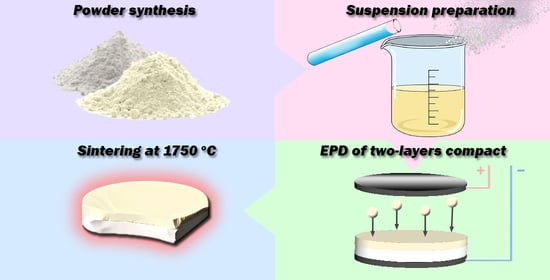

Electrophoretic Deposition of One- and Two-Layer Compacts of Holmium and Yttrium Oxide Nanopowders for Magneto-Optical Ceramics Fabrication

Abstract

:1. Introduction

2. Materials and Methods

2.1. Nanopowders and Suspensions of (Y0.9La0.1)2O3

2.2. Nanopowders and Suspensions of (Ho0.95La0.05)2O3

2.3. Characterization of the Suspensions and Electrophoretic Deposition (EPD)

2.3.1. Electrophoretic Deposition of One-Layer Compacts

2.3.2. Electrophoretic Deposition of Two-Layer Compacts

2.4. Sintering of the Ceramics

3. Results

3.1. Characteristics of (Y0.9La0.1)2O3 Nanopowders and Suspensions

3.2. Characteristics of (Ho0.95La0.05)2O3 Nanopowders and Suspensions

4. Discussion

4.1. Electrophoretic Deposition of Single-Layer Compacts from Suspensions of the YLa Nanopowders

4.2. Electrophoretic Deposition of One-Layer Compacts from Suspensions of HoLa Nanopowder

4.3. Electrophoretic Deposition of Two-Layer Compacts

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Snetkov, I.; Li, J. Selection of Magneto-Optical Material for a Faraday Isolator Operating in High-Power Laser Radiation. Magnetochemistry 2022, 8, 168. [Google Scholar] [CrossRef]

- Ikesue, A.; Aung, Y.L. Synthesis and Performance of Advanced Ceramic Lasers. J. Am. Ceram. Soc. 2006, 89, 1936–1944. [Google Scholar] [CrossRef]

- Tang, F.; Cao, Y.; Huang, J.; Liu, H.; Guo, W.; Wang, W. Fabrication and Laser Behavior of Composite Yb:YAG Ceramic. J. Am. Ceram. Soc. 2012, 95, 56–69. [Google Scholar] [CrossRef]

- Fujioka, K.; Guo, X.; Maruyama, M.; Kawanaka, J.; Miyanaga, N. Room-temperature bonding with post-heat treatment for composite Yb:YAG ceramic lasers. Opt. Mater. 2019, 91, 344–348. [Google Scholar] [CrossRef]

- Mukhin, I.; Perevezentsev, E.; Palashov, O. Fabrication of composite laser elements by a new thermal diffusion bonding method. Opt. Mater. Express 2014, 4, 266. [Google Scholar] [CrossRef]

- Kupp, E.R.; Messing, G.L.; Anderson, J.M.; Gopalan, V.; Dumm, J.Q.; Kraisinger, C.; Ter-Gabrielyan, N.; Merkle, L.D.; Dubinskii, M.; Simonaitis-Castillo, V.K.; et al. Co-casting and optical characteristics of transparent segmented composite Er:YAG laser ceramics. J. Mater. Res. 2010, 25, 476–483. [Google Scholar] [CrossRef]

- Ichikawa, H.; Yamaguchi, K.; Katsumata, T.; Shoji, I. High-power and highly efficient composite laser with an anti-reflection coated layer between a laser crystal and a diamond heat spreader fabricated by room-temperature bonding. Opt. Express 2017, 25, 22797. [Google Scholar] [CrossRef]

- Balabanov, S.; Filofeev, S.; Ivanov, M.; Kaigorodov, A.; Kuznetsov, D.; Hu, D.J.; Li, J.; Palashov, O.; Permin, D.; Rostokina, E.; et al. Fabrication and characterizations of holmium oxide based magneto-optical ceramics. Opt. Mater. 2020, 101, 109741. [Google Scholar] [CrossRef]

- Jin, L.; Zhou, G.; Shimai, S.; Zhang, J.; Wang, S. ZrO2-doped Y2O3 transparent ceramics via slip casting and vacuum sintering. J. Eur. Ceram. Soc. 2010, 30, 2139–2143. [Google Scholar] [CrossRef]

- Dutta, S.K.; Gazza, G.E.; Bull, M.R. Gazza, Transparent Y2O3 by hot-pressing. Mater. Res. Bull. 1969, 4, 791–796. [Google Scholar] [CrossRef]

- Majima, K.; Niimi, N.; Watanabe, M.; Katsuyama, S.; Nagai, H. Effect of LiF addition on the preparation of transparent Y2O3 by the vacuum hot pressing method. J. Alloys Compd. 1993, 193, 280–282. [Google Scholar] [CrossRef]

