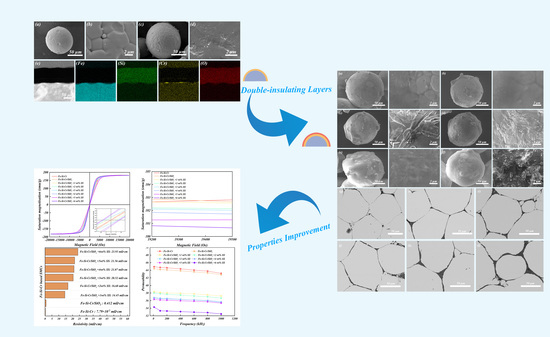

Fabrication and Soft Magnetic Properties of Fe–Si–Cr Composites with Double-Insulating Layers Suitable for High-Frequency Power Applications

Abstract

:1. Introduction

2. Experimental

2.1. Chemicals

2.2. Synthesis

2.3. Characterization

3. Results and Discussion

3.1. Microstructures of Fe–Si–Cr/SiO2 Core-Shell Materials

3.2. Microstructures and Magnetic Properties of the Alloy Powders and SMCs with Double Layers

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, D.; Wu, C.; Yan, M.; Wang, J. Correlating the microstructure, growth mechanism and magnetic properties of FeSiAl soft magnetic composites fabricated via HNO3 oxidation. Acta Mater. 2018, 146, 294–303. [Google Scholar] [CrossRef]

- Wu, X.; Ding, J.; Kong, Y.; Sun, Z.; Shao, G.; Li, B.; Wu, J.; Zhong, Y.; Shen, X.; Cui, S. Synthesis of a novel three-dimensional Na2SO4@SiO2@Al2O3-SiO2 phase change material doped aerogel composite with high thermal resistance and latent heat. Ceram. Int. 2018, 44, 21855–21865. [Google Scholar] [CrossRef]

- Zhong, X.; Chen, J.; Wang, L.; Li, B.; Li, L. Properties of FeSiAl-based soft magnetic composites with AlN/Al2O3 and hybrid phosphate–silane insulation coatings. J. Alloys Compd. 2018, 735, 1603–1610. [Google Scholar] [CrossRef]

- Evangelista, L.L.; Filho, A.I.R.; Silva, B.S.; Hammes, G.; Binder, C.; Klein, A.N.; Drago, V. Magnetic properties optimization of an iron-based soft magnetic composite coated by nano-ZnO and boron oxide. J. Magn. Magn. Mater. 2021, 539, 168319. [Google Scholar] [CrossRef]

- Taghvaei, A.H.; Shokrollahi, H.; Janghorban, K.; Abiri, H. Eddy current and total power loss separation in the iron–phosphate–polyepoxy soft magnetic composites. Mater. Des. 2009, 30, 3989–3995. [Google Scholar] [CrossRef]

- Wu, Z.; Xian, C.; Jia, J.; Liao, X.; Kong, H.; Xu, K. Formation Process of the Integrated Core(Fe-6.5wt.%Si)@Shell(SiO2) Structure Obtained via Fluidized Bed Chemical Vapor Deposition. Metals 2020, 10, 520. [Google Scholar] [CrossRef]

- Wang, R.; He, Y.; Kong, H.; Wang, J.; Wu, Z.; Wang, H. Influence of sintering temperature on heterogeneous-interface structural evolution and magnetic properties of Fe–Si soft magnetic powder cores. Ceram. Int. 2022, 48, 29854–29861. [Google Scholar] [CrossRef]

- Gemeay, A.H.; Keshta, B.E.; El-Sharkawy, R.G.; Zaki, A.B. Chemical insight into the adsorption of reactive wool dyes onto amine-functionalized magnetite/silica core-shell from industrial wastewaters. Environ. Sci. Pollut. Res. Int. 2020, 27, 32341–32358. [Google Scholar] [CrossRef]

- de Moura, S.G.; Ramalho, T.C.; de Oliveira, L.C.A.; Dauzakier, L.C.L.; Magalhães, F. Photocatalytic degradation of methylene blue dye by TiO2 supported on magnetic core shell (Si@Fe) surface. J. Iran. Chem. Soc. 2022, 19, 921–935. [Google Scholar] [CrossRef]

- Kim, M.T. Deposition behavior of hexamethydisiloxane films based on the FTIR analysis of Si–O–Si and Si–CH3 bonds. Thin Solid Films 1997, 311, 157–163. [Google Scholar] [CrossRef]

