3.1. Characterisation of Fibre

The wood fibre and flour samples used throughout the analysis were given coded names and acronyms, such as wood flour (F), digested fibre (D), digested and ultrasonic-treated fibre (DU), digested and bleached fibre (DB), and digested bleached and ultrasonic-treated fibre (DBU).

SEM was used to investigate the fibre surfaces after all processing steps and variables. The images of digested fibre show that the separation of fibres from the wood chips has started to occur (

Figure 1A), and some single fibres are present. However, fibre bundles are still present, and further processing could improve separation. The texture of the fibre surface (

Figure 1B) suggests that localised lignin and extractives remain on the surface [

24]. The presence of fibre bundles further suggests lignin and extractives are present on the fibre surfaces, acting to bind the cellulosic fibres together in fibre bundles [

7].

Figure 1C,D shows the surface of the digested and ultrasonic-treated fibres. The surfaces are visually smoother than those of the alkali pulped fibres, signifying that ultrasonic treatment has removed some of the lignin and extractives from the surface of the fibres. The images indicate that further fibre separation has occurred during the ultrasonic treatment, and fibrillation is starting to occur as small fibrils can be seen on the surface. Both fibres and cellulose fibrils within the fibres are held in place by lignin and extractives. Therefore, the potential fibre separation and fibrillation of the fibre surface indicate further removal of lignin and extractives holding the fibres and microfibrils together [

7]. The potential reduction of lignin and extractives agrees with the literature, where ultrasonic treatment has been found to remove lignin and extractives from wood flour [

16].

Figure 1E,F shows the fibre surface of the digested and bleached fibres. The fibres in the images are seen to have a more textured surface than the digested fibre. This surface is likely a result of the removal of localised lignin and extractives from the fibre surfaces during the bleaching process, exposing the microfibrils in the fibre. This theory agrees with the literature, where a rougher surface was obtained from hydrogen peroxide bleaching, where it was subsequently used to improve interfacial strength in the corresponding composites [

13]. Hydrogen peroxide bleaching is also known to remove lignin content [

25]. The images also imply that more fibre separation has occurred, and more individual fibres are present (compared to the digested fibre). The potential increase in fibre separation is likely the result of the removal of lignin and extractives, which naturally hold the fibres together in fibre bundles.

The digested, bleached, and ultrasonic-treated fibres can be seen in

Figure 1G–I. The use of ultrasonic treatment after bleaching the fibres shows significant fibrillation of the fibres and the exposure of microfibres and potentially nano fibres. The added fibrillation from the ultrasonic treatment increases the surface area of the fibres, suggesting a potential for more interaction and better interfacial strength between the fibres and matrix.

The fibrillation induced by the ultrasonic treatment can increase the interfacial strength of composites through the presence of microfibrils and increased surface area. However, literature has equally shown that mechanical processing to induce fibrillation can also damage the fibres and reduce fibre length, with the potential of decreasing composite strength [

7].

Figure 1G,H shows significant fibrillation induced by the ultrasonic treatment after the bleaching process, suggesting potential for the fibre strength and length to be decreased due to the ultrasonic process, and therefore potential to reduce corresponding composite mechanical properties.

Figure 1I reveals that the fibres tend to agglomerate after the treatment, as shown by the large group of fibres. This phenomenon has the potential to reduce the mixing of matrix and fibres during compounding, therefore reducing the wetting of fibres and reducing composite properties.

The results from the fibre quality analysis were used to study the fibres’ geometry, including width, length, aspect ratios, number of shives (bundles), and fines.

Table 1 summarises the information recorded for all fibre processing variables.

It can be seen that bleaching of the digested fibres reduced the diameter of the fibres without any effect on fibre length. Literature suggests that increased chemical processing results in a reduction in fibre width and the reduction in corresponding kappa number, indicating the removal of lignin [

26]. Therefore, the reduction in fibre width due to the bleaching further suggests the removal of lignin and extractives from the fibre surface, reinforcing the results of the SEM. The number of bundles or shives is also seen to decrease after the bleaching of fibres, which further suggests the reduction of lignin and extractives in the fibres, which are known to hold fibre bundles together [

7].

