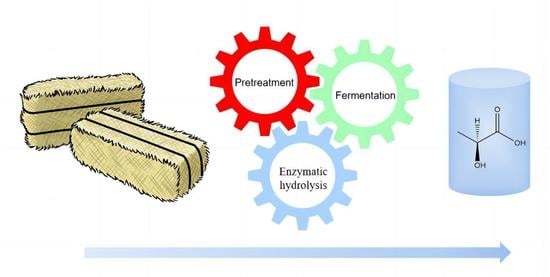

Ammonia–Mechanical Pretreatment of Wheat Straw for the Production of Lactic Acid and High-Quality Lignin

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Pretreatment of Biomass

2.3. Enzymatic Hydrolysis of Biomass

2.4. l-Lactic Acid Fermentation

2.5. Component Analysis of Biomass and Fermentation Analysis

2.6. Characterization of Wheat Straw and Lignin

2.6.1. Microstructure Analysis

2.6.2. Ultimate Analysis

2.6.3. Fourier Transform Infrared (FTIR) Spectroscopy

2.6.4. Two-dimensional 1H-13C Heteronuclear Single Quantum Coherence (HSQC) NMR Spectroscopy

2.6.5. The Radical Scavenging Activity of Lignin

2.7. Experimental Design and Statistical Analysis

3. Results and Discussion

3.1. The Ammonia–Mechanical Pretreatment Process and Enzymatic Hydrolysis of Wheat Straw

3.2. l-Lactic Acid Fermentation

3.3. Mass Balance under the Optimal Reaction Condition

3.4. Microstructure of Pretreatment Residue

3.5. Structural Characterization of Extracted Lignin

3.5.1. FTIR and Ultimate Analysis

3.5.2. Two-dimensional 1H-13C HSQC NMR Analysis

3.5.3. The Radical Scavenging Activity of Lignin

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Castillo Martinez, F.A.; Balciunas, E.M.; Salgado, J.M.; Domínguez González, J.M.; Converti, A.; de Souza Oliveira, R.P. Lactic acid properties, applications and production: A Review. Trends Food Sci. Technol. 2013, 30, 70–83. [Google Scholar] [CrossRef]

- Yankov, D. Fermentative lactic acid production from lignocellulosic feedstocks: From source to purified product. Front. Chem. 2022, 10, 823005. [Google Scholar] [CrossRef] [PubMed]

- Lin, H.-T.V.; Huang, M.Y.; Kao, T.Y.; Lu, W.J.; Lin, H.J.; Pan, C.L. Production of lactic acid from seaweed hydrolysates via lactic acid bacteria fermentation. Fermentation 2020, 6, 37. [Google Scholar] [CrossRef] [Green Version]

- Abdel-Rahman, M.A.; Tashiro, Y.; Sonomoto, K. Lactic acid production from lignocellulose-derived sugars using lactic acid bacteria: Overview and Limits. J. Biotechnol. 2011, 156, 286–301. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Kim, Y.-M.; Lebaka, V.R.; Wee, Y.J. Lactic acid for green chemical industry: Recent advances in and future prospects for production technology, recovery, and applications. Fermentation 2022, 8, 609. [Google Scholar] [CrossRef]

- Raj, T.; Chandrasekhar, K.; Naresh Kumar, A.; Kim, S.H. Lignocellulosic biomass as renewable feedstock for biodegradable and recyclable plastics production: A sustainable approach. Renew. Sustain. Energy Rev. 2022, 158, 112130. [Google Scholar] [CrossRef]

- Mankar, A.R.; Pandey, A.; Modak, A.; Pant, K.K. Pretreatment of lignocellulosic biomass: A review on recent advances. Bioresour. Technol. 2021, 334, 125235. [Google Scholar] [CrossRef] [PubMed]

- Faiz Norrrahim, M.N.; Ilyas, R.A.; Nurazzi, N.M.; Asmal Rani, M.S.; Nur Atikah, M.S.; Shazleen, S.S. Chemical pretreatment of lignocellulosic biomass for the production of bioproducts: An overview. Appl. Sci. Eng. Prog. 2021, 14, 588–605. [Google Scholar] [CrossRef]

