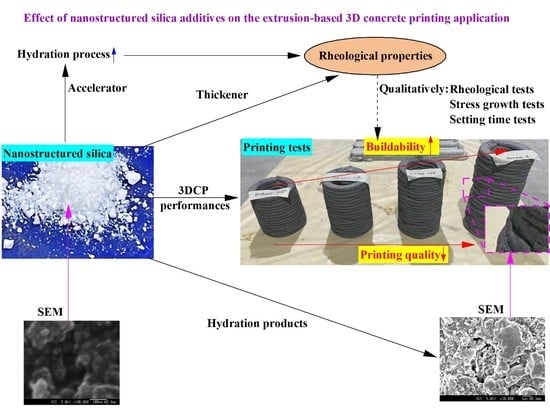

Effect of Nanostructured Silica Additives on the Extrusion-Based 3D Concrete Printing Application

Abstract

:1. Introduction

2. Materials and Methods

2.1. Methods

2.2. Material and Mixing Process

2.3. Experimental Design

2.3.1. Rheological Test

2.3.2. Stress Growth Test

2.3.3. Setting Time

2.3.4. Printing Test

2.3.5. Scanning Electron Microscopy (SEM) Analysis

3. Results and Discussion

3.1. Rheological Test Results

3.2. Stress Growth Test Results

3.3. Setting Time Results

3.4. Printing Test Results

3.5. Comparison of Different Test Results

3.6. Scanning Electron Microscopy (SEM) Analysis Results

4. Conclusions

- 1.

- Through rheological tests, it confirms that the nanostructured silica tends to improve the static yield stress, dynamic yield stress, and plastic viscosity. To determine the fresh cementitious material with the highest thixotropy, the optimal dosage of nanostructured silica is 0.75% by the weight of the total 3DCP mixture.

- 2.

- Stress growth tests demonstrate that nanostructured silica has similar effects as an organic thickener and accelerator since it improves the initial value and growth rate of the static yield stress. Its corresponding effect on accelerating hydration is also proved by decreasing the initial setting time of the 3DCP mixtures in setting time tests.

- 3.

- The printing tests indicate that the nanostructured silica tends to benefit the 3DCP buildability but negatively affects the printing quality correlated to material pumpability. These trends are consistent with the effects of the nanostructured silica on the static yield stress and dynamic yield stress in the rheological tests.

- 4.

- By comparing different failure criteria, it shows that for all nanostructured-modified 3DCP cementitious materials, the static yield stress from rheological tests can only quantitively predict the failure caused by gravity-induced vertical stress. Thus, printing tests are still essential to evaluate the printing performance of nanostructured-silica-modified cementitious materials.

- 5.

- The results of SEM show that the hydration product of CH is reacted with nanostructured silica and converted into C-S-H due to the pozzolanic reaction. However, heavy carbonation tends to appear with the increasing dosage of nanostructured silica.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Seol, Y.J.; Kang, H.W.; Lee, S.J.; Atala, A.; Yoo, J.J. Bioprinting technology and its applications. Eur. J. Cardiothorac. Surg. 2014, 46, 342–348. [Google Scholar] [CrossRef] [PubMed]

- Tian, X.; Wu, L.; Gu, D.; Yuan, S.; Zhao, Y.; Li, X.; Ouyang, L.; Song, B.; Gao, T.; He, J.; et al. Roadmap for Additive Manufacturing: Toward Intellectualization and Industrialization. Chin. J. Mech. Eng. Addit. Manuf. Front. 2022, 1, 100014. [Google Scholar] [CrossRef]

- Burger, J.; Lloret-Fritschi, E.; Scotto, F.; Demoulin, T.; Gebhard, L.; Mata-Falcón, J.; Gramazio, F.; Kohler, M.; Flatt, R.J. Eggshell: Ultra-Thin Three-Dimensional Printed Formwork for Concrete Structures. 3d Print. Addit. Manuf. 2020, 7, 48–59. [Google Scholar] [CrossRef]

- Jipa, A.; Reiter, L.; Flatt, R.J.; Dillenburger, B. Environmental stress cracking of 3D-printed polymers exposed to concrete. Addit. Manuf. 2022, 58, 103026. [Google Scholar] [CrossRef]

- Labonnote, N.; Rønnquist, A.; Manum, B.; Rüther, P. Additive construction: State-of-the-art, challenges and opportunities. Autom. Constr. 2016, 72, 347–366. [Google Scholar] [CrossRef]

- Ma, G.; Wang, L. A critical review of preparation design and workability measurement of concrete material for largescale 3D printing. Front. Struct. Civ. Eng. 2017, 12, 382–400. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Bos, F.P.; Perrot, A.; da Silva, W.R.L.; Nerella, V.N.; Fataei, S.; Wolfs, R.J.M.; Sonebi, M.; Roussel, N. Extrusion-based additive manufacturing with cement-based materials—Production steps, processes, and their underlying physics: A review. Cem. Concr. Res. 2020, 132, 106037. [Google Scholar] [CrossRef]

