Improvement of Malvar Wine Quality by Use of Locally-Selected Saccharomyces cerevisiae Strains

Abstract

:1. Introduction

2. Experimental Section

2.1. Yeast Strains and Vinification Procedure

2.2. Yeast Isolation, Identification, and Typification

2.3. Enological Parameters of the Fermentation Assays

2.4. Determination of Carboxylic Acids of the Malvar Wines

2.5. Determination of the Volatile Fraction of the Fermentations

2.6. Sensory Analysis

2.7. Statistical Analysis

3. Results and Discussion

3.1. Fermentation Kinetics

3.2. Implantation Rate

3.3. Principal Enological Parameters of the Fermentation Assays

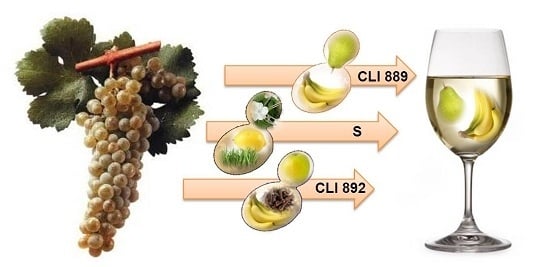

3.4. Aromatic Profile of Malvar Wines Fermented with Different Yeast Strains

3.5. Sensory Analysis of Wines

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Cordero-Bueso, G.; Esteve-Zarzoso, B.; Cabellos, J.M.; Gil-Díaz, M.; Arroyo, T. Biotechnological potential of non-Saccharomyces yeasts isolated during spontaneous fermentations of Malvar (Vitis viniferacv L). Eur. Food Res. Technol. 2013, 236, 193–207. [Google Scholar] [CrossRef]

- Laffort, J.F.; Romat, H.; Darriet, P. Les levuresetl’expressionaromatique des vinsblancs. Rev. Oenol. 1989, 53, 9–12. [Google Scholar]

- Günata, Y.Z.; Dugelay, I.; Sapis, J.C.; Baumes, R.; Bayonove, C. Role of enzymes in the use of the flavor potential from grape glycosides in winemaking. In Progress in Flavor Precursor Studies; Schreier, P., Winter-Halter, P., Eds.; Allured Publishing Corporation: Carol Stream, IL, USA, 1993; Volume 3, pp. 219–234. [Google Scholar]

- Swiegers, J.H.; Bartowsky, E.J.; Henschke, P.A.; Pretorius, I.S. Yeast and bacteria modulation of wine aroma and flavor. Aust. J. Grape Wine Res. 2005, 11, 139–173. [Google Scholar] [CrossRef]

- Swiegers, J.H.; Pretorius, I.S. Yeast modulation of wine flavor. Adv. Appl. Microbiol. 2007, 57, 131–175. [Google Scholar]

- Carrascosa, A.V.; Bartolomé, B.; Robredo, A.; León, A.; Cebollero, E.; Juega, M.; Nuñez, Y.P.; Martínez, M.C.; Martínez-Rodríguez, A.J. Influence of locally-selected yeast on the chemical and sensorial properties of Albariño White wines. LWT Food Sci. Technol. 2012, 46, 319–325. [Google Scholar] [CrossRef]

- Varela, C.; Siebert, T.; Cozzolino, D.; Rose, L.; McLean, H.; Henschke, P. Discovering a chemical basis for differentiating wines made by fermentation with wild indigineous and inoculated yeasts; role of yeast volatile compounds. Aust. J. Grape Wine Res. 2009, 15, 238–248. [Google Scholar] [CrossRef]

- Vigentini, I.; Fabrizio, V.; Faccincani, M.; Picozzi, C.; Comasio, A.; Foschino, R. Dynamics of Saccharomyces cerevisiae populations in controlled and spontaneous fermentations for Franciacorta D.O.C.G. base wine production. Ann. Microbiol. 2013, 64, 639–651. [Google Scholar] [CrossRef]

- Capece, A.; Pietrafesa, R.; Romano, P. Experimental approach for target selection of wild wine yeasts from spontaneous fermentation of “Inzolia” grapes. World J. Microbiol. Biotechnol. 2011, 27, 2775–2783. [Google Scholar] [CrossRef]