- Sun, K.; Feng, S.; Jiang, Q.; Li, X.; Li, Y.; Fan, R.; An, Y.; Wang, J. Intergranular insulating reduced iron powder-carbonyl iron powder/SiO2-Al2O3 soft magnetic composites with high saturation magnetic flux density and low core loss. J. Magn. Magn. Mater. 2020, 493, 165705. [Google Scholar] [CrossRef]

- Tarhan, İ.; Derin, Z.; Erdem, M.A. The study of Middle Bronze Age pottery from Yassıtepe Höyük site in İzmir, Turkey, by FTIR and XRD with chemometrics. J. Archaeol. Sci. Rep. 2022, 42, 103401. [Google Scholar]

- Swamy, S.K.K.; Ramaprasad, A.T. FTIR signal assignment in Chitin using density functional theory calculations—A monomer approximation. Mater. Today Proc. 2022, 66, 2504–2507. [Google Scholar] [CrossRef]

- Lebugle, A.; Axelsson, U.; Nyholm, R.; Mårtensson, N. Experimental and Core Level Binding Energies for the Metals. Phys. Scr. 1981, 23, 825–827. [Google Scholar] [CrossRef]

- Guo, Y.; Jian, X.; Zhang, L.; Mu, C.; Yin, L.; Xie, J.; Mahmood, N.; Dou, S.; Che, R.; Deng, L. Plasma-induced FeSiAl@Al2O3@SiO2 core–shell structure for exceptional microwave absorption and anti-oxidation at high temperature. Chem. Eng. J. 2020, 384, 123371. [Google Scholar] [CrossRef]

- González-Flores, K.E.; Horley, P.; Cabañas-Tay, S.A.; Pérez-García, S.A.; Licea-Jiménez, L.; Palacios-Huerta, L.; Aceves-Mijares, M.; Moreno-Moreno, M.; Morales-Sánchez, A. Analysis of the conduction mechanisms responsible for multilevel bipolar resistive switching of SiO2/Si multilayer structures. Superlattices Microstruct. 2020, 137, 106347. [Google Scholar] [CrossRef]

- Dong, B.; Qin, W.; Su, Y.; Wang, X. Magnetic properties of FeSiCr@MgO soft magnetic composites prepared by magnesium acetate pyrolysis for high-frequency applications. J. Magn. Magn. Mater. 2021, 539, 168350. [Google Scholar] [CrossRef]

- Tajabadi, M.; Rahmani, I.; Mirkazemi, S.M.; Orimi, H.G. Insights into the synthesis optimization of Fe@SiO2 Core-Shell nanostructure as a highly efficient nano-heater for magnetic hyperthermia treatment. Adv. Powder Technol. 2021, 33, 103366. [Google Scholar] [CrossRef]

- Zheng, J.; Zheng, D.; Qiao, L.; Ying, Y.; Tang, Y.; Cai, W.; Li, W.; Yu, J.; Li, J.; Che, S. High permeability and low core loss Fe-based soft magnetic composites with Co-Ba composite ferrite insulation layer obtained by sol-gel method. J. Alloys Compd. 2022, 893, 663. [Google Scholar] [CrossRef]

- Dippong, T.; Levei, E.A.; Leostean, C.; Cadar, O. Impact of annealing temperature and ferrite content embedded in SiO2 matrix on the structure, morphology and magnetic characteristics of (Co0.4Mn0.6Fe2O4)δ (SiO2)100-δ nanocomposites. J. Alloys Compd. 2021, 868, 159203. [Google Scholar] [CrossRef]

- Guan, W.W.; Shi, X.Y.; Xu, T.T.; Wan, K.; Zhang, B.W.; Liu, W.; Su, H.L.; Zou, Z.Q.; Du, Y.W. Synthesis of well-insulated Fe–Si–Al soft magnetic composites via a silane-assisted organic/inorganic composite coating route. J. Phys. Chem. Solids 2021, 150, 109841. [Google Scholar] [CrossRef]

- Nell, M.M.; Schauerte, B.; Brimmers, T.; Hameyer, K. Simulation of iron losses in induction machines using an iron loss model for rotating magnetization loci in no electrical steel. COMPEL-Int. J. Comput. Math. Electr. Electron. Eng. 2022, 41, 600–614. [Google Scholar] [CrossRef]