- Jose, D.; Kitiborwornkul, N.; Sriariyanun, M.; Keerthi, K. A review on chemical pretreatment methods of lignocellulosic biomass: Recent advances and progress. Appl. Sci. Eng. Prog. 2022, 15, 6210. [Google Scholar] [CrossRef]

- Kucharska, K.; Rybarczyk, P.; Hołowacz, I.; Łukajtis, R.; Glinka, M.; Kamiński, M. Pretreatment of lignocellulosic materials as substrates for fermentation processes. Molecules 2018, 23, 2937. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.S.; Lee, Y.Y.; Kim, T.H. A review on alkaline pretreatment technology for bioconversion of lignocellulosic biomass. Bioresour. Technol. 2016, 199, 42–48. [Google Scholar] [CrossRef] [PubMed]

- Tang, C.; Shan, J.; Chen, Y.; Zhong, L.; Shen, T.; Zhu, C.; Ying, H. Organic amine catalytic organosolv pretreatment of corn stover for enzymatic saccharification and high-quality lignin. Bioresour. Technol. 2017, 232, 222–228. [Google Scholar] [CrossRef] [PubMed]

- Zhong, L.; Zhang, X.; Tang, C.; Chen, Y.; Shen, T.; Zhu, C.; Ying, H. Hydrazine hydrate and organosolv synergetic pretreatment of corn stover to enhance enzymatic saccharification and co-production of high-quality antioxidant lignin. Bioresour. Technol. 2018, 268, 677–683. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Kim, T.H. Low-liquid pretreatment of corn stover with aqueous ammonia. Bioresour. Technol. 2011, 102, 4779–4786. [Google Scholar] [CrossRef]

- Le, T.D.T.; Nguyen Truong, V.P.; Ngo, M.T.T.; Kim, T.H.; Oh, K.K. Pretreatment of corn stover using an extremely low-liquid ammonia (ELLA) method for the effective utilization of sugars in simultaneous saccharification and fermentation (SSF) of ethanol. Fermentation 2021, 7, 191. [Google Scholar] [CrossRef]

- Lau, M.W.; Gunawan, C.; Dale, B.E. The impacts of pretreatment on the fermentability of pretreated lignocellulosic biomass: A comparative evaluation between ammonia fiber expansion and dilute acid pretreatment. Biotechnol. Biofuels 2009, 2, 30. [Google Scholar] [CrossRef] [Green Version]

- Duque, A.; Manzanares, P.; Ballesteros, M. Extrusion as a pretreatment for lignocellulosic biomass: Fundamentals and applications. Renew. Energy 2017, 114, 1427–1441. [Google Scholar] [CrossRef]

- José, Á.H.M.; Moura, E.A.B.; Rodrigues Jr, D.; Kleingesinds, E.K.; Rodrigues, R.C.L.B. A residue-free and effective corncob extrusion pretreatment for the enhancement of high solids loading enzymatic hydrolysis to produce sugars. Ind. Crops Prod. 2022, 188, 115655. [Google Scholar] [CrossRef]

- Phojaroen, J.; Jiradechakorn, T.; Kirdponpattara, S.; Sriariyanun, M.; Junthip, J.; Chuetor, S. Performance evaluation of combined hydrothermal-mechanical pretreatment of lignocellulosic biomass for enzymatic enhancement. Polymers 2022, 14, 2313. [Google Scholar] [CrossRef]

- Areepak, C.; Jiradechakorn, T.; Chuetor, S.; Phalakornkule, C.; Sriariyanun, M.; Raita, M.; Champreda, V.; Laosiripojana, N. Improvement of lignocellulosic pretreatment efficiency by combined chemo—Mechanical pretreatment for energy consumption reduction and biofuel production. Renew. Energy 2022, 182, 1094–1102. [Google Scholar] [CrossRef]

