Microstructure Analysis and Strength Characterization of Recycled Base and Sub-Base Materials Using Scanning Electron Microscope

Abstract

:1. Introduction

2. Materials and Methods

2.1. Unconfined Compressive Strength Sample Preparation

2.2. Scanning Election Microscopy

2.3. Sample Preparation for Microscopic Observation

2.4. Image Analysis

3. Results and Analysis

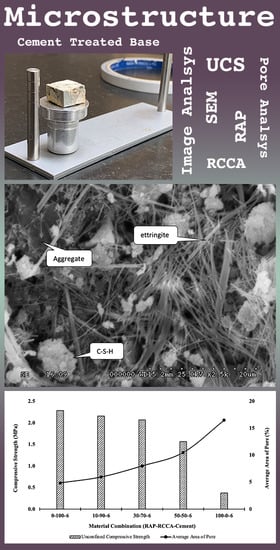

3.1. Qualitative Analysis

3.2. Pore Analysis

3.3. Porosity and Compressive Strength

3.4. Energy Dispersive Spectroscopy

3.5. Ca/Si Ratio and Compressive Strength

4. Discussion

5. Conclusions

- Microscopic photographs can distinguish between recycled aggregate and natural aggregates. Recycled aggregates are weaker than natural aggregates. Microstructure of recycled aggregates are heterogeneous, irregular and inconsistent. Recycled crushed concrete is progressively broken up and mostly covered by old cement mortar and fine fractions.

- Recycled asphalt aggregates are mostly covered by asphalt layer that prevents formation of new cement-aggregate bonding. Replacing greater portion of RAP in aggregate blends significantly reduces the compressive strength and stiffness.

- Porosity of hundred percent RAP blend material is around three times the porosity of hundred percent RCCA blend material. Porosity increases gradually with the increase of RAP as a replacement of RCCA.

- Compressive strength decreases linearly as the area of poresincreases. Compressive strength increases with the increase of weight percentage of silicon while the strength decreases with the increase in calcium percentage.

- Compressive strength is higher at low Ca/Si ratio but lower at high Ca/Si value. Strength increases linearly with the decrease in Ca/Si ratio.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| C&D | Construction and Demolition debris |

| EDS | Energy Dispersive X-ray Spectroscopy |

| ITZ | Interfacial Transition Zone |

| NA | Natural Aggregate |

| RA | Recycle Aggregate |

| RAP | Reclaimed Asphalt Pavement |

| RCCA | Recycled Crushed Concrete Aggregate |

| SEM | Scanning Electron Microscope |

| UCS | Unconfined Compressive Strength |

References

- Copeland, A. Reclaimed Asphalt Pavement in Asphalt Mixtures: State of the Practice; Technical report (No. FHWA-HRT-11-021); Federal Highway Administration, Office of Research, Development, and Technology: Washington, DC, USA, 2011. [Google Scholar]

- Potturi, A. Evaluation of resilient modulus of cement and cement-fiber treated reclaimed asphalt pavement (RAP) aggregates. J. Mater. Civ. Eng. 2007, 17–22. [Google Scholar]

- Ordonez, C.A. Characterization of cemented and fiber-reinforced RAP aggregate materials for base/sub-base applications. J. Mater. Civ. Eng. 2007, 7–16. [Google Scholar]

- Taha, R.; Ali, G.; Basma, A.; Al-Turk, O. Evaluation of reclaimed asphalt pavement aggregate in road bases and subbases. Transp. Res. Rec. 1999, 1652, 264–269. [Google Scholar] [CrossRef]

- Rana, A. Evaluation of Recycled Material Performance in Highway Applications and Optimization of Their Use. Ph.D. Thesis, Texas Tech University, Lubbok, TX, USA, 2004. [Google Scholar]

- Sobhan, K.; Mashnad, M. Mechanical stabilization of cemented soil–fly ash mixtures with recycled plastic strips. J. Environ. Eng. 2003, 129, 943–947. [Google Scholar] [CrossRef]

- Taha, R.; Al-Harthy, A.; Al-Shamsi, K.; Al-Zubeidi, M. Cement stabilization of reclaimed asphalt pavement aggregate for road bases and subbases. J. Mater. Civ. Eng. 2002, 14, 239–245. [Google Scholar] [CrossRef]

- Guthrie, W.S.; Cooley, D.; Eggett, D.L. Effects of reclaimed asphalt pavement on mechanical properties of base materials. Transp. Res. Rec. 2007, 2005, 44–52. [Google Scholar] [CrossRef] [Green Version]

- Grilli, A.; Bocci, E.; Graziani, A. Influence of reclaimed asphalt content on the mechanical behaviour of cement-treated mixtures. Road Mater. Pavement Des. 2013, 14, 666–678. [Google Scholar] [CrossRef]

