Comparison of the Estimation Ability of the Tensile Index of Paper Impregnated by UF-Modified Starch Adhesive Using ANFIS and MLR

Abstract

:1. Introduction

2. Materials and Methods

2.1. Nano Silica

2.2. Preparation of the Starch Adhesive

2.3. Preparation of the UF-Starch Adhesive

2.4. Characterization of Complex by FTIR and TEM

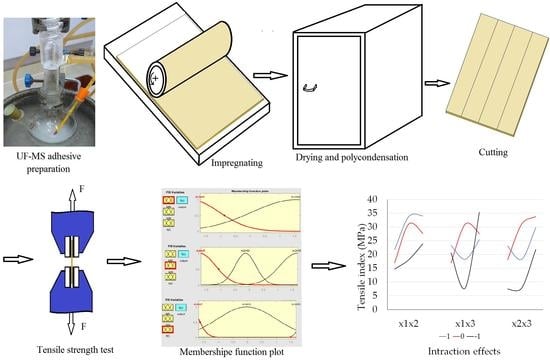

2.5. Preparation of the Impregnated Paper Test Specimens

2.6. Design of Experiment (DOE)

2.7. Modeling

2.7.1. The Multiple Linear Regression (MLR) Model

2.7.2. The Adaptive Neuro-Fuzzy Inference System (ANFIS) Model

3. Results and Discussion

3.1. Statistical Analyses

3.2. Characterization Analysis

3.3. Evaluation of the Models

4. Conclusions

- The correlation analysis showed that there is a significant relationship between the tensile index of the paper impregnated by resin and the MR, WR and NC.

- The comparison of the models produced to estimate the tensile index showed that R2 was more in the ANFIS model while RMSE, MAE and SSE values were less in the ANFIS model. According to the statistics, the ANFIS model has showed a better performance to predict the response being examined compared to the MLR.

- The starch modified by some functional groups including carbonyl, hydroxyl, etc., can react with the UF resin confirmed by FTIR spectroscope. Based on the TEM analysis, adding silica nanoparticles resulted in more matrix connection and its better distribution, but when increasing nanoparticles to the maximum level, the uniform distribution of nanoparticles was affected negatively.

- Increasing nano-silica beyond the middle level, the tensile index increased continuously as the WR increased. Increasing the MR and NC to the middle level, the tensile index increased. The intensity of the effect of the increase in the modified starch consumption has been much more than that of the effect of MR and NC.

Author Contributions

Funding

Conflicts of Interest

References

- Oktay, S.; Kızılcan, N.; Bengu, B. Oxidized cornstarch—Urea wood adhesive for interior particleboard production. Int. J. Adhes. Adhes. 2021, 110, 102947. [Google Scholar] [CrossRef]

- Zhao, X.-F.; Peng, L.-Q.; Wang, H.-L.; Wang, Y.-B.; Zhang, H. Environment-friendly urea-oxidized starch adhesive with zero formaldehyde-emission. Carbohydr. Polym. 2018, 181, 1112–1118. [Google Scholar] [CrossRef] [PubMed]

- Lubis, M.A.R.; Park, B.D. Modification of urea-formalde-hyde resin adhesives with oxidized starch using blocked pMDI for plywood. J. Adhes. Sci. Technol. 2018, 32, 2667–2681. [Google Scholar] [CrossRef]

- Raj, R.; Sadhu, S.D. Effect of varying ratio of starch in melamine-formaldehyde/starch based adhesive and its properties. Bull. Mater. Sci. 2021, 44, 162. [Google Scholar] [CrossRef]

- Lubis, M.A.R.; Park, B.-D. Modification of oxidized starch polymer with nanoclay for enhanced adhesion and free formaldehyde emission of plywood. J. Polym. Environ. 2021, 29, 2993–3003. [Google Scholar] [CrossRef]

- Gul, W.; Alrobei, H.; Shah, S.R.A.; Khan, A. Effect of iron oxide nanoparticles on the physical properties of medium density fiberboard. Polymers 2020, 12, 2911. [Google Scholar] [CrossRef]

- Gul, W.; Akbar Shah, S.R.; Khan, A.; Pruncu, C.I. Characterization of zinc oxide-urea formaldehyde nano resin and its impact on the physical performance of medium-density fiberboard. Polymers 2021, 13, 371. [Google Scholar] [CrossRef]