- Chuetor, S.; Ruiz, T.; Barakat, A.; Laosiripojana, N.; Champreda, V.; Sriariyanun, M. Evaluation of rice straw biopowder from alkaline-mechanical pretreatment by hydro-textural approach. Bioresour. Technol. 2021, 323, 124619. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; van der Heide, E.; Wang, H.; Li, B.; Yu, G.; Mu, X. Alkaline twin-screw extrusion pretreatment for fermentable sugar production. Biotechnol. Biofuels 2013, 6, 97. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Choi, C.H.; Oh, K.K. Application of a continuous twin screw-driven process for dilute acid pretreatment of rape straw. Bioresour. Technol. 2012, 110, 349–354. [Google Scholar] [CrossRef] [PubMed]

- Björkman, A. Studies on the finely divided wood. Part I. Extraction of lignin with neutral solvents. Svensk Paperstid. 1956, 59, 477–485. [Google Scholar]

- He, M.K.; He, Y.L.; Li, Z.Q.; Zhao, L.N.; Zhang, S.Q.; Liu, H.M.; Qin, Z. Structural characterization of lignin and lignin-carbohydrate complex (LCC) of sesame hull. Int. J. Biol. Macromol. 2022, 209, 258–267. [Google Scholar] [CrossRef] [PubMed]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D. Determination of structural carbohydrates and lignin in biomass. Natl. Renew. Energy Lab. 2008, 1617, 1–16. [Google Scholar]

- Tang, C.; Chen, Y.; Liu, J.; Shen, T.; Cao, Z.; Shan, J.; Zhu, C.; Ying, H. Sustainable biobutanol production using alkali-catalyzed organosolv pretreated cornstalks. Ind. Crops Prod. 2017, 95, 383–392. [Google Scholar] [CrossRef]

- Yoo, J.; Alavi, S.; Vadlani, P.; Amanor-Boadu, V. Thermo-mechanical extrusion pretreatment for conversion of soybean hulls to fermentable sugars. Bioresour. Technol. 2011, 102, 7583–7590. [Google Scholar] [CrossRef] [Green Version]

- Zheng, J.; Rehmann, L. Extrusion pretreatment of lignocellulosic biomass: A review. Int. J. Mol. Sci. 2014, 15, 18967–18984. [Google Scholar] [CrossRef] [Green Version]

- Li, G.; Sun, Y.; Guo, W.; Yuan, L. Comparison of various pretreatment strategies and their effect on chemistry and structure of sugar beet pulp. J. Clean. Prod. 2018, 181, 217–223. [Google Scholar] [CrossRef]

- De Assis Castro, R.C.; Fonseca, B.G.; dos Santos, H.T.L.; Ferreira, I.S.; Mussatto, S.I.; Roberto, I.C. Alkaline deacetylation as a strategy to improve sugars recovery and ethanol production from rice straw hemicellulose and cellulose. Ind. Crops Prod. 2017, 106, 65–73. [Google Scholar] [CrossRef]

- Alawad, I.; Ibrahim, H. Pretreatment of agricultural lignocellulosic biomass for fermentable sugar: Opportunities, challenges, and future trends. Biomass Convers. Biorefinery 2022, accepted. [Google Scholar] [CrossRef]

- Usmani, Z.; Sharma, M.; Awasthi, A.K.; Lukk, T.; Tuohy, M.G.; Gong, L.; Nguyen-Tri, P.; Goddard, A.D.; Bill, R.M.; Nayak, S.C.; et al. Lignocellulosic biorefineries: The current state of challenges and strategies for efficient commercialization. Renew. Sustain. Energy Rev. 2021, 148, 111258. [Google Scholar] [CrossRef]

- Haldar, D.; Purkait, M.K. A review on the environment-friendly emerging techniques for pretreatment of lignocellulosic biomass: Mechanistic insight and advancements. Chemosphere 2021, 264, 128523. [Google Scholar] [CrossRef] [PubMed]