- Balabanov, S.; Filofeev, S.; Kaygorodov, A.; Khrustov, V.; Kuznetsov, D.; Novikova, A.; Permin, D.; Popov, P.; Ivanov, M. Hot pressing of Ho2O3 and Dy2O3 based magneto-optical ceramics. Opt. Mater. X 2022, 13, 100125. [Google Scholar] [CrossRef]

- Ikesue, A.; Kamata, K.; Yoshida, K. Synthesis of Transparent Nd-doped HfO2-Y2O3 Ceramics Using HIP. J. Am. Ceram. Soc. 1996, 79, 359–364. [Google Scholar] [CrossRef]

- Mouzon, J.; Maitre, A.; Frisk, L.; Lehto, N.; Odén, M. Fabrication of transparent yttria by HIP and the glass-encapsulation method. J. Eur. Ceram. Soc. 2009, 29, 311–316. [Google Scholar] [CrossRef]

- Hu, D.; Li, X.; Zhang, L.; Snetkov, I.; Chen, P.; Dai, Z.; Balabanov, S.; Palashov, O.; Li, J. Terbium (III) Oxide (Tb2O3) Transparent Ceramics by Two-Step Sintering from Precipitated Powder. Magnetochemistry 2022, 8, 73. [Google Scholar] [CrossRef]

- Xin, Y.; Xu, T.; Wang, Y.; Luo, P.; Li, W.; Kang, B.; Mei, B.; Jing, W. Effect of ZrO2 Content on Microstructure Evolution and Sintering Properties of (Tb0.7Lu0.3)2O3 Magneto-Optic Transparent Ceramics. Magnetochemistry 2022, 8, 175. [Google Scholar] [CrossRef]

- Yin, D.; Wang, J.; Ni, M.; Liu, P.; Dong, Z.; Tang, D. Fabrication of Highly Transparent Y2O3 Ceramics with CaO as Sintering Aid. Materials 2021, 14, 444. [Google Scholar] [CrossRef]

- Chaim, R.; Shlayer, A.; Estournes, C. Densification of nanocrystalline Y2O3 ceramic powder by spark plasma sintering. J. Eur. Ceram. Soc. 2009, 29, 91–98. [Google Scholar] [CrossRef]

- Frage, N.; Cohen, S.; Meir, S.; Kalabukhov, S.; Dariel, M.P. Spark plasma sintering (SPS) of transparent magnesium-aluminate spinel. J. Mater. Sci. 2007, 42, 3273–3275. [Google Scholar] [CrossRef]

- Appiagyei, K.A.; Messing, G.L.; Dumm, J.Q. Aqueous slip casting of transparent yttrium aluminum garnet (YAG) ceramics. Ceram. Int. 2008, 34, 1309–1313. [Google Scholar] [CrossRef]

- Bredol, M.; Micior, J.; Klemme, S. Electrophoretic deposition of alumina, yttria, yttrium aluminium garnet and lutetium aluminium garnet. J. Mater. Sci. 2014, 49, 6975–6985. [Google Scholar] [CrossRef]

- Derjaguin, B.V.; Dukhin, S.S.; Shilov, V.N. Kinetic aspects of electrochemistry of disperse systems. Part I. Introduction. Adv. Colloid. Interface Sci. 1980, 13, 141–152. [Google Scholar] [CrossRef]

- Ivanov, M.; Kalinina, E.; Kopylov, Y.; Kravchenko, V.; Krutikova, I.; Kynast, U.; Li, J.; Leznina, M.; Medvedev, A. Highly transparent Yb-doped (LaxY1−x)2O3 ceramics prepared through colloidal methods of nanoparticles compaction. J. Eur. Ceram. Soc. 2016, 36, 4251–4259. [Google Scholar] [CrossRef]

- Kalinina, E.; Ivanov, M. The Electrophoretic Deposition of Nanopowders Based on Yttrium Oxide for Bulk Ceramics Fabrication. Inorganics 2022, 10, 243. [Google Scholar] [CrossRef]

- Ivanov, M.; Kopylov, Y.; Kravchenko, V.; Zayats, S. Sintering and optical quality of highly transparent Yb-doped yttrium lanthanum oxide ceramics. Phys. Status Solidi (C) Curr. Top. Solid. State Phys. 2013, 10, 940–944. [Google Scholar] [CrossRef]

- Nakamura, Y.; Isobe, K.; Morita, H.; Yamazaki, S.; Kawaguchi, S. Metal complexes containing acetylacetone as a neutral ligand. Inorg. Chem. 1972, 11, 1573–1578. [Google Scholar] [CrossRef]

- Della Negra, M.; Foghmoes, S.P.V.; Klemensø, T. Complementary analysis techniques applied on optimizing suspensions of yttria stabilized zirconia. Ceram. Int. 2016, 42, 14443–14451. [Google Scholar] [CrossRef]

- Bhattacharjee, S. DLS and zeta potential—What they are and what they are not? J. Control Release 2016, 235, 337–351. [Google Scholar] [CrossRef]