- Liu, Z.; Li, M.; Tay, Y.W.D.; Weng, Y.; Wong, T.N.; Tan, M.J. Rotation nozzle and numerical simulation of mass distribution at corners in 3D cementitious material printing. Addit. Manuf. 2020, 34, 101190. [Google Scholar] [CrossRef]

- de Soto, B.G.; Agustí-Juan, I.; Hunhevicz, J.; Joss, S.; Graser, K.; Habert, G.; Adey, B.T. Productivity of digital fabrication in construction: Cost and time analysis of a robotically built wall. Autom. Constr. 2018, 92, 297–311. [Google Scholar] [CrossRef]

- Paul, S.C.; Tay, Y.W.D.; Panda, B.; Tan, M.J. Fresh and hardened properties of 3D printable cementitious materials for building and construction. Arch. Civ. Mech. Eng. 2018, 18, 311–319. [Google Scholar] [CrossRef]

- De Schutter, G.; Lesage, K.; Mechtcherine, V.; Nerella, V.N.; Habert, G.; Agusti-Juan, I. Vision of 3D printing with concrete—Technical, economic and environmental potentials. Cem. Concr. Res. 2018, 112, 25–36. [Google Scholar] [CrossRef]

- Buswell, R.A.; Soar, R.C.; Gibb, A.G.F.; Thorpe, A. Freeform Construction: Mega-scale Rapid Manufacturing for construction. Autom. Constr. 2007, 16, 224–231. [Google Scholar] [CrossRef]

- Suiker, A.S.J.; Wolfs, R.J.M.; Lucas, S.M.; Salet, T.A.M. Elastic buckling and plastic collapse during 3D concrete printing. Cem. Concr. Res. 2020, 135, 106016. [Google Scholar] [CrossRef]

- Weng, Y.; Li, M.; Tan, M.J.; Qian, S. Design 3D printing cementitious materials via Fuller Thompson theory and Marson-Percy model. Constr. Build. Mater. 2018, 163, 600–610. [Google Scholar] [CrossRef]

- Kruger, J.; Zeranka, S.; van Zijl, G. An ab initio approach for thixotropy characterisation of (nanoparticle-infused) 3D printable concrete. Constr. Build. Mater. 2019, 224, 372–386. [Google Scholar] [CrossRef]

- Weng, Y.; Li, M.; Zhang, D.; Tan, M.J.; Qian, S. Investigation of interlayer adhesion of 3D printable cementitious material from the aspect of printing process. Cem. Concr. Res. 2021, 143, 106386. [Google Scholar] [CrossRef]

- Ramakrishnan, S.; Kanagasuntharam, S.; Sanjayan, J. In-line activation of cementitious materials for 3D concrete printing. Cem. Concr. Compos. 2022, 131, 104598. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete; Longman: London, UK, 1995; Volume 4. [Google Scholar]

- Kruger, J.; Zeranka, S.; van Zijl, G. A rheology-based quasi-static shape retention model for digitally fabricated concrete. Constr. Build. Mater. 2020, 254, 119241. [Google Scholar] [CrossRef]

- Jiang, Q.; Liu, Q.; Wu, S.; Zheng, H.; Sun, W. Modification effect of nanosilica and polypropylene fiber for extrusion-based 3D printing concrete: Printability and mechanical anisotropy. Addit. Manuf. 2022, 56, 102944. [Google Scholar] [CrossRef]

- Mendoza Reales, O.A.; Duda, P.; Silva, E.C.C.M.; Paiva, M.D.M.; Filho, R.D.T. Nanosilica particles as structural buildup agents for 3D printing with Portland cement pastes. Constr. Build. Mater. 2019, 219, 91–100. [Google Scholar] [CrossRef]

- Lavergne, F.; Belhadi, R.; Carriat, J.; Ben Fraj, A. Effect of nano-silica particles on the hydration, the rheology and the strength development of a blended cement paste. Cem. Concr. Compos. 2019, 95, 42–55. [Google Scholar] [CrossRef]

- Mohammed, A.; Rafiq, S.; Mahmood, W.; Noaman, R.; Al-Darkazali, H.; Ghafor, K.; Qadir, W. Microstructure characterizations, thermal properties, yield stress, plastic viscosity and compression strength of cement paste modified with nanosilica. J. Mater. Res. Technol. 2020, 9, 10941–10956. [Google Scholar] [CrossRef]

- Balapour, M.; Joshaghani, A.; Althoey, F. Nano-SiO2 contribution to mechanical, durability, fresh and microstructural characteristics of concrete: A review. Constr. Build. Mater. 2018, 181, 27–41. [Google Scholar] [CrossRef]