- Narisetty, V.; Cox, R.; Bommareddy, R.; Agrawal, D.; Ahmad, E.; Pant, K.K.; Chandel, A.K.; Bhatia, S.K.; Kumar, D.; Binod, P.; et al. Valorisation of xylose to renewable fuels and chemicals, an essential step in augmenting the commercial viability of lignocellulosic biorefineries. Sustain. Energy Fuels 2022, 6, 29–65. [Google Scholar] [CrossRef]

- Nagarajan, D.; Oktarina, N.; Chen, P.T.; Chen, C.Y.; Lee, D.J.; Chang, J.S. Fermentative lactic acid production from seaweed hydrolysate using Lactobacillus sp. and Weissella sp. Bioresour. Technol. 2022, 344, 126166. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, H.; Yang, Y.; Zhou, X.; Xiu, Z. High-efficient L-lactic acid production from inedible starchy biomass by one-step open fermentation using thermotolerant lactobacillus rhamnosus dut1908. Bioprocess Biosyst. Eng. 2021, 44, 1935–1941. [Google Scholar] [CrossRef]

- Deng, Y.; Qiu, Y.; Yao, Y.; Ayiania, M.; Davaritouchaee, M. Weak-base pretreatment to increase biomethane production from wheat straw. Environ. Sci. Pollut. Res. 2020, 27, 37989–38003. [Google Scholar] [CrossRef]

- Qiao, X.; Zhao, C.; Shao, Q.; Hassan, M. Structural characterization of corn stover lignin after hydrogen peroxide presoaking prior to ammonia fiber expansion pretreatment. Energy Fuels 2018, 32, 6022–6030. [Google Scholar] [CrossRef]

- Zhao, C.; Qiao, X.; Shao, Q.; Hassan, M.; Ma, Z.; Yao, L. Synergistic effect of hydrogen peroxide and ammonia on lignin. Ind. Crops Prod. 2020, 146, 112177. [Google Scholar] [CrossRef]

- Mittal, A.; Katahira, R.; Donohoe, B.S.; Pattathil, S.; Kandemkavil, S.; Reed, M.L.; Biddy, M.J.; Beckham, G.T. Ammonia pretreatment of corn stover enables facile lignin extraction. ACS Sustain. Chem. Eng. 2017, 5, 2544–2561. [Google Scholar] [CrossRef]

- Miyamoto, T.; Mihashi, A.; Yamamura, M.; Tobimatsu, Y.; Suzuki, S.; Takada, R.; Kobayashi, Y.; Umezawa, T. Comparative analysis of lignin chemical structures of sugarcane bagasse pretreated by alkaline, hydrothermal, and dilute sulfuric acid methods. Ind. Crops Prod. 2018, 121, 124–131. [Google Scholar] [CrossRef]

- Zhang, L.; Xu, Z.; Cort, J.R.; Vuorinen, T.; Yang, B. Flowthrough pretreatment of softwood under water-only and alkali conditions. Energy Fuels 2020, 34, 16310–16319. [Google Scholar] [CrossRef]

- Lu, X.; Gu, X.; Shi, Y. A review on lignin antioxidants: Their sources, isolations, antioxidant activities and various applications. Int. J. Biol. Macromol. 2022, 210, 716–741. [Google Scholar] [CrossRef]

| Entry | X1 c | X2 d | X3 e | Solid Remain % | Cellulose % | Hemicellulose % | Lignin % | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Content | Recovery | Content | Recovery | Content | Delignification | |||||