- Zheng, Y.; Zheng, Y.; Ning, R. Effects of nanoparticles SiO2 on the performance of nanocomposites. Mater. Lett. 2003, 57, 2940–2944. [Google Scholar] [CrossRef]

- Shi, J.; Li, J.; Zhou, W.; Zhang, D. Improvement of wood properties by urea–formaldehyde resin and nano-SiO2. Front. Forest. China 2007, 2, 104–109. [Google Scholar] [CrossRef]

- Ranjbaran, S.; Nazerian, M.; Kermanian, H.; Koosha, M.; Rasooly Garmaroody, E. High strength papers impregnated with urea/melamine formaldehyde resin/nanosilica nanocomposite coatings: The effects of paper type, blend ratio and nano-content. Mater. Today Commun. 2020, 25, 101300. [Google Scholar] [CrossRef]

- Roumeli, E.; Papadopoulou, E.; Pavlidou, E.; Vourlias, G.; Bikiaris, D.; Paraskevopoulos, K.M.; Chrissafis, K. Synthesis, characterization and thermal analysis of urea–formaldehyde/nanoSiO2 resins. Thermochim. Acta. 2012, 527, 33–39. [Google Scholar] [CrossRef]

- Zaghloul, M.M.Y.; Mohamed, Y.S.; El-Gamal, H. Fatigue and tensile behaviors of fiber-reinforced thermosetting composites embedded with nanoparticles. J. Compos. Mater. 2018, 53, 709–718. [Google Scholar] [CrossRef]

- Zaghloul, M.Y.M.; Zaghloul, M.M.Y.; Zaghloul, M.M.Y. Developments in polyester composite materials—An in-depth review on natural fibres and nano fillers. Compos. Struct. 2021, 278, 114698. [Google Scholar] [CrossRef]

- Tabari, H.; Marofi, S.; Sabziparvar, A.A. Estimation of daily pan evaporation using artificial neural network and multivariate non-linear regression. Irrig. Sci. 2010, 28, 399–406. [Google Scholar] [CrossRef]

- Qaderi, K.; Akbarifard, S.; Madadi, M.R.; Bakhtiari, B. Optimal operation of multi-reservoirs by water cycle algorithm. Proc. Inst. Civ. Eng. Water Manag. 2017, 171, 179–190. [Google Scholar] [CrossRef]

- Tay, J.-H.; Zhang, X. Neural fuzzy modeling of anaerobic biological wastewater treatment systems. J. Environ. Eng. 1999, 125, 1149–1159. [Google Scholar] [CrossRef] [Green Version]

- Azamathulla, H.M.; Chang, C.K.; Ghani, A.; Ariffin, J.; Zakaria, N.A.; Abu Hasan, Z. An ANFIS-based approach for predicting the bed load for moderately sized rivers. J. Hydro-Environ. Res. 2009, 3, 35–44. [Google Scholar] [CrossRef]

- Nwobi-Okoye, C.C.; Anyichie, M.K.; Atuanya, C.U. RSM and ANN modeling for production of newbouldia laevies fibre and recycled high density polyethylene composite: Multi objective optimization using genetic algorithm. Fibers. Polym. 2020, 21, 898–909. [Google Scholar] [CrossRef]

- Khan, M.A.; Aslam, F.; Javed, M.F.; Alabduljabbar, H.; Deifalla, A.F. New prediction models for the compressive strength and dry-thermal conductivity of bio-composites using novel machine learning algorithms. J. Clean. Prod. 2022, 350, 131364. [Google Scholar] [CrossRef]

- Nazerian, M.; Naderi, F.; Partovinia, A.; Papadopoulos, A.N.; Younesi-Kordkheili, H. Developing adaptive neuro-fuzzy inference system-based models to predict the bending strength of polyurethane foam-cored sandwich panels. Proc. Inst. Mech. Eng. L. 2022, 236, 3–22. [Google Scholar] [CrossRef]

- Nazerian, M.; Razavi, S.A.; Partovinia, A.; Vatankhah, E.; Razmpour, Z. Comparison of different modeling methods toward predictive capability evaluation of the bonding strength of wood laminated products. Proc. Inst. Mech. Eng. E J. Process Mech. Eng. 2021, 236, 991–1003. [Google Scholar] [CrossRef]

- Zaghloul, M.M.Y.; Zaghloul, M.Y.M.; Zaghloul, M.M.Y. Experimental and modeling analysis of mechanical-electrical behaviors of polypropylene composites filled with graphite and MWCNT fillers. Polym. Test. 2017, 63, 467–474. [Google Scholar] [CrossRef]

