Batch Fermentation Options for High Titer Bioethanol Production from a SPORL Pretreated Douglas-Fir Forest Residue without Detoxification

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

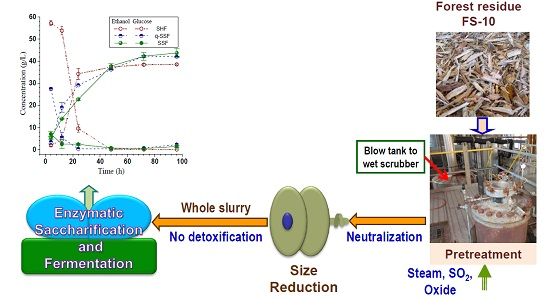

2.2. Pretreatment

2.3. Enzymatic Hydrolysis

2.4. Enzymatic Saccharification and Fermentation

2.5. Analytical Methods

3. Results and Discussion

3.1. Compositional Analysis of SPORL Pretreated Douglas-Fir Residue

3.2. Evaluation of Pretreatment Effectiveness and Effect of Enzyme Loading on Saccharification

3.3. Comprison of Three Different Fermentation Options on Ethanol Production

3.4. Comprison of Different Enzyme Loadings in SSF Fermentation

3.5. Effect of Nutrient Supplementation on the Ethanol Production

3.6. Effect of Sterilization

3.7. Effect of Yeast Loading on the Ethanol Production

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- U.S. DOE. Breaking the Biological Barriers to Cellulosic Ethanol: A Joint Research Agenda. In A Research Road Map Resulting from the Biomass to Biofuel Workshop Sponsored by The Department of Energy; U.S. Department of Energy: Rockville, MD, USA, 2005. [Google Scholar]

- National Research Council. Renewable Fuel Standard: Potential Economic and Environmental Effects of US Biofuel Policy; The Natinal Academies Press: Washington, WA, USA, 2011. [Google Scholar]

- Gan, J.; Smith, C.T. Availability of logging residues and potential for electricity production and carbon displacement in the USA. Biomass Bioenerg. 2006, 30, 1011–1020. [Google Scholar] [CrossRef]

- Perlack, R.D.; Stokes, B.J.; DOE. 2011. U.S. Billion-Ton Update: Biomass Supply for a Bioenergy and Bioproducts Industry; Oakridge National Laboratory: Oak Ridge, TN, USA, 2011.

- Zhu, J.Y.; Pan, X.J. Woody Biomass Pretreatment for Cellulosic Ethanol Production: Technology and Energy Consumption Evaluation. Bioresour. Technol. 2010, 101, 4992–5002. [Google Scholar] [CrossRef] [PubMed]

- Larsson, S.; Palmqvist, E.; Hahn-Hagerdal, B.; Tengborg, C.; Stenberg, K.; Zacchi, G.; Nilvebrant, N.-O. The generation of fermentation inhibitors during dilute acid hydrolysis of softwood. Enzyme Microb. Technol. 1999, 24, 151–159. [Google Scholar] [CrossRef]

- Zhou, H.; Leu, S.-Y.; Wu, X.; Zhu, J.Y.; Gleisner, R.; Yang, D.; Qiu, X.; Horn, E. Comparisons of high titer ethanol production and lignosulfonate properties by SPORL pretreatment of lodgepole pine at two temperatures. RSC Adv. 2014, 4, 27033–27038. [Google Scholar] [CrossRef]

- Zhang, C.; Houtman, C.J.; Zhu, J.Y. Using low temperature to balance enzymatic saccharification and furan formation in SPORL pretreatment of Douglas-fir. Process Biochem. 2014, 49, 466–473. [Google Scholar] [CrossRef]

- Cheng, J.; Leu, S.-Y.; Zhu, J.Y.; Gleisner, R. High titer and yield ethanol production from undetoxified whole slurry of Douglas-fir forest residue using pH-profiling in SPORL. Biotechnol. Biofuels 2015, 8, 22. [Google Scholar] [CrossRef] [PubMed]