- Henry, D. The cataphoresis of suspended particles. Part I.—The equation of cataphoresis, Proceedings of the Royal Society of London. Series A. Contain. Pap. A Math. Phys. Character 1931, 133, 106–129. [Google Scholar] [CrossRef]

- Zhang, X.; Huang, X.; Liu, Z.; Feng, Y.; Jiang, N.; Wu, L.; Yang, Z.; Xie, T.; Li, J. Fabrication, microstructure and properties of transparent Yb:Y2O3 ceramics from co-precipitated nanopowders. Opt. Mater. 2021, 122, 111792. [Google Scholar] [CrossRef]

| Powders | Dispersion Medium | ζ–Potential, mV |

|---|---|---|

| 76YLa | iPrOH | +4 |

| iPrOH + AcAc (1 mg/m2) | +49 | |

| iPrOH + AcAc (1 mg/m2) + PVB (1 mg/m2) | +29 | |

| 76YLa_milling | iPrOH | +11 |

| iPrOH + AcAc (1 mg/m2) | +49 | |

| 80YLa | iPrOH | +13 |

| iPrOH + AcAc (1 mg/m2) | +69 | |

| iPrOH + AcAc (1 mg/m2) + PVB (1 mg/m2) | +67 | |

| HoLa | iPrOH | +16 |

| iPrOH + AcAc (1 mg/m2) | +86 | |

| iPrOH + AcAc (1 mg/m2) + PVB (1 mg/m2) | +80 |

| Sample | Suspension | Dispersion Medium | Mode of EPD (Voltage, Time); Mass/Thickness/Density of the Green Body |

|---|---|---|---|

| 76YLa_1 | 76YLa_AcAc | iPrOH/AcAc | 20 V, 150 min; 440 mg/1.6 mm/43% |

| 76YLa_2 | 76YLa_PVB aged for 14 days | iPrOH/AcAc/PVB | 20 V, 150 min; 175 mg/1 mm/32% |

| 76YLa_3 | 76YLa_milling | iPrOH/AcAc | 20 V, 150 min; 524 mg/2.5 mm/37% |

| 80YLa_1 | 80YLa | iPrOH/AcAc/PVB | 20 V, 120 min; 250 mg/1.5 mm/38% |

| 80YLa_2 | 80YLa aged for 14 days | iPrOH/AcAc/PVB | 20 V, 120 min; 171 mg/1.0 mm/32% |

| HoLa_1 | HoLa_AcAc | iPrOH/AcAc | 40 V, 120 min; 751 mg/1.9 mm/30% |

| HoLa_2 | HoLa_PVB | iPrOH/AcAc/PVB | 40 V, 120 min; 447 mg/1.5 mm/32% |

| Sample | Suspension | Dispersion Medium | Mode of EPD (Voltage, Time); Mass/Thickness/Fraction of the Layer | Density of the Green Body, % of Theoretical * |

|---|---|---|---|---|

| 76YLa/HoLa_1 | 76YLa_milling | iPrOH/AcAc | 20 V, 120 min; 570 mg/1.6 mm/0.62 | 46 |

| HoLa_PVB | iPrOH/AcAc/PVB | 40 V, 150 min; 356 mg/1.0 mm/0.38 | ||

| 80YLa/HoLa_2 | 80YLa_PVB | iPrOH/AcAc/PVB | 20 V, 120 min; 266 mg/0.7 mm/0.58 | 46 |

| HoLa_PVB | iPrOH/AcAc/PVB | 40 V, 90 min; 190 mg/0.5 mm/0.42 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kalinina, E.G.; Kundikova, N.D.; Kuznetsov, D.K.; Ivanov, M.G. Electrophoretic Deposition of One- and Two-Layer Compacts of Holmium and Yttrium Oxide Nanopowders for Magneto-Optical Ceramics Fabrication. Magnetochemistry 2023, 9, 227. https://doi.org/10.3390/magnetochemistry9110227

Kalinina EG, Kundikova ND, Kuznetsov DK, Ivanov MG. Electrophoretic Deposition of One- and Two-Layer Compacts of Holmium and Yttrium Oxide Nanopowders for Magneto-Optical Ceramics Fabrication. Magnetochemistry. 2023; 9(11):227. https://doi.org/10.3390/magnetochemistry9110227

Chicago/Turabian StyleKalinina, Elena G., Nataliya D. Kundikova, Dmitrii K. Kuznetsov, and Maxim G. Ivanov. 2023. "Electrophoretic Deposition of One- and Two-Layer Compacts of Holmium and Yttrium Oxide Nanopowders for Magneto-Optical Ceramics Fabrication" Magnetochemistry 9, no. 11: 227. https://doi.org/10.3390/magnetochemistry9110227

APA StyleKalinina, E. G., Kundikova, N. D., Kuznetsov, D. K., & Ivanov, M. G. (2023). Electrophoretic Deposition of One- and Two-Layer Compacts of Holmium and Yttrium Oxide Nanopowders for Magneto-Optical Ceramics Fabrication. Magnetochemistry, 9(11), 227. https://doi.org/10.3390/magnetochemistry9110227