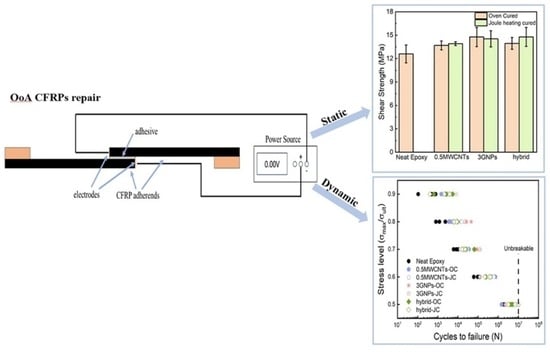

Static and Dynamic Mechanical Behavior of Carbon Fiber Reinforced Plastic (CFRP) Single-Lap Shear Joints Joule-Bonded with Conductive Epoxy Nanocomposites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fabrication and Characterization of Oven Cured Epoxy Nanocomposites

2.3. CFRPs Repair through Adhesively Bonded Joints

3. Results and Discussion

3.1. Electrical Conductivity of the Epoxy Nanocomposites

3.2. Microstructure of the Epoxy Nanocomposites

3.3. CFRPs Repair by Joule Heat Curing of the Conductive Epoxy Nanocomposites

3.4. Mechanical Properties of the Adhesively Bonded Single Lap Joints

3.4.1. Lap Shear Tests

3.4.2. Fatigue Tests

3.4.3. Failure Mechanism of the Adhesively Bonded Joints

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Meng, F.; Olivetti, E.A.; Zhao, Y.; Chang, J.C.; Pickering, S.J.; McKechnie, J. Comparing Life Cycle Energy and Global Warming Potential of Carbon Fiber Composite Recycling Technologies and Waste Management Options. ACS Sustain. Chem. Eng. 2018, 6, 9854–9865. [Google Scholar] [CrossRef]

- Industry ARC. Composite Materials Market—Forecast (2024–2030). Available online: https://www.industryarc.com/Report/246/composite-materials-market-analysis-report.html (accessed on 18 January 2024).

- Amilhat, J. Fly the Green Deal, Europe’s Vision for Sustainable Aviation, Report of the Advisory Council for Aviation Research and Innovation in Europe (ACARE). Available online: https://www.acare4europe.org/wp-content/uploads/2022/06/20220815_Fly-the-green-deal_LR-1.pdf (accessed on 4 March 2024).

- Tsai, W.-H.; Chang, Y.-C.; Lin, S.-J.; Chen, H.-C.; Chu, P.-Y. A Green Approach to the Weight Reduction of Aircraft Cabins. J. Air Transp. Manag. 2014, 40, 65–77. [Google Scholar] [CrossRef]

- Zhang, J.; Chevali, V.S.; Wang, H.; Wang, C.-H. Current Status of Carbon Fibre and Carbon Fibre Composites Recycling. Compos. Part B Eng. 2020, 193, 108053. [Google Scholar] [CrossRef]

- McConnell, V.P. Launching the Carbon Fibre Recycling Industry. Reinf. Plast. 2010, 54, 33–37. [Google Scholar] [CrossRef]

- Rademacker, T. Challenges in CFRP Recycling; Federal Ministry for Economic Affairs and Energy: Berlin, Germany, 2018; pp. 24–25. [Google Scholar]

- Vinson, J.R. Mechanical Fastening of Polymer Composites. Polym. Eng. Sci. 1989, 29, 1332–1339. [Google Scholar] [CrossRef]

- Banea, M.D.; da Silva, L.F.M. Adhesively Bonded Joints in Composite Materials: An Overview. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2009, 223, 1–18. [Google Scholar] [CrossRef]

- Kinloch, A.J.; Lee, J.H.; Taylor, A.C.; Sprenger, S.; Eger, C.; Egan, D. Toughening Structural Adhesives via Nano- and Micro-Phase Inclusions. J. Adhes. 2003, 79, 867–873. [Google Scholar] [CrossRef]

- Saba, N.; Jawaid, M.; Alothman, O.Y.; Paridah, M.; Hassan, A. Recent Advances in Epoxy Resin, Natural Fiber-Reinforced Epoxy Composites and Their Applications. J. Reinf. Plast. Compos. 2016, 35, 447–470. [Google Scholar] [CrossRef]

- Ahmadi, Z. Nanostructured Epoxy Adhesives: A Review. Prog. Org. Coat. 2019, 135, 449–453. [Google Scholar] [CrossRef]