- Kolias, S. Mechanical properties of cement-treated mixtures of milled bituminous concrete and crushed aggregates. Mater. Struct. 1996, 29, 411–417. [Google Scholar] [CrossRef]

- Sagoe-Crentsil, K.K.; Brown, T.; Taylor, A.H. Performance of concrete made with commercially produced coarse recycled concrete aggregate. Cem. Concr. Res. 2001, 31, 707–712. [Google Scholar] [CrossRef]

- Akhtar, A.; Sarmah, A.K. Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. J. Clean. Prod. 2018, 186, 262–281. [Google Scholar] [CrossRef]

- Silva, R.V.; De Brito, J.; Dhir, R.K. Properties and composition of recycled aggregates from construction and demolition waste suitable for concrete production. Constr. Build. Mater. 2014, 65, 201–217. [Google Scholar] [CrossRef]

- Diamond, S. Considerations in image analysis as applied to investigations of the ITZ in concrete. Cem. Concr. Compos. 2001, 23, 171–178. [Google Scholar] [CrossRef]

- Solyman, M. Classification of Recycled Sands and their Applications as Fine Aggregates for Concrete and Bituminous Mixtures. Klassifizierung von Recycling -Brechsanden und ihre Anwendungen für Beton und für Straßenbaustoffe. Ph.D. Thesis, University of Kassel, Kassel, Germany, 2005; p. 170. [Google Scholar]

- Evangelista, L.; Guedes, M.; De Brito, J.; Ferro, A.C.; Pereira, M. Physical, chemical and mineralogical properties of fine recycled aggregates made from concrete waste. Constr. Build. Mater. 2015, 86, 178–188. [Google Scholar] [CrossRef]

- Evangelista, L.; Guedes, M. Microstructural studies on recycled aggregate concrete. New Trends -Eco-Effic. Recycl. Concr. 2018, 24, 425–451. [Google Scholar] [CrossRef]

- Ollivier, J.P.; Maso, J.C.; Bourdette, B. Interfacial transition zone in concrete. Adv. CEM. Based Mater. 1995, 2, 30–38. [Google Scholar] [CrossRef]

- Poon, C.; Shui, Z.; Lam, L. Effect of microstructure of ITZ on compressive strength of concrete prepared with recycled aggregates. Constr. Build. Mater. 2004, 18, 461–468. [Google Scholar] [CrossRef]

- Faysal, M. Structural Competency and Environmental Soundness of the Recycled Base Material in North Texas. Ph.D. Thesis, University of Texas at Arlington, Arlington, TX, USA, 2017. [Google Scholar]

- TxDOT-113-E. TxDOT-113-E: Laboratory Compaction Characteristics and Moisture-Density Relationship of Base Materials. In TxDOT Research Reports and Products; TxDOT: Austin, TX, USA, 2016; pp. 1–15. [Google Scholar]

- TxDOT-120-E. Soil-Cement Testing. In Texas Department of Transportation; TxDOT: Austin, TX, USA, 2013; pp. 5–9. [Google Scholar]

- Goldstein, J.I.; Newbury, D.E.; Echlin, P.; Joy, D.C.; Fiori, C.; Lifshin, E. Scanning Electron Microscopy and X-Ray Microanalysis; Plenum Press: New York, NY, USA, 1981. [Google Scholar]

- Evangelista, L.; Guedes, M. 14 - Microstructural studies on recycled aggregate concrete. In New Trends in Eco-Efficient and Recycled Concrete; de Brito, J., Agrela, F., Eds.; Woodhead Publishing Series in Civil and Structural Engineering; Woodhead Publishing: Cambridge, UK, 2019; pp. 425–451. [Google Scholar] [CrossRef]

- Scrivener, K.; Snellings, R.; Lothenbach, B. A Practical Guide to Microstructural Analysis of Cementitious Materials; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Bonifazi, G.; Capobianco, G.; Serranti, S.; Eggimann, M.; Wagner, E.; Di Maio, F.; Lotfi, S. The ITZ in concrete with natural and recycled aggregates: Study of microstructures based on image and SEM analysis. In Proceedings of the 15th Euroseminar on Microscopy Applied to Building Materials, Delft, The Netherlands, 16–19 June 2015; pp. 299–308. [Google Scholar]

- Tang, Y.q.; Zhou, J.; Hong, J.; Yang, P.; Wang, J.x. Quantitative analysis of the microstructure of Shanghai muddy clay before and after freezing. Bull. Eng. Geol. Environ. 2012, 71, 309–316. [Google Scholar] [CrossRef]

- Domone, J.; Illston, J. Concrete. In Construction Materials: Their Nature and Behaviour; CRC Press: Boca Raton, FL, USA, 1998; pp. 89–195. [Google Scholar]

