Immersion Freezing of a Scots Pine Single Seed in a Water-Saturated Dispersion Medium: Mathematical Modelling

Abstract

:1. Introduction

- uniformity of seeds morphometric characteristics and their placement in seed capsules, providing increased accuracy of seeding, since without placing seeds in capsules, according to Masarei et al. [10], due to the heterogeneity of the size and shape of seeds, the depth of their sealing is significantly different even from ground-based seeding;

- aerodynamic stability and strength of the seed capsule, and the ability to manufacture it in the field [11].

- immutable initial seed germination potential or possible additional activation of growth processes and increased nutrient supply.

2. Materials and Methods

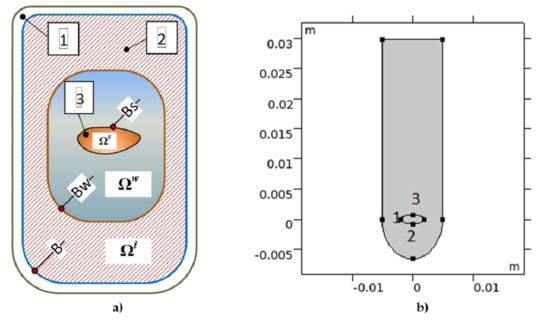

3. Mathematical Model

- (I).

- The front of the phase transition of a saturated coarse—dispersed system “sand-water” is a region with a dimension one less than the dimension of the problem, i.e., the interphase boundary is “sharp”, not blurred, which is true when the proportion of bound water in a capillary-porous system is insignificant compared to the proportion of free water;

- (II).

- The influence of the temperature gradient on the transfer of moisture in the system can be ignored;

- (III).

- The seed has water only in the bound state.

3.1. Heat Task Definition

3.2. Diffusion Task Definition

4. Numerical Modelling

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Novikov, A.I.; Ersson, B.T. Aerial seeding of forests in Russia: A selected literature analysis. In IOP Conference Series: Earth and Environmental Science, Proceedings of the International Jubilee Scientific and Practical Conference "Innovative Directions of Development of the Forestry Complex", Voronezh, Russia, 4–5 October 2018; IOP Publishing Ltd.: Bristol, UK, 2019; Volume 226, p. 012051. [Google Scholar]

- Morkovina, S.S.; Vovchenko, N.G.; Novikov, A.I.; Sokolov, S.V.; Dornyak, O.R. Seed Aerial Sowing Device. RU Patent 2 712 516, 21 May 2019. [Google Scholar]

- Sokolov, S.V.; Novikov, A.I.; Ivetić, V. Determining the initial orientation for navigation-measurement systems of mobile apparatus in reforestation. Inventions 2019, 4, 56. [Google Scholar] [CrossRef] [Green Version]

- Grossnickle, S.C.; Ivetić, V. Direct Seeding in Reforestation—A Field Performance Review. Reforesta 2017, 4, 94–142. [Google Scholar] [CrossRef]

- Mansuy, N.; Burton, P.J.; Stanturf, J.; Beatty, C.; Mooney, C.; Besseau, P.; Degenhardt, D.; MacAfee, K.; Lapointe, R. Scaling up forest landscape restoration in Canada in an era of cumulative effects and climate change. For. Policy Econ. 2020, 116, 102177. [Google Scholar] [CrossRef]

- Stanturf, J.A.; Palik, B.J.; Dumroese, R.K. Contemporary forest restoration: A review emphasizing function. For. Ecol. Manag. 2014, 331, 292–323. [Google Scholar] [CrossRef]

- Elliott, S.; Chairuangsri, S.; Kuaraksa, C.; Sangkum, S.; Sinhaseni, K.; Shannon, D.; Nippanon, P.; Manohan, B. Collaboration and Conflict—Developing Forest Restoration Techniques for Northern Thailand’s Upper Watersheds Whilst Meeting the Needs of Science and Communities. Forests 2019, 10, 732. [Google Scholar] [CrossRef] [Green Version]

- Sokolov, S.; Marshakov, D.; Novikov, A.I. The Current Spectrum Formation of a Non-Periodic Signal: A Differential Approach. Inventions 2020, 5, 15. [Google Scholar] [CrossRef] [Green Version]

- Sokolov, S.V.; Novikov, A.I. Adaptive estimation of UVs navigation parameters by irregular inertial-satellite measurements. Int. J. Intell. Unmanned Syst. (Manuscript Status: Accepted).

