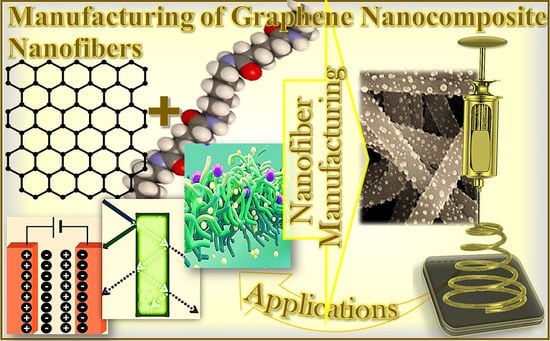

Nanocomposite Nanofibers of Graphene—Fundamentals and Systematic Developments

Abstract

:1. Introduction

2. Polymer and Polymer Nanocomposite Nanofibers

- i.

- In the electrospinning technique, the feed rate can influence the polymer solution delivery speed and jet intensity [57]. Consequently, the feed rate has been found to affect the diameter and morphology of the nanofibers. Increasing the polymer solution feed rate may enhance the fiber diameter, whereas slow flow may form thin fibers.

- ii.

- Distance between the spinneret tip and collector has been found to affect the morphology and fiber diameter [58]. The optimum distance between the tip and collector provides sufficient time to dry the nanofibers and avoid bead formation. Furthermore, the increasing distance results in more round solid fibers.

- iii.

- The sufficiently high voltage between a needle and metal collector is important to overcome the surface tension holding a drop of liquid at the needle tip [59]. Consequently, a thin fluid jet is projected out. The solvent is easily evaporated during the trajectory between the needle and collector. Hence, fibers with homogeneous surfaces and small diameters have been developed. The low electric field cannot provide enough jet elongation to generate uniform fibers.

- iv.

- The pumping pressure also influences the flow of polymer solution during the electrospinning process [60]. Very low pumping pressure may increase the nanofiber diameter and bead formation.

3. Graphene

4. Manufacturing and Properties of Polymer/Graphene Nanocomposite Nanofibers

5. Applications of Polymer/Graphene Nanocomposite Nanofiber

6. Future Prospects

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lee, J.K.Y.; Chen, N.; Peng, S.; Li, L.; Tian, L.; Thakor, N.; Ramakrishna, S. Polymer-based composites by electrospinning: Preparation & functionalization with nanocarbons. Prog. Polym. Sci. 2018, 86, 40–84. [Google Scholar]

- Ichakpa, M.; Goodyear, M.; Duthie, J.; Duthie, M.; Wisely, R.; MacPherson, A.; Keyte, J.; Pancholi, K.; Njuguna, J. Investigation on Mechanical and Thermal Properties of 3D-Printed Polyamide 6, Graphene Oxide and Glass-Fibre-Reinforced Composites under Dry, Wet and High Temperature Conditions. J. Compos. Sci. 2023, 7, 227. [Google Scholar] [CrossRef]

- Kausar, A.; Ahmad, I.; Zhao, T.; Eisa, M.; Aldaghri, O.; Gupta, M.; Bocchetta, P. Green-Synthesized Graphene for Supercapacitors—Modern Perspectives. J. Compos. Sci. 2023, 7, 108. [Google Scholar] [CrossRef]

- Alegaonkar, A.P.; Alegaonkar, P.S. Nanocarbons: Preparation, Assessments, and Applications; CRC Press: Boca Raton, FL, USA, 2023. [Google Scholar]

- Sokolov, M.; Nugmanova, A.; Shkolin, A.; Zvyagina, A.; Senchikhin, I.; Kalinina, M. Ion-Mediated Self-Assembly of Graphene Oxide and Functionalized Perylene Diimides into Hybrid Materials with Photocatalytic Properties. J. Compos. Sci. 2023, 7, 14. [Google Scholar] [CrossRef]

- Kausar, A.; Ahmad, I.; Bocchetta, P. High-performance corrosion-resistant polymer/graphene nanomaterials for biomedical relevance. J. Compos. Sci. 2022, 6, 362. [Google Scholar] [CrossRef]

- Al-Dhahebi, A.M.; Ling, J.; Krishnan, S.G.; Yousefzadeh, M.; Elumalai, N.K.; Saheed, M.S.M.; Ramakrishna, S.; Jose, R. Electrospinning research and products: The road and the way forward. Appl. Phys. Rev. 2022, 9, 011319. [Google Scholar] [CrossRef]

- Zhang, X.; Ru, Z.; Sun, Y.; Zhang, M.; Wang, J.; Ge, M.; Liu, H.; Wu, S.; Cao, C.; Ren, X. Recent advances in applications for air pollutants purification and perspectives of electrospun nanofibers. J. Clean. Prod. 2022, 378, 134567. [Google Scholar] [CrossRef]

- Bulut, U.; Sayin, V.O.; Altin, Y.; Cevher, S.C.; Cirpan, A.; Bedeloglu, A.C.; Soylemez, S. A flexible carbon nanofiber and conjugated polymer-based electrode for glucose sensing. Microchem. J. 2023, 184, 108148. [Google Scholar] [CrossRef]

- Nair, A.B.; Shamsudeen, S.P.; Joys, M.; Varghese, N. Future Perspectives of Polymer Supercapacitors for Advanced Energy Storage Applications. In Polymer Nanocomposites in Supercapacitors; CRC Press: Boca Raton, FL, USA, 2023; pp. 237–257. [Google Scholar]

- Xu, X.; Lv, H.; Zhang, M.; Wang, M.; Zhou, Y.; Liu, Y.; Yu, D.-G. Recent progress in electrospun nanofibers and their applications in heavy metal wastewater treatment. Front. Chem. Sci. Eng. 2023, 17, 249–275. [Google Scholar] [CrossRef]

- Maliszewska, I.; Czapka, T. Electrospun Polymer Nanofibers with Antimicrobial Activity. Polymers 2022, 14, 1661. [Google Scholar] [CrossRef]

- Shinde, S.S.; Kher, J.A. A review on polyaniline and its noble metal composites. Int. J. Innov. Res. Sci. Eng. Technol. 2014, 3, 16570–16576. [Google Scholar] [CrossRef]

- Zhao, G.; Shi, L.; Yang, G.; Zhuang, X.; Cheng, B. 3D fibrous aerogels from 1D polymer nanofibers for energy and environmental applications. J. Mater. Chem. A 2023, 11, 512–547. [Google Scholar] [CrossRef]

- Nemati, S.; Kim, S.-j.; Shin, Y.M.; Shin, H. Current progress in application of polymeric nanofibers to tissue engineering. Nano Converg. 2019, 6, 36. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chaudhari, S.; Sharma, Y.; Archana, P.S.; Jose, R.; Ramakrishna, S.; Mhaisalkar, S.; Srinivasan, M. Electrospun polyaniline nanofibers web electrodes for supercapacitors. J. Appl. Polym. Sci. 2013, 129, 1660–1668. [Google Scholar] [CrossRef]

- Aliheidari, N.; Aliahmad, N.; Agarwal, M.; Dalir, H. Electrospun Nanofibers for Label-Free Sensor Applications. Sensors 2019, 19, 3587. [Google Scholar] [CrossRef] [Green Version]

- Ibrahim, H.M.; Klingner, A. A review on electrospun polymeric nanofibers: Production parameters and potential applications. Polym. Test. 2020, 90, 106647. [Google Scholar] [CrossRef]

- Wang, C.; Wang, J.; Zeng, L.; Qiao, Z.; Liu, X.; Liu, H.; Zhang, J.; Ding, J. Fabrication of electrospun polymer nanofibers with diverse morphologies. Molecules 2019, 24, 834. [Google Scholar] [CrossRef] [Green Version]

- Zhang, F.; Fan, J.b.; Wang, S. Interfacial polymerization: From chemistry to functional materials. Angew. Chem. Int. Ed. 2020, 59, 21840–21856. [Google Scholar] [CrossRef]

- Raaijmakers, M.J.; Benes, N.E. Current trends in interfacial polymerization chemistry. Prog. Polym. Sci. 2016, 63, 86–142. [Google Scholar] [CrossRef]

- Beachley, V.; Wen, X. Polymer nanofibrous structures: Fabrication, biofunctionalization, and cell interactions. Prog. Polym. Sci. 2010, 35, 868–892. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Lu, Y. Centrifugal spinning: An alternative approach to fabricate nanofibers at high speed and low cost. Polym. Rev. 2014, 54, 677–701. [Google Scholar] [CrossRef]

- Huang, Y.; Song, J.; Yang, C.; Long, Y.; Wu, H. Scalable manufacturing and applications of nanofibers. Mater. Today 2019, 28, 98–113. [Google Scholar] [CrossRef]

- Liapis, A.I.; Bruttini, R. Freeze drying. In Handbook of Industrial Drying; CRC Press: Boca Raton, FL, USA, 2020; pp. 309–343. [Google Scholar]

- Stojanovska, E.; Canbay, E.; Pampal, E.S.; Calisir, M.D.; Agma, O.; Polat, Y.; Simsek, R.; Gundogdu, N.S.; Akgul, Y.; Kilic, A. A review on non-electro nanofibre spinning techniques. RSC Adv. 2016, 6, 83783–83801. [Google Scholar] [CrossRef]

- Malgras, V.; Ji, Q.; Kamachi, Y.; Mori, T.; Shieh, F.-K.; Wu, K.C.-W.; Ariga, K.; Yamauchi, Y. Templated synthesis for nanoarchitectured porous materials. Bull. Chem. Soc. Jpn. 2015, 88, 1171–1200. [Google Scholar] [CrossRef]

- Zhang, Z.-M.; Duan, Y.-S.; Xu, Q.; Zhang, B. A review on nanofiber fabrication with the effect of high-speed centrifugal force field. J. Eng. Fibers Fabr. 2019, 14, 1558925019867517. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Nain, A.S. Suspended micro/nanofiber hierarchical biological scaffolds fabricated using non-electrospinning STEP technique. Langmuir 2014, 30, 13641–13649. [Google Scholar] [CrossRef]

- Jin, L.; Xu, Q.; Li, C.; Huang, J.; Zhang, Y.; Wu, D.; Wang, Z. Engineering 3D aligned nanofibers for regulation of cell growth behavior. Macromol. Mater. Eng. 2017, 302, 1600448. [Google Scholar] [CrossRef]

- Fajardo-Diaz, J.L.; Morelos-Gomez, A.; Cruz-Silva, R.; Ishii, K.; Yasuike, T.; Kawakatsu, T.; Yamanaka, A.; Tejima, S.; Izu, K.; Saito, S. Low-pressure reverse osmosis membrane made of cellulose nanofiber and carbon nanotube polyamide nano-nanocomposite for high purity water production. Chem. Eng. J. 2022, 448, 137359. [Google Scholar] [CrossRef]