- Csoma, H.; Zakany, N.; Capece, A.; Romano, P.; Sipiczki, M. Biological diversity of Saccharomyces yeasts of spontaneously fermenting wines in four wine regions: Comparative genotypic and phenotypic analysis. Int. J. Food Microbiol. 2010, 140, 239–248. [Google Scholar] [CrossRef] [PubMed]

- Esteve-Zarzoso, B.; Gostincar, A.; Bobet, R.; Uruburu, F.; Querol, A. Selection and molecular characterization of wine yeasts isolated from the “El Penedes” area Spain. Food Microbiol. 2000, 17, 553–562. [Google Scholar] [CrossRef]

- Orlic, S.; Redzepovic, S.; Jeromel, A.; Herjavec, S.; Iacumin, L. Influence of indigenous Saccharomyces paradoxus strains on Chardonnay wine fermentation aroma. Int. J. Food Sci. Technol. 2007, 42, 95–101. [Google Scholar] [CrossRef]

- Fleet, G.H. Wine yeast for the future. FEMS Yeast Res. 2008, 8, 979–995. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez, M.E.; Infante, J.J.; Molina, M.; Domínguez, M.; Rebordinos, L.; Cantoral, J.M. Genomic characterization and selection of wine yeast to conduct industrial fermentations of a white wine produced in a SW Spain winery. J. Appl. Microbiol. 2010, 108, 1292–1302. [Google Scholar] [CrossRef] [PubMed]

- Suzzi, G.; Arfelli, G.; Schirone, M.; Corsetti, A.; Perpetuini, G.; Tofalo, R. Effect of grape indigenous Saccharomyces cerevisiae strains on Montepulciano d’Abruzzo red wine quality. Food Res. Int. 2012, 46, 22–29. [Google Scholar] [CrossRef]

- Arroyo, T. Estudio de la influencia de diferentes tratamientos enológicos en la evolución de la microbiota y en la calidad de los vinos elaborados con la variedad “Airén”, en la D.O. “Vinos de Madrid”. Ph.D. Thesis, University of Alcalá, Alcalá de Henares, Madrid, Spain, 2000. [Google Scholar]

- Cordero-Bueso, G.; Arroyo, T.; Serrano, A.; Tello, J.; Aporta, I.; Vélez, M.D.; Valero, E. Influence of the farming system and vine variety on yeast communities associated with grape-berries. Int. J. Food Microbiol. 2011, 45, 132–139. [Google Scholar] [CrossRef] [PubMed]

- Esteve-Zarzoso, B.; Belloch, C.; Uruburu, F.; Querol, A. Identification of yeast by RFLP analysis of the 5.8 rRNA and the two ribosomal internal transcribed spacers. Int. J. Syst. Bacteriol. 1999, 49, 329–337. [Google Scholar] [CrossRef] [PubMed]

- Vaudano, E.; Garcia-Moruno, E. Discrimination of Saccharomyces cerevisiae wine strains using microsatellite multiplex PCR and band pattern analysis. Food Microbiol. 2008, 25, 56–64. [Google Scholar] [CrossRef] [PubMed]

- Gil, M.; Cabellos, J.M.; Arroyo, T.; Prodanov, M. Characterization of the volatile fraction of young wines from the Denomination of Origin “Vinos de Madrid” Spain. Anal. Chim. Acta 2006, 563, 145–153. [Google Scholar] [CrossRef]

- International Organization for Standardization. ISO 11035. Sensory Analysis—Identification and Selection of Descriptors for Establishing a Sensory Profile by Multidimensional Approach; ISO: Geneva, Switzerland, 1994. [Google Scholar]

- International Organization for Standardization. ISO 8589. Sensory Analysis—General Guidance for the Design of Test Room; ISO: Geneva, Switzerland, 2007. [Google Scholar]

- International Organization for Standardization. ISO 8586-1. Sensory Analysis—General Guidance for the Selection, Training, and Monitoring of Assessors. Part 1: Selected Assessors; ISO: Geneva, Switzerland, 1993. [Google Scholar]

- Lozano, J.; Santos, J.P.; Arroyo, T.; Aznar, M.; Cabellos, J.M.; Gil, M.; Horrillo, M.C. Correlating e-nose responses to wine sensorial descriptors and gas Chromatography—Mass spectrometry profiles using partial least squares regression analysis. Sens. Actuators B 2007, 127, 267–276. [Google Scholar] [CrossRef]

