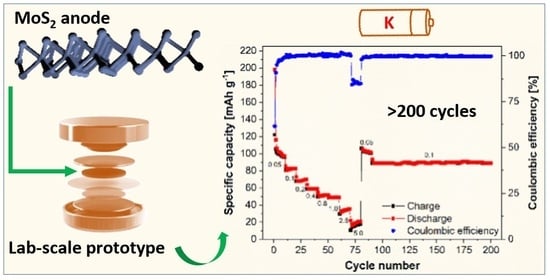

An Exploratory Study of MoS2 as Anode Material for Potassium Batteries

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Long, J.; Yang, Z.; Yang, F.; Cuan, J.; Wu, J. Electrospun core-shell Mn3O4/carbon fibers as high-performance cathode materials for aqueous zinc-ion batteries. Electrochim. Acta 2020, 344, 136155. [Google Scholar] [CrossRef]

- Nederstedt, H.; Jannasch, P. Poly(p-phenylene)s tethered with oligo(ethylene oxide): Synthesis by Yamamoto polymerization and properties as solid polymer electrolytes. Polym. Chem. 2020, 11, 2418–2429. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Li, J.; He, X.; Zhang, X.; Yan, B.; Hou, X.; Du, L.; Placke, T.; Winter, M.; Li, J. A three-dimensional TiO2-Graphene architecture with superior Li ion and Na ion storage performance. J. Power Sources 2020, 461, 228129. [Google Scholar] [CrossRef]

- Li, L.; Deng, Y.; Chen, G. Status and prospect of garnet/polymer solid composite electrolytes for all-solid-state lithium batteries. J. Energy Chem. 2020, 50, 154–177. [Google Scholar] [CrossRef]

- Liu, F.; Li, T.; Yang, Y.; Yan, J.; Li, N.; Xue, J.; Huo, H.; Zhou, J.; Li, L. Investigation on the Copolymer Electrolyte of Poly(1,3-dioxolane-co-formaldehyde). Macromol. Rapid Commun. 2020, 41, e2000047. [Google Scholar] [CrossRef]

- Kou, Z.; Liu, C.; Miao, C.; Mei, P.; Yan, X.; Xiao, W. High-performance gel polymer electrolytes using P (VDF-HFP) doped with appropriate porous carbon powders as the matrix for lithium-ion batteries. Ionics 2020, 26, 1729–1737. [Google Scholar] [CrossRef]

- González, F.; Garcia-Calvo, O.; Tiemblo, P.; García, N.; Fedeli, E.; Thieu, T.; Urdampilleta, I.; Kvasha, A. Synergy of inorganic fillers in composite thermoplastic polymer/ionic liquid/LiTFSI electrolytes. J. Electrochem. Soc. 2020, 167, 070519. [Google Scholar] [CrossRef] [Green Version]

- Cao, X.; Cheng, J.; Zhang, X.; Zhou, D.; Tong, Y. Composite Polymer Electrolyte based on Liquid Crystalline Copolymer with High-temperature Stability and Bendability for All-solid-state Lithium-ion Batteries. Int. J. Electrochem. Sci. 2020, 15, 677–695. [Google Scholar] [CrossRef]

- Yang, X.; Luo, J.; Sun, X. Towards high-performance solid-state Li–S batteries: From fundamental understanding to engineering design. Chem. Soc. Rev. 2020, 49, 2140–2195. [Google Scholar] [CrossRef]

- Costa, C.M.; Lizundia, E.; Lanceros-Méndez, S. Review—Polymers for advanced lithium-ion batteries: State of the art and future needs on polymers for the different battery components. Prog. Energy Combust. Sci. 2020, 79, 100846. [Google Scholar] [CrossRef]

- Boz, B.; Dev, T.; Salvadori, A.; Schaefer, J.L. Electrolyte and electrode designs for enhanced ion transport properties to enable high performance lithium batteries. J. Electrochem. Soc. 2021, 168, 090501. [Google Scholar] [CrossRef]

- Zhang, D.; Tan, C.; Ou, T.; Zhang, S.; Li, L.; Ji, X. Constructing advanced electrode materials for low-temperature lithium-ion batteries: A review. Energy Rep. 2022, 8, 4525–4534. [Google Scholar] [CrossRef]

- Eshetu, G.G.; Elia, G.A.; Armand, M.; Forsyth, M.; Komaba, S.; Rojo, T.; Passerini, S. Electrolytes and interphases in sodium-based rechargeable batteries: Recent advances and perspectives. Adv. Energy Mater. 2020, 10, 2000093. [Google Scholar] [CrossRef] [Green Version]