- Amer Flayeh, A.; Jawad Kadhim, H. Enhancing the physical properties of polystyrene nanofibers by adding multiwall carbon nanotubes and natural dye. Fuller. Nanotub. Carbon Nanostruct. 2022, 30, 1090–1096. [Google Scholar] [CrossRef]

- Liao, Y.; Zhang, C.; Zhang, Y.; Strong, V.; Tang, J.; Li, X.-G.; Kalantar-Zadeh, K.; Hoek, E.M.; Wang, K.L.; Kaner, R.B. Carbon nanotube/polyaniline composite nanofibers: Facile synthesis and chemosensors. Nano Lett. 2011, 11, 954–959. [Google Scholar] [CrossRef]

- Patil, P.T.; Anwane, R.S.; Kondawar, S.B. Development of electrospun polyaniline/ZnO composite nanofibers for LPG sensing. Procedia Mater. Sci. 2015, 10, 195–204. [Google Scholar] [CrossRef] [Green Version]

- Kayaci, F.; Ozgit-Akgun, C.; Donmez, I.; Biyikli, N.; Uyar, T. Polymer-inorganic core-shell nanofibers by electrospinning and atomic layer deposition: Flexible nylon-ZnO core-shell nanofiber mats and their photocatalytic activity. ACS Appl. Mater. Interfaces 2012, 4, 6185–6194. [Google Scholar] [CrossRef]

- Kellenberger, A.; Plesu, N.; Mihali, M.T.-L.; Vaszilcsin, N. Synthesis of polyaniline nanostructures by electrochemical deposition on niobium. Polymer 2013, 54, 3166–3174. [Google Scholar] [CrossRef]

- Snari, R.M.; Bayazeed, A.; Ibarhiam, S.F.; Alnoman, R.B.; Attar, R.; Abumelha, H.M.; El-Metwaly, N.M. Solution blowing spinning of polylactate/polyvinyl alcohol/ZnO nanocomposite toward green and sustainable preparation of wound dressing nanofibrous films. Microsc. Res. Tech. 2022, 85, 3860–3870. [Google Scholar] [CrossRef] [PubMed]

- Costa, R.G.; Brichi, G.S.; Ribeiro, C.; Mattoso, L.H. Nanocomposite fibers of poly(lactic acid)/titanium dioxide prepared by solution blow spinning. Polym. Bull. 2016, 73, 2973–2985. [Google Scholar] [CrossRef]

- Ikegame, M.; Tajima, K.; Aida, T. Template synthesis of polypyrrole nanofibers insulated within one-dimensional silicate channels: Hexagonal versus lamellar for recombination of polarons into bipolarons. Angew. Chem. Int. Ed. 2003, 42, 2154–2157. [Google Scholar] [CrossRef] [PubMed]

- Huang, J. Syntheses and applications of conducting polymer polyaniline nanofibers. Pure Appl. Chem. 2006, 78, 15–27. [Google Scholar] [CrossRef]

- Shah, A.A.; Cho, Y.H.; Nam, S.-E.; Park, A.; Park, Y.-I.; Park, H. High performance thin-film nanocomposite forward osmosis membrane based on PVDF/bentonite nanofiber support. J. Ind. Eng. Chem. 2020, 86, 90–99. [Google Scholar] [CrossRef]

- Li, Y.; Li, J.; Soria, R.B.; Volodine, A.; Van der Bruggen, B. Aramid nanofiber and modified ZIF-8 constructed porous nanocomposite membrane for organic solvent nanofiltration. J. Membr. Sci. 2020, 603, 118002. [Google Scholar] [CrossRef]

- Huang, Y.; Zhou, T.; He, S.; Xiao, H.; Dai, H.; Yuan, B.; Chen, X.; Yang, X. Flame-retardant polyvinyl alcohol/cellulose nanofibers hybrid carbon aerogel by freeze drying with ultra-low phosphorus. Appl. Surf. Sci. 2019, 497, 143775. [Google Scholar] [CrossRef]

- Mueller, S.; Sapkota, J.; Nicharat, A.; Zimmermann, T.; Tingaut, P.; Weder, C.; Foster, E.J. Influence of the nanofiber dimensions on the properties of nanocellulose/poly(vinyl alcohol) aerogels. J. Appl. Polym. Sci. 2015, 132, 41740. [Google Scholar] [CrossRef]

- Qian, L.; Zhang, H. Controlled freezing and freeze drying: A versatile route for porous and micro-/nano-structured materials. J. Chem. Technol. Biotechnol. 2011, 86, 172–184. [Google Scholar] [CrossRef]

- Abdal-hay, A.; Hamdy Makhlouf, A.S.; Khalil, K.A. Novel, facile, single-step technique of polymer/TiO2 nanofiber composites membrane for photodegradation of methylene blue. ACS Appl. Mater. Interfaces 2015, 7, 13329–13341. [Google Scholar] [CrossRef] [PubMed]

- Pan, Z.; Zhai, J.; Shen, B. Multilayer hierarchical interfaces with high energy density in polymer nanocomposites composed of BaTiO3@TiO2@Al2O3 nanofibers. J. Mater. Chem. A 2017, 5, 15217–15226. [Google Scholar] [CrossRef]

- Zhang, Y.; Venugopal, J.R.; El-Turki, A.; Ramakrishna, S.; Su, B.; Lim, C.T. Electrospun biomimetic nanocomposite nanofibers of hydroxyapatite/chitosan for bone tissue engineering. Biomaterials 2008, 29, 4314–4322. [Google Scholar] [CrossRef] [PubMed]

- Chang, W.-M.; Wang, C.-C.; Chen, C.-Y. Plasma-induced polyaniline grafted on carbon nanotube-embedded carbon nanofibers for high-performance supercapacitors. Electrochim. Acta 2016, 212, 130–140. [Google Scholar] [CrossRef]

- Rezaei, F.; Gorbanev, Y.; Chys, M.; Nikiforov, A.; Van Hulle, S.W.; Cos, P.; Bogaerts, A.; De Geyter, N. Investigation of plasma-induced chemistry in organic solutions for enhanced electrospun PLA nanofibers. Plasma Process. Polym. 2018, 15, 1700226. [Google Scholar] [CrossRef]

- Mittal, V. Synthesis Techniques for Polymer Nanocomposites; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Arjmandi, S.K.; Khademzadeh Yeganeh, J.; Zare, Y.; Rhee, K.Y. Development of Kovacs model for electrical conductivity of carbon nanofiber-polymer systems. Sci. Rep. 2023, 13, 7. [Google Scholar] [CrossRef] [PubMed]

- Sundaray, B.; Choi, A.; Park, Y.W. Highly conducting electrospun polyaniline-polyethylene oxide nanofibrous membranes filled with single-walled carbon nanotubes. Synth. Met. 2010, 160, 984–988. [Google Scholar] [CrossRef]

- Kausar, A. Thermally conducting polymer/nanocarbon and polymer/inorganic nanoparticle nanocomposite: A review. Polym. -Plast. Technol. Mater. 2020, 59, 895–909. [Google Scholar] [CrossRef]

- Takeno, H.; Shikano, R.; Kikuchi, R. Mechanical Performance of Corn Starch/Poly(Vinyl Alcohol) Composite Hydrogels Reinforced by Inorganic Nanoparticles and Cellulose Nanofibers. Gels 2022, 8, 514. [Google Scholar] [CrossRef]

- Shin, Y.J.; Kameoka, J. Amperometric cholesterol biosensor using layer-by-layer adsorption technique onto electrospun polyaniline nanofibers. J. Ind. Eng. Chem. 2012, 18, 193–197. [Google Scholar] [CrossRef]

- Haider, A.; Haider, S.; Kang, I.-K. A comprehensive review summarizing the effect of electrospinning parameters and potential applications of nanofibers in biomedical and biotechnology. Arab. J. Chem. 2018, 11, 1165–1188. [Google Scholar] [CrossRef]

- Meyer, M. Processing of collagen based biomaterials and the resulting materials properties. Biomed. Eng. Online 2019, 18, 24. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ding, J.; Zhang, J.; Li, J.; Li, D.; Xiao, C.; Xiao, H.; Yang, H.; Zhuang, X.; Chen, X. Electrospun polymer biomaterials. Prog. Polym. Sci. 2019, 90, 1–34. [Google Scholar] [CrossRef]

- Bhardwaj, N.; Kundu, S.C. Electrospinning: A fascinating fiber fabrication technique. Biotechnol. Adv. 2010, 28, 325–347. [Google Scholar] [CrossRef]

- Cooley, J.F. Improved Methods of and Apparatus for Electrically Separating the Relatively Volatile Liquid Component from the Component of Relatively Fixed Substances of Composite Fluids. UK Patent GB 06385, 1900. [Google Scholar]

- Tan, N.P.; Cabatingan, L.K.; Lim, K.J.A. Synthesis of TiO2 nanofiber by solution blow spinning (SBS) method. Key Eng. Mater. 2020, 858, 122–128. [Google Scholar] [CrossRef]

- Sinha-Ray, S.; Sinha-Ray, S.; Yarin, A.L.; Pourdeyhimi, B. Theoretical and experimental investigation of physical mechanisms responsible for polymer nanofiber formation in solution blowing. Polymer 2015, 56, 452–463. [Google Scholar] [CrossRef]

- Medeiros, E.S.; Glenn, G.M.; Klamczynski, A.P.; Orts, W.J.; Mattoso, L.H. Solution blow spinning: A new method to produce micro-and nanofibers from polymer solutions. J. Appl. Polym. Sci. 2009, 113, 2322–2330. [Google Scholar] [CrossRef]

- Liu, R.; Xu, X.; Zhuang, X.; Cheng, B. Solution blowing of chitosan/PVA hydrogel nanofiber mats. Carbohydr. Polym. 2014, 101, 1116–1121. [Google Scholar] [CrossRef]

- Oliveira, J.E.; Mattoso, L.H.; Orts, W.J.; Medeiros, E.S. Structural and morphological characterization of micro and nanofibers produced by electrospinning and solution blow spinning: A comparative study. Adv. Mater. Sci. Eng. 2013, 2013, 409572. [Google Scholar] [CrossRef] [Green Version]

- Wu, X.F.; Yarin, A.L. Recent progress in interfacial toughening and damage self-healing of polymer composites based on electrospun and solution-blown nanofibers: An overview. J. Appl. Polym. Sci. 2013, 130, 2225–2237. [Google Scholar] [CrossRef]

- Xu, H.; Yagi, S.; Ashour, S.; Du, L.; Hoque, M.E.; Tan, L. A Review on Current Nanofiber Technologies: Electrospinning, Centrifugal Spinning, and Electro-Centrifugal Spinning. Macromol. Mater. Eng. 2023, 308, 2200502. [Google Scholar] [CrossRef]

