FDM Printability of PLA Based-Materials: The Key Role of the Rheological Behavior. Polymers 2022, 14, 1754. [Google Scholar] [CrossRef] [PubMed]

- Alam, M.A.; Krishnanand; Patel, A.; Purohit, R.; Taufik, M. Thermal analysis for improvement of mechanical properties in fused filament fabricated parts. Int. J. Interact. Des. Manuf. (IJIDeM) 2022, 17, 603–635. [Google Scholar] [CrossRef]

- Kim, N.P. 3D-Printed Conductive Carbon-Infused Thermoplastic Polyurethane. Polymers 2020, 12, 1224. [Google Scholar] [CrossRef]

- Tzounis, L.; Petousis, M.; Grammatikos, S.; Vidakis, N. 3D Printed Thermoelectric Polyurethane/Multiwalled Carbon Nanotube Nanocomposites: A Novel Approach towards the Fabrication of Flexible and Stretchable Organic Thermoelectrics. Materials 2020, 13, 2879. [Google Scholar] [CrossRef]

- Christ, J.F.; Aliheidari, N.; Ameli, A.; Pötschke, P. 3D printed highly elastic strain sensors of multiwalled carbon nanotube/thermoplastic polyurethane nanocomposites. Mater. Des. 2017, 131, 394–401. [Google Scholar] [CrossRef]

- Park, S.-H.; Hwang, J.; Park, G.-S.; Ha, J.-H.; Zhang, M.; Kim, D.; Yun, D.-J.; Lee, S.; Lee, S.H. Modeling the electrical resistivity of polymer composites with segregated structures. Nat. Commun. 2019, 10, 2537. [Google Scholar] [CrossRef]

| Nanocomposites | Feeder Speed (rpm) | Screw Speed (rpm) | Zone 2 (°C) | Zone 3 (°C) | Zone 4 (°C) | Zone 5 (°C) | Zone 6 (°C) | Zone 7 (°C) | Zone 8 (°C) | Die (°C) |

|---|---|---|---|---|---|---|---|---|---|---|

| rTPU, mTPU_1001 | 20–30 | 300 | 100 | 180 | 205 | 210 | 210 | 210 | 210 | 210 |

| Matrix | Additive/MB | Contents by Weight % of Nanofiller | Reference Name (X = 1, 5, 10, 15; Y = 1, 5, 10) |

|---|---|---|---|

| rTPU | MWCNTs_csCVD | 1–5–10–15% | rTPU/MWCNTs_csCVD_Xwt |

| MWCNTs_cfCVD_bp | rTPU/MWCNTs_cfCVD_bp_Xwt | ||

| MWCNTs_com | rTPU/MWCNTs_com_Xwt | ||

| mTPU_1001 | 1–5–10% * | rTPU/mTPU_1001_Ywt |

| Nanocomposites | Tmould (°C) | Tmelt (°C) | P (bar) |

|---|---|---|---|

| rTPU, mTPU_1001 | 65 | 215–225 | 10–12 |

| 3D Printing Conditions | Nanocomposites rTPU, mTPU_1001 |

|---|---|

| Temperature bed (°C) | 60 |

| Nozzle temperature (°C) | 240 |

| Printing speed (mm/s) | 30 |

| Layer thickness (mm) | 0.2 |

| Fill density (%) | 100 |

| Composition | σ′ at 0.1 Hz (S/cm) | Composition | σ′ at 0.1 Hz (S/cm) |

|---|---|---|---|

| rTPU/MWCNTs_csCVD_1wt_3D | 2 × 10−12 | rTPU_IM | 7 × 10−14 |

| rTPU/MWCNTs_csCVD_5wt_3D | 5 × 10−12 | rTPU/MWCNTs_csCVD_15wt_IM | 4 × 10−12 |

| rTPU/MWCNTs_csCVD_10wt_3D | 10−12 | rTPU/MWCNTs_csCVD_15wt_3D | 3 × 10−12 |

| rTPU/MWCNTs_csCVD_15wt_3D | 3 × 10−12 | rTPU/MWCNTs_com_15wt_3D | 10−9 |

| rTPU/mTPU_1001_1wt_3D | 6 × 10−9 | rTPU/MWCNTs_cfCVD_bp_15wt_3D | 1 × 10−12 |

| rTPU/mTPU_1001_5wt_3D | 5 × 10−11 | ||

| mTPU_1001_10wt_3D | 6 × 10−7 |

| Applied Voltage (V) | 3.00 | 9.00 | 12.00 | 15.00 |

|---|---|---|---|---|

| Image IR |  |  |  |  |

| Measured T (°C) | 28.80 ± 5.00 | 84.10 ± 6.00 | 104.00 ± 10.00 | 177.00 ± 18.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Loura, N.; Gkartzou, E.; Trompeta, A.-F.; Konstantopoulos, G.; Klonos, P.A.; Kyritsis, A.; Charitidis, C.A. Development of CNT-Based Nanocomposites with Ohmic Heating Capability towards Self-Healing Applications in Extrusion-Based 3D Printing Technologies. C 2023, 9, 111. https://doi.org/10.3390/c9040111

Loura N, Gkartzou E, Trompeta A-F, Konstantopoulos G, Klonos PA, Kyritsis A, Charitidis CA. Development of CNT-Based Nanocomposites with Ohmic Heating Capability towards Self-Healing Applications in Extrusion-Based 3D Printing Technologies. C. 2023; 9(4):111. https://doi.org/10.3390/c9040111

Chicago/Turabian StyleLoura, Niki, Eleni Gkartzou, Aikaterini-Flora Trompeta, Georgios Konstantopoulos, Panagiotis A. Klonos, Apostolos Kyritsis, and Costas A. Charitidis. 2023. "Development of CNT-Based Nanocomposites with Ohmic Heating Capability towards Self-Healing Applications in Extrusion-Based 3D Printing Technologies" C 9, no. 4: 111. https://doi.org/10.3390/c9040111

APA StyleLoura, N., Gkartzou, E., Trompeta, A. -F., Konstantopoulos, G., Klonos, P. A., Kyritsis, A., & Charitidis, C. A. (2023). Development of CNT-Based Nanocomposites with Ohmic Heating Capability towards Self-Healing Applications in Extrusion-Based 3D Printing Technologies. C, 9(4), 111. https://doi.org/10.3390/c9040111