- Gu, F.; Gilles, W.; Gleisner, R.; Zhu, J.Y. Fermentative high titer ethanol production from a Douglas-fir forest residue without detoxification using SPORL: High SO2 loading at a low temperature. Ind. Biotechnol. 2016, 12, 168–175. [Google Scholar] [CrossRef]

- Zhu, J.Y.; Chandra, M.S.; Gu, F.; Gleisner, R.; Reiner, R.; Sessions, J.; Marrs, G.; Gao, J.; Anderson, D. Using sulfite chemistry for robust bioconversion of Douglas-fir forest residue to bioethanol at high titer and lignosulfonate: A pilot-scale evaluation. Bioresour. Technol. 2015, 179, 390–397. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.; Zhu, J.Y.; Gleisner, R.; Qiu, X.; Horn, E.; Negron, J. Pilot-scale demonstration of SPORL for bioconversion of lodgepole pine to bio-ethanol and lignosulfonate. Holzforschung 2016, 70, 21–30. [Google Scholar]

- Zhou, H.; Lan, T.; Dien, B.S.; Hector, R.E.; Zhu, J.Y. Comparisons of Five Saccharomyces cerevisiae strains for Ethanol Production from SPORL Pretreated Lodgepole Pine. Biotechnol. Prog. 2014, 30, 1076–1083. [Google Scholar] [CrossRef] [PubMed]

- Almeida, J.R.M.; Runquist, D.; Sànchez Nogué, V.; Lidén, G.; Gorwa-Grauslund, M.F. Stress-related challenges in pentose fermentation to ethanol by the yeast Saccharomyces cerevisiae. Biotechnol. J. 2011, 6, 286–299. [Google Scholar] [CrossRef] [PubMed]

- Hoyer, K.; Galbe, M.; Zacchi, G. The effect of prehydrolysis and improved mixing on high-solids batch simultaneous saccharification and fermentation of spruce to ethanol. Process Biochem. 2013, 48, 289–293. [Google Scholar] [CrossRef]

- Zhu, J.Y.; Pan, X.J.; Wang, G.S.; Gleisner, R. Sulfite pretreatment (SPORL) for robust enzymatic saccharification of spruce and red pine. Bioresour. Technol. 2009, 100, 2411–2418. [Google Scholar] [CrossRef] [PubMed]

- Leu, S.-Y.; Gleisner, R.; Zhu, J.Y.; Sessions, J.; Marrs, G. Robust Enzymatic Saccharification of a Douglas-fir Forest Harvest Residue by SPORL. Biomass Bioenerg. 2013, 59, 393–401. [Google Scholar] [CrossRef]

- Yamamoto, M.; Niskanen, T.; Iakovlev, M.; Ojamo, H.; van Heiningen, A. The effect of bark on sulfur dioxide-ethanol-water fractionation and enzymatic hydrolysis of forest biomass. Bioresour. Technol. 2014, 167, 390–397. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Zhu, J.Y.; Gleisner, R.; Sessions, J. Fractionation of Forest Residues of Douglas-fir for Fermentable Sugar Production by SPORL Pretreatment. Bioenerg. Res. 2012, 5, 978–988. [Google Scholar] [CrossRef] [Green Version]

- Wood, T.M.; Bhat, M. Methods for Measuring Cellulase Activities. In Methods in Enzymology; Colowick, S.P., Kaplan, N.O., Eds.; Academic Press, Inc.: New York, NY, USA, 1988; pp. 87–112. [Google Scholar]

- Hector, R.E.; Dien, B.S.; Cotta, M.A.; Qureshi, N. Engineering industrial Saccharomyces cerevisiae strains for xylose fermentation and comparison for switchgrass conversion. J. Ind. Microbio. Biotechnol. 2011, 38, 1193–1202. [Google Scholar] [CrossRef] [PubMed]