- Ren, L.; Kotha, S.P. Centrifugal jet spinning for highly efficient and large-scale fabrication of barium titanate nanofibers. Mater. Lett. 2014, 117, 153–157. [Google Scholar] [CrossRef] [Green Version]

- Marjuban, S.M.H.; Rahman, M.; Duza, S.S.; Ahmed, M.B.; Patel, D.K.; Rahman, M.S.; Lozano, K. Recent Advances in Centrifugal Spinning and Their Applications in Tissue Engineering. Polymers 2023, 15, 1253. [Google Scholar] [CrossRef]

- Alsharif, A.M. Power law liquid jets’ trajectories and instability during centrifugal spinning. Alex. Eng. J. 2023, 68, 301–314. [Google Scholar] [CrossRef]

- Huang, Y.; Duan, Y.; Ding, Y.; Bu, N.; Pan, Y.; Lu, N.; Yin, Z. Versatile, kinetically controlled, high precision electrohydrodynamic writing of micro/nanofibers. Sci. Rep. 2014, 4, 5949. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Duan, Y.; Ding, Y.; Xu, Z.; Huang, Y.; Yin, Z. Helix electrohydrodynamic printing of highly aligned serpentine micro/nanofibers. Polymers 2017, 9, 434. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, Z.; He, H.; Fu, W.; Ji, D.; Ramakrishna, S. Electro-hydrodynamic direct-writing technology toward patterned ultra-thin fibers: Advances, materials and applications. Nano Today 2020, 35, 100942. [Google Scholar] [CrossRef]

- Yin, Z.; Huang, Y.; Duan, Y.; Zhang, H. Electrohydrodynamic Direct-Writing for Flexible Electronic Manufacturing; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Gao, Y.; Zhang, Y.; Chen, P.; Li, Y.; Liu, M.; Gao, T.; Ma, D.; Chen, Y.; Cheng, Z.; Qiu, X. Toward single-layer uniform hexagonal boron nitride-graphene patchworks with zigzag linking edges. Nano Lett. 2013, 13, 3439–3443. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.-e.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [Green Version]

- Barkan, T. Graphene: The hype versus commercial reality. Nat. Nanotechnol. 2019, 14, 904–906. [Google Scholar] [CrossRef] [PubMed]

- Wei, C.; Negishi, R.; Ogawa, Y.; Akabori, M.; Taniyasu, Y.; Kobayashi, Y. Turbostratic multilayer graphene synthesis on CVD graphene template toward improving electrical performance. Jpn. J. Appl. Phys. 2019, 58, SIIB04. [Google Scholar] [CrossRef]

- Narayanam, P.K.; Botcha, V.D.; Ghosh, M.; Major, S.S. Growth and Photocatalytic Behaviour of Transparent Reduced GO-ZnO Nanocomposite Sheets. Nanotechnology 2019, 30, 485601. [Google Scholar] [CrossRef]

- Shen, X.J.; Zeng, X.L.; Dang, C.Y. Graphene Composites. Handb. Graphene 2019, 1, 1–25. [Google Scholar]

- Zandiatashbar, A.; Lee, G.-H.; An, S.J.; Lee, S.; Mathew, N.; Terrones, M.; Hayashi, T.; Picu, C.R.; Hone, J.; Koratkar, N. Effect of defects on the intrinsic strength and stiffness of graphene. Nat. Commun. 2014, 5, 3186. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhou, Q.; Xia, G.; Du, M.; Lu, Y.; Xu, H. Scotch-tape-like exfoliation effect of graphene quantum dots for efficient preparation of graphene nanosheets in water. Appl. Surf. Sci. 2019, 483, 52–59. [Google Scholar] [CrossRef]

- Pei, S.; Cheng, H.-M. The reduction of graphene oxide. Carbon 2012, 50, 3210–3228. [Google Scholar] [CrossRef]

- Brodie, B.C. XIII. On the atomic weight of graphite. Philos. Trans. R. Soc. Lond. 1859, 149, 249–259. [Google Scholar]

- Feicht, P.; Biskupek, J.; Gorelik, T.E.; Renner, J.; Halbig, C.E.; Maranska, M.; Puchtler, F.; Kaiser, U.; Eigler, S. Brodie's or Hummers’ method: Oxidation conditions determine the structure of graphene oxide. Chem. A Eur. J. 2019, 25, 8955–8959. [Google Scholar] [CrossRef] [PubMed]

- Hummers Jr, W.S.; Offeman, R.E. Preparation of graphitic oxide. J. Am. Chem. Soc. 1958, 80, 1339. [Google Scholar] [CrossRef]

- Lee, H.; Lee, K.S. Interlayer Distance Controlled Graphene, Supercapacitor and Method of Producing the Same. U.S. Patent 10,214,422, 26 February 2019. [Google Scholar]

- Bikiaris, N.D.; Koumentakou, I.; Samiotaki, C.; Meimaroglou, D.; Varytimidou, D.; Karatza, A.; Kalantzis, Z.; Roussou, M.; Bikiaris, R.D.; Papageorgiou, G.Z. Recent Advances in the Investigation of Poly(lactic acid) (PLA) Nanocomposites: Incorporation of Various Nanofillers and their Properties and Applications. Polymers 2023, 15, 1196. [Google Scholar] [CrossRef] [PubMed]

- Huang, Z.; Li, L.; Wang, Y.; Zhang, C.; Liu, T. Polyaniline/graphene nanocomposites towards high-performance supercapacitors: A review. Compos. Commun. 2018, 8, 83–91. [Google Scholar] [CrossRef]

- Wazalwar, R.; Sahu, M. Novel applications of graphene in the aerospace industry. In Novel Applications of Carbon Based Nano-materials; CRC Press: Boca Raton, FL, USA, 2022; pp. 180–198. [Google Scholar]

- Tang, C.; Titirici, M.-M.; Zhang, Q. A review of nanocarbons in energy electrocatalysis: Multifunctional substrates and highly active sites. J. Energy Chem. 2017, 26, 1077–1093. [Google Scholar] [CrossRef] [Green Version]

- Han, J.T.; Jang, J.I.; Cho, J.Y.; Hwang, J.Y.; Woo, J.S.; Jeong, H.J.; Jeong, S.Y.; Seo, S.H.; Lee, G.-W. Synthesis of nanobelt-like 1-dimensional silver/nanocarbon hybrid materials for flexible and wearable electronics. Sci. Rep. 2017, 7, 4931. [Google Scholar] [CrossRef] [Green Version]

- Marconcini, P.; Macucci, M. Transport Simulation of Graphene Devices with a Generic Potential in the Presence of an Orthogonal Magnetic Field. Nanomaterials 2022, 12, 1087. [Google Scholar] [CrossRef]

- Panwar, N.; Soehartono, A.M.; Chan, K.K.; Zeng, S.; Xu, G.; Qu, J.; Coquet, P.; Yong, K.-T.; Chen, X. Nanocarbons for biology and medicine: Sensing, imaging, and drug delivery. Chem. Rev. 2019, 119, 9559–9656. [Google Scholar] [CrossRef]

- Kausar, A. Applications of polymer/graphene nanocomposite membranes: A review. Mater. Res. Innov. 2019, 23, 276–287. [Google Scholar] [CrossRef]

- Abdali, H.; Ajji, A. Preparation of electrospun nanocomposite nanofibers of polyaniline/poly(methyl methacrylate) with amino-functionalized graphene. Polymers 2017, 9, 453. [Google Scholar] [CrossRef]

- Ramazani, S.; Karimi, M. Study the molecular structure of poly(ε-caprolactone)/graphene oxide and graphene nanocomposite nanofibers. J. Mech. Behav. Biomed. Mater. 2016, 61, 484–492. [Google Scholar] [CrossRef]

- Bagheri, M.; Mahmoodzadeh, A. Polycaprolactone/graphene nanocomposites: Synthesis, characterization and mechanical properties of electrospun nanofibers. J. Inorg. Organomet. Polym. Mater. 2020, 30, 1566–1577. [Google Scholar] [CrossRef]

- Ramazani, S.; Karimi, M. Aligned poly(ε-caprolactone)/graphene oxide and reduced graphene oxide nanocomposite nanofibers: Morphological, mechanical and structural properties. Mater. Sci. Eng. C 2015, 56, 325–334. [Google Scholar] [CrossRef] [PubMed]

- Li, B.; Yuan, H.; Zhang, Y. Transparent PMMA-based nanocomposite using electrospun graphene-incorporated PA-6 nanofibers as the reinforcement. Compos. Sci. Technol. 2013, 89, 134–141. [Google Scholar] [CrossRef]

- Pan, X.; Shen, L.; Schenning, A.P.; Bastiaansen, C.W. Transparent, high-thermal-conductivity ultradrawn polyethylene/graphene nanocomposite films. Adv. Mater. 2019, 31, 1904348. [Google Scholar] [CrossRef] [PubMed]

- Sahoo, S.; Dhibar, S.; Hatui, G.; Bhattacharya, P.; Das, C.K. Graphene/polypyrrole nanofiber nanocomposite as electrode material for electrochemical supercapacitor. Polymer 2013, 54, 1033–1042. [Google Scholar] [CrossRef]

- Mo, M.; Chen, C.; Gao, H.; Chen, M.; Li, D. Wet-spinning assembly of cellulose nanofibers reinforced graphene/polypyrrole microfibers for high performance fiber-shaped supercapacitors. Electrochim. Acta 2018, 269, 11–20. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, A.; Zhou, X.; Chen, F.; Fu, Q. Fabrication of aramid nanofiber-wrapped graphene fibers by coaxial spinning. Carbon 2020, 165, 340–348. [Google Scholar] [CrossRef]

- León-Boigues, L.; Flores, A.; Gómez-Fatou, M.A.; Vega, J.F.; Ellis, G.J.; Salavagione, H.J. PET/Graphene Nanocomposite Fibers Obtained by Dry-Jet Wet-Spinning for Conductive Textiles. Polymers 2023, 15, 1245. [Google Scholar] [CrossRef]

- Ganguly, S. Preparation/processing of polymer-graphene composites by different techniques. In Polymer Nanocomposites Containing Graphene; Elsevier: Amsterdam, The Netherlands, 2022; pp. 45–74. [Google Scholar]

- Jeong, K.; Kim, D.H.; Chung, Y.S.; Hwang, S.K.; Hwang, H.Y.; Kim, S.S. Effect of processing parameters of the continuous wet spinning system on the crystal phase of PVDF fibers. J. Appl. Polym. Sci. 2018, 135, 45712. [Google Scholar] [CrossRef]

- Huang, T.; Marshall, L.R.; Armantrout, J.E.; Yembrick, S.; Dunn, W.H.; Oconnor, J.M.; Mueller, T.; Avgousti, M.; Wetzel, M.D. Production of Nanofibers by Melt Spinning. U.S. Patent 20080242171A1, 2 October 2008. [Google Scholar]