- Zaghloul, M.M.Y.; Zaghloul, M.M.Y. Influence of flame retardant magnesium hydroxide on the mechanical properties of high density polyethylene composites. J. Reinf. Plast. Compos. 2017, 36, 1802–1816. [Google Scholar] [CrossRef]

- Zaghloul, M.M.Y. Mechanical properties of linear low-density polyethylene fire-retarded with melamine polyphosphate. J. Appl. Polym. Sci. 2018, 134, 46770. [Google Scholar] [CrossRef]

- Fuseini, M.; Zaghloul, M.M.Y. Qualitative and statistical approaches of the electrophoretic deposition kinetics of polyaniline copper coating. Prog. Org. Coat. 2022, 171, 1–13. [Google Scholar] [CrossRef]

- Bardak, S.; Sari, B.; Nemli, G.; Kirci, H.; Baharoglu, M. The effect of décor paper properties and adhesive type on some properties of particleboard. Int. J. Adhes. Adhes. 2011, 31, 412–415. [Google Scholar] [CrossRef]

- Nemli, G.; Colakoglu, G. The influence of lamination technique on the properties of particleboard. Build. Environ. 2005, 40, 83–87. [Google Scholar] [CrossRef]

- TAPPI (Technical Association of the Pulp and Paper Industry). Tensile Breaking Properties of Paper and Paperboard; TAPPI 494 om-01; American National: Andersonville, GA, USA, 2001. [Google Scholar]

- Kashi, H.; Emamgholizadeh, S.; Ghorbani, H. Estimation of soil infiltration and cation exchange capacity based on multiple regression, ANN (RBF, MLP), and ANFIS models. Commun. Soil. Sci. Plant. Anal. 2014, 45, 1195–1213. [Google Scholar] [CrossRef]

- Wali, W.A.; Al-Shamma’a, A.I.; Hassan, K.H.; Cullen, J.D. Online genetic-ANFIS temperature control for advanced microwave biodiesel reactor. J. Process Control. 2012, 22, 1256e72. [Google Scholar] [CrossRef]

- Tang, M.; Wen, S.; Liu, D. Effects of heating- or caustic-digested starch on its flocculation on hematite. Miner. Process. Extr. Metall. Rev. 2016, 37, 49–57. [Google Scholar] [CrossRef]

- Siimer, K.; Kaljuvee, T.; Christjanson, P. Thermal behavior of urea-formaldehyde resins during curing. J. Therm. Anal. Calorim. 2003, 72, 607–617. [Google Scholar] [CrossRef]

- Zhu, X.; Xu, E.; Lin, R.; Wang, X.; Gao, Z. Decreasing the formaldehyde emission in urea-formaldehyde using modified starch by strongly acid process. J. Appl. Polym. Sci. 2014, 131, 40202. [Google Scholar] [CrossRef]

- Sheng, Y.; Wang, Q.; Xu, X.C.; Wen, J. Oxidation of cornstarch using oxygen as oxidant without catalyst. LWT-Food Sci. Technol. 2011, 44, 139–144. [Google Scholar] [CrossRef]

- Liu, T.Y.; Ma, Y.; Yu, S.F.; Shi, J.; Xue, S. The effect of ball milling treatment on structure and porosity of maize starch granule. Innov. Food Sci. Emerg. Technol. 2011, 12, 586–593. [Google Scholar] [CrossRef]

- Bruice, P.Y. Mass Spectrometry, Infrared Spectroscopy, and Ultraviolet/Visible Spectroscopy, 6th ed.; American National: State College, PA, USA, 2010; p. 1263. [Google Scholar]

- Joglekar, A.; May, A. Product excellence through design of experiments. Cereal Foods World. 1987, 32, 857–868. [Google Scholar]

- Sarve, A.; Sonawane, S.S.; Varma, M.N. Ultrasound assisted biodiesel production from sesame (Sesamum indicum L.) oil using barium hydroxide as a heterogeneous catalyst: Comparative assessment of prediction abilities between response surface methodology (RSM) and artificial neural network (ANN). Ultrason. Sonochem. 2015, 26, 218–228. [Google Scholar] [CrossRef]

- Nuryawan, A.; Park, B.D.; Singh, A.P. Penetration of urea-formaldehyde resins with different formaldehyde/urea mole ratios into soft-wood tissues. Wood Sci. Technol. 2014, 48, 889–902. [Google Scholar] [CrossRef]