- Vilanova, M.; Masneuf-Pomarède, I.; Dubourdieu, D. Influence of Saccharomyces cerevisiae strains on general composition and sensorial properties of white wines made from Vitis vinifera cv. Albariño. Food Technol. Biotechnol. 2005, 43, 79–83. [Google Scholar]

- Remize, F.; Roustan, J.L.; Sablayrolles, J.M.; Barre, P.; Dequin, S. Glycerol overproduction by engineered Saccharomyces cerevisiae wine yeast strains leads to substantial changes in byproduct formation and to a stimulation of fermentation rate in stationary phase. Appl. Environ. Microbiol. 1999, 65, 143–149. [Google Scholar] [PubMed]

- Erasmus, D.J.; Cliff, M.; van Vuuren, H.J.J. Impact of yeast strain on the production of acetic acid, glycerol, and the sensory attributes of icewine. Am. J. Enol. Viticult. 2004, 55, 371–378. [Google Scholar]

- Duarte, F.W.; Dias, R.D.; Oliveira, J.M.; Vilanova, M.; Teixeira, J.A.; Almeida e Silva, J.B.; Schwan, R.F. Raspberry Rubusidaeus L. wine: Yeast selection, sensory evaluation and instrumental analysis of volatile and other compounds. Food Res. Int. 2010, 43, 2303–2314. [Google Scholar] [CrossRef]

- Falqué, E.; Fernández, E.; Dubourdieu, D. Differentation of white wines by their aromatic index. Talanta 2001, 54, 271–281. [Google Scholar] [CrossRef]

- Escudero, A.; Asensio, E.; Cacho, J.; Ferreira, V. Sensory and chemical changes of young white wines stored under oxygen. An assessment of the role played by aldehydes and some other important odorants. Food Chem. 2002, 77, 325–331. [Google Scholar] [CrossRef]

- Arroyo, T.; Lozano, J.; Cabellos, J.M.; Gil-Díaz, M.; Santos, J.P.; Horrillos, M.C. Evaluation of wine aromatic compounds by a sensory human panel and an electronic nose. J. Agric. Food Chem. 2009, 57, 11449–11582. [Google Scholar] [CrossRef] [PubMed]

- Santos, J.P.; Arroyo, T.; Aleixandre, M.; Lozano, J.; Sayago, I.; García, M.; Fernández, M.J.; Arés, L.; Gutiérrez, J.; Cabellos, J.M.; et al. A comparative study of sensor array and GC-MS: application to Madrid wines characterization. Sens. Actuators B 2004, 102, 299–307. [Google Scholar] [CrossRef]

- Hernández-Orte, P.; Cersosimo, M.; Loscos, N.; Cacho, J.; García-Moruno, E.; Ferreira, V. The development of varietal aroma from non-floral grapes by yeast of different genera. Food Chem. 2008, 107, 1064–1077. [Google Scholar] [CrossRef]

- Rojas, V.; Gil, J.V.; Piñaga, F.; Manzanares, P. Acetate ester formation in wine by mixed cultures in laboratory fermentations. Int. J. Food Microbiol. 2003, 86, 181–188. [Google Scholar] [CrossRef]

- Valero, E.; Moyano, L.; Millán, M.C.; Medina, M.; Ortega, J.M. Higher alcohols and esters production by Saccharomyces cerevisiae. Influence of the initial oxygenation of the grape must. Food Chem. 2002, 78, 57–61. [Google Scholar] [CrossRef]

- Gómez-Míguez, M.J.; Cacho, J.F.; Ferreira, V.; Vicario, I.M.; Heredia, F.J. Volatile components of Zalema white wines. Food Chem. 2007, 100, 1464–1473. [Google Scholar] [CrossRef]

- Grando, M.S.; Versini, G.; Nicolini, G.; Mattivi, F. Selective use of wine yeast strains having different volatile phenols production. Vitis 1993, 32, 43–50. [Google Scholar]

- Feuillat, M. Yeast macromolecules: Origin, composition, and enological interest. Am. J. Enol. Vitic. 2003, 54, 211–213. [Google Scholar]

- Noble, A.C.; Bursick, G.F. The contribution of glycerol to perceived viscosity and sweetness in white wine. Am. J. Enol. Vitic. 1984, 35, 110–112. [Google Scholar]