- Jirsak, O.; Sanetrnik, F.; Lukas, D.; Kotek, V.; Martinova, L.; Chaloupek, J. Method of Nanofibres Production from a Polymer Solution Using Electrostatic Spinning and a Device for Carrying Out the Method. U.S. Patent 7,585,437, 8 September 2009. [Google Scholar]

- Li, X.; Cao, M.; Zhang, H.; Zhou, L.; Cheng, S.; Yao, J.-L.; Fan, L.-J. Surface-enhanced Raman scattering-active substrates of electrospun polyvinyl alcohol/gold–silver nanofibers. J. Colloid Interface Sci. 2012, 382, 28–35. [Google Scholar] [CrossRef]

- Ismagilov, Z.R.; Shalagina, A.E.; Podyacheva, O.Y.; Ischenko, A.V.; Kibis, L.S.; Boronin, A.I.; Chesalov, Y.A.; Kochubey, D.I.; Romanenko, A.I.; Anikeeva, O.B. Structure and electrical conductivity of nitrogen-doped carbon nanofibers. Carbon 2009, 47, 1922–1929. [Google Scholar] [CrossRef]

- Liu, Y.-L.; Li, Y.; Xu, J.-T.; Fan, Z.-Q. Cooperative effect of electrospinning and nanoclay on formation of polar crystalline phases in poly(vinylidene fluoride). ACS Appl. Mater. Interfaces 2010, 2, 1759–1768. [Google Scholar] [CrossRef] [PubMed]

- Scarlet, R.; Manea, L.R.; Sandu, I.; Cramariuc, B.; Sandu, A.V. The Influence of the Needle-Collector Distance Upon the Characteristics of the Polyetherimide Nanofibres Obtained by Electrospinning. Rev. Chim. 2012, 63, 777–782. [Google Scholar]

- Mahmoudi, N.; Simchi, A. On the biological performance of graphene oxide-modified chitosan/polyvinyl pyrrolidone nanocomposite membranes: In vitro and in vivo effects of graphene oxide. Mater. Sci. Eng. C 2017, 70, 121–131. [Google Scholar] [CrossRef] [PubMed]

- Park, S.; Park, K.; Yoon, H.; Son, J.; Min, T.; Kim, G. Apparatus for preparing electrospun nanofibers: Designing an electrospinning process for nanofiber fabrication. Polym. Int. 2007, 56, 1361–1366. [Google Scholar] [CrossRef]

- Li, Y.; Zhu, J.; Cheng, H.; Li, G.; Cho, H.; Jiang, M.; Gao, Q.; Zhang, X. Developments of advanced electrospinning techniques: A critical review. Adv. Mater. Technol. 2021, 6, 2100410. [Google Scholar] [CrossRef]

- Li, X.; Chen, W.; Qian, Q.; Huang, H.; Chen, Y.; Wang, Z.; Chen, Q.; Yang, J.; Li, J.; Mai, Y.W. Electrospinning-based strategies for battery materials. Adv. Energy Mater. 2021, 11, 2000845. [Google Scholar] [CrossRef]

- Luraghi, A.; Peri, F.; Moroni, L. Electrospinning for drug delivery applications: A review. J. Control. Release 2021, 334, 463–484. [Google Scholar] [CrossRef]

- Yadav, T.C.; Srivastava, A.K.; Mishra, P.; Singh, D.; Raghuwanshi, N.; Singh, N.K.; Singh, A.K.; Tiwari, S.K.; Prasad, R.; Pruthi, V. Electrospinning: An efficient biopolymer-based micro-and nanofibers fabrication technique. In Next Generation Biomanufacturing Technologies; ACS Publications: Columbus, OH, USA, 2019; pp. 209–241. [Google Scholar]

- Yu, D.-G.; Li, Q.; Song, W.; Xu, L.; Zhang, K.; Zhou, T. Advanced technique-based combination of innovation education and safety education in higher education. J. Chem. Educ. 2023, 100, 507–516. [Google Scholar] [CrossRef]

- Hosseini Ravandi, S.A.; Sadrjahani, M.; Valipouri, A.; Dabirian, F.; Ko, F.K. Recently developed electrospinning methods: A review. Text. Res. J. 2022, 92, 5130–5145. [Google Scholar] [CrossRef]

- Liu, Y.; Hao, M.; Zhou, C.; Yang, B.; Jiang, S.; Huang, J.; Chen, Z.; Liu, Y.; Ramakrishna, S. Scale-up strategies for electrospun nanofiber production. In Electrospun and Nanofibrous Membranes; Elsevier: Amsterdam, The Netherlands, 2023; pp. 205–266. [Google Scholar]

- Jha, C.B.; Santhosh, S.; Singh, C.; Bose, S.; Manna, K.; Varshney, R.; Mathur, R. Electrospun nanofiber a smart drug carriers: Production methods, problems, solutions, and applications. In Fiber and Textile Engineering in Drug Delivery Systems, Elsevier: Amsterdam, The Netherlands, 2023; pp. 285–306.

- Sun, L.; Miyagi, D.; Cai, Y.; Ullah, A.; Haider, M.K.; Zhu, C.; Gopiraman, M.; Kim, I.S. Rational construction of hierarchical nanocomposites by growing dense polyaniline nanoarrays on carbon black-functionalized carbon nanofiber backbone for freestanding supercapacitor electrodes. J. Energy Storage 2023, 61, 106738. [Google Scholar] [CrossRef]

- Jiang, J.; Liu, Y.; Chen, J.; Wang, X.; Yu, Z.; Li, W.; Zheng, G. In-situ molding of micro three-dimensional columnar structure by electric-field-focused electrospinning. Mater. Today Commun. 2023, 35, 105589. [Google Scholar] [CrossRef]

- Sumitha, M.; Xavier, T. Synthesis and electrochemical characterization of electrospun biocompatible Poly(ε-caprolactone) and Polyaniline nanofiber composite electrode materials for various biosensing applications. Mater. Today: Proc. 2023, 80, 1297–1305. [Google Scholar] [CrossRef]

- Wang, R.; Jing, Y. The effect of inorganic salt on the morphology and nucleation of polyaniline nanofibers synthesized via self-assembly. Des. Monomers Polym. 2023, 26, 45–53. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Wei, S.; Chen, Y.; Ye, H.; Xue, S.; Niu, Q.J. Sulfonated polyaniline interlayer with controllable doping conditions for high-performance nanofiltration. J. Membr. Sci. 2023, 672, 121478. [Google Scholar] [CrossRef]

- Mostafaei, A.; Nasirpouri, F. Epoxy/polyaniline-ZnO nanorods hybrid nanocomposite coatings: Synthesis, characterization and corrosion protection performance of conducting paints. Prog. Org. Coat. 2014, 77, 146–159. [Google Scholar] [CrossRef]

- Menzel, V.C.; Tudela, I. Additive manufacturing of polyaniline-based materials: An opportunity for new designs and applications in energy and biotechnology. Curr. Opin. Chem. Eng. 2022, 35, 100742. [Google Scholar] [CrossRef]

- Nakagaito, A.N.; Nogi, M.; Yano, H. Displays from transparent films of natural nanofibers. MRS Bull. 2010, 35, 214–218. [Google Scholar] [CrossRef]

- Andrady, A.L. Science and Technology of Polymer Nanofibers; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Zhou, S.; Zhang, H.; Zhao, Q.; Wang, X.; Li, J.; Wang, F. Graphene-wrapped polyaniline nanofibers as electrode materials for organic supercapacitors. Carbon 2013, 52, 440–450. [Google Scholar] [CrossRef]

- Huang, J.; Kaner, R.B. The intrinsic nanofibrillar morphology of polyaniline. Chem. Commun. 2006, 4, 367–376. [Google Scholar] [CrossRef]

- Sapurina, I.; Stejskal, J. The mechanism of the oxidative polymerization of aniline and the formation of supramolecular polyaniline structures. Polym. Int. 2008, 57, 1295–1325. [Google Scholar] [CrossRef]

- Ehsani, A.; Heidari, A.A.; Shiri, H.M. Electrochemical pseudocapacitors based on ternary nanocomposite of conductive polymer/graphene/metal oxide: An introduction and review to it in recent studies. Chem. Rec. 2019, 19, 908–926. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Zhang, L.L.; Zhao, X.; Wu, J. Graphene/polyaniline nanofiber composites as supercapacitor electrodes. Chem. Mater. 2010, 22, 1392–1401. [Google Scholar] [CrossRef]

- Mao, L.; Zhang, K.; Chan, H.S.O.; Wu, J. Surfactant-stabilized graphene/polyaniline nanofiber composites for high performance supercapacitor electrode. J. Mater. Chem. 2012, 22, 80–85. [Google Scholar] [CrossRef]

- Noh, Y.J.; Joh, H.-I.; Yu, J.; Hwang, S.H.; Lee, S.; Lee, C.H.; Kim, S.Y.; Youn, J.R. Ultra-high dispersion of graphene in polymer composite via solvent free fabrication and functionalization. Sci. Rep. 2015, 5, 9141. [Google Scholar] [CrossRef]

- Wei, T.; Luo, G.; Fan, Z.; Zheng, C.; Yan, J.; Yao, C.; Li, W.; Zhang, C. Preparation of graphene nanosheet/polymer composites using in situ reduction–extractive dispersion. Carbon 2009, 47, 2296–2299. [Google Scholar] [CrossRef]

- Liu, S.; Tian, J.; Wang, L.; Li, H.; Zhang, Y.; Sun, X. Stable aqueous dispersion of graphene nanosheets: Noncovalent functionalization by a polymeric reducing agent and their subsequent decoration with Ag nanoparticles for enzymeless hydrogen peroxide detection. Macromolecules 2010, 43, 10078–10083. [Google Scholar] [CrossRef]

- Xu, D.; Xu, Q.; Wang, K.; Chen, J.; Chen, Z. Fabrication of free-standing hierarchical carbon nanofiber/graphene oxide/polyaniline films for supercapacitors. ACS Appl. Mater. Interfaces 2014, 6, 200–209. [Google Scholar] [CrossRef] [PubMed]

- Jin, J.; Rafiq, R.; Gill, Y.Q.; Song, M. Preparation and characterization of high performance of graphene/nylon nanocomposites. Eur. Polym. J. 2013, 49, 2617–2626. [Google Scholar] [CrossRef]

- Zhuang, Y.; Cao, X.; Zhang, J.; Ma, Y.; Shang, X.; Lu, J.; Yang, S.; Zheng, K.; Ma, Y. Monomer casting nylon/graphene nanocomposite with both improved thermal conductivity and mechanical performance. Compos. Part A Appl. Sci. Manuf. 2019, 120, 49–55. [Google Scholar] [CrossRef]

- Pan, B.; Zhang, S.; Li, W.; Zhao, J.; Liu, J.; Zhang, Y.; Zhang, Y. Tribological and mechanical investigation of MC nylon reinforced by modified graphene oxide. Wear 2012, 294, 395–401. [Google Scholar] [CrossRef]