- Evangelista, L.; Guedes, M.; Ferro, A.; de Brito, J. Microstructure of concrete prepared with construction recycled aggregates. Microsc. Microanal. 2013, 19, 147–148. [Google Scholar] [CrossRef] [Green Version]

- Diamond, S. The microstructure of cement paste and concrete—A visual primer. Cem. Concr. Compos. 2004, 26, 919–933. [Google Scholar] [CrossRef]

- Falchetto, A.C.; Moon, K.H.; Wistuba, M.P. Microstructural analysis of asphalt mixtures containing recycled asphalt materials using digital image processing. In Proceedings of the 6th Eurasphalt & Eurobitume Congress, Prague, Czech Republic, 1–3 June 2016. [Google Scholar]

- Kumar, R.; Bhattacharjee, B. Porosity, pore size distribution and in situ strength of concrete. CEM. Concr. Res. 2003, 33, 155–164. [Google Scholar] [CrossRef]

- Largo, O.R.; de la Villa, R.V.; de Rojas, M.S.; Frías, M. Novel use of kaolin wastes in blended cements. J. Am. Ceram. Soc. 2009, 92, 2443–2446. [Google Scholar] [CrossRef]

- van Breugel, K.; Koenders, E.; Guang, Y.; Lura, P. Modelling of transport phenomena at cement matrix—Aggregate interfaces. Interface Sci. 2004, 12, 423–431. [Google Scholar] [CrossRef]

- Li, J.; Yu, Q.; Huang, H.; Yin, S. Effects of Ca/Si Ratio, Aluminum and Magnesium on the Carbonation Behavior of Calcium Silicate Hydrate. Materials 2019, 12, 1268. [Google Scholar] [CrossRef] [Green Version]

- Kunther, W.; Ferreiro, S.; Skibsted, J. Influence of the Ca/Si ratio on the compressive strength of cementitious calcium–silicate–hydrate binders. J. Mater. Chem. A 2017, 5, 17401–17412. [Google Scholar] [CrossRef] [Green Version]

- Kjellsen, K.O.; Monsøy, A.; Isachsen, K.; Detwiler, R.J. Preparation of flat-polished specimens for SEM-backscattered electron imaging and X-ray microanalysis - Importance of epoxy impregnation. CEM. Concr. Res. 2003, 33, 611–616. [Google Scholar] [CrossRef]

| Mixture Identification | M1 | M2 | M3 | M4 | M5 | |

|---|---|---|---|---|---|---|

| 0-100-6 | 10-90-6 | 30-70-6 | 50-50-6 | 100-0-6 | ||

| Combination | RAP | 0 | 10 | 30 | 50 | 100 |

| RCCA | 100 | 90 | 70 | 50 | 0 | |

| Cement | 6 | 6 | 6 | 6 | 6 | |

| Combination ID | Area of Pores (%) | Average Area of Pores | |

|---|---|---|---|

| M1 | 3.767 | 4.85 | |

| 5.820 | |||

| 7.458 | |||

| 2.345 | |||

| M2 | 3.690 | 5.95 | |

| 6.580 | |||

| 5.140 | |||

| 8.381 | |||

| M3 | 9.713 | 8.01 | |

| 7.121 | |||

| 3.907 | |||

| 11.290 | |||

| M4 | 11.387 | 10.49 | |

| 5.980 | |||

| 15.489 | |||

| 9.088 | |||

| M5 | 9.607 | 16.49 | |

| 3.437 | |||

| 20.365 | |||

| 32.543 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Imtiaz, T.; Ahmed, A.; Hossain, M.S.; Faysal, M. Microstructure Analysis and Strength Characterization of Recycled Base and Sub-Base Materials Using Scanning Electron Microscope. Infrastructures 2020, 5, 70. https://doi.org/10.3390/infrastructures5090070

Imtiaz T, Ahmed A, Hossain MS, Faysal M. Microstructure Analysis and Strength Characterization of Recycled Base and Sub-Base Materials Using Scanning Electron Microscope. Infrastructures. 2020; 5(9):70. https://doi.org/10.3390/infrastructures5090070

Chicago/Turabian StyleImtiaz, Tanvir, Asif Ahmed, MD Sahadat Hossain, and Mohammad Faysal. 2020. "Microstructure Analysis and Strength Characterization of Recycled Base and Sub-Base Materials Using Scanning Electron Microscope" Infrastructures 5, no. 9: 70. https://doi.org/10.3390/infrastructures5090070

APA StyleImtiaz, T., Ahmed, A., Hossain, M. S., & Faysal, M. (2020). Microstructure Analysis and Strength Characterization of Recycled Base and Sub-Base Materials Using Scanning Electron Microscope. Infrastructures, 5(9), 70. https://doi.org/10.3390/infrastructures5090070