| Raw | - | - | - | - | 34.91 | - | 22.58 | - | 23.03 | - |

| 1 a | 15 | 3:1 | 6 | 57.40 | 49.00 | 80.56 | 23.22 | 59.03 | 15.05 | 62.50 |

| 2 a | 25 | 2:1 | 6 | 63.00 | 44.32 | 79.98 | 21.77 | 60.73 | 16.89 | 53.81 |

| 3 a | 25 | 3:1 | 4 | 64.10 | 45.80 | 84.09 | 22.55 | 64.02 | 16.75 | 53.37 |

| 4 a | 15 | 2:1 | 4 | 52.31 | 38.09 | 57.07 | 20.52 | 47.55 | 18.03 | 59.05 |

| 5 a | 15 | 3:1 | 2 | 59.14 | 44.86 | 76.00 | 23.89 | 62.56 | 17.55 | 54.94 |

| 6 a | 15 | 1:1 | 2 | 55.56 | 35.93 | 57.19 | 19.62 | 48.27 | 18.75 | 54.77 |

| 7 a | 25 | 2:1 | 2 | 61.29 | 40.16 | 70.50 | 23.22 | 63.03 | 18.65 | 50.36 |

| 8 a | 25 | 1:1 | 4 | 72.63 | 41.15 | 85.61 | 21.19 | 68.16 | 19.77 | 37.67 |

| 9 a | 15 | 2:1 | 4 | 58.42 | 44.69 | 74.79 | 23.25 | 60.15 | 15.45 | 60.80 |

| 10 a | 5 | 2:1 | 6 | 69.26 | 41.80 | 82.93 | 21.95 | 67.32 | 20.83 | 37.36 |

| 11 a | 5 | 3:1 | 4 | 58.38 | 47.13 | 78.81 | 23.76 | 61.44 | 16.83 | 57.35 |

| 12 a | 5 | 2:1 | 2 | 68.16 | 40.72 | 79.51 | 22.49 | 67.90 | 20.07 | 40.60 |

| 13 a | 5 | 1:1 | 4 | 62.08 | 41.40 | 73.63 | 22.43 | 61.67 | 20.95 | 43.54 |

| 14 a | 15 | 2:1 | 4 | 58.16 | 40.35 | 67.23 | 21.19 | 54.58 | 16.21 | 59.06 |

| 15 a | 15 | 2:1 | 4 | 51.02 | 39.84 | 58.23 | 21.34 | 48.22 | 16.17 | 64.17 |

| 16 a | 15 | 2:1 | 4 | 51.02 | 39.02 | 57.03 | 20.62 | 46.58 | 17.40 | 61.45 |

| 17 a | 15 | 1:1 | 6 | 65.85 | 34.86 | 65.75 | 19.16 | 55.88 | 17.24 | 50.70 |

| 18 b | 19 | 2.1:1 | 4.8 | 60.36 | 50.26 | 86.90 | 25.65 | 68.57 | 14.32 | 62.47 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, Y.; Liu, H.; Shan, J.; Sun, B.; Chen, Y.; Ji, L.; Ji, X.; Wang, J.; Zhu, C.; Ying, H. Ammonia–Mechanical Pretreatment of Wheat Straw for the Production of Lactic Acid and High-Quality Lignin. Fermentation 2023, 9, 177. https://doi.org/10.3390/fermentation9020177

Cao Y, Liu H, Shan J, Sun B, Chen Y, Ji L, Ji X, Wang J, Zhu C, Ying H. Ammonia–Mechanical Pretreatment of Wheat Straw for the Production of Lactic Acid and High-Quality Lignin. Fermentation. 2023; 9(2):177. https://doi.org/10.3390/fermentation9020177

Chicago/Turabian StyleCao, Yulian, Haifeng Liu, Junqiang Shan, Baijun Sun, Yanjun Chen, Lei Ji, Xingxiang Ji, Jian Wang, Chenjie Zhu, and Hanjie Ying. 2023. "Ammonia–Mechanical Pretreatment of Wheat Straw for the Production of Lactic Acid and High-Quality Lignin" Fermentation 9, no. 2: 177. https://doi.org/10.3390/fermentation9020177

APA StyleCao, Y., Liu, H., Shan, J., Sun, B., Chen, Y., Ji, L., Ji, X., Wang, J., Zhu, C., & Ying, H. (2023). Ammonia–Mechanical Pretreatment of Wheat Straw for the Production of Lactic Acid and High-Quality Lignin. Fermentation, 9(2), 177. https://doi.org/10.3390/fermentation9020177