- Lee, J.-G.; Kim, D.-Y.; Mali, M.G.; Al-Deyab, S.S.; Swihart, M.T.; Yoon, S.S. Supersonically blown nylon-6 nanofibers entangled with graphene flakes for water purification. Nanoscale 2015, 7, 19027–19035. [Google Scholar] [CrossRef] [PubMed]

- Maccaferri, E.; Mazzocchetti, L.; Benelli, T.; Zucchelli, A.; Giorgini, L. Morphology, thermal, mechanical properties and ageing of nylon 6,6/graphene nanofibers as Nano2 materials. Compos. Part B Eng. 2019, 166, 120–129. [Google Scholar] [CrossRef]

- Xu, Z.; Liu, Y.; Zhao, X.; Peng, L.; Sun, H.; Xu, Y.; Ren, X.; Jin, C.; Xu, P.; Wang, M. Ultrastiff and strong graphene fibers via full-scale synergetic defect engineering. Adv. Mater. 2016, 28, 6449–6456. [Google Scholar] [CrossRef]

- Leyva-Porras, C.; Ornelas-Gutiérrez, C.; Miki-Yoshida, M.; Avila-Vega, Y.I.; Macossay, J.; Bonilla-Cruz, J. EELS analysis of Nylon 6 nanofibers reinforced with nitroxide-functionalized graphene oxide. Carbon 2014, 70, 164–172. [Google Scholar] [CrossRef] [Green Version]

- Weise, B.A.; Wirth, K.G.; Völkel, L.; Morgenstern, M.; Seide, G. Pilot-scale fabrication and analysis of graphene-nanocomposite fibers. Carbon 2019, 144, 351–361. [Google Scholar] [CrossRef]

- Li, B.; Wu, N.; Yang, Y.; Pan, F.; Wang, C.; Wang, G.; Xiao, L.; Liu, W.; Liu, J.; Zeng, Z. Graphene Oxide-Assisted Multiple Cross-Linking of MXene for Large-Area, High-Strength, Oxidation-Resistant, and Multifunctional Films. Adv. Funct. Mater. 2023, 33, 2213357. [Google Scholar] [CrossRef]

- Jia, Y.; Chen, L.; Yu, H.; Zhang, Y.; Dong, F. Graphene oxide/polystyrene composite nanofibers on quartz crystal microbalance electrode for the ammonia detection. RSC Adv. 2015, 5, 40620–40627. [Google Scholar] [CrossRef]

- Yu, Y.-H.; Lin, Y.-Y.; Lin, C.-H.; Chan, C.-C.; Huang, Y.-C. High-performance polystyrene/graphene-based nanocomposites with excellent anti-corrosion properties. Polym. Chem. 2014, 5, 535–550. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, Y.; Zhang, H.-B.; Li, X.; Gui, C.-X.; Yu, Z.-Z. Enhanced electromagnetic interference shielding efficiency of polystyrene/graphene composites with magnetic Fe3O4 nanoparticles. Carbon 2015, 82, 67–76. [Google Scholar] [CrossRef]

- Ruan, K.; Guo, Y.; Tang, Y.; Zhang, Y.; Zhang, J.; He, M.; Kong, J.; Gu, J. Improved thermal conductivities in polystyrene nanocomposites by incorporating thermal reduced graphene oxide via electrospinning-hot press technique. Compos. Commun. 2018, 10, 68–72. [Google Scholar] [CrossRef]

- Huang, J.; Deng, H.; Song, D.; Xu, H. Electrospun polystyrene/graphene nanofiber film as a novel adsorbent of thin film microextraction for extraction of aldehydes in human exhaled breath condensates. Anal. Chim. Acta 2015, 878, 102–108. [Google Scholar] [CrossRef] [PubMed]

- Ponnamma, D.; Nair, S.S.; Parangusan, H.; Hassan, M.K.; Adham, S.; Karim, A.; Al Ali Al-Maadeed, M. White graphene-cobalt oxide hybrid filler reinforced polystyrene nanofibers for selective oil absorption. Polymers 2019, 12, 4. [Google Scholar] [CrossRef] [Green Version]

- Wu, N.; Yang, Y.; Wang, C.; Wu, Q.; Pan, F.; Zhang, R.; Liu, J.; Zeng, Z. Ultrathin cellulose nanofiber assisted ambient-pressure-dried, ultralight, mechanically robust, multifunctional MXene aerogels. Adv. Mater. 2023, 35, 2207969. [Google Scholar] [CrossRef] [PubMed]

- Afzal, H.M.; Shehzad, F.; Zubair, M.; Bakather, O.Y.; Al-Harthi, M.A. Influence of microwave irradiation on thermal properties of PVA and PVA/graphene nanocomposites. J. Therm. Anal. Calorim. 2020, 139, 353–365. [Google Scholar] [CrossRef]

- Li, C.; Vongsvivut, J.; She, X.; Li, Y.; She, F.; Kong, L. New insight into non-isothermal crystallization of PVA–graphene composites. Phys. Chem. Chem. Phys. 2014, 16, 22145–22158. [Google Scholar] [CrossRef] [PubMed]

- Liang, J.; Huang, Y.; Zhang, L.; Wang, Y.; Ma, Y.; Guo, T.; Chen, Y. Molecular-level dispersion of graphene into poly(vinyl alcohol) and effective reinforcement of their nanocomposites. Adv. Funct. Mater. 2009, 19, 2297–2302. [Google Scholar] [CrossRef]

- Abdah, M.A.A.M.; Zubair, N.A.; Azman, N.H.N.; Sulaiman, Y. Fabrication of PEDOT coated PVA-GO nanofiber for supercapacitor. Mater. Chem. Phys. 2017, 192, 161–169. [Google Scholar] [CrossRef]

- Barzegar, F.; Bello, A.; Fabiane, M.; Khamlich, S.; Momodu, D.; Taghizadeh, F.; Dangbegnon, J.; Manyala, N. Preparation and characterization of poly(vinyl alcohol)/graphene nanofibers synthesized by electrospinning. J. Phys. Chem. Solids 2015, 77, 139–145. [Google Scholar] [CrossRef] [Green Version]

- Bao, Q.; Zhang, H.; Yang, J.x.; Wang, S.; Tang, D.Y.; Jose, R.; Ramakrishna, S.; Lim, C.T.; Loh, K.P. Graphene-polymer nanofiber membrane for ultrafast photonics. Adv. Funct. Mater. 2010, 20, 782–791. [Google Scholar] [CrossRef]

- Verma, R.; Kumar Gupta, S.; Lamba, N.P.; Singh, B.K.; Singh, S.; Bahadur, V.; Chauhan, M.S. Graphene and Graphene Based Nanocomposites for Bio-Medical and Bio-safety Applications. ChemistrySelect 2023, 8, e202204337. [Google Scholar] [CrossRef]

- Anwer, A.H.; Ahtesham, A.; Shoeb, M.; Mashkoor, F.; Ansari, M.Z.; Zhu, S.; Jeong, C. State-of-the-art advances in nanocomposite and bio-nanocomposite polymeric materials: A comprehensive review. Adv. Colloid Interface Sci. 2023, 318, 102955. [Google Scholar] [CrossRef]

- Bhattacharya, A. A Feasibility Study of the Bioinspired Green Manufacturing of Nanocomposite Materials. In Bioinspired and Green Synthesis of Nanostructures: A Sustainable Approach; Sen, M., Mukherjee, M., Eds.; Wiley, Scrivener Publishing LLC.: Hoboken, NJ, USA, 2023; pp. 231–261. [Google Scholar]

- Ibrahim, M.A.; Alhalafi, M.H.; Emam, E.-A.M.; Ibrahim, H.; Mosaad, R.M. A Review of Chitosan and Chitosan Nanofiber: Preparation, Characterization, and Its Potential Applications. Polymers 2023, 15, 2820. [Google Scholar] [CrossRef] [PubMed]

- Neibolts, N.; Platnieks, O.; Gaidukovs, S.; Barkane, A.; Thakur, V.; Filipova, I.; Mihai, G.; Zelca, Z.; Yamaguchi, K.; Enachescu, M. Needle-free electrospinning of nanofibrillated cellulose and graphene nanoplatelets based sustainable poly(butylene succinate) nanofibers. Mater. Today Chem. 2020, 17, 100301. [Google Scholar] [CrossRef]

- De Faria, A.F.; Perreault, F.; Shaulsky, E.; Arias Chavez, L.H.; Elimelech, M. Antimicrobial electrospun biopolymer nanofiber mats functionalized with graphene oxide-silver nanocomposites. ACS Appl. Mater. Interfaces 2015, 7, 12751–12759. [Google Scholar] [CrossRef] [PubMed]

- Yoon, O.J.; Jung, C.Y.; Sohn, I.Y.; Kim, H.J.; Hong, B.; Jhon, M.S.; Lee, N.-E. Nanocomposite nanofibers of poly(D, L-lactic-co-glycolic acid) and graphene oxide nanosheets. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1978–1984. [Google Scholar] [CrossRef]

- Jayakumar, A.; Mathew, S.; Radoor, S.; Kim, J.T.; Rhim, J.-W.; Siengchin, S. Recent advances in two-dimensional nanomaterials: Properties, antimicrobial, and drug delivery application of nanocomposites. Mater. Today Chem. 2023, 30, 101492. [Google Scholar] [CrossRef]

- Salavagione, H.J.; Gómez-Fatou, M.A.; Shuttleworth, P.S.; Ellis, G.J. New perspectives on graphene/polymer fibers and fabrics for smart textiles: The relevance of the polymer/graphene interphase. Front. Mater. 2018, 5, 18. [Google Scholar] [CrossRef] [Green Version]

- Mishra, S.; Singh, S.K.; Singh, A. Polymer Graphene-Based Nanofibers and Their Application for Batteries. In Electrospinning of Graphene, Springer: Berlin/Heidelberg, Germany, 2021; pp. 119–148.