Ultrasonic treatment reduced the mean fibre length and had minimal effect on the fibre width, resulting in a lower aspect ratio. However, the results suggest that ultrasonic treatment (Sample DU) reduced the number of shives or fibre bundles, reinforcing the results of the SEM where more individual fibres were visually present, and separation of fibre bundles had been improved.

The ultrasonic treatment of the digested and bleached fibres was found to reduce the length of the fibres from 1.18 to 0.66 mm, a reduction of 44%. Furthermore, the percentage of fines, weighted by length, was increased from 1.03% to 16.66%. Although the SEM suggested the potential to increase interfacial strength due to fibrillation of the fibres, the large reduction in fibre length and increased number of fines in the fibres further suggests the potential of reducing composite properties due to reduced fibre reinforcement capability.

The analysis shows that the use of ultrasonic treatment increases the fibre width. After ultrasonic treatment, the mean fibre width of the digested fibres slightly increased from 32.39 to 32.62 µm (comparing D and DU fibre) and increased the mean width of the bleached fibres from 31.47 to 32.76 um (comparing DB and DBU fibre). The apparent increase in width is likely due to the additional fibrillation surrounding the fibres, which resulted in an apparent fibre width that is larger than the actual fibres. The SEM reinforces this, as the difference was larger in the width of the bleached fibres, where substantially more fibrillation was indicated. It is likely that the actual width of the fibres has been reduced due to the microfibrils being separated from the primary wall of the cellulosic fibres and the potential removal of lignin from the fibre surface.

The results of the analysis also show that the number of shives increased with the ultrasonic treatment in the digested and bleached fibres (comparing DB and DBU fibre). The shives measured are likely a result of the agglomeration of fibres, indicated in

Figure 1I of the SEM results, being measured as shives.

The digestion process aimed to reduce the content of lignin, hemicellulose, and extractives, in a single step. Literature on Kraft pulping indicates that hemicellulose is originally removed at a faster rate than lignin [

27]. The digestion process also appears to follow this trend, as the spectra in

Figure 2 indicates the removal of most of the hemicellulose in the digestion process, whereas residual lignin appears to remain. A clear peak in the wood flour spectra at 1726 cm

−1 is specific to -COOH and C=O functional groups, which are specifically found in hemicellulose. The spectra for all other fibres do not contain this peak, suggesting that hemicellulose has primarily been removed during the digestion process [

28].

The spectra suggest a reduction of lignin in the digestion and bleaching processes. The peaks at 1511 cm

−1 represent the functional group C=C, and are assigned to aromatic rings of lignin, specifically indicating guaiacyl (G) units. The indication of G units of lignin makes sense, as the lignin in soft woods such as

Pinus radiata is known to primarily be composed of G units [

29]. The spectra show a reduction in the 1511 cm

−1 in the digested fibre and a further reduction in the peak after bleaching. The reduction in the size of the peak indicates partial removal of lignin from the fibre during these chemical processes. This removal of lignin is further inferred by reducing peaks at 1460 cm

−1, indicating the reduction in C-H functional groups assigned to lignin. However, lignin was still clearly present in all samples, shown by the small peaks still present at 1511 cm

−1, 1460 cm

−1, and the peaks remaining at 1120 cm

−1 and 1039 cm

−1, which all indicate functional groups found in lignin. The presence of lignin even after bleaching is expected; literature from the pulp and paper industry suggests that the bleaching of pulp can take up to seven different chemical treatments due to the difficulty of removing lignin [

25,

28].

The figure suggests that the use of ultrasonic treatment with NaOH gives no significant change in the peak, indicating little change in the constituents present in the fibres. However, the FTIR spectra used is qualitative, and the processing could have small unseen effects on the constituents present in the fibres.

X-ray diffraction (XRD) was used to analyse the crystallinity of the timber and fibres. The crystallinity index of the wood flour and fibres gives further insight into the constituents in the timber, and the XRD spectra provides insight into any potential changes to the crystalline cellulose. The crystallinity index was calculated using the Segal method using the spectra in

Figure 3. The resulting crystallinity indices (Xc) are displayed in

Figure 3 along with the spectra. The results show that the crystallinity index increases with progressing chemical processing. The crystallinity index increased from 41.9% for the timber, to 67.2% for the digested fibres (comparing F and D samples). Furthermore, the crystallinity index increased to 71.5% because of the bleaching process (comparing D and DB samples). The increase in the crystallinity index was likely due to the removal of amorphous material, including lignin, hemicellulose, and other extractives. This reduction in amorphous constituents is confirmed by the SEM, fibre quality analysis, and FTIR discussed earlier.