- Lan, T.Q.; Lou, H.; Zhu, J.Y. Enzymatic saccharification of lignocelluloses should be conducted at elevated pH 5.2–6.2. Bioenerg. Res. 2013, 6, 476–485. [Google Scholar] [CrossRef]

- Lou, H.; Zhu, J.Y.; Lan, T.Q.; Lai, H.; Qiu, X. pH-induced lignin surface modification to reduce nonspecific cellulase binding and enhance enzymatic saccharification of lignocelluloses. ChemSusChem 2013, 6, 919–927. [Google Scholar] [CrossRef] [PubMed]

- Luo, X.; Gleisner, R.; Tian, S.; Negron, J.; Horn, E.; Pan, X.J.; Zhu, J.Y. Evaluation of mountain beetle infested lodgepole pine for cellulosic ethanol production by SPORL pretreatment. Ind. Eng. Chem. Res. 2010, 49, 8258–8266. [Google Scholar] [CrossRef]

- Holtzapple, M.; Cognata, M.; Shu, Y.; Hendrickson, C. Inhibition of Trichoderma reesei cellulase by sugars and solvents. Biotechnol. Bioeng. 1990, 36, 275–287. [Google Scholar] [CrossRef] [PubMed]

- Gauss, W.F.; Suzuki, S.; Takagi, M. Manufacture of Alcohol from Cellulosic Materials Using Plural Ferments. U.S. Patent 3990944 A, 9 November 1976. [Google Scholar]

- Olofsson, K.; Bertilsson, M.; Lidén, G. A short review on SSF—An interesting process option for ethanol production from lignocellulosic feedstocks. Biotechnol. Biofuels 2008, 1, 7. [Google Scholar] [CrossRef] [PubMed]

- Sassner, P.; Galbe, M.; Zacchi, G. Bioethanol production based on simultaneous saccharification and fermentation of steam-pretreated Salix at high dry-matter content. Enzyme Microb. Technol. 2006, 39, 756–762. [Google Scholar] [CrossRef]

| Untreated FS-10 | Pretreated FS-10 Wet Solids | Freely Drainable Liquor 1 | Total Recovery (%) | |

|---|---|---|---|---|

| Wet weight (kg) | 66.41 | 126.50 | 94.35 | 88.1 |

| Oven dry solids (kg) | 50 | 43.97 | 7.25 | 101.0 2 |

| Klason lignin (kg) | 14.65 | 8.67 | 5.27 | 95.2 |

| Arabinan (kg) | 0.51 | 0.32 | ||

| Galatan (kg) | 1.00 | 1.13 | ||

| Glucan (kg) | 20.49 | 17.27 | 0.63 (6.72) | 87.4 |

| Mannan (kg) | 4.84 | 3.57 | 1.67 (17.66) | 108.3 |

| Xylan (kg) | 2.85 | 1.76 | 0.78 (8.29) | 89.1 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, M.; Ji, H.; Zhu, J.Y. Batch Fermentation Options for High Titer Bioethanol Production from a SPORL Pretreated Douglas-Fir Forest Residue without Detoxification. Fermentation 2016, 2, 16. https://doi.org/10.3390/fermentation2030016

Yang M, Ji H, Zhu JY. Batch Fermentation Options for High Titer Bioethanol Production from a SPORL Pretreated Douglas-Fir Forest Residue without Detoxification. Fermentation. 2016; 2(3):16. https://doi.org/10.3390/fermentation2030016

Chicago/Turabian StyleYang, Mingyan, Hairui Ji, and J.Y. Zhu. 2016. "Batch Fermentation Options for High Titer Bioethanol Production from a SPORL Pretreated Douglas-Fir Forest Residue without Detoxification" Fermentation 2, no. 3: 16. https://doi.org/10.3390/fermentation2030016

APA StyleYang, M., Ji, H., & Zhu, J. Y. (2016). Batch Fermentation Options for High Titer Bioethanol Production from a SPORL Pretreated Douglas-Fir Forest Residue without Detoxification. Fermentation, 2(3), 16. https://doi.org/10.3390/fermentation2030016