- Ahmed, J.; Tabish, T.A.; Zhang, S.; Edirisinghe, M. Porous graphene composite polymer fibres. Polymers 2020, 13, 76. [Google Scholar] [CrossRef]

- Amir, A.; Mahalingam, S.; Wu, X.; Porwal, H.; Colombo, P.; Reece, M.; Edirisinghe, M. Graphene nanoplatelets loaded polyurethane and phenolic resin fibres by combination of pressure and gyration. Compos. Sci. Technol. 2016, 129, 173–182. [Google Scholar] [CrossRef]

- Matharu, R.K.; Porwal, H.; Ciric, L.; Edirisinghe, M. The effect of graphene-poly(methyl methacrylate) fibres on microbial growth. Interface Focus 2018, 8, 20170058. [Google Scholar] [CrossRef] [Green Version]

- Solís Pinargote, N.W.; Smirnov, A.; Peretyagin, N.; Seleznev, A.; Peretyagin, P. Direct ink writing technology (3d printing) of graphene-based ceramic nanocomposites: A review. Nanomaterials 2020, 10, 1300. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhou, W.; Cao, K.; Hu, X.; Gao, L.; Lu, Y. Architectured graphene and its composites: Manufacturing and structural applications. Compos. Part A Appl. Sci. Manuf. 2021, 140, 106177. [Google Scholar] [CrossRef]

- Alarifi, I.M. A Review on Factors Affecting Machinability and Properties of Fiber-Reinforced Polymer Composites. J. Nat. Fibers 2023, 20, 2154304. [Google Scholar] [CrossRef]

- Yuan, M.; Teng, Z.; Wang, S.; Xu, Y.; Wu, P.; Zhu, Y.; Wang, C.; Wang, G. Polymeric carbon nitride modified polyacrylonitrile fabrics with efficient self-cleaning and water disinfection under visible light. Chem. Eng. J. 2020, 391, 123506. [Google Scholar] [CrossRef]

- Wu, K.; Wang, J.; Liu, D.; Lei, C.; Liu, D.; Lei, W.; Fu, Q. Highly Thermoconductive, Thermostable, and Super-Flexible Film by Engineering 1D Rigid Rod-Like Aramid Nanofiber/2D Boron Nitride Nanosheets. Adv. Mater. 2020, 32, 1906939. [Google Scholar] [CrossRef]

- Cheng, J.; Pu, H.; Du, J. A processing method with high efficiency for low density polyethylene nanofibers reinforced by aligned carbon nanotubes via nanolayer coextrusion. Polymer 2017, 111, 222–228. [Google Scholar] [CrossRef]

- Qiu, Q.; Chen, S.; Li, Y.; Yang, Y.; Zhang, H.; Quan, Z.; Qin, X.; Wang, R.; Yu, J. Functional nanofibers embedded into textiles for durable antibacterial properties. Chem. Eng. J. 2020, 384, 123241. [Google Scholar] [CrossRef]

- Barzoki, P.K.; Latifi, M.; Rezadoust, A. The outstanding effect of nanomat geometry on the interlaminar fracture toughness behavior out of autoclave made glass/phenolic composites under mode-I loading. Eng. Fract. Mech. 2019, 205, 108–119. [Google Scholar] [CrossRef]

- Pillai, R.R.; Thomas, V. Plasma Surface Engineering of Natural and Sustainable Polymeric Derivatives and Their Potential Applications. Polymers 2023, 15, 400. [Google Scholar] [CrossRef]

- Jung, J.; Sodano, H.A. Aramid nanofiber reinforced rubber compounds for the application of tire tread with high abrasion resistance and fuel saving efficiency. ACS Appl. Polym. Mater. 2020, 2, 4874–4884. [Google Scholar] [CrossRef]

- Chung, J.; Kwak, S.-Y. Solvent-assisted heat treatment for enhanced chemical stability and mechanical strength of meta-aramid nanofibers. Eur. Polym. J. 2018, 107, 46–53. [Google Scholar] [CrossRef]

- Shi, W.; Hu, B.; Zhang, H.; Li, J.; Yang, J.; Liu, J. Carbon-Encapsulated Iron Oxide Nanoparticles in Self-Supporting Carbon Nanofiber for High-Performance Supercapacitor in Acid Electrolyte with Superior Stability. ACS Appl. Energy Mater. 2020, 3, 12652–12661. [Google Scholar] [CrossRef]

- Kumar, T.S.M.; Kumar, K.S.; Rajini, N.; Siengchin, S.; Ayrilmis, N.; Rajulu, A.V. A comprehensive review of electrospun nanofibers: Food and packaging perspective. Compos. Part B Eng. 2019, 175, 107074. [Google Scholar] [CrossRef]

- Akampumuza, O.; Gao, H.; Zhang, H.; Wu, D.; Qin, X.H. Raising nanofiber output: The progress, mechanisms, challenges, and reasons for the pursuit. Macromol. Mater. Eng. 2018, 303, 1700269. [Google Scholar] [CrossRef]

- Navaratnam, S.; Selvaranjan, K.; Jayasooriya, D.; Rajeev, P.; Sanjayan, J. Applications of natural and synthetic fiber reinforced polymer in infrastructure: A suitability assessment. J. Build. Eng. 2023, 66, 105835. [Google Scholar] [CrossRef]

- Adapa, S.K. Prospects of Natural Fiber-Reinforced Polymer Composites for Additive Manufacturing Applications: A Review. JOM 2023, 75, 920–940. [Google Scholar] [CrossRef]

- Shin, M.K.; Lee, B.; Kim, S.H.; Lee, J.A.; Spinks, G.M.; Gambhir, S.; Wallace, G.G.; Kozlov, M.E.; Baughman, R.H.; Kim, S.J. Synergistic toughening of composite fibres by self-alignment of reduced graphene oxide and carbon nanotubes. Nat. Commun. 2012, 3, 650. [Google Scholar] [CrossRef] [Green Version]

- Kaczor-Urbanowicz, K.E.; Martín Carreras-Presas, C.; Kaczor, T.; Tu, M.; Wei, F.; Garcia-Godoy, F.; Wong, D.T. Emerging technologies for salivaomics in cancer detection. J. Cell. Mol. Med. 2017, 21, 640–647. [Google Scholar] [CrossRef]

- Glyva, V.; Kovalenko, V.; Levchenko, L.; Tykhenko, O. Research into protective properties of electromagnetic screens based on the metal-containing nanostructures. Вoстoчнo-Еврoпейский Журнал Передoвых Технoлoгий 2017, 3, 50–56. [Google Scholar] [CrossRef] [Green Version]

- Lu, T.; Gu, H.; Hu, Y.; Zhao, T.; Zhu, P.; Sun, R.; Wong, C.-P. Three Dimensional Copper Foam-Filled Elastic Conductive Composites with Simultaneously Enhanced Mechanical, Electrical, Thermal and Electromagnetic Interference (EMI) Shielding Properties. In Proceedings of the 2019 IEEE 69th Electronic Components and Technology Conference (ECTC), Las Vegas, NV, USA, 28–31 May 2019; IEEE: Singapore, 2019; pp. 1916–1920. [Google Scholar]

- Qin, R.; Hu, M.; Zhang, N.; Guo, Z.; Yan, Z.; Li, J.; Liu, J.; Shan, G.; Yang, J. Flexible Fabrication of Flexible Electronics: A General Laser Ablation Strategy for Robust Large-Area Copper-Based Electronics. Adv. Electron. Mater. 2019, 5, 1900365. [Google Scholar] [CrossRef]

- Shahzad, F.; Alhabeb, M.; Hatter, C.B.; Anasori, B.; Hong, S.M.; Koo, C.M.; Gogotsi, Y. Electromagnetic interference shielding with 2D transition metal carbides (MXenes). Science 2016, 353, 1137–1140. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ji, H.; Zhao, R.; Zhang, N.; Jin, C.; Lu, X.; Wang, C. Lightweight and flexible electrospun polymer nanofiber/metal nanoparticle hybrid membrane for high-performance electromagnetic interference shielding. NPG Asia Mater. 2018, 10, 749–760. [Google Scholar] [CrossRef]

- Kumar, S.; Purohit, R.; Malik, M. Properties and applications of polymer matrix nano composite materials. Mater. Today Proc. 2015, 2, 3704–3711. [Google Scholar] [CrossRef]

- Liu, F.; Dong, S.; Zhang, Z.; Dai, X.; Xin, Y.; Wang, X.; Liu, K.; Yuan, Z.; Zhang, J.; Chen, M. Polyaniline/MWCNT Nanocomposite as Sensor for Electroanalytical Determination of Phenol in Oil Field Wastewater. Int. J. Electrochem. Sci. 2019, 14, 9122–9131. [Google Scholar] [CrossRef]

- Joseph, N.; Varghese, J.; Sebastian, M.T. A facile formulation and excellent electromagnetic absorption of room temperature curable polyaniline nanofiber based inks. J. Mater. Chem. C 2016, 4, 999–1008. [Google Scholar] [CrossRef]

- Lyu, J.; Zhao, X.; Hou, X.; Zhang, Y.; Li, T.; Yan, Y. Electromagnetic interference shielding based on a high strength polyaniline-aramid nanocomposite. Compos. Sci. Technol. 2017, 149, 159–165. [Google Scholar] [CrossRef]

- Larcher, D.; Tarascon, J.-M. Towards greener and more sustainable batteries for electrical energy storage. Nat. Chem. 2015, 7, 19. [Google Scholar] [CrossRef]

- Li, X.; Wei, B. Supercapacitors based on nanostructured carbon. Nano Energy 2013, 2, 159–173. [Google Scholar] [CrossRef]

- Szubzda, B.; Szmaja, A.; Ozimek, M.; Mazurkiewicz, S. Polymer membranes as separators for supercapacitors. Appl. Phys. A 2014, 117, 1801–1809. [Google Scholar] [CrossRef]

- Wang, C.; Murugadoss, V.; Kong, J.; He, Z.; Mai, X.; Shao, Q.; Chen, Y.; Guo, L.; Liu, C.; Angaiah, S. Overview of carbon nanostructures and nanocomposites for electromagnetic wave shielding. Carbon 2018, 140, 696–733. [Google Scholar] [CrossRef]

- Yang, Z.; Hao, X.; Chen, S.; Ma, Z.; Wang, W.; Wang, C.; Yue, L.; Sun, H.; Shao, Q.; Murugadoss, V. Long-term antibacterial stable reduced graphene oxide nanocomposites loaded with cuprous oxide nanoparticles. J. Colloid Interface Sci. 2019, 533, 13–23. [Google Scholar] [CrossRef] [PubMed]

- Jiang, D.; Murugadoss, V.; Wang, Y.; Lin, J.; Ding, T.; Wang, Z.; Shao, Q.; Wang, C.; Liu, H.; Lu, N. Electromagnetic interference shielding polymers and nanocomposites-a review. Polym. Rev. 2019, 59, 280–337. [Google Scholar] [CrossRef]

- Shearer, C.J.; Cherevan, A.; Eder, D. Application and future challenges of functional nanocarbon hybrids. Adv. Mater. 2014, 26, 2295–2318. [Google Scholar] [CrossRef] [PubMed]

- Rose, A.; Prasad, K.G.; Sakthivel, T.; Gunasekaran, V.; Maiyalagan, T.; Vijayakumar, T. Electrochemical analysis of graphene oxide/polyaniline/polyvinyl alcohol composite nanofibers for supercapacitor applications. Appl. Surf. Sci. 2018, 449, 551–557. [Google Scholar] [CrossRef]

- Hofmeister, W.H.; Terekhov, A.Y.; Da Costa, J.L.V. Semipermeable Ultrathin Polymer Membranes. U.S. Patent 16/943,956, 19 November 2020. [Google Scholar]