- Wang, Y.; Xiong, H.; Wang, Z.; Din, Z.; Chen, L. Effects of different durations of acid hydrolysis on the properties of starch-based wood adhesive. Int. J. Biol. Macromol. 2017, 103, 819–828. [Google Scholar] [CrossRef]

- Moubarik, A.; Charrier, B.; Allal, A.; Charrier, F.; Pizzi, A. Development and optimization of a new formaldehyde-free cornstarch and tannin wood adhesive. Eur. J. Wood Wood Prod. 2009, 68, 167–177. [Google Scholar] [CrossRef] [Green Version]

- Tako, M.; Hizukuri, S. Gelatinization mechanism of potato starch. Carbohydr. Res. 2002, 48, 397–401. [Google Scholar] [CrossRef]

- Cardoso, M.B. From Rice Starch to Amylose Crystals: Alkaline Extraction of Rice Starch, Solution Properties of Amylose and Crystal Structure of V-Amylose Inclusion Complexes; Université Joseph Fourier: Grenoble, France, 2007. [Google Scholar]

- Vanier, N.L.; Da Rosa Zavareze, E.; Pinto, V.Z.; Klein, B.; Botelho, F.T.; Dias, A.R.G.; Elisa, M.C. Physicochemical, crystallinity, pasting and morphological properties of bean starch oxidized by different concentrations of sodium hypochlorite. Food Chem. 2012, 131, 1255–1262. [Google Scholar] [CrossRef]

- Cho, M.L.; Choi, W.S.; You, S.G. Steady and dynamic shear rheology of fucoidan-buckwheat starch mixtures. Starch-Stärke 2009, 61, 282–290. [Google Scholar] [CrossRef]

- Karim, A.A.; Norziah, M.H.; Seow, C.C. Methods for the study of starch retrogradation. Food Chem. 2000, 71, 9–36. [Google Scholar] [CrossRef]

- Xing, J.; Li, T.; Yu, Y.; Chen, C.; Chang, J. Development and characterization of a new bio-adhesive for wood using cassava starch and bio-oil. Int. J. Adhes. Adhes. 2018, 87, 91–97. [Google Scholar] [CrossRef]

- Mou, S.; Lu, Y.; Jiang, Y. A facile and cheap coating method to prepareSiO2/melamine-formaldehyde and SiO2/urea-formaldehyde composite microspheres. Appl. Surf. Sci. 2016, 384, 258–262. [Google Scholar] [CrossRef]

| Material | Properties |

|---|---|

| Nano silica | Specific surface area: 210 m2/g, purity 99.5%, mean dimensions 20 nm |

| NaOCl | Molecular mass: 74.44 g/mol, density: 1.11 g/mL, purity: 15%, pH: 11 |

| NaOH | Molecular mass: 39.99 g/mol, density: 2.13 g/mL, purity: 99.5%, pH: 13 |

| H2SO4 | Molecular mass: 98.078 g/mol, density: 1.834 g/mL, purity: 98.5% |

| HCl | Molecular mass: 36.46 g/mol, density: 1.2 g/mL, purity: 98%, pka: −6.3 |

| Urea | Molecular mass: 60.06 g/mol, density: 1.33 g/cm3, purity: 40%, pH: ≈7 |

| Formaldehyde | Molecular mass: 30.03 g/mol, density: 0.81.53 g/cm3, purity: 37.5%, pH: 2.5 |