- Ugliano, M.; Henschke, P.A. Yeasts and wine flavour. In Wine Chemistry and Biochemistry; Moreno-Arribas, M.V., Polo, M.C., Eds.; Springer Verlag: New York, NY, USA, 2009; pp. 313–392. [Google Scholar]

- Scacco, A.; Oliva, D.; Di Maio, S.; Polizzotto, G.; Genna, G.; Tripodi, G.; Lanza, C.M.; Verzera, A. Indigenous Saccharomyces cerevisiae strains and their influence on the quality of Cataratto, Inzolia and Grillo white wines. Food Res. Int. 2012, 46, 1–9. [Google Scholar] [CrossRef]

- Campo, E.; Ferreira, V.; Escudero, A.; Marqués, J.C.; Cacho, J. Quantitative gas chromatography-olfactometry and chemical quantitative study of the aroma of four Madeira wines. Anal. Chim. Acta 2006, 563, 180–187. [Google Scholar] [CrossRef]

| Parameters | S | CLI 889 | CLI 892 | F | Sig |

|---|---|---|---|---|---|

| Alcoholic degree % (v/v) | 12.50 ± 0.08 a | 12.54 ± 0.06 a | 12.70 ± 0.02 b | 9.69 | 0.0132 |

| Fermentative capacity | 12.00 ± 0.07 a | 12.61 ± 0.01 c | 12.50 ± 0.01 b | 186.53 | 0.0000 |

| V50 | 18.00 ± 0.04 b | 15.45 ± 0.64 a | 20.30 ± 0.2 c | 128.70 | 0.0000 |

| VF | 6.7 ± 0.3 b | 5.40 ± 0.42 a | 4.9 ± 0.7 a | 10.27 | 0.0115 |

| pH | 3.81 ± 0.01 b | 3.77 ± 0.01 a | 3.79 ± 0.02 b | 7.94 | 0.0206 |

| Free SO2 (mg/L) | 6.0 ± 0.3 a | 9.5 ± 0.71 b | 10.0 ± 1.0 b | 26.82 | 0.0010 |

| Total SO2 (mg/L) | 15.0 ± 2.7 | 16.1 ± 1.56 | 14.0 ± 2.0 | 0.72 | 0.5230 |

| Volatile acidity (g/L; acetic acid) | 0.14 ± 0.01 a | 0.23 ± 0.03 b | 0.31 ± 0.04 c | 25.04 | 0.0012 |

| Titratable acidity (g/L; tartaric acid) | 4.90 ± 0.07 a | 5.14 ± 0.06 b | 5.20 ± 0.07 b | 16.93 | 0.0034 |

| Citric acid (g/L) | 0.31 ± 0.01 b | 0.30 ± 0.00 a,b | 0.29 ± 0.01 a | 4.00 | 0.0787 |

| Malic acid (g/L) | 2.82 ± 0.05 b | 2.58 ± 0.01 a | 2.72 ± 0.09 b | 27.44 | 0.0010 |

| Lactic acid (g/L) | 0.59 ± 0.06 b | 0.55 ± 0.02 b | 0.45 ± 0.04 a | 8.36 | 0.0184 |

| Acetic acid (g/L) | 0.17 ± 0.01 a | 0.32 ± 0.02 b | 0.39 ± 0.03 c | 69.14 | 0.0001 |

| Succinic acid (g/L) | 0.29 ± 0.01 a,b | 0.28 ± 0.00 a | 0.31 ± 0.01 b | 5.55 | 0.0433 |

| Reducing sugar (g/L) | 1.5 ± 0.3 | 1.55 ± 0.07 | 1.3 ± 0.2 | 1.17 | 0.3730 |

| Glycerol (g/L) | 7.1 ± 1.6 a,b | 7.85 ± 0.92 b | 4.40 ± 1.5 a | 5.13 | 0.0503 |

| 2,3-butanodiol (mg/L) | 373.5 ± 67.5 a | 386.8 ± 16.3 a | 518.4 ± 91.2 b | 7.86 | 0.0211 |

| Compound (mg/L) | S | CLI 889 | CLI 892 | F | Sig | ODE | OTH (mg/L) | OAV * | ||

|---|---|---|---|---|---|---|---|---|---|---|

| S | CLI 889 | CLI 892 | ||||||||

| Acetaldehyde | 50.75 ± 8.85 a | 69.61 ± 8.19 b | 60.35 ± 10.30 ab | 3.18 | 0.1142 | Pleasant, fruity | 0.0025 2 | 20.30 | 27.84 | 24.14 |