- Centea, T.; Grunenfelder, L.K.; Nutt, S.R. A Review of Out-of-Autoclave Prepregs—Material Properties, Process Phenomena, and Manufacturing Considerations. Compos. Part A Appl. Sci. Manuf. 2015, 70, 132–154. [Google Scholar] [CrossRef]

- Kernin, A.; Wan, K.; Liu, Y.; Shi, X.; Kong, J.; Bilotti, E.; Peijs, T.; Zhang, H. The Effect of Graphene Network Formation on the Electrical, Mechanical, and Multifunctional Properties of Graphene/Epoxy Nanocomposites. Compos. Sci. Technol. 2019, 169, 224–231. [Google Scholar] [CrossRef]

- Redondo, O.; Prolongo, S.G.; Campo, M.; Sbarufatti, C.; Giglio, M. Anti-Icing and de-Icing Coatings Based Joule’s Heating of Graphene Nanoplatelets. Compos. Sci. Technol. 2018, 164, 65–73. [Google Scholar] [CrossRef]

- Mas, B.; Fernández-Blázquez, J.P.; Duval, J.; Bunyan, H.; Vilatela, J.J. Thermoset Curing through Joule Heating of Nanocarbons for Composite Manufacture, Repair and Soldering. Carbon 2013, 63, 523–529. [Google Scholar] [CrossRef]

- Prolongo, S.G.; Moriche, R.; Del Rosario, G.; Jiménez-Suárez, A.; Prolongo, M.G.; Ureña, A. Joule Effect Self-Heating of Epoxy Composites Reinforced with Graphitic Nanofillers. J. Polym. Res. 2016, 23, 189. [Google Scholar] [CrossRef]

- Xia, T.; Zeng, D.; Li, Z.; Young, R.J.; Vallés, C.; Kinloch, I.A. Electrically Conductive GNP/Epoxy Composites for out-of-Autoclave Thermoset Curing through Joule Heating. Compos. Sci. Technol. 2018, 164, 304–312. [Google Scholar] [CrossRef]

- Huang, Y.; Xia, T.; Kinloch, I.; Vallés, C. Graphene Nanoplatelets/Epoxy Nanocomposites as Conductive Adhesives for out-of-Autoclave in-Situ CFRPs Repair. Compos. Sci. Technol. 2023, 237, 110007. [Google Scholar] [CrossRef]

- Marouf, B.T.; Mai, Y.-W.; Bagheri, R.; Pearson, R.A. Toughening of Epoxy Nanocomposites: Nano and Hybrid Effects. Polym. Rev. 2016, 56, 70–112. [Google Scholar] [CrossRef]

- Kinloch, A.J. Toughening Epoxy Adhesives to Meet Today’s Challenges. MRS Bull. 2003, 28, 445–448. [Google Scholar] [CrossRef]

- Kang, M.-H.; Choi, J.-H.; Kweon, J.-H. Fatigue Life Evaluation and Crack Detection of the Adhesive Joint with Carbon Nanotubes. Compos. Struct. 2014, 108, 417–422. [Google Scholar] [CrossRef]

- Sadigh, M.A.S.; Marami, G. Enhancing Fatigue Life in Adhesively Bonded Joints Using Reduced Graphene Oxide Additive: Experimental and Numerical Evaluation. Int. J. Adhes. Adhes. 2018, 84, 283–290. [Google Scholar] [CrossRef]

- Young, R.J.; Liu, M.; Kinloch, I.A.; Li, S.; Zhao, X.; Vallés, C.; Papageorgiou, D.G. The Mechanics of Reinforcement of Polymers by Graphene Nanoplatelets. Compos. Sci. Technol. 2018, 154, 110–116. [Google Scholar] [CrossRef]

- Last, B.J.; Thouless, D.J. Percolation Theory and Electrical Conductivity. Phys. Rev. Lett. 1971, 27, 1719–1721. [Google Scholar] [CrossRef]

- Bauhofer, W.; Kovacs, J.Z. A Review and Analysis of Electrical Percolation in Carbon Nanotube Polymer Composites. Compos. Sci. Technol. 2009, 69, 1486–1498. [Google Scholar] [CrossRef]

- Singh, N.P.; Gupta, V.K.; Singh, A.P. Graphene and Carbon Nanotube Reinforced Epoxy Nanocomposites: A Review. Polymer 2019, 180, 121724. [Google Scholar] [CrossRef]