| Run | Coded Values | Actual Values | T.I. | ||||

|---|---|---|---|---|---|---|---|

| x1 | x2 | x3 | MR | WR. | NC | ||

| 1 | 1.68 | 0 | 0 | 2.84 | 20 | 3 | 42 |

| 2 | 1 | −1 | −1 | 2.5 | 10 | 1.5 | 26.1 |

| 3 | −1.68 | 0 | 0 | 1.16 | 20 | 3 | 28.6 |

| 4 | 0 | 1.68 | 0 | 2 | 36.8 | 3 | 47.7 |

| 5 | −1 | −1 | −1 | 1.5 | 10 | 1.5 | 10 |

| 6 | 0 | −1.68 | 0 | 2 | 3.18 | 3 | 22 |

| 7 | 0 | 0 | −1.68 | 2 | 20 | 0.477 | 11.1 |

| 8 | −1 | −1 | 1 | 1.5 | 10 | 4.5 | 30.8 |

| 9 | −1 | −1 | −1 | 1.5 | 10 | 1.5 | 12.5 |

| 10 | 0 | 0 | −1.68 | 2 | 20 | 0.477 | 11.2 |

| 11 | 0 | 0 | 1.68 | 2 | 20 | 5.52 | 26 |

| 12 | −1 | 1 | 1 | 1.5 | 30 | 4.5 | 38.4 |

| 13 | −1 | −1 | −1 | 1.5 | 10 | 1.5 | 13.7 |

| 14 | 1 | 1 | 1 | 2.5 | 30 | 4.5 | 35.1 |

| 15 | −1.68 | 0 | 0 | 1.16 | 20 | 3 | 22.8 |

| 16 | −1 | 1 | −1 | 1.5 | 30 | 1.5 | 30 |

| 17 | 0 | 0 | −1.68 | 2 | 20 | 0.477 | 10.1 |

| 18 | −1 | 1 | −1 | 1.5 | 30 | 1.5 | 32.2 |

| 19 | −1 | −1 | 1 | 1.5 | 10 | 4.5 | 30 |

| 20 | −1 | 1 | −1 | 1.5 | 30 | 1.5 | 27.9 |

| 21 | 0 | 1.68 | 0 | 2 | 36.8 | 3 | 48.9 |

| 22 | 0 | −1.68 | 0 | 2 | 3.18 | 3 | 26.4 |

| 23 | 0 | 1.68 | 0 | 2 | 36.8 | 3 | 47.5 |

| 24 | 1 | −1 | −1 | 2.5 | 10 | 1.5 | 25.6 |

| 25 | 1 | −1 | −1 | 2.5 | 10 | 1.5 | 25.6 |

| 26 | 0 | −1.68 | 0 | 2 | 3.18 | 3 | 28.9 |

| 27 | 1 | 1 | −1 | 2.5 | 30 | 1.5 | 40.5 |

| 28 | 0 | 0 | 0 | 2 | 20 | 3 | 31.6 |

| 29 | 0 | 0 | 0 | 2 | 20 | 3 | 31.2 |

| 30 | 0 | 0 | 0 | 2 | 20 | 3 | 30.5 |

| 31 | 0 | 0 | 0 | 2 | 20 | 3 | 31 |

| 32 | −1.68 | 0 | 0 | 1.16 | 20 | 3 | 21.6 |

| 33 | −1 | 1 | 1 | 1.5 | 30 | 4.5 | 40.8 |

| 34 | 0 | 0 | 0 | 2 | 20 | 3 | 31 |

| 35 | 1 | 1 | 1 | 2.5 | 30 | 4.5 | 40 |

| 36 | 1 | 1 | 1 | 2.5 | 30 | 4.5 | 40.2 |

| 37 | −1 | −1 | 1 | 1.5 | 10 | 4.5 | 16.2 |

| 38 | −1 | 1 | 1 | 1.5 | 30 | 4.5 | 40.6 |

| 39 | 0 | 0 | 0 | 2 | 20 | 3 | 30.2 |

| 40 | 1 | −1 | 1 | 2.5 | 10 | 4.5 | 32.6 |

| 41 | 0 | 0 | 1.68 | 2 | 20 | 5.52 | 27.3 |

| 42 | 1 | −1 | 1 | 2.5 | 10 | 4.5 | 30.6 |

| 43 | 1 | 1 | −1 | 2.5 | 30 | 1.5 | 42 |

| 44 | 1 | −1 | 1 | 2.5 | 10 | 4.5 | 33.2 |

| 45 | 0 | 0 | 1.68 | 2 | 20 | 5.52 | 25 |

| 46 | 1 | 1 | −1 | 2.5 | 30 | 1.5 | 41.7 |

| 47 | 1.68 | 0 | 0 | 2.84 | 20 | 3 | 35.7 |

| 48 | 1.68 | 0 | 0 | 2.84 | 20 | 3 | 34.3 |

| Sequential Model of Squares | ||||||

|---|---|---|---|---|---|---|

| Source | Sum of Squares | Df | Mean Square | F-Value | p-Value | |

| Mean vs. Total | 4.31 × 104 | 1 | 43,100 | |||

| Linear vs. Mean | 3040 | 3 | 1010 | |||

| 2FI vs. Linear | 255 | 3 | 84.9 | 27 | <0.0001 | |

| Quadratic vs. 2FI | 1070 | 3 | 355 | 2.48 | 0.0741 | |

| Cubic vs. Quadratic | 26.1 | 4 | 6.53 | 40.2 | <0.0001 | Sug. |

| Residual | 310 | 34 | 9.11 | 0.717 | 0.586 | Alia. |

| Total | 47,800 | 48 | 997 | |||

| Lack of Fit Tests | ||||||

| Linear 2FI | 1.39 × 103 1.13 × 103 | 11 8 | 126 142 | 15.5 17.4 | <0.0001 <0.0001 | |