| Acetoin | tr a | 2.4±1.03 b | 1.27±0.73 ab | 8.14 | 0.0195 | Flowery, wet | 150.0 1 | <0.1 | <0.1 | <0.1 |

| Ethyl acetate | 68.71 ± 1.01 a | 69.28 ± 4.41 a | 64.65 ± 10.66 a | 0.43 | 0.6700 | Fruit, solvent | 12.26 1 | 5.60 | 5.65 | 5.27 |

| 1-Propanol | 35.02 ± 1.83 b | 36.63 ± 1.41 b | 25.80 ± 2.58 a | 25.63 | 0.0012 | Alcohol, ripe fruit | 306.0 1 | 0.11 | 0.11 | <0.1 |

| Isobutanol | 37.39 ± 0.58 b | 39.50 ± 1.53 b | 23.52 ± 2.63 a | 70.62 | 0.0001 | Fusel, alcohol | 40.00 1 | 0.93 | 0.98 | 0.58 |

| Isoamylic alcohols | 175.23 ± 1.74 b | 182.20 ± 2.99 c | 156.38 ± 3.25 a | 71.47 | 0.0001 | Bitter, harsh | 30.00 1 | 5.84 | 6.07 | 5.21 |

| Σ Higher major alcohols | 247.65 ± 0.66 b | 258.13 ± 5.63 b | 205.71 ± 8.45 a | 66.86 | 0.0001 | |||||

| 1-Hexanol | 0.81 ± 0.01 a | 0.95 ± 0.00 a | 1.00 ± 0.06 a | 0.42 | 0.6754 | Green grass | 8.00 1 | 0.1 | 0.11 | 0.12 |

| 2-Phenylethanol | 10.79 ± 0.29 b | 9.29 ± 0.85 a | 9.99 ± 0.82 ab | 3.46 | 0.100 | Roses | 14.00 1 | 0.77 | 0.66 | 0.71 |

| Σ Higher minor alcohols | 11.59 ± 0.27 b | 10.22 ± 0.83 a | 10.99 ± 0.80 ab | 3.03 | 0.1233 | |||||

| Isobutyl acetate | 0.16 ± 0.00 b | 0.18 ± 0.00 c | 0.13 ± 0.01 a | 37.75 | 0.0004 | Sweet fruit | 1.60 1 | 0.1 | 0.11 | <0.1 |

| Isoamyl acetate | 7.66 ± 0.18 b | 9.37 ± 0.54 c | 6.19 ± 0.08 a | 67.73 | 0.0001 | Banana | 0.030 1 | 255.33 | 312.33 | 206.33 |

| Hexyl acetate | 0.14 ± 0.01 b | 0.19 ± 0.02 b | 0.06 ± 0.05 a | 11.07 | 0.0097 | Fruity, green, pear | 0.020 3 | 7.00 | 9.50 | 3.00 |

| Phenylethyl acetate | 0.56 ± 0.03 b | 0.56 ± 0.07 b | 0.38 ± 0.04 a | 13.14 | 0.0064 | Pleasant, flowery | 0.250 1 | 2.24 | 2.24 | 1.52 |

| Σ Higher alcohol acetates | 8.38 ± 0.20 b | 10.10 ± 0.62 c | 6.70 ± 0.04 a | 61.06 | 0.0001 | |||||

| Ethyl butyrate | 0.33 ± 0.01 ab | 0.39 ± 0.00 b | 0.27 ± 0.06 a | 10.24 | 0.0116 | Acid fruit | 0.020 1 | 16.5 | 19.50 | 13.5 |

| Ethyl hexanoate | 0.60 ± 0.05 b | 0.52 ± 0.07 ab | 0.39 ± 0.13 a | 4.16 | 0.0735 | Green apple | 0.014 1 | 42.86 | 37.14 | 27.86 |

| Ethyl octanoate | 1.01 ± 0.25 a | 1.10 ± 0.11 a | 0.73 ± 0.42 a | 1.34 | 0.3314 | Sweet, soap | 0.005 1 | 202.00 | 220.00 | 146.00 |