The results from the XRD analysis show that the use of ultrasonic treatment after digestion also increases the crystallinity index, which is likely due to the removal of small amounts of amorphous constituents (comparing D and DU fibre). However, the crystallinity index is reduced after the ultrasonic treatment of the bleached fibres (comparing DB and DBU fibre). The spectra in

Figure 3 show a shoulder peak emerging at roughly 20°, which is more obvious in the DBU fibre. The peak suggests the transformation from cellulose Iβ to cellulose II, resulting in the formation of the peak at 20° (corresponding to the 110 plane in cellulose II) and the reduction in the peak corresponding to the 002 plane. The potential transformation of small amounts of cellulose Iβ to cellulose II explains the reduction in the calculated crystallinity index caused by the high amounts of energy during the ultrasonic treatment. This reduction also shows the limitations of the Segal method used for calculating the crystallinity index [

30,

31].

TGA was used to analyse the thermal degradation of the treated timber and fibres.

Figure 4 shows the TG and DTG (1st derivative of TG) analysis for all fibres and wood flour samples and

Table 2 summarises the mass change, onset temperature, and peak degradation temperatures. The DTG results show the first derivative of the TG results, providing peaks that represent the rate of thermal degradation. Variances in the TG and DTG for the fibre samples are likely due to differences in the content of cellulose, lignin, hemicellulose, and extractives. Previous studies suggest that “hemicellulose decomposes at a lower temperature range (220–315 °C) than cellulose (300–400 °C), while lignin decomposes over a broad range of temperatures (150–900 °C)” [

32]. However, it has been reported that the heavy metals can affect the thermal conductivity of the material, potentially affecting the thermal degradation properties [

10].

The results of the TG testing indicate an initial change in mass at approximately 100 °C in all samples, suggesting the presence of water. The DTG of wood flour shows a major peak at 360 °C, and shoulder peaks at 260.7 and 326 °C, likely indicating the lignin and hemicellulose in the timber degrading before the cellulose. The samples all show initial thermal degradation at approximately 200 °C, most likely due to the presence of lignin, which degrades at lower temperatures than the other major constituents. This is most significant in the wood flour; however, it occurs in all samples.

ICP–MS was used to analyse the heavy metal content in the reinforcement materials. The results of the analysis are shown in

Table 3. In New Zealand, H 3.2 CCA-treated timber requires the total concentration of heavy metals to be 0.37 wt.% (in the timber) as defined by NZS 3640 [

33]. However, the sum of the three heavy metals in the timber adds to 0.42 wt.%, which is slightly higher than the New Zealand standard. The specific content of copper, chromium, and arsenic in the timber was measured to be 0.0839 wt.%, 0.13785 wt.%, and 0.0968 wt.%, respectively, inferring proportions of 26.8% Cu, 41.2% Cr and 32.0% As. The results fit reasonably well with the relative proportions required by NZS 3640 in the CCA treatment of 23–25% Cu, 38–45% Cr, and 30–37% As [

33]. The copper concentration is the only heavy metal lying outside the expected range (1.3% higher than expected). The small differences in heavy metal content compared to the NZ standard are potentially due to variation within the timber and the small sample size of wood flour used for testing. However, the results are very similar to the New Zealand standard and can be regarded as an accurate representation of the trend in the heavy metal content in the wood flour and fibres.