- Masarei, M.; Guzzomi, A.L.; Merritt, D.J.; Erickson, T.E. Factoring restoration practitioner perceptions into future design of mechanical direct seeders for native seeds. Restor. Ecol. 2019, 27, 1251–1262. [Google Scholar] [CrossRef]

- Vovchenko, N.G.; Novikov, A.I.; Sokolov, S.V.; Tishchenko, E.N. New technology for encapsulating conditioned seeds to increase aerial seeding efficiency. IOP Conf. Ser. Earth Environ. Sci. 2020. under review. [Google Scholar]

- Albekov, A.U.; Drapalyuk, M.V.; Morkovina, S.S.; Vovchenko, N.G.; Novikov, A.I.; Sokolov, S.V.; Novikova, T.P. Seed Encapsulation Method for Aerial Seeding. RU Patent 2 710 721, 20 January 2020. [Google Scholar]

- Gornish, E.; Arnold, H.; Fehmi, J. Review of seed pelletizing strategies for arid land restoration. Restor. Ecol. 2019, 27, 1206–1211. [Google Scholar] [CrossRef]

- Elias, S.G.; Copeland, L.O.; McDonald, M.B.; Baalbaki, R.Z. Seed Testing: Principles and Practices; Michigan State University Press: East Lansing, MI, USA, 2012; ISBN 9781611860399. [Google Scholar]

- Pita, J.M.; Barrero, S.; Escudero, A. Cryopreservation: An alternative method for the conservation of endangered populations of two Iberian pines (Pinus nigra Arnold and Pinus sylvestris L.). Silvae Genet. 1997, 46, 250–252. [Google Scholar]

- Sirman, D.; Blyalova, M.; Seilbek, Z. Influence of cryofreezing on germination of seeds of some members of the genus pine (Pinus) on the background of the use of one-and two-component cryoprotectors. In Proceedings of the Theory and Practice of Scientific Research, Neftekamsk, Russia, 27 September 2018; pp. 11–25. [Google Scholar]

- Butenko, O.U.; Bondarenko, A.S.; Pelevina, N.N. Influence of freezing and thawing on the germination of pine and spruce seeds. Proc. St. Petersburg For. Res. Inst. 2014, 1, 38–46. [Google Scholar]

- Jabłoński, M.; Tylek, P.; Walczyk, J.; Tadeusiewicz, R.; Piłat, A. Colour-based binary discrimination of scarified quercus robur acorns under varying illumination. Sensors 2016, 16, 1319. [Google Scholar] [CrossRef] [Green Version]

- Pukacki, P.M.; Juszczyk, K. Desiccation sensitivity and cryopreservation of the embryonic axes of the seeds of two Acer species. Trees 2015, 29, 385–396. [Google Scholar] [CrossRef] [Green Version]

- Safina, G.F.; Nikolayeva, M.A. Prospects for cryopreservation of seeds used to store the genetic. Biosphere 2014, 6, 365. [Google Scholar]

- Tikhonova, N.A.; Tikhonova, I.V.; Aniskina, A.A.; Loskutov, S.R.; Semenyakin, D.A. The results of comparison of low-temperature exotherms and endotherm during freezing and melting water in the tissues of 2-year-old needles in some species of coniferous trees. Conifers Boreal Area 2017, 35, 53–60. [Google Scholar]

- Zorrilla, S.E.; Rubiolo, A.C. Mathematical modeling for immersion chilling and freezing of foods. Part II: Model solution. J. Food Eng. 2005, 66, 339–351. [Google Scholar] [CrossRef]

- Zorrilla, S.E.; Rubiolo, A.C. Mathematical modeling for immersion chilling and freezing of foods. Part I: Model development. J. Food Eng. 2005, 66, 329–338. [Google Scholar] [CrossRef]

- Lucas, T.; Raoult-Wack, A.L. Immersion chilling and freezing: Phase change and mass transfer in model food. J. Food Sci. 1996, 61, 127–132. [Google Scholar] [CrossRef]

- Lucas, T.; Chourot, J.M.; Bohuon, P.; Flick, D. Freezing a porous medium in contact with a concentrated aqueous freezant: Numerical modelling of coupled and heat mass transport. Int. J. Heat Mass Transf. 2001, 44, 2093–2106. [Google Scholar] [CrossRef]

- Chourot, J.M.; Lauwers, J.; Massoji, N.; Lucas, T. Behaviour of green beans during the immersion chilling and freezing. Int. J. Food Sci. Technol. 2001, 36, 179–187. [Google Scholar] [CrossRef]

- Sun, Q.; Zhao, X.; Zhang, C.; Xia, X.; Sun, F.; Kong, B. Ultrasound-assisted immersion freezing accelerates the freezing process and improves the quality of common carp (Cyprinus carpio) at different power levels. LWT 2019, 108, 106–112. [Google Scholar] [CrossRef]