| Ethyl decanoate | 0.08 ± 0.06 b | 0.23 ± 0.02 c | tr a | 28.09 | 0.0009 | Pleasant, soap | 0.200 1 | 0.40 | 1.15 | <0.1 |

| Σ Fatty acid esters | 2.01 ± 0.37 a | 2.22 ± 0.19 a | 1.40 ± 0.0.58 a | 3.21 | 0.1127 | |||||

| Ethyl lactate | tr a | 2.24 ± 1.01 b | tr a | 14.57 | 0.005 | Lactic | 0.157 2 | <0.1 | 14.26 | <0.1 |

| Diethyl succinate | 0.03 ± 0.01 a | 0.09 ± 0.04 b | 0.05 ± 0.01 ab | 4.67 | 0.0599 | Apple, fruity | 0.20 2 | 0.15 | 0.45 | 0.25 |

| Isobutyric acid | 3.01 ± 0.02 a | 3.02 ± 0.03 a | 2.91 ± 0.01 a | 0.94 | 0.4429 | acid, fatty | 0.230 1 | 13.09 | 13.13 | 12.65 |

| Butyric acid | 1.90 ± 0.04 a | 1.93 ± 0.21 a | 1.31 ± 1.14 a | 0.81 | 0.4876 | Cheese | 0.173 1 | 10.98 | 11.15 | 7.57 |

| Isovaleric acid | 0.08 ± 0.06 a | 0.26 ± 0.07 b | 0.02 ± 0.01 a | 14.60 | 0.005 | Blue cheese | 0.033 1 | 2.42 | 7.87 | 0.60 |

| Σ SCFA | 6.67 ± 0.07 a | 6.65 ± 0.15 a | 6.08 ± 1.06 a | 0.88 | 0.4640 | |||||

| Hexanoic acid | 4.97 ± 0.23 a | 4.29 ± 0.36 a | 4.54 ± 0.11 ab | 5.27 | 0.0477 | Cheese | 0.420 1 | 11.83 | 10.21 | 10.80 |

| Octanoic acid | 6.11 ± 0.20 c | 5.45 ± 0.50 b | 5.07 ± 0.20 a | 17.91 | 0.0030 | Rancid, harsh | 0.500 1 | 12.22 | 10.90 | 10.14 |

| Decanoic acid | 3.70 ± 0.77 a | 3.68 ± 0.32 a | 2.85 ± 0.21 a | 2.89 | 0.1319 | Fatty | 1.00 1 | 3.70 | 3.68 | 2.85 |

| Σ MCFA | 14.78 ± 1.20 b | 13.39 ± 1.15 ab | 12.46 ± 0.35 a | 4.23 | 0.0713 | |||||

| 4-Vinylguaiacol | 0.47 ± 0.18 ab | 0.53 ± 0.04 b | 0.29 ± 0.09 a | 3.33 | 0.1062 | Pleasant, phenolic | 1.10 1 | 0.42 | 0.48 | 0.26 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cordero-Bueso, G.; Esteve-Zarzoso, B.; Gil-Díaz, M.; García, M.; Cabellos, J.M.; Arroyo, T. Improvement of Malvar Wine Quality by Use of Locally-Selected Saccharomyces cerevisiae Strains. Fermentation 2016, 2, 7. https://doi.org/10.3390/fermentation2010007

Cordero-Bueso G, Esteve-Zarzoso B, Gil-Díaz M, García M, Cabellos JM, Arroyo T. Improvement of Malvar Wine Quality by Use of Locally-Selected Saccharomyces cerevisiae Strains. Fermentation. 2016; 2(1):7. https://doi.org/10.3390/fermentation2010007

Chicago/Turabian StyleCordero-Bueso, Gustavo, Braulio Esteve-Zarzoso, Mar Gil-Díaz, Margarita García, Juan Mariano Cabellos, and Teresa Arroyo. 2016. "Improvement of Malvar Wine Quality by Use of Locally-Selected Saccharomyces cerevisiae Strains" Fermentation 2, no. 1: 7. https://doi.org/10.3390/fermentation2010007

APA StyleCordero-Bueso, G., Esteve-Zarzoso, B., Gil-Díaz, M., García, M., Cabellos, J. M., & Arroyo, T. (2016). Improvement of Malvar Wine Quality by Use of Locally-Selected Saccharomyces cerevisiae Strains. Fermentation, 2(1), 7. https://doi.org/10.3390/fermentation2010007