- Mora-Boza, A.; López-Ruiz, E.; López-Donaire, M.L.; Jiménez, G.; Aguilar, M.R.; Marchal, J.A.; Pedraz, J.L.; Vázquez-Lasa, B.; Román, J.S.; Gálvez-Martín, P. Evaluation of Glycerylphytate Crosslinked Semi-and Interpenetrated Polymer Membranes of Hyaluronic Acid and Chitosan for Tissue Engineering. Polymers 2020, 12, 2661. [Google Scholar] [CrossRef]

- Morales-Zamudio, L.; Lozano, T.; Caballero-Briones, F.; Zamudio, M.A.; Angeles-San Martin, M.E.; de Lira-Gomez, P.; Martinez-Colunga, G.; Rodriguez-Gonzalez, F.; Neira, G.; Sanchez-Valdes, S. Structure and Mechanical Properties of Graphene Oxide-Reinforced Polycarbonate. Mater. Chem. Phys. 2020, 261, 124180. [Google Scholar] [CrossRef]

- Bonetti, L.; Fiorati, A.; Serafini, A.; Masotti, G.; Tana, F.; D'Agostino, A.; Draghi, L.; Altomare, L.; Chiesa, R.; Farè, S. Graphene nanoplatelets composite membranes for thermal comfort enhancement in performance textiles. J. Appl. Polym. Sci. 2020, 138, 49645. [Google Scholar] [CrossRef]

- Sierra-Solache, R.; Muro, C.; Maciel, A.; Illescas, J.; Díaz, M.; Carbajal-Franco, G.; Hernández, O. Water recovery from textile wastewater treatment by encapsulated cells of Phanerochaete chrysosporium and ultrafiltration system. Biologia 2020, 75, 1717–1729. [Google Scholar] [CrossRef]

- Wang, H.; Zhou, J.; Sun, J.; Wang, Y.; Ma, Y.; Bai, Z.; Zhao, Y.; Zhang, W. Hierarchically Flower-Like Cobalt Oxide@Doped-Sn Carbon Nanofiber with Core-Shell structure as Anodes for Lithium Ion Battery. Int. J. Electrochem. Sci 2020, 15, 9849–9863. [Google Scholar] [CrossRef]

- Liang, C.; Zhao, P.; Xie, N.; Wang, S.; Huang, Y.; Lu, L.; Cheng, X. Enhanced comprehensive performance of polymer-CSA cement coating with graphene oxide. Constr. Build. Mater. 2023, 363, 129885. [Google Scholar] [CrossRef]

- Zou, L.; Li, Y.; Cao, S.; Ye, B. Gold nanoparticles/polyaniline Langmuir-Blodgett Film modified glassy carbon electrode as voltammetric sensor for detection of epinephrine and uric acid. Talanta 2013, 117, 333–337. [Google Scholar] [CrossRef] [PubMed]

- Mo, Y.; Yang, M.; Lu, Z.; Huang, F. Preparation and tribological performance of chemically-modified reduced graphene oxide/polyacrylonitrile composites. Compos. Part A Appl. Sci. Manuf. 2013, 54, 153–158. [Google Scholar] [CrossRef]

- Cai, C.; Zhang, Y.; Li, M.; Chen, Y.; Zhang, R.; Wang, X.; Wu, Q.; Chen, T.; Sun, P. Multiple-responsive shape memory polyacrylonitrile/graphene nanocomposites with rapid self-healing and recycling properties. RSC Adv. 2018, 8, 1225–1231. [Google Scholar] [CrossRef]

- Armentano, I.; Dottori, M.; Puglia, D.; Kenny, J.M. Effects of carbon nanotubes (CNTs) on the processing and in-vitro degradation of poly(DL-lactide-co-glycolide)/CNT films. J. Mater. Sci. Mater. Med. 2008, 19, 2377–2387. [Google Scholar] [CrossRef]

- Wang, M.; Cai, L.; Jin, Q.; Zhang, H.; Fang, S.; Qu, X.; Zhang, Z.; Zhang, Q. One-pot composite synthesis of three-dimensional graphene oxide/poly(vinyl alcohol)/TiO2 microspheres for organic dye removal. Sep. Purif. Technol. 2017, 172, 217–226. [Google Scholar] [CrossRef]

- Grant, J.J.; Pillai, S.C.; Hehir, S.; McAfee, M.; Breen, A. Biomedical applications of electrospun graphene oxide. ACS Biomater. Sci. Eng. 2021, 7, 1278–1301. [Google Scholar] [CrossRef]

- Lai, L.; Shen, Z.; Lin, J. Conducting Polymer/Graphene-Based Material Composites, and Methods for Preparing the Composites. U.S. Patent 9,734,954, 15 August 2017. [Google Scholar]

- Barzegar, F. Synthesis and Characterization of Polymer/Graphene Electrospun Nanofibers; University of Pretoria: Pretoria, South Africa, 2013. [Google Scholar]

- Shemshaki, N.S.; Laurencin, C. Graphene-Based Nanofibers for Skeletal Muscle Tissue Regeneration. U.S. Patent 17/352,189, 30 December 2021. [Google Scholar]

- Clauss, A.D.; Pan, G.; Wietfeldt, N.R.; Hall, M.C.; Taft, D.D. Polymer-Graphene Nanocomposites. U.S. Patent 9790334B2, 17 October 2017. [Google Scholar]

- Chen, L.; Li, J.; Chen, Z.; Gu, Z.; Yan, L.; Zhao, F.; Zhang, A. Toxicological evaluation of graphene-family nanomaterials. J. Nanosci. Nanotechnol. 2020, 20, 1993–2006. [Google Scholar] [CrossRef] [PubMed]

- Chowdhury, S.M.; Lalwani, G.; Zhang, K.; Yang, J.Y.; Neville, K.; Sitharaman, B. Cell specific cytotoxicity and uptake of graphene nanoribbons. Biomaterials 2013, 34, 283–293. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jain, V.P.; Chaudhary, S.; Sharma, D.; Dabas, N.; Lalji, R.S.K.; Singh, B.K.; Jaiswar, G. Advanced functionalized nanographene oxide as a biomedical agent for drug delivery and anti-cancerous therapy: A review. Eur. Polym. J. 2021, 142, 110124. [Google Scholar] [CrossRef]

- Gupta, K.; Kaushik, A.; Singhal, S. Amelioration of adsorptive efficacy by synergistic assemblage of functionalized graphene oxide with esterified cellulose nanofibers for mitigation of pharmaceutical waste. J. Hazard. Mater. 2022, 424, 127541. [Google Scholar]

- Ahmed, M.; Mansour, S.; Al-Wafi, R.; Menazea, A. Composition and design of nanofibrous scaffolds of Mg/Se-hydroxyapatite/graphene oxide@ε-polycaprolactone for wound healing applications. J. Mater. Res. Technol. 2020, 9, 7472–7485. [Google Scholar] [CrossRef]

- Jiang, S. Biodegradable Graphene Oxide Biocomposite Fibrous Membrane, Preparation Method and Uses Thereof. U.S. Patent 16/387,071, 22 October 2020. [Google Scholar]

- Goenka, S.; Sant, V.; Sant, S. Graphene-based nanomaterials for drug delivery and tissue engineering. J. Control. Release 2014, 173, 75–88. [Google Scholar] [CrossRef] [PubMed]

- Othman, F.E.C.; Yusof, N.; Ismail, A.F. Activated-Carbon Nanofibers/Graphene Nanocomposites and Their Adsorption Performance Towards Carbon Dioxide. Chem. Eng. Technol. 2020, 43, 2023–2030. [Google Scholar] [CrossRef]

- Boroojeni, F.R.; Mashayekhan, S.; Abbaszadeh, H.-A.; Ansarizadeh, M.; Khoramgah, M.-S.; Movaghar, V.R. Bioinspired Nanofiber Scaffold for Differentiating Bone Marrow-Derived Neural Stem Cells to Oligodendrocyte-Like Cells: Design, Fabrication, and Characterization. Int. J. Nanomed. 2020, 15, 3903–3920. [Google Scholar] [CrossRef]

- Pinto, A.M.; Cabral, J.; Tanaka, D.A.P.; Mendes, A.M.; Magalhães, F.D. Effect of incorporation of graphene oxide and graphene nanoplatelets on mechanical and gas permeability properties of poly(lactic acid) films. Polym. Int. 2013, 62, 33–40. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Bonaccorso, F.; Fal’Ko, V.; Novoselov, K.S.; Roche, S.; Bøggild, P.; Borini, S.; Koppens, F.H.; Palermo, V.; Pugno, N. Science and technology roadmap for graphene, related two-dimensional crystals, and hybrid systems. Nanoscale 2015, 7, 4598–4810. [Google Scholar] [CrossRef] [Green Version]

- Parandeh, S.; Kharaziha, M.; Karimzadeh, F.; Hosseinabadi, F. Triboelectric nanogenerators based on graphene oxide coated nanocomposite fibers for biomedical applications. Nanotechnology 2020, 31, 385402. [Google Scholar] [CrossRef]

- Parandeh, S.; Kharaziha, M.; Karimzadeh, F. An eco-friendly triboelectric hybrid nanogenerators based on graphene oxide incorporated polycaprolactone fibers and cellulose paper. Nano Energy 2019, 59, 412–421. [Google Scholar] [CrossRef]

- Baek, S.H.; Roh, J.; Park, C.Y.; Kim, M.W.; Shi, R.; Kailasa, S.K.; Park, T.J. Cu-nanoflower decorated gold nanoparticles-graphene oxide nanofiber as electrochemical biosensor for glucose detection. Mater. Sci. Eng. C 2020, 107, 110273. [Google Scholar] [CrossRef]

- Wang, Y.; Hao, J.; Huang, Z.; Zheng, G.; Dai, K.; Liu, C.; Shen, C. Flexible electrically resistive-type strain sensors based on reduced graphene oxide-decorated electrospun polymer fibrous mats for human motion monitoring. Carbon 2018, 126, 360–371. [Google Scholar] [CrossRef]

- Bahrami, S.; Solouk, A.; Mirzadeh, H.; Seifalian, A.M. Electroconductive polyurethane/graphene nanocomposite for biomedical applications. Compos. Part B Eng. 2019, 168, 421–431. [Google Scholar] [CrossRef]

- Orasugh, J.T.; Ray, S.S. Graphene-Based Electrospun Fibrous Materials with Enhanced EMI Shielding: Recent Developments and Future Perspectives. ACS Omega 2022, 7, 33699–33718. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.; Li, J.; Li, Y.; He, X.; Yuan, Y. Lightweight and flexible hybrid film based on delicate design of electrospun nanofibers for high-performance electromagnetic interference shielding. Nanoscale 2019, 11, 8616–8625. [Google Scholar] [CrossRef]