Table 3 shows how the concentration of heavy metals changes with the treatment of the timber and fibres. The results show that the concentration of arsenic was reduced by 99.8% from the wood flour to the digested fibres and was further reduced with further treatment. The reduction in arsenic content signifies that the fibres could potentially be used safely in wood–plastic composite applications, as arsenic is considered the most toxic of the three heavy metals [

34]. The concentration of copper and chromium was also reduced after digestion, bleaching, and ultrasonic treatments. The reduction in the concentration of chromium was less than that of arsenic (Cr was reduced from 1728.5 to 957.9 ppm from the treated timber to digested fibres, respectively). The concentration of copper was found to only decrease from 1126.4 to 1093.6 ppm (comparing the timber and digested fibre). Bleaching with hydrogen peroxide was found to reduce both copper and chromium in the fibre and further reduce the arsenic content. In contrast, ultrasonic treatment had the least effect on the heavy metal content.

The variable changes in heavy metal concentration (i.e., comparing changes in Cu, Cr, and As concentration) in the digested fibre are likely a result of how the heavy metals are fixed into the timber. The literature is very unclear on the exact chemistry of the fixation of preservatives into timber; however, a recent report suggests that the heavy metals are fixed in the timber in the forms of chromium (III) arsenate, chromium (III) hydroxide and wood carboxylate–copper (II) complexes [

35]. The removal of 99.8% of As suggests the removal of the majority of the chromium (III) arsenate in the timber during the digestion process. The potential reduction of chromium (III) arsenate in the timber would agree with the results; although, As is almost completely removed, and the concentration of Cr is roughly halved, which is likely due to the chromium (III) hydroxide remaining in the fibre. Thus, the results infer that the chromium (III) arsenate is fixed primarily into the alkali soluble constituents of the timber (such as hemicellulose and lignin). However, the concentration of copper and chromium changes less, which could result from chromium (III) hydroxide and carboxylate–copper (II) complexes potentially being evenly distributed and fixed throughout all the timber constituents (including cellulose).

When considering the yields of the digestion, ultrasonic, and bleaching processes, the mass of heavy metals in the fibres compared to the original mass of heavy metals in the timber is significantly reduced. Therefore, a significant portion of the heavy metals from the timber can be expected to be in the fibre treatment solutions after processing (digestion, bleaching, and ultrasonic treatment solutions). The presence of the heavy metals will likely alter any potential commercial-scale recovery of water, biomass, or chemicals from the solutions, and will require further research. The highly alkaline solutions used for processing may precipitate the heavy metals allowing for their removal [

36]. However, more research is required to investigate this possibility.

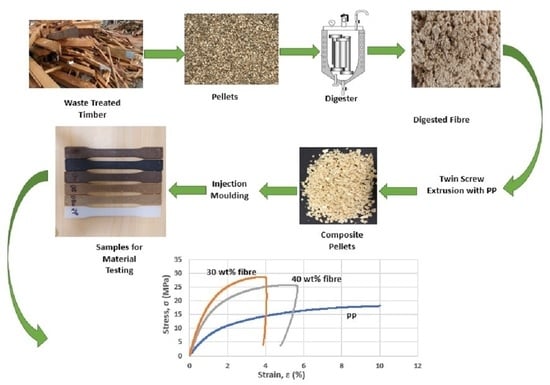

3.2. Characterisation of Composites

Composites were assessed for their mechanical properties and for the potential of leaching.

Table 4 and

Figure 5 show the tensile properties of the composites.

Figure 5 shows a typical stress–strain curve from the tensile testing of polypropylene used as a matrix material, 30 wt% DB fibre composites and 40 wt% DB fibre composites. The DB 30 wt% fibre composites is representative of the curve from all of the 30 wt% composites. The figure shows that the addition of more fibre increases the strength and stiffness of the composites. However, the failure strain is reduced with the addition of more fibre.

Table 4 shows the tensile properties of the PP and composites produced in this study. A higher tensile strength was attained in the fibre composites than wood flour composites. The highest TS obtained was from the composites produced with DU fibres, and the highest young’s modulus (YM) was from the composites produced using D fibre. The results show that the bleaching process reduced the average TS and YM of corresponding composites. When comparing composites produced with D and DB fibres, the average TS was reduced from 26.74 to 25.37 MPa, and the YM from 1928.92 to 1896.13 MPa.