- Vipulanandan, C.; Mohammed, A. Smart Cement Compressive Piezoresistive, Stress-Strain, and Strength Behavior with Nanosilica Modification. J. Test. Eval. 2019, 47, 1479–1501. [Google Scholar] [CrossRef]

- Rahimzadeh, C.Y.; Salih, A.; Barzinjy, A.A. Systematic Multiscale Models to Predict the Compressive Strength of Cement Paste as a Function of Microsilica and Nanosilica Contents, Water/Cement Ratio, and Curing Ages. Sustainability 2022, 14, 1723. [Google Scholar] [CrossRef]

- Abdalla, A.A.; Salih Mohammed, A.; Rafiq, S.; Noaman, R.; Sarwar Qadir, W.; Ghafor, K.; Al-Darkazali, H.; Fairs, R. Microstructure, chemical compositions, and soft computing models to evaluate the influence of silicon dioxide and calcium oxide on the compressive strength of cement mortar modified with cement kiln dust. Constr. Build. Mater. 2022, 341, 127668. [Google Scholar] [CrossRef]

- Abdalla, A.; Salih, A. Microstructure and chemical characterizations with soft computing models to evaluate the influence of calcium oxide and silicon dioxide in the fly ash and cement kiln dust on the compressive strength of cement mortar. Resour. Conserv. Recycl. Adv. 2022, 15, 200090. [Google Scholar] [CrossRef]

- Bos, F.P.; Kruger, P.J.; Lucas, S.S.; van Zijl, G.P.A.G. Juxtaposing fresh material characterisation methods for buildability assessment of 3D printable cementitious mortars. Cem. Concr. Compos. 2021, 120, 104024. [Google Scholar] [CrossRef]

- Lu, B.; Weng, Y.; Li, M.; Qian, Y.; Leong, K.F.; Tan, M.J.; Qian, S. A systematical review of 3D printable cementitious materials. Construction and Building Materials 2019, 207, 477–490. [Google Scholar] [CrossRef]

- Ma, S.; Qian, Y.; Kawashima, S. Experimental and modeling study on the non-linear structural build-up of fresh cement pastes incorporating viscosity modifying admixtures. Cem. Concr. Res. 2018, 108, 1–9. [Google Scholar] [CrossRef]

- Roussel, N. Rheological requirements for printable concretes. Cem. Concr. Res. 2018, 112, 76–85. [Google Scholar] [CrossRef]

- Qian, Y. Characterization of Structural Rebuilding and Shear Migration in Cementitious Materials in Consideration of Thixotropy; Columbia University: New York, NY, USA, 2017. [Google Scholar]

- ASTM-C191; Standard Test Methods for Time of Setting of Hydraulic Cement by Vicat Needle. American Society for Tesing and Materials: West Conshohocken, PA, USA, 2014. [CrossRef]

- Yang, H.; Monasterio, M.; Zheng, D.; Cui, H.; Tang, W.; Bao, X.; Chen, X. Effects of nano silica on the properties of cement-based materials: A comprehensive review. Constr. Build. Mater. 2021, 282, 122715. [Google Scholar] [CrossRef]

- Leemann, A.; Winnefeld, F. The effect of viscosity modifying agents on mortar and concrete. Cem. Concr. Compos. 2007, 29, 341–349. [Google Scholar] [CrossRef]

- Roussel, N. A thixotropy model for fresh fluid concretes: Theory, validation and applications. Cem. Concr. Res. 2006, 36, 1797–1806. [Google Scholar] [CrossRef]

- Sikora, P.; Chung, S.-Y.; Liard, M.; Lootens, D.; Dorn, T.; Kamm, P.H.; Stephan, D.; Abd Elrahman, M. The effects of nanosilica on the fresh and hardened properties of 3D printable mortars. Constr. Build. Mater. 2021, 281, 122574. [Google Scholar] [CrossRef]

- Kruger, J.; Zeranka, S.; van Zijl, G. 3D concrete printing: A lower bound analytical model for buildability performance quantification. Autom. Constr. 2019, 106, 102904. [Google Scholar] [CrossRef]

- Alexandridis, A.; Gardner, N. Mechanical behaviour of fresh concrete. Cem. Concr. Res. 1981, 11, 323–339. [Google Scholar] [CrossRef]

- Suiker, A.S.J. Mechanical performance of wall structures in 3D printing processes: Theory, design tools and experiments. Int. J. Mech. Sci. 2018, 137, 145–170. [Google Scholar] [CrossRef]