- Dong, M.; Zhang, H.; Tzounis, L.; Santagiuliana, G.; Bilotti, E.; Papageorgiou, D.G. Multifunctional Epoxy Nanocomposites Reinforced by Two-Dimensional Materials: A Review. Carbon 2021, 185, 57–81. [Google Scholar] [CrossRef]

- Kyrylyuk, A.V.; Hermant, M.C.; Schilling, T.; Klumperman, B.; Koning, C.E.; van der Schoot, P. Controlling Electrical Percolation in Multicomponent Carbon Nanotube Dispersions. Nat. Nanotechnol. 2011, 6, 364–369. [Google Scholar] [CrossRef] [PubMed]

- Mouritz, A. Fatigue of Aerospace Materials. In Introduction to Aerospace Materials; Elsevier: Amsterdam, The Netherlands, 2012; pp. 469–497. ISBN 978-1-85573-946-8. [Google Scholar]

- Johnsen, B.B.; Kinloch, A.J.; Mohammed, R.D.; Taylor, A.C.; Sprenger, S. Toughening Mechanisms of Nanoparticle-Modified Epoxy Polymers. Polymer 2007, 48, 530–541. [Google Scholar] [CrossRef]

- Parente, J.M.; Santos, P.; Valvez, S.; Silva, M.P.; Reis, P.N.B. Fatigue Behaviour of Graphene Composites: An Overview. Procedia Struct. Integr. 2020, 25, 282–293. [Google Scholar] [CrossRef]

- Hsieh, T.H.; Kinloch, A.J.; Masania, K.; Taylor, A.C.; Sprenger, S. The Mechanisms and Mechanics of the Toughening of Epoxy Polymers Modified with Silica Nanoparticles. Polymer 2010, 51, 6284–6294. [Google Scholar] [CrossRef]

- Knoll, J.B.; Riecken, B.T.; Kosmann, N.; Chandrasekaran, S.; Schulte, K.; Fiedler, B. The Effect of Carbon Nanoparticles on the Fatigue Performance of Carbon Fibre Reinforced Epoxy. Compos. Part A Appl. Sci. Manuf. 2014, 67, 233–240. [Google Scholar] [CrossRef]

- Casas-Rodriguez, J.P.; Ashcroft, I.A.; Silberschmidt, V.V. Damage in Adhesively Bonded CFRP Joints: Sinusoidal and Impact-Fatigue. Compos. Sci. Technol. 2008, 68, 2663–2670. [Google Scholar] [CrossRef]

- Pang, Y.-Y.; Wu, G.; Su, Z.-L.; He, X.-Y. Experimental Study on the Carbon-Fiber-Reinforced Polymer–Steel Interfaces Based on Carbon-Fiber-Reinforced Polymer Delamination Failures and Hybrid Failures. Adv. Struct. Eng. 2020, 23, 2247–2260. [Google Scholar] [CrossRef]

- Rahman, N.M.; Sun, C.T. Strength Calculation of Composite Single Lap Joints with Fiber-Tear-Failure. Compos. Part B Eng. 2014, 62, 249–255. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Y.; Kinloch, I.A.; Vallés, C. Static and Dynamic Mechanical Behavior of Carbon Fiber Reinforced Plastic (CFRP) Single-Lap Shear Joints Joule-Bonded with Conductive Epoxy Nanocomposites. J. Compos. Sci. 2024, 8, 112. https://doi.org/10.3390/jcs8030112

Huang Y, Kinloch IA, Vallés C. Static and Dynamic Mechanical Behavior of Carbon Fiber Reinforced Plastic (CFRP) Single-Lap Shear Joints Joule-Bonded with Conductive Epoxy Nanocomposites. Journal of Composites Science. 2024; 8(3):112. https://doi.org/10.3390/jcs8030112

Chicago/Turabian StyleHuang, Yuheng, Ian A. Kinloch, and Cristina Vallés. 2024. "Static and Dynamic Mechanical Behavior of Carbon Fiber Reinforced Plastic (CFRP) Single-Lap Shear Joints Joule-Bonded with Conductive Epoxy Nanocomposites" Journal of Composites Science 8, no. 3: 112. https://doi.org/10.3390/jcs8030112

APA StyleHuang, Y., Kinloch, I. A., & Vallés, C. (2024). Static and Dynamic Mechanical Behavior of Carbon Fiber Reinforced Plastic (CFRP) Single-Lap Shear Joints Joule-Bonded with Conductive Epoxy Nanocomposites. Journal of Composites Science, 8(3), 112. https://doi.org/10.3390/jcs8030112