The ultrasonic treatment had similar effects for both the digested and digested and bleached fibres. The inclusion of an ultrasonic treatment was found to increase the average TS and decrease the YM for composites in both cases (comparing D and DU fibre composites and DB and DBU fibre composites). The increase in TS is likely due to the increase in the surface area caused by the fibrillation from the ultrasonic treatment shown in the results of the SEM of fibre surfaces (

Figure 1C,G). The increase in fibre surface area has the potential to increase interfacial strength and therefore improve composite TS. Furthermore, the reduction in YM is likely a result of the decrease in fibre length induced by the ultrasonic treatment, which was shown in the fibre quality analysis (

Table 1). The reduction in length is likely to have reduced fibre reinforcement efficiency, as the length of the fibre that the load is transferred to is reduced [

18]. The results from the tensile testing of the fibre composites are all very similar. The COV and the results of the Anova test indicate that the differences in the YM of the fibre composites are statistically insignificant, and the tensile strength was higher for digested fibre than digested and bleached fibre, and the use of ultraosinc treament did not make a statistically signifigant difference.

The bleached fibres had the lowest heavy metal content, likely giving an advantage as a commercially viable product. Furthermore, the TS of the composites were only slightly lower than the digested fibre composites, and there was no statistically significant difference in the YM. Composites were produced using 40 wt.% digested and bleached fibre, 4 wt.% MAPP, and 56 wt.% PP, to provide a better understanding of the mechanical performance attainable.

Table 4 shows that the resulting average tensile strength was found to be 27.61 MPa, the highest strength properties attained from any composites tested during this study. The modulus increased compared to the composites with 30 wt.% bleached fibres, and a modulus of 2.33 GPa was attained. Due to the high YM and failure strain attained from the extruded 40 wt.% DB fibre composites, the composites could be regarded as having the most useable mechanical properties.

The results from the composites with 40 wt.% fibre suggest that the wetting of the fibres using the extruder is still good with the increased fibre content, therefore providing good interfacial strength and increased mechanical performance.

The failure surfaces of the composites were studied using SEM to understand the failure mechanisms during tensile testing. Overall, the composites showed minimal differences between the composites produced with varying fibre treatments.

Figure 6 shows some examples of failure surfaces of the composites. The long matrix ‘tongues’ shown in the figures indicate that the composites fail in a ductile manner caused by plastic deformation of the matrix of the same magnitude (if not bigger) of the fibres within the composite. The composites also indicate a non-homogenous failure surface in all composites, which could potentially suggest poor mixing during the extrusion or poor compatibility with the fibres and matrix resulting in a non-homogenous mix of fibres and polymer through the composites cross-section. The figure also indicates some porosity within the composites. This could further lead to reduced composite strength, as it acts as stress concentrations in the material while testing. Overall, the SEM indicates that the composite performance could be improved with improved processing.

Creep testing was undertaken over a 12 h period to understand the influence of the introduction of fibres to PP on the viscoelastic behaviour. The 40 wt.% DB fibre composites were used for the study since they showed the most appropriate mechanical properties for the construction sector. PP was used as a comparison. The composite and PP were tested at 15 and 30% of their specific flexural strength. The PP flexural strength was 23.56 MPa, and the DB composites flexural strength was 45.19 MPa. The resultant flexural strain was measured over a 12 h period and shown in

Figure 7.

Figure 7 shows that for tests at both 15 and 30% of the flexural strength, PP has a higher flexural strain than the composites, even though the applied stress was lower. Furthermore, the results indicate that the creep rate is higher in the PP than the DB fibre composites in both tests. Both the differences in strain and creep rate between PP and composites appear to be more pronounced in the 30% strength tests than the 15% tests.

Figure 7 also shows that the creep curve for the DB fibre composites follows a smooth line that is potentially starting to plateau in both 15 and 30% tests over a 12 h period. However, the PP curve for the 30% test has an initial plateau at roughly 15,000 s before starting to accelerate again later in the test. This curvature is potentially indicative of the PP sample reaching a tertiary creep phase as the creep rate starts to accelerate at the end of the test. However, it is also possible that it is due to other factors, such as the complex semi-crystalline structure of PP. The data suggest that using the DB fibres is useful for reducing the strain in the composites and the creep rate in the material. Furthermore, it is possible that the introduction of wood fibres has increased the time taken to induce tertiary stress, which is important for structural application in the building sector, where tertiary creep should be avoided [

37,

38].