- Guo, Z.; Wang, J.; Chen, W.; Chen, D.; Sun, H.; Xue, Z.; Wang, C. Crystal-like microstructural Finemet/FeSi compound powder core with excellent soft magnetic properties and its loss separation analysis. Mater. Des. 2020, 192, 108769. [Google Scholar] [CrossRef]

- Qiu, Y.; Wang, R.; He, Y.; Kong, H.; Li, S.; Wu, Z. Effects of axial pressure on the evolution of core–shell heterogeneous structures and magnetic properties of Fe–Si soft magnetic powder cores during hot-press sintering. RSC Adv. 2022, 12, 19875–19884. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Li, S.; Zhang, W.; Peng, K. Influence of processed parameters on the magnetic properties of Fe/Fe3O4 composite cores. J. Mater. Sci. Mater. Electron. 2020, 32, 1233–1241. [Google Scholar] [CrossRef]

- Huang, Z.; Huang, H.; He, H.; Wu, Z.; Wang, X.; Wang, R. Effect of Various Metal Oxide Insulating Layers on the Magnetic Properties of Fe-Si-Cr Systems. Coatings 2023, 13, 804. [Google Scholar] [CrossRef]

- Hsiang, H.; Wang, S.; Chen, C. Electromagnetic properties of FeSiCr alloy powders modified with amorphous SiO2. J. Magn. Magn. Mater. 2020, 514, 167151. [Google Scholar] [CrossRef]

- Guo, R.; Yu, G.; Zhu, M.; Qiu, Y.; Wu, G.; Zhou, H. Regulation of magnetic and electrical performances in core- shell-structured FeSiCr@BaTiO3 soft magnetic composites. J. Alloys Compd. 2022, 895, 162724. [Google Scholar] [CrossRef]

- Yu, H.; Zhou, S.; Zhang, G.; Dong, B.; Meng, L.; Li, Z. The phosphating effect on the properties of FeSiCr alloy powder. J. Magn. Magn. Mater. 2022, 552, 168741. [Google Scholar] [CrossRef]

| Sample | Density (g/cm3) |

|---|---|

| Fe-Si-Cr SMCs | 7.11 ± 0.015 |

| Fe-Si-Cr/SiO2 SMCs | 7.02 ± 0.017 |

| Fe-Si-Cr/SiO2 SMCs with 1 wt% SS | 6.52 ± 0.017 |

| Fe-Si-Cr/SiO2 SMCs with 2 wt% SS | 6.43 ± 0.023 |

| Fe-Si-Cr/SiO2 SMCs with 3 wt% SS | 6.39 ± 0.007 |

| Fe-Si-Cr/SiO2 SMCs with 4 wt% SS | 6.27 ± 0.012 |

| Fe-Si-Cr/SiO2 SMCs with 5 wt% SS | 5.85 ± 0.025 |

| Fe-Si-Cr/SiO2 SMCs with 6 wt% SS | 5.69 ± 0.031 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Z.; Huang, H.; He, H.; Li, K.; Wu, Z.; Wang, R. Fabrication and Soft Magnetic Properties of Fe–Si–Cr Composites with Double-Insulating Layers Suitable for High-Frequency Power Applications. Magnetochemistry 2023, 9, 145. https://doi.org/10.3390/magnetochemistry9060145

Huang Z, Huang H, He H, Li K, Wu Z, Wang R. Fabrication and Soft Magnetic Properties of Fe–Si–Cr Composites with Double-Insulating Layers Suitable for High-Frequency Power Applications. Magnetochemistry. 2023; 9(6):145. https://doi.org/10.3390/magnetochemistry9060145

Chicago/Turabian StyleHuang, Zhenyi, Huaqin Huang, Hao He, Kaixuan Li, Zhaoyang Wu, and Rui Wang. 2023. "Fabrication and Soft Magnetic Properties of Fe–Si–Cr Composites with Double-Insulating Layers Suitable for High-Frequency Power Applications" Magnetochemistry 9, no. 6: 145. https://doi.org/10.3390/magnetochemistry9060145

APA StyleHuang, Z., Huang, H., He, H., Li, K., Wu, Z., & Wang, R. (2023). Fabrication and Soft Magnetic Properties of Fe–Si–Cr Composites with Double-Insulating Layers Suitable for High-Frequency Power Applications. Magnetochemistry, 9(6), 145. https://doi.org/10.3390/magnetochemistry9060145