- Chen, G.; Huang, J.; Gu, J.; Peng, S.; Xiang, X.; Chen, K.; Yang, X.; Guan, L.; Jiang, X.; Hou, L. Highly tough supramolecular double network hydrogel electrolytes for an artificial flexible and low-temperature tolerant sensor. J. Mater. Chem. A 2020, 8, 6776–6784. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, J.; Zhang, J.; Hao, S.; Duan, X.; Song, H.; Zhang, J. Novel chemically cross-linked chitosan-cellulose based ionogel with self-healability, high ionic conductivity, and high thermo-mechanical stability. Cellulose 2020, 27, 5121–5133. [Google Scholar] [CrossRef]

- Gao, Y.; Pan, Z.; Sun, J.; Liu, Z.; Wang, J. High-Energy Batteries: Beyond Lithium-Ion and Their Long Road to Commercialisation. Nano-Micro Lett. 2022, 14, 94. [Google Scholar] [CrossRef]

- Zaman, W.; Hatzell, K.B. Processing and manufacturing of next generation lithium-based all solid-state batteries. Curr. Opin. Solid State Mater. Sci. 2022, 26, 101003. [Google Scholar] [CrossRef]

- Cheng, J.; Cao, X.; Zhou, D.; Tong, Y. Preparation of SiO2 grafted polyimidazole solid electrolyte for lithium-ion batteries. Ionics 2020, 26, 3883–3892. [Google Scholar] [CrossRef]

- Rao, J.; Wang, X.; Yunis, R.; Ranganathan, V.; Howlett, P.C.; MacFarlane, D.R.; Forsyth, M.; Zhu, H. A novel proton conducting ionogel electrolyte based on poly (ionic liquids) and protic ionic liquid. Electrochim. Acta 2020, 346, 136224. [Google Scholar] [CrossRef]

- Shi, M.; Xiao, P.; Yang, C.; Sheng, Y.; Wang, B.; Jiang, J.; Zhao, L.; Yan, C.J. Scalable gas-phase synthesis of 3D microflowers confining MnO2 nanowires for highly-durable aqueous zinc-ion batteries. J. Power Sources 2020, 463, 228209. [Google Scholar] [CrossRef]

- Xu, J.; Dou, S.; Cui, X.; Liu, W.; Zhang, Z.; Deng, Y.; Hu, W.; Chen, Y. Potassium-based electrochemical energy storage devices: Development status and future prospect. Energy Storage Mater. 2021, 34, 85–106. [Google Scholar] [CrossRef]

- Meng, Y.; Nie, C.; Guo, W.; Liu, D.; Chen, Y.; Ju, Z.; Zhuang, Q. Inorganic cathode materials for potassium ion batteries. Mater. Today Energy 2022, 25, 100982. [Google Scholar] [CrossRef]

- Lei, H.; Li, J.; Zhang, X.; Ma, L.; Ji, Z.; Wang, Z.; Pan, L.; Tan, S.; Mai, W. A review of hard carbon anode: Rational design and advanced characterization in potassium ion batteries. InfoMat 2022, 4, e12272. [Google Scholar] [CrossRef]

- Tyagi, A.; Puravankara, S. Insights into the diverse precursor-based micro-spherical hard carbons as anode materials for sodium–ion and potassium–ion batteries. Mater. Adv. 2022, 3, 810–836. [Google Scholar]

- Liu, Y.; Gao, C.; Dai, L.; Deng, Q.; Wang, L.; Luo, J.; Liu, S.; Hu, N. The features and progress of electrolyte for potassium ion batteries. Small 2020, 16, 2004096. [Google Scholar] [CrossRef]

- Trano, S.; Corsini, F.; Pascuzzi, G.; Giove, E.; Fagiolari, L.; Amici, J.; Francia, C.; Turri, S.; Bodoardo, S.; Griffini, G.; et al. Lignin as Polymer Electrolyte Precursor for Stable and Sustainable Potassium Batteries. ChemSusChem 2022, 15, e202200294. [Google Scholar] [CrossRef]

- Manarin, E.; Corsini, F.; Trano, S.; Fagiolari, L.; Amici, J.; Francia, C.; Bodoardo, S.; Turri, S.; Bella, F.; Griffini, G. Cardanol-Derived Epoxy Resins as Biobased Gel Polymer Electrolytes for Potassium-Ion Conduction. ACS Applied Polym. Mater. 2022, 4, 3855–3865. [Google Scholar] [CrossRef]