Variances in temperatures may have affected the test results due to the susceptibility of polymer properties to variance in temperature. However, it is unlikely that the small differences in the temperature during testing affected the trends found in the results.

The testing gives insight into the improvement of creep properties when fibres are added to polymers to alter properties. However, to understand long-term application potential, more testing and further research is required to understand creep performance in this time frame and whether tertiary creep can be avoided [

39].

Figure 8 shows the cumulative leaching of copper, chromium, and arsenic from 30 wt.% wood flour (F), digested fibre (D), and digested and bleached fibre (DB) composites over a 14-day period (cumulative leaching values after 14 days are summarised in

Table 5). The experimentation took place by measuring only one sample of leachate per composite material at each time interval, and the accuracy of the results could be increased through testing replicates. Furthermore, although the results of all of the testing were above the quantitative limit of the ICP–MS experimentation, some of the results indicate extremely low levels of heavy metals (especially the leaching of As from D and DB fibre composites), and the results of samples with very low levels of leaching are potentially susceptible to errors in the methods undertaken or contamination. However, the results shown in the figures give a clear trend in leaching properties between samples.

The recorded leaching values of the wood flour composites were lower than other studies, likely due to the low content of wood flour in the composites allowing for better encapsulation in the matrix, therefore restricting water penetrating the composites and reducing the ability of the heavy metals to leach out [

9,

10].

The results shown in

Figure 8 and

Table 5 show that the leaching of copper is higher from all materials than the leaching of chromium and arsenic. This is interesting as the content of chromium in both the wood flour and digested fibres is higher than the other heavy metals, as shown in

Table 3. The arsenic leaching from the wood flour was also significantly higher than the chromium leaching.

The leaching of copper and arsenic appears to be directly related to the heavy metal content in the flour and fibres. The concentration and leaching of copper were very similar for wood flour and digested fibres, and the concentration and leaching of copper were much lower for the digested and bleached fibres. The properties were very similar for arsenic; the wood flour has a high concentration of arsenic and leaches the most, whereas the D and DB fibres have very low concentrations of arsenic, and the corresponding leaching was also minimal.

Differing from the copper and arsenic leaching properties, the leaching of chromium does not appear to directly relate to the content in the wood flour and fibres. The wood flour has the highest chromium content, whereas the digested fibres appear to leach the most over a two-week period. The digested fibre composites were seen to absorb the most moisture, which has the potential to allow for more chromium to leach out of the composites. However, the leaching of chromium from the DB fibre composites suggests that there was further reasoning. Leaching and moisture absorption of the wood flour composites and the digested and bleached fibre composites appeared to be very similar; however, the content of chromium in the DB fibres is approximately five times less than that of the wood flour (353.16 ppm compared to 1728.5 ppm). Therefore, it is likely that the fixation of chromium into the composites was altered with the digestion process due to the high temperature, and pressure in the alkali solution. This could be a result of residual chromium (III) arsenate, which is expected to have been primarily removed, now being more susceptible to leaching, or an alteration in the fixation of chromium (III) hydroxide. However, it should be noted that the leaching was all measured to be in the same magnitude of ppb, and it is possible that small amounts of contamination could have caused the differences in results.

The maximum acceptable values (MAV) for the heavy metals in New Zealand’s drinking water are 2000, 50, and 10 ppb for Cu, Cr, and As, respectively [

40]. The leaching from composites produced with D and DB fibres both meet these standards, as seen in

Table 5. Therefore, even if there were small amounts of contamination or error in the measurements, the samples are still below the MAV for safe drinking water.

The literature on using WPC produced with waste CCA-treated timber indicated that one of the largest concerns was the heavy metal content and the potential for leaching when in application. Furthermore, the two studies that investigated leaching from WPC showed leachate levels that were significantly higher than the MAV for safe drinking water and used this as a justification for their concerns. However, the results of this study suggest that the use of chemical processing to obtain wood fibres from CCA-treated timber has the potential to be used in the wood–plastic composite materials with leachate levels significantly lower than the MAV of drinking water. Therefore, the leaching test results indicate the potential for safe usage and application of composites produced with wood fibres from waste CCA-treated timber, even when in contact with people.