- Li, W.; Shaikh, F.U.A.; Wang, L.; Lu, Y.; Wang, B.; Jiang, C.; Su, Y. Experimental study on shear property and rheological characteristic of superfine cement grouts with nano-SiO2 addition. Constr. Build. Mater. 2019, 228, 117046. [Google Scholar] [CrossRef]

| Name of Mixture | Silica Type | Premix Cement | River Sand (0–2 mm) | Silica Fume | Water | Nanostructured Silica |

|---|---|---|---|---|---|---|

| REF | NA | 1151.30 | 590.00 | 28.80 | 413.70 | - |

| SIP380_0.25% | Solid | 1151.30 | 590.00 | 28.80 | 413.70 | 5.46 |

| SIP380_0.50% | Solid | 1151.30 | 590.00 | 28.80 | 413.70 | 10.92 |

| SIP380_0.75% | Solid | 1151.30 | 590.00 | 28.80 | 413.70 | 16.38 |

| SIP380_1.00% | Solid | 1151.30 | 590.00 | 28.80 | 413.70 | 21.84 |

| W7520P_0.25% | Liquid | 1151.30 | 590.00 | 28.80 | 413.70 | 5.46 |

| W7520P_0.50% | Liquid | 1151.30 | 590.00 | 28.80 | 413.70 | 10.92 |

| W7520P_0.75% | Liquid | 1151.30 | 590.00 | 28.80 | 413.70 | 16.38 |

| W7520P_1.00% | Liquid | 1151.30 | 590.00 | 28.80 | 413.70 | 21.84 |

| Mixing Time (min) | Rotational Speed (rpm) | Solid Powder Case | The Liquid Aqueous Dispersion of Nanostructured Silica Case |

|---|---|---|---|

| 0.5 | 33 | Sand + nanostructured silica | Sand |

| 0.5 | 61 | - | - |

| 0.5 | 33 | Premix cement + silica fume | Premix cement + silica fume |

| 0.5 | 61 | - | - |

| 1.0 | 33 | Water | Water + nanostructured silica |

| 0.5 | 61 | - | - |

| 1.0 | 113 | - | - |

| Mixture | Static Yield Stress | R2 |

|---|---|---|

| REF | τs = 38t + 1122 | 0.7873 |

| SIP380_0.25% | τs = 55t + 1643 | 0.9736 |

| SIP380_0.50% | τs = 49t + 2094 | 0.9168 |

| SIP380_0.75% | τs = 65t + 2838 | 0.9232 |

| SIP380_1.00% | τs = 68t + 4274 | 0.9209 |

| W7520P_0.25% | τs = 35t + 1537 | 0.9795 |

| W7520P_0.50% | τs = 52t + 2877 | 0.9392 |

| W7520P_0.75% | τs = 65t + 3989 | 0.9687 |

| W7520P_1.00% | NA | NA |

| Mixture | τs | σu (Pa) | σu/τs | φ (°) |

|---|---|---|---|---|

| REF | 1110 | 2678 | 2.41 | 10.68 |

| SIP380_0.25% | 1503 | 3296 | 2.19 | 5.27 |

| SIP380_0.50% | 1893 | 4120 | 2.18 | 4.84 |

| SIP380_0.75% | 3233 | 4738 | 1.47 | <0 |

| SIP380_1.00% | 3942 | 5768 | 1.46 | <0 |

| W7520P_0.25% | 2021 | 2472 | 1.22 | <0 |

| W7520P_0.50% | 2437 | 4120 | 1.69 | <0 |

| W7520P_0.75% | 4388 | 7416 | 1.69 | <0 |

| W7520P_1.00% | - | - | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Li, M.; Moo, G.S.J.; Kobayashi, H.; Wong, T.N.; Tan, M.J. Effect of Nanostructured Silica Additives on the Extrusion-Based 3D Concrete Printing Application. J. Compos. Sci. 2023, 7, 191. https://doi.org/10.3390/jcs7050191

Liu Z, Li M, Moo GSJ, Kobayashi H, Wong TN, Tan MJ. Effect of Nanostructured Silica Additives on the Extrusion-Based 3D Concrete Printing Application. Journal of Composites Science. 2023; 7(5):191. https://doi.org/10.3390/jcs7050191

Chicago/Turabian StyleLiu, Zhenbang, Mingyang Li, Guo Sheng James Moo, Hitoshi Kobayashi, Teck Neng Wong, and Ming Jen Tan. 2023. "Effect of Nanostructured Silica Additives on the Extrusion-Based 3D Concrete Printing Application" Journal of Composites Science 7, no. 5: 191. https://doi.org/10.3390/jcs7050191

APA StyleLiu, Z., Li, M., Moo, G. S. J., Kobayashi, H., Wong, T. N., & Tan, M. J. (2023). Effect of Nanostructured Silica Additives on the Extrusion-Based 3D Concrete Printing Application. Journal of Composites Science, 7(5), 191. https://doi.org/10.3390/jcs7050191