- Liu, S.; Kang, L.; Henzie, J.; Zhang, J.; Ha, J.; Amin, M.A.; Hossain, M.S.A.; Jun, S.C.; Yamauchi, Y. Recent advances and perspectives of battery-type anode materials for potassium ion storage. ACS Nano 2021, 15, 18931–18973. [Google Scholar] [CrossRef]

- Wang, Z.; Selbach, S.M.; Grande, T. Van der Waals density functional study of the energetics of alkali metal intercalation in graphite. RSC Adv. 2014, 4, 3973–3983. [Google Scholar] [CrossRef] [Green Version]

- Wu, X.Y.; Leonard, D.P.; Ji, X.L. Emerging non-aqueous potassium-ion batteries: Challenges and opportunities. Chem. Mater. 2017, 29, 5031–5042. [Google Scholar] [CrossRef]

- Eftekhari, A.; Jian, Z.; Ji, X. Potassium secondary batteries. ACS Appl. Mater. Interfaces 2017, 9, 4404–4419. [Google Scholar] [CrossRef] [PubMed]

- Jian, Z.L.; Luo, W.; Ji, X.L. Carbon electrodes for K-ion batteries. J. Am. Chem. Soc. 2015, 137, 11566–11569. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Zhou, J.; Wang, Z.; Zhao, L.; Li, P.; Yang, Y.; Yang, C.; Huang, H.; Guo, S. Short-range order in mesoporous carbon boosts potassium-ion battery performance. Adv. Energy Mater. 2018, 8, 1701648. [Google Scholar] [CrossRef]

- Zhang, R.; Li, H.; Li, R.; Wei, D.; Kang, W.; Ju, Z.; Xiong, S. Short-range order in mesoporous carbon boosts potassium-ion battery performance. Chem. Commun. 2019, 55, 14147–14150. [Google Scholar] [CrossRef]

- Lei, Y.; Qui, L.; Liu, R.; Lau, K.C.; Wu, Y.; Zhai, D.; Li, B.; Kang, F. Exploring stability of nonaqueous electrolytes for potassium-ion batteries. ACS Appl. Energy Mater. 2018, 1, 1828–1833. [Google Scholar] [CrossRef]

- Fan, L.; Ma, R.; Zhang, Q.; Jia, X.; Lu, B. Graphite Anode for a Potassium-Ion Battery with Unprecedented Performance. Angew. Chem. Int. Ed. 2019, 58, 10610–10615. [Google Scholar] [CrossRef]

- Fan, L.; Hu, Y.; Rao, A.M.; Zhou, J.; Hou, Z.; Wang, C.; Lu, B. Prospects of electrode materials and electrolytes for practical potassium-based batteries. Small Methods 2021, 5, 2101131. [Google Scholar] [CrossRef]

- Zhang, J.; Lai, L.; Wang, H.; Chen, M.; Shen, Z.X. Energy storage mechanisms of anode materials for potassium ion batteries. Mater. Today Energy 2021, 21, 100747. [Google Scholar] [CrossRef]

- Wang, D.; Tian, K.H.; Wang, J.; Wang, Z.Y.; Luo, S.H.; Liu, Y.G.; Wang, Q.; Zhang, Y.H.; Hao, A.M.; Yi, T.F. Sulfur-doped 3D hierarchical porous carbon network toward excellent potassium-ion storage performance. Rare Met. 2021, 40, 2464–2473. [Google Scholar] [CrossRef]

- Wang, F.; Liu, Y.; Wei, H.J.; Li, T.F.; Xiong, X.H.; Wei, S.Z.; Ren, F.Z.; Volinsky, A.A. Recent advances and perspective in metal coordination materials-based electrode materials for potassium-ion batteries. Rare Met. 2021, 40, 448–470. [Google Scholar] [CrossRef]

- Du, P.; Cao, L.; Zhang, B.; Wang, C.; Xiao, Z.; Zhang, J.; Wang, D.; Ou, X. Recent Progress on Heterostructure Materials for Next-Generation Sodium/Potassium Ion Batteries. Renew. Sustain. Energy Rev. 2021, 151, 111640. [Google Scholar] [CrossRef]