- Novikov, A.I.; Drapalyuk, M.; Dornyak, O.; Zelikov, V.; Ivetić, V. The Effect of Motion Time of a Scots Pine Single Seed on Mobile Optoelectronic Grader Efficiency: A Mathematical Patterning. Inventions 2019, 4, 55. [Google Scholar] [CrossRef] [Green Version]

- Novikov, A.I.; Sokolov, S.; Drapalyuk, M.; Zelikov, V.; Ivetić, V. Performance of Scots Pine Seedlings from Seeds Graded by Colour. Forests 2019, 10, 1064. [Google Scholar] [CrossRef] [Green Version]

- Lykov, A.V. Heat and Mass Exchange; Energiya: Moscow, Russia, 1978. [Google Scholar]

- Whitaker, S. Simultaneous Heat, Mass, and Momentum Transfer in Porous Media: A Theory of Drying. In Advances in Heat Transfer; Elsevier: Amsterdam, The Netherlands, 1977. [Google Scholar]

- Pavlov, A.R. Mathematical Modeling of Heat and Mass Transfer and Temperature Deformations in Building Materials at Phase Transitions; Nauka: Novosibirsk, Russia, 2001. [Google Scholar]

- Nikolaev, P.V. Substantiation of Parameters of Soil Freezing Technology Using Solid Carbon Dioxide in Underground Construction. Ph.D. Thesis, National University of Science and Technology MISiS, Moscow, Russia, 2016. [Google Scholar]

| Conventional Letter | Name | Means | Unit |

|---|---|---|---|

| Thermal conductivity coefficient of water | 0.56 | W (m K)−1 | |

| Thermal conductivity coefficient of ice | 2.26 | W (m K)−1 | |

| Thermal conductivity coefficient of silica | 8 | W (m K)−1 | |

| Thermal conductivity coefficient of air | 0.034 | W (m K)−1 | |

| Thermal conductivity coefficient of solid phase of the single seed | 0.04 | W (m K)−1 | |

| Water density | 1000 | kg m−3 | |

| Ice density | 920 | kg m−3 | |

| Silica density | 2650 | kg m−3 | |

| Air density | 1.225 | kg m−3 | |

| Seed solid phase density | 1500 | kg m−3 | |

| Water heat capacity | 4212 | J (kg K)−1 | |

| Ice heat capacity | 1970 | J (kg K)−1 | |

| Silica heat capacity | 750 | J (kg K)−1 | |

| Air heat capacity | 1000 | J (kg K)−1 | |

| Seed solid phase heat capacity | 2400 | J (kg K)−1 | |

| Volume content of air in the seed | 0.6 | – | |

| Volume content of water in the seed | 0.048 | – | |

| Volume content of the solid phase in the seed | 0.352 | – | |

| m | Volume content of air in loose dry sand | 0.7 | – |

| Tc | Temperature of the cooling agent | 19,465 (–78,5) 1 | K (°C) |

| T0 | The initial temperature of the sample | 29,315 (+20) | K (°C) |

| L | Specific heat of phase transition «water–ice» | 33.3 × 104 | J kg−1 |

| Coefficient of moisture conductivity in the seed | 1 × 10−10 | m2 s−1 | |

| The coefficient of hydraulic conductivity in a sand dispersion | 1 × 10−7 | m2 s−1 | |

| Moisture transfer coefficient | 2 × 10−6 | m s−1 | |

| Heat transfer coefficient «solid CO2—dispersion» | 100 | W (m2 K)−1 | |

| a | Seed length | 4 | mm |

| b | Seed thickness | 1.5 | mm |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dornyak, O.; Novikov, A. Immersion Freezing of a Scots Pine Single Seed in a Water-Saturated Dispersion Medium: Mathematical Modelling. Inventions 2020, 5, 51. https://doi.org/10.3390/inventions5040051

Dornyak O, Novikov A. Immersion Freezing of a Scots Pine Single Seed in a Water-Saturated Dispersion Medium: Mathematical Modelling. Inventions. 2020; 5(4):51. https://doi.org/10.3390/inventions5040051

Chicago/Turabian StyleDornyak, Olga, and Arthur Novikov. 2020. "Immersion Freezing of a Scots Pine Single Seed in a Water-Saturated Dispersion Medium: Mathematical Modelling" Inventions 5, no. 4: 51. https://doi.org/10.3390/inventions5040051

APA StyleDornyak, O., & Novikov, A. (2020). Immersion Freezing of a Scots Pine Single Seed in a Water-Saturated Dispersion Medium: Mathematical Modelling. Inventions, 5(4), 51. https://doi.org/10.3390/inventions5040051