| Quadratic | 67.5 | 5 | 13.5 | 1.66 | 0.172 | Sug. |

| Cubic Pure error | 41.4 268 | 1 33 | 41.4 8.13 | 5.09 | 0.0308 | Alia. |

| Model Summary Statistics | ||||||

| Std. d. | R2 | Adjusted R2 | Predicted R2 | Press | ||

| Linear | 6.13 | 0.648 | 0.624 | 0.574 | 2000 | |

| 2FI | 5.85 | 0.702 | 0.658 | 0.621 | 1780 | |

| Quadratic | 2.97 | 0.929 | 0.912 | 0.884 | 546 | Sug. |

| Cubic | 3.02 | 0.934 | 0.909 | 0.861 | 651 | Alia. |

| Source | Sum of Squares | Df | Mean Squares | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 4.36 × 103 | 8 | 545 | 62.2 | <0.0001 |

| x1-MR | 591 | 1 | 591 | 67.5 | <0.0001 |

| x1-WR | 1.84 × 103 | 1 | 1.84 × 103 | 210 | <0.0001 |

| x3-NC | 609 | 1 | 609 | 69.5 | <0.0001 |

| x1x2 | 39.9 | 1 | 39.9 | 4.56 | 0.0391 |

| x1x3 | 151 | 1 | 151 | 17.3 | 0.000171 |

| x2x3 | 63.5 | 1 | 63.5 | 7.26 | 0.0104 |

| x22 | 195 | 1 | 195 | 22.3 | <0.0001 |

| x32 | 573 | 1 | 573 | 65.4 | <0.0001 |

| Residual | 341 | 39 | 8.76 | ||

| Lack of Fit | 73.1 | 6 | 12.2 | 1.5 | 0.209 |

| Pure Error | 268 | 33 | 8.13 | ||

| Cor Total | 4.7 × 103 | 47 |

| Training Data Set | All Data Set | |||

|---|---|---|---|---|

| MLR | ANFIS | MLR | ANFIS | |

| R2 | 0.5174 | 0.9612 | 0.4818 | 0.9261 |

| RMSE | 17.48 | 1.8168 | 18.66 | 2.7232 |

| MAE | 14.04 | 1.2942 | 14.95 | 1.5812 |

| SSE | 14,557 | 112.22 | 16,727 | 355.96 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nazerian, M.; Kashi, H.R.; Rudi, H.; Papadopoulos, A.N.; Vatankhah, E.; Foti, D.; Kermaniyan, H. Comparison of the Estimation Ability of the Tensile Index of Paper Impregnated by UF-Modified Starch Adhesive Using ANFIS and MLR. J. Compos. Sci. 2022, 6, 341. https://doi.org/10.3390/jcs6110341

Nazerian M, Kashi HR, Rudi H, Papadopoulos AN, Vatankhah E, Foti D, Kermaniyan H. Comparison of the Estimation Ability of the Tensile Index of Paper Impregnated by UF-Modified Starch Adhesive Using ANFIS and MLR. Journal of Composites Science. 2022; 6(11):341. https://doi.org/10.3390/jcs6110341

Chicago/Turabian StyleNazerian, Morteza, Hossin Ranjbar Kashi, Hamidreza Rudi, Antonios N. Papadopoulos, Elham Vatankhah, Dafni Foti, and Hossin Kermaniyan. 2022. "Comparison of the Estimation Ability of the Tensile Index of Paper Impregnated by UF-Modified Starch Adhesive Using ANFIS and MLR" Journal of Composites Science 6, no. 11: 341. https://doi.org/10.3390/jcs6110341

APA StyleNazerian, M., Kashi, H. R., Rudi, H., Papadopoulos, A. N., Vatankhah, E., Foti, D., & Kermaniyan, H. (2022). Comparison of the Estimation Ability of the Tensile Index of Paper Impregnated by UF-Modified Starch Adhesive Using ANFIS and MLR. Journal of Composites Science, 6(11), 341. https://doi.org/10.3390/jcs6110341