- Yuan, F.; Zhang, W.; Zhang, D.; Wang, Q.; Li, Z.; Li, W.; Sun, H.; Wang, B.; Wu, Y.A. Recent progress in electrochemical performance of carbon-based anodes for potassium-ion batteries based on first principles calculations. Nanotechnology 2021, 32, 472003. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, S.M.; Suo, G.; Wang, W.A.; Xi, K.; Iqbal, S.B. Improvement in potassium ion batteries electrodes: Recent developments and efficient approaches. J. Energy Chem. 2021, 62, 307–337. [Google Scholar] [CrossRef]

- Zhang, W.; Yin, J.; Wang, W.; Bayhan, Z.; Alshareef, H.N. Status of rechargeable potassium batteries. Nano Energy 2021, 83, 105792. [Google Scholar] [CrossRef]

- Ren, X.; Zhao, Q.; McCulloch, W.D.; Wu, Y. MoS2 as a long-life host material for potassium ion intercalation. Nano Res. 2017, 10, 1313–1321. [Google Scholar] [CrossRef]

- Zhang, J.; Cui, P.; Gu, Y.; Wu, D.; Tao, S.; Qian, B.; Chu, W.; Song, L. Encapsulating carbon-coated MoS2 nanosheets within a nitrogen-doped graphene network for high-performance potassium-ion storage. Adv. Mater. Interfaces 2019, 6, 1901066. [Google Scholar] [CrossRef]

- Jiang, Q.; Wang, L.; Chen, J.; Huang, Z.; Yang, H.-J.; Zhou, T.; Hu, J. Enhancing potassium-ion battery performance by MoS2 coated nitrogen-doped hollow carbon matrix. J. Alloys Compd. 2021, 855, 157505. [Google Scholar] [CrossRef]

- Zhou, Y.; Han, Q.; Liu, Y.; Wang, Y.; Jiang, F.; Wang, N.; Bai, Z.; Dou, S. Molybdenum chalcogenides based anode materials for alkali metal ions batteries: Beyond lithium ion batteries. Energy Storage Mater. 2022, 50, 308–333. [Google Scholar] [CrossRef]

- Rehman, J.; Fan, X.; Laref, A.; Dinh, V.A.; Zheng, W.T. Potential anodic applications of 2D MoS2 for K-ion batteries. J. Alloy. Compd. 2021, 865, 158782. [Google Scholar] [CrossRef]

- Choi, J.H.; Park, G.D.; Kang, Y.C. Potassium-ion storage mechanism of MoS2-WS2-C microspheres and their excellent electrochemical properties. Chem. Eng. J. 2021, 408, 127278. [Google Scholar] [CrossRef]

- Chong, S.; Sun, L.; Shu, C.; Guo, S.; Liu, Y.; Wang, W.; Liu, H.K. Chemical bonding boosts nano-rose-like MoS2 anchored on reduced graphene oxide for superior potassium-ion storage. Nano Energy 2019, 63, 103868. [Google Scholar] [CrossRef]

- Hosaka, T.; Matsuyama, T.; Kubota, K.; Tatara, R.; Komaba, S. KFSA/glyme electrolytes for 4 V-class K-ion batteries. J. Mater. Chem. A 2020, 8, 23766–23771. [Google Scholar] [CrossRef]

- Madec, L.; Gabaudan, V.; Gachot, G.; Stievano, L.; Monconduit, L.; Martinez, H. Paving the way for K-ion batteries: Role of electrolyte reactivity through the example of Sb-based electrodes. ACS Appl. Mater. Interfaces 2018, 10, 34116–34122. [Google Scholar] [CrossRef] [PubMed]

- Okoshi, M.; Yamada, Y.; Komaba, S.; Yamada, A.; Nakai, H. Theoretical analysis of interactions between potassium ions and organic electrolyte solvents: A comparison with lithium, sodium, and magnesium ions. J. Electrochem. Soc. 2017, 164, A54–A60. [Google Scholar] [CrossRef]

- Hosaka, T.; Komaba, S. Development of Nonaqueous Electrolytes for High-Voltage K-Ion Batteries. Bull. Chem. Soc. Jpn. 2022, 95, 569–581. [Google Scholar] [CrossRef]

- Na, J.H.; Kang, Y.C.; Park, S.K. Electrospun MOF-based ZnSe nanocrystals confined in N-doped mesoporous carbon fibers as anode materials for potassium ion batteries with long-term cycling stability. Chem. Eng. J. 2021, 425, 131651. [Google Scholar] [CrossRef]