- Guo, H.; Chen, Y.; Li, Y.; Zhou, W.; Xu, W.; Pang, L.; Fan, X.; Jiang, S. Electrospun fibrous materials and their applications for electromagnetic interference shielding: A review. Compos. Part A Appl. Sci. Manuf. 2021, 143, 106309. [Google Scholar] [CrossRef]

- Li, X.-Y.; Yan, Y.; Zhang, B.; Bai, T.-J.; Wang, Z.-Z.; He, T.-S. PAN-derived electrospun nanofibers for supercapacitor applications: Ongoing approaches and challenges. J. Mater. Sci. 2021, 56, 10745–10781. [Google Scholar] [CrossRef]

- Ullah, K.; Khan, B.M.; Rashid, A.U.; Oh, W.C. Perspective Chapter: Graphene Based Nanocomposites for Supercapacitor Electrodes. In Updates on Supercapacitors; IntechOpen: London, UK, 2022. [Google Scholar]

- Ahmed, F.E.; Lalia, B.S.; Hashaikeh, R. A review on electrospinning for membrane fabrication: Challenges and applications. Desalination 2015, 356, 15–30. [Google Scholar] [CrossRef]

- Liu, T.; Lyv, J.; Xu, Y.; Zheng, C.; Liu, Y.; Fu, R.; Liang, L.; Wu, J.; Zhang, Z. Graphene-based woven filter membrane with excellent strength and efficiency for water desalination. Desalination 2022, 533, 115775. [Google Scholar] [CrossRef]

- Fang, Q.; Zhou, X.; Deng, W.; Zheng, Z.; Liu, Z. Freestanding bacterial cellulose-graphene oxide composite membranes with high mechanical strength for selective ion permeation. Sci. Rep. 2016, 6, 33185. [Google Scholar] [CrossRef] [Green Version]

- Banerjee, A.N. Graphene and its derivatives as biomedical materials: Future prospects and challenges. Interface Focus 2018, 8, 20170056. [Google Scholar] [CrossRef]

- Shin, S.R.; Li, Y.-C.; Jang, H.L.; Khoshakhlagh, P.; Akbari, M.; Nasajpour, A.; Zhang, Y.S.; Tamayol, A.; Khademhosseini, A. Graphene-based materials for tissue engineering. Adv. Drug Deliv. Rev. 2016, 105, 255–274. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Biru, E.I.; Necolau, M.I.; Zainea, A.; Iovu, H. Graphene Oxide-Protein-Based Scaffolds for Tissue Engineering: Recent Advances and Applications. Polymers 2022, 14, 1032. [Google Scholar] [CrossRef] [PubMed]

- Kaur, H.; Garg, R.; Singh, S.; Jana, A.; Bathula, C.; Kim, H.-S.; Kumbar, S.G.; Mittal, M. Progress and challenges of graphene and its congeners for biomedical applications: Drug delivery, gene delivery, biosensing, bioimaging, and tissue engineering. J. Mol. Liq. 2022, 368, 120703. [Google Scholar] [CrossRef]

| Methods | Electrospinning | Solution Blowing | Template Synthesis | Phase Inversion | Freeze Drying | STEP Techniques |

|---|---|---|---|---|---|---|

| Nanofiber diameter range | 40 nm to 2 μm | 40 nm to several μm | 40 nm to a few hundred nanometers | 50 nm to 1 μm | 50 nm– 1 μm | 50 nm to several μm |

| Production rate (injection rate) | 5 μL/min | 20 μL/min | - | - | - | 15–100 μL/min |

| Influencing parameters | Voltages, viscosity, solution feeding rate, distance | Nozzle geometry, viscosity, solution feeding rate, gas pressure | Template shape, template pore size | Solvent properties, polymer concentration | Freezing rate, solvent features, polymer concentration | Polymer type, molecular weight, solvent properties, substrate, speed |

| Voltage requirement | 10–40 kV | NO | ~30 V (for electropolymerization) | No | No | No |

| Industrialization | Yes | Yes | No | No | No | No |

| Possibility of producing aligned nanofibers | Yes | Yes | Yes | Yes | Yes | Yes |

| Possibility for melt spinning | Yes | Yes | Yes | No | No | No |

| Possibility for spinning from highly concentrated polymer solutions | Yes | Yes | No | No | No | Yes |

| Production of core/shell nanofibers | Yes | Yes | Hollow | Yes | Yes | No |

| Production of polymer/composite fiber | Polyamide; polystyrene; polyaniline; polyamide/carbon nanotube; polystyrene/carbon nanotube; polyaniline/single-walled carbon nanotube nanofibers; polyaniline/zinc oxide; the nylon 6,6/zinc oxide; polyaniline/titania | Poly(vinyl alcohol); poly (lactic acid); poly(vinyl alcohol)/zinc oxide; poly(lactic acid)/titanium dioxide | Polypyrrole; polyaniline; polypyrrole/silica; | Poly(vinyl fluoride); aramid; poly(vinyl fluoride)/bentonite; aramid/zeolite | Poly(vinyl alcohol); poly(vinyl alcohol)/cellulose; | Polymer/titania; polymer/titania/alumina; hydroxyapatite/chitosan |

| Refs. | [31,32,33,34,35,36] | [37,38] | [39,40] | [41,42] | [43,44,45] | [46,47,48] |

| Polymer/ Nanocomposite | Technique | Diameter/ Size | Solvent/ Concentration | Flow Rate | Voltage Requirement | Physical Properties | Ref. |

|---|---|---|---|---|---|---|---|

| Polyaniline/poly (methyl methacrylate)/amino-functionalized graphene. | Electrospinning | 35–133 nm | Dimethyl formamide | 0.3 mL/h | 18–20 kV | Thermal stability | [97] |

| Poly(ε-caprolactone)/ graphene oxide | Electrospinning | 201–264 nm | Glacial acetic acid; 1.5 w/v% | 1 mL/h | 12 kV | Increment in tensile stress by 189% | [98] |

| Poly(ε-caprolactone)/ graphene | Electrospinning | 121–154 nm | Dichloromethane/methanol; 10–12 wt.% | 0.8–1 mL/h | 15–17 kV | Young’s modulus tensile strength of 3771 MPa and 56.08 MPa, respectively | [99] |

| Poly(ε-caprolactone)/ reduced graphene oxide | Electrospinning | 100–130 nm | Glacial acetic acid; 1.5 w/v% | 1 mL/h | 12 kV | Tensile strength increase by 304 % | [100] |

| Polyamide/graphene | Electrospinning | 76–338 nm | Hexafluoroisopropanol; 0.005–0.01 wt.% | 0.05 mL/h | 8–10 kV | Increase in tensile strength, Young’s modulus fracture, toughness by 56%, 113%, and 250%, respectively | [101] |

| Polyethylene/graphene | Drawing | - | Xylene; 0.1 wt.% | Draw ratio 30–70 | - | Thermal conductivity ≈ 75 W m−1 K−1 ρ−1 | [102] |

| Polypyrrole/graphene | Template method | 80–100 nm | NaOH and acidic solutions | - | - | Specific capacitance 466 Fg−1; energy density 165.7 Wh/Kg | [103] |

| Polypyrrole/graphene | Wet spinning method | 40 µm | Acidic solution; ethanol: water; ~10 mg/ml | - | - | Tensile strength 364.3 MPa; specific capacitance 334 mF cm−2 | [104] |

| Aramid/graphene | Co-axial spinning | ~8 nm | Dimethyl sulfoxide | 2, 4, 6 mL/h | - | Increase in ultimate tensile stress by 700% | [105] |

| Polyethylene terephthalate/graphene | Dry-jet wet spinning | - | Methanol; 3 mg/mL | Air gap ~3 cm; pressure 25.0 psi | - | Percolation threshold 0.2 S/cm | [106] |

| Electrospun Solution | Graphene Content ppm (wt.%) | Flow Rate/mL/h | Electric Potential/kV | Distance/cm | Humidity (%) |

|---|---|---|---|---|---|

| NY-0G | 0 | 0.32 | 20.0 | 17.0 | 38–40 |

| NY-0.05G | 500 (0.05) | 0.23 | 20.8 | 18.0 | 43–45 |

| NY-0.1G | 1000 (0.1) | 0.25 | 21.0 | 18.0 | 54–45 |

| NY-1.5G | 15,000 (1.5) | 0.17 | 18.0 | 18.0 | 39–31 |

| NY-2G | 20,000 (2.0) | 0.50 | 16.7 | 15.0 | 33–35 |

| NY-5G | 50,000 (5.0) | 0.70 | 17.3 | 15.0 | 28–30 |

| NY-8G | 80,000 (8.0) | 0.30 | 15.1 | 20.0 | 24–26 |

| NY-15G | 150,000 (15.0) | 0.50 | 20.0 | 15.0 | 31–33 |

| Sample | Tensile Strength (MPa) | Young’s Modulus (MPa) | |

|---|---|---|---|

| Non-irradiated | PS PS/Co-O PS/hBN PS/hBCo-O | 28.54 ± 1.1 30.47 ± 2.3 35.44 ± 2.5 48.24 ± 2.6 | 72.50 ± 6.44 76.33 ± 2.21 77.65 ± 4.05 98.15 ± 4.79 |

| Irradiated | PS PS/Co-O PS/hBN PS/hBCo-O | 30.87 ± 1.3 31.05 ± 2.2 38.25 ± 1.7 52.54 ± 2.1 | 73.30 ± 9.01 77.88 ± 8.75 82.03 ± 2.45 110.35 ± 4.55 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kausar, A.; Ahmad, I.; Zhao, T.; Aldaghri, O.; Ibnaouf, K.H.; Eisa, M.H. Nanocomposite Nanofibers of Graphene—Fundamentals and Systematic Developments. J. Compos. Sci. 2023, 7, 323. https://doi.org/10.3390/jcs7080323

Kausar A, Ahmad I, Zhao T, Aldaghri O, Ibnaouf KH, Eisa MH. Nanocomposite Nanofibers of Graphene—Fundamentals and Systematic Developments. Journal of Composites Science. 2023; 7(8):323. https://doi.org/10.3390/jcs7080323

Chicago/Turabian StyleKausar, Ayesha, Ishaq Ahmad, Tingkai Zhao, Osamah Aldaghri, Khalid H. Ibnaouf, and M. H. Eisa. 2023. "Nanocomposite Nanofibers of Graphene—Fundamentals and Systematic Developments" Journal of Composites Science 7, no. 8: 323. https://doi.org/10.3390/jcs7080323

APA StyleKausar, A., Ahmad, I., Zhao, T., Aldaghri, O., Ibnaouf, K. H., & Eisa, M. H. (2023). Nanocomposite Nanofibers of Graphene—Fundamentals and Systematic Developments. Journal of Composites Science, 7(8), 323. https://doi.org/10.3390/jcs7080323