- Wang, B.; Peng, Y.; Yuan, F.; Liu, Q.; Sun, L.; Zhang, P.; Wang, Q.; Li, Z.; Wu, Y.A. A comprehensive review of carbons anode for potassium-ion battery: Fast kinetic, structure stability and electrochemical. J. Power Sources 2021, 484, 229244. [Google Scholar] [CrossRef]

- Dong, X.; Xing, Z.; Zheng, G.; Gao, X.; Hong, H.; Ju, Z.; Zhuang, Q. MoS2/N-doped graphene aerogles composite anode for high performance sodium/potassium ion batteries. Electrochim. Acta 2020, 339, 135932. [Google Scholar] [CrossRef]

- Bella, F.; Verna, A.; Gerbaldi, C. Patterning dye-sensitized solar cell photoanodes through a polymeric approach: A perspective. Mater. Sci. Semicond. Process. 2018, 73, 92–98. [Google Scholar] [CrossRef]

- Bella, F.; Popovic, J.; Lamberti, A.; Tresso, E.; Gerbaldi, C.; Maier, J. Interfacial effects in solid–liquid electrolytes for improved stability and performance of dye-sensitized solar cells. ACS Appl. Mater. Interfaces 2017, 9, 37797–37803. [Google Scholar] [CrossRef]

- Bella, F.; Lamberti, A.; Bianco, S.; Tresso, E.; Gerbaldi, C.; Pirri, C.F. Floating Photovoltaics: Floating, Flexible Polymeric Dye-Sensitized Solar-Cell Architecture: The Way of Near-Future Photovoltaics. Adv. Mater. Technol. 2016, 1, 1600002. [Google Scholar] [CrossRef]

- Gerosa, M.; Sacco, A.; Scalia, A.; Bella, F.; Chiodoni, A.; Quaglio, M.; Tresso, E.; Bianco, S. Toward totally flexible dye-sensitized solar cells based on titanium grids and polymeric electrolyte. IEEE J. Photovoltaics 2016, 6, 498–505. [Google Scholar] [CrossRef]

- Sacco, A.; Bella, F.; de la Pierre, S.; Castellino, M.; Bianco, S.; Bongiovanni, R.; Pirri, C.F. Electrodes/electrolyte interfaces in the presence of a surface-modified photopolymer electrolyte: Application in dye-sensitized solar cells. ChemPhysChem 2015, 16, 960–969. [Google Scholar] [CrossRef] [PubMed]

- Veeramalai, C.P.; Li, F.; Liu, Y.; Xu, Z.; Guo, T.; Kim, T.W. Enhanced field emission properties of molybdenum disulphide few layer nanosheets synthesized by hydrothermal method. Appl. Surf. Sci. 2016, 389, 1017–1022. [Google Scholar] [CrossRef]

| Cycle | R1 [Ω] | R2 [Ω] | R3 [Ω] |

|---|---|---|---|

| 3 | 4.11 | 9.41 | 5490 |

| 4 | 4.38 | 15.13 | 4320 |

| 7 | 9.02 | 11.58 | 2193 |

| 8 | 10.88 | 10.89 | 2259 |

| 10 | 13.31 | 40.18 | 1646 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fagiolari, L.; Versaci, D.; Di Berardino, F.; Amici, J.; Francia, C.; Bodoardo, S.; Bella, F. An Exploratory Study of MoS2 as Anode Material for Potassium Batteries. Batteries 2022, 8, 242. https://doi.org/10.3390/batteries8110242

Fagiolari L, Versaci D, Di Berardino F, Amici J, Francia C, Bodoardo S, Bella F. An Exploratory Study of MoS2 as Anode Material for Potassium Batteries. Batteries. 2022; 8(11):242. https://doi.org/10.3390/batteries8110242

Chicago/Turabian StyleFagiolari, Lucia, Daniele Versaci, Federica Di Berardino, Julia Amici, Carlotta Francia, Silvia Bodoardo, and Federico Bella. 2022. "An Exploratory Study of MoS2 as Anode Material for Potassium Batteries" Batteries 8, no. 11: 242. https://doi.org/10.3390/batteries8110242

APA StyleFagiolari, L., Versaci, D., Di Berardino, F., Amici, J., Francia, C., Bodoardo, S., & Bella, F. (2022). An Exploratory Study of MoS2 as Anode Material for Potassium Batteries. Batteries, 8(11), 242. https://doi.org